Process for preparing feed gas for synthetic ammonia by two-stage furnace coal gasification taking cold-pressed briquette as raw material

A technology of coal gasification and ammonia synthesis, which is applied in the field of raw material gas for synthesis of ammonia by two-stage furnace coal gasification using cold briquettes as raw materials, which can solve the problems of high manufacturing costs, disappearing profit margins of hot-extruded briquettes and cold-extruded briquettes, etc. problem, to achieve the effect of less crushing, small drop height difference, and simplified production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

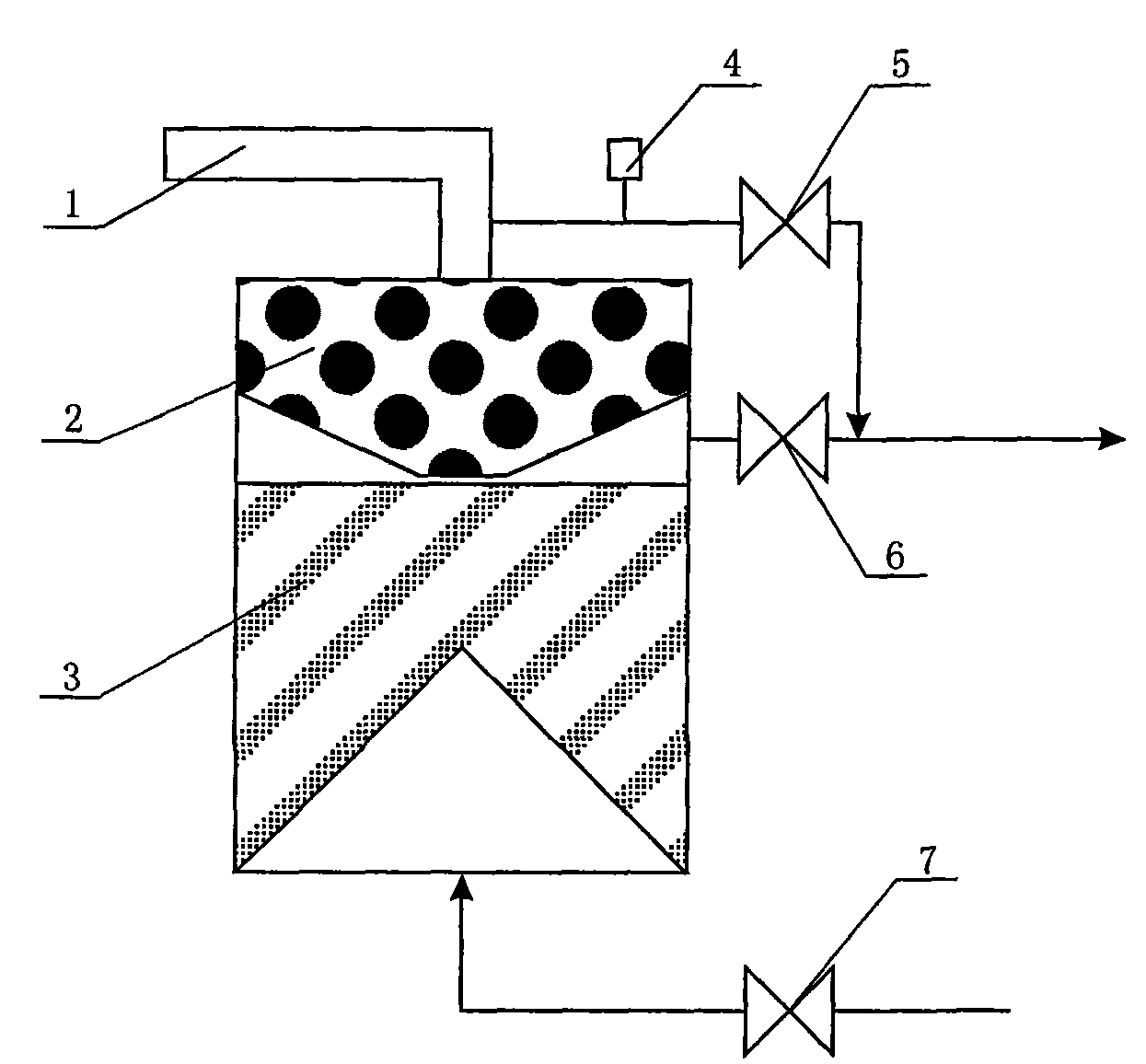

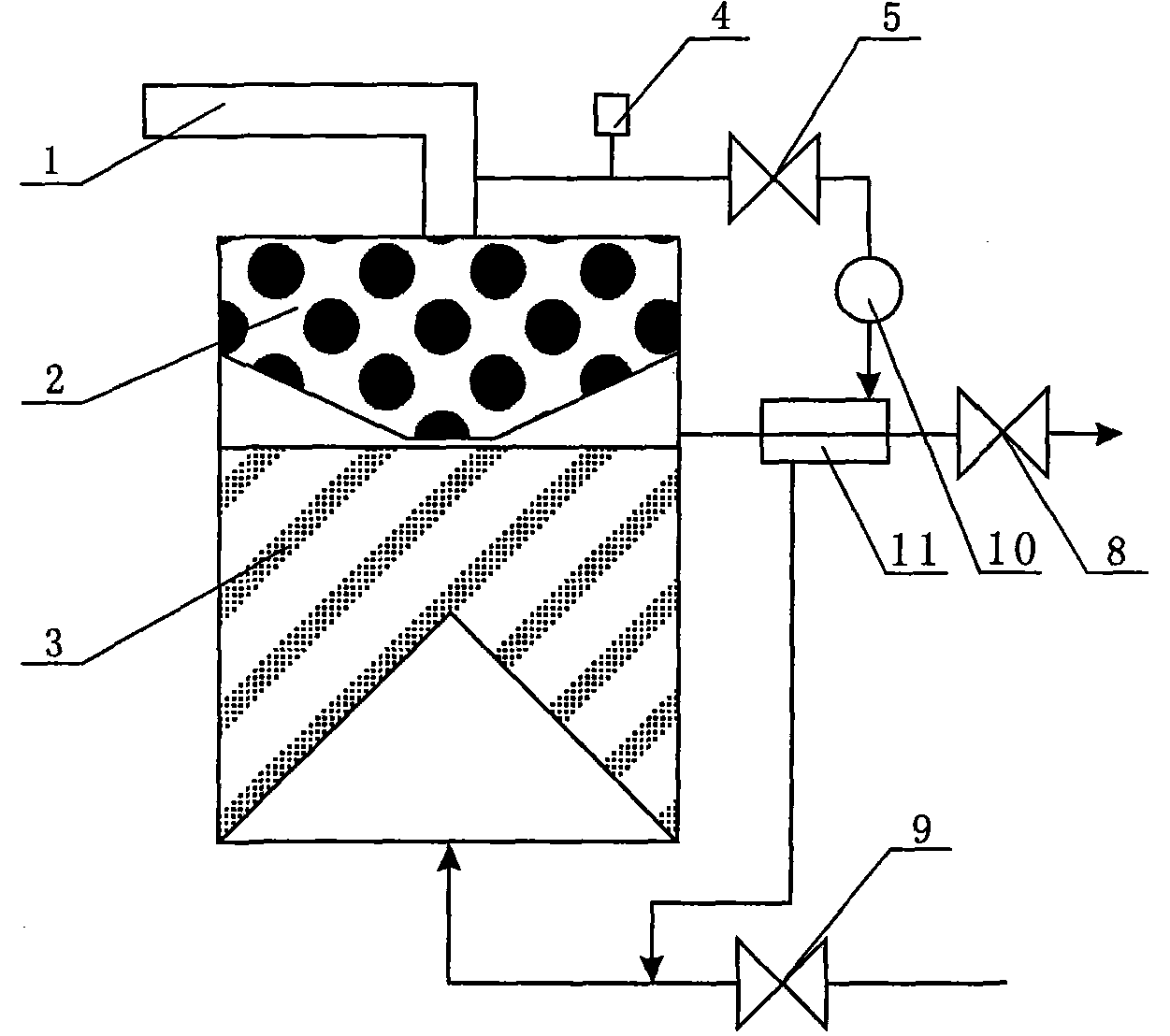

[0011] Such as figure 1 As shown in the blowing stage of a two-stage furnace coal gasification method for producing raw material gas for ammonia synthesis using cold briquette as raw material, the auxiliary facilities of the gas generator include: briquette extruder 1, thermocouple 4, drying valve 5, Three gas valves 6 and blowing valves 7, etc., the briquette extruder 1 can continuously deliver cold briquettes to the gas generator, and the cold briquettes waiting to be dried are stored in the briquette drying section 2; during the blowing stage, The air enters the gas generator through the blowing valve 7, and after the blowing flue gas exits the briquette gasification section 3, part of the blowing flue gas passes through the three-gas valve 6 and goes directly to the three-gas combustion chamber for combustion, and the other part of the blowing flue gas is dried by the briquette Section 2, drying the valve 5, then mixing with the blowing flue gas from the three-gas valve 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com