Flue gas-based combined desulfuration and denitration method and special device for method

A technology for desulfurization and denitrification and flue gas, which is applied in the direction of separation methods, chemical instruments and methods, and separation of dispersed particles. It can solve the problems of difficult control of flue gas flow, non-uniform distribution, and low denitrification efficiency, so as to improve desulfurization and denitrification efficiency. , easy processing, and the effect of improving denitrification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

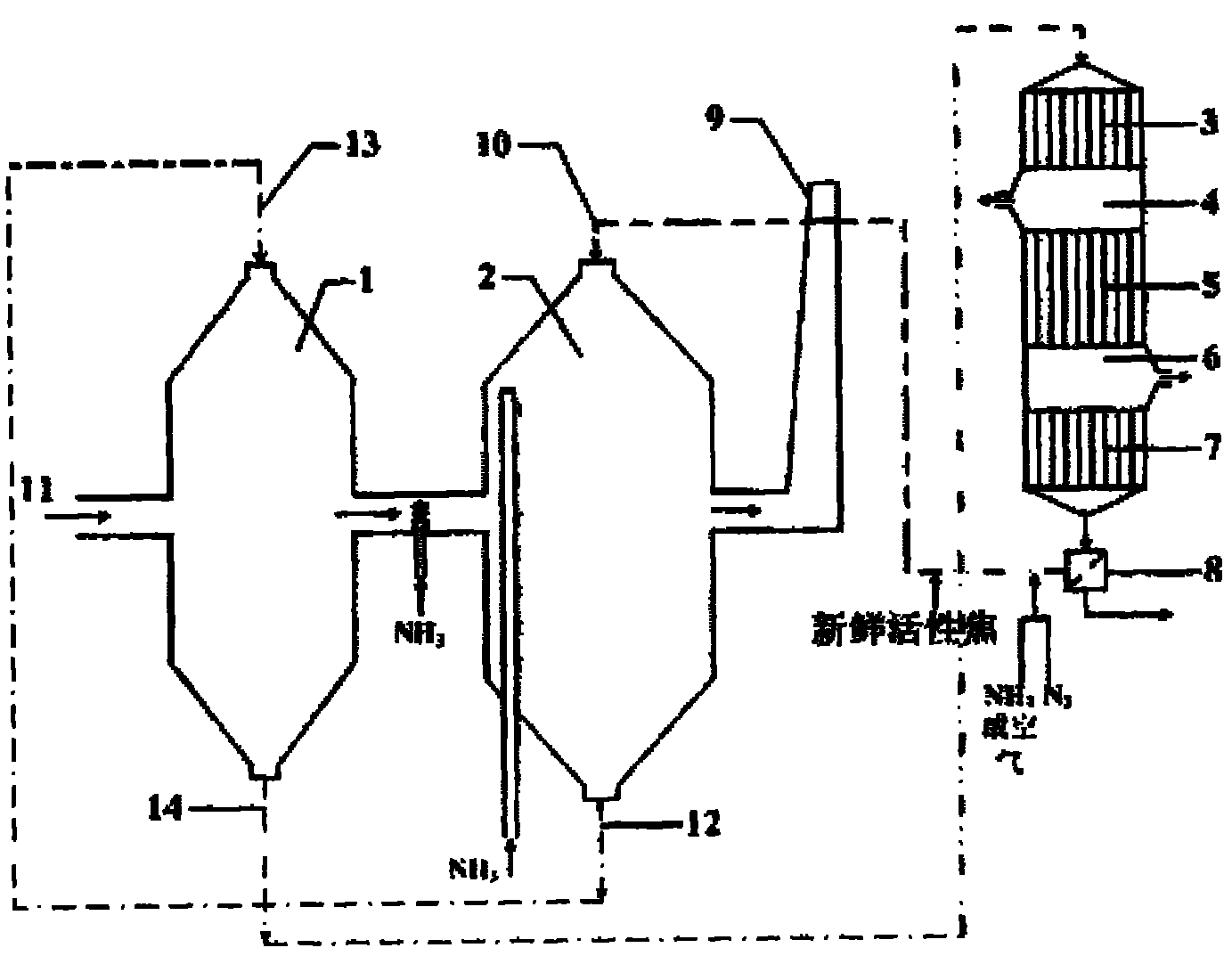

[0035] Example 1, flue gas combined desulfurization and denitrification device

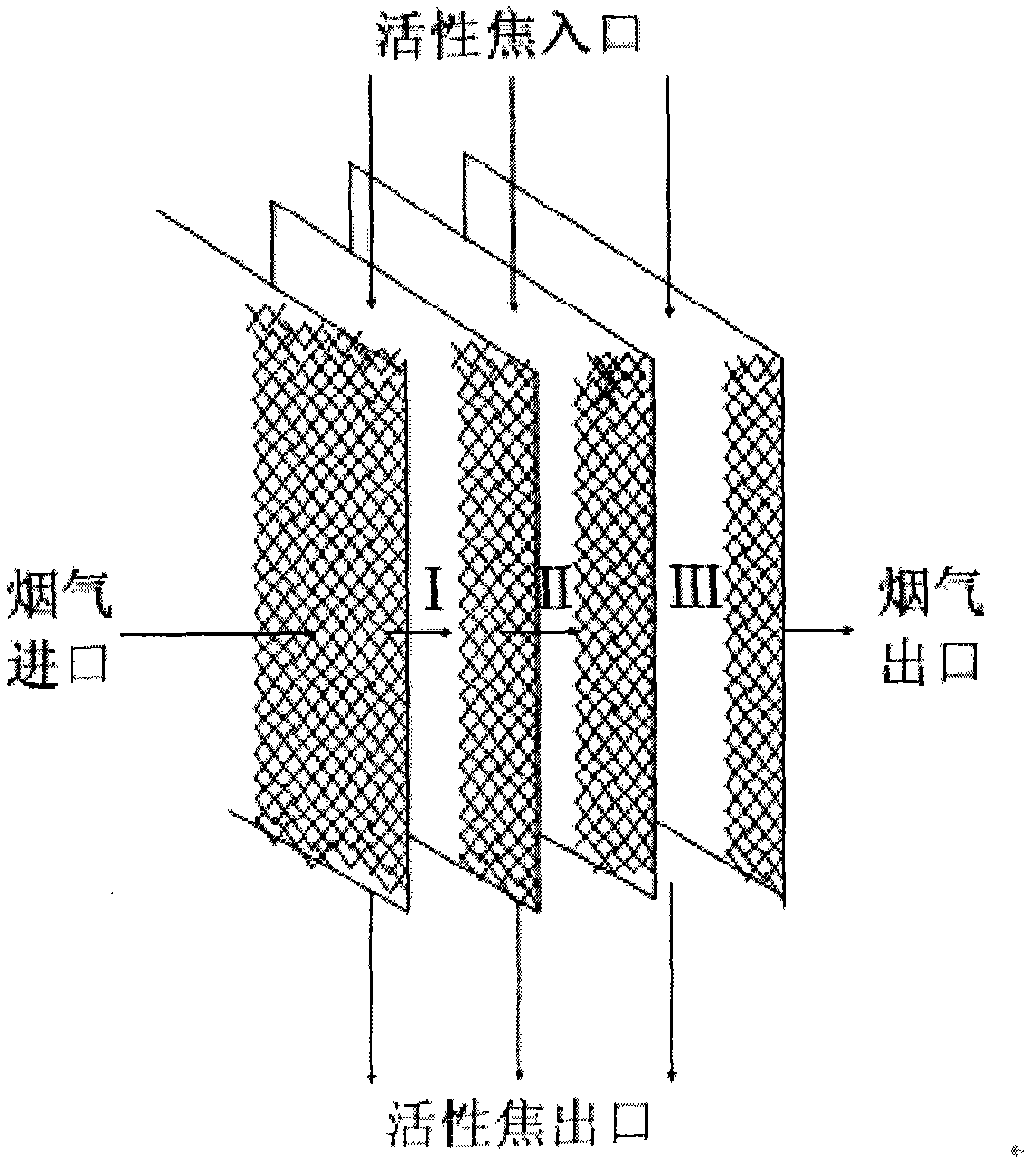

[0036] The schematic diagram of the device is shown in figure 1 As shown, each mark in the figure is as follows: 1 desulfurization reactor, 2 denitrification reactor, 3 NO desorption zone, 4 NO enrichment zone, 5 SO 2 Desorption zone, 6 SO 2 Enrichment zone, 7 active coke cooling zone, 8 screening device, 9 flue gas outlet, 10 active coke denitrification reactor inlet, 11 flue gas inlet, 12 active coke denitrification reactor outlet, 13 active coke desulfurization reactor inlet, 14 Active coke desulfurization reactor outlet.

[0037] The combined flue gas desulfurization and denitration device of the present invention comprises a desulfurization reactor 1 and a denitration reactor 2, the desulfurization reactor 1 and the denitration reactor 2 are connected in series, and the volume of the denitration reactor 2 is 1.5 times the volume of the desulfurization reactor 1; Reactor 1 is located on the...

Embodiment 2

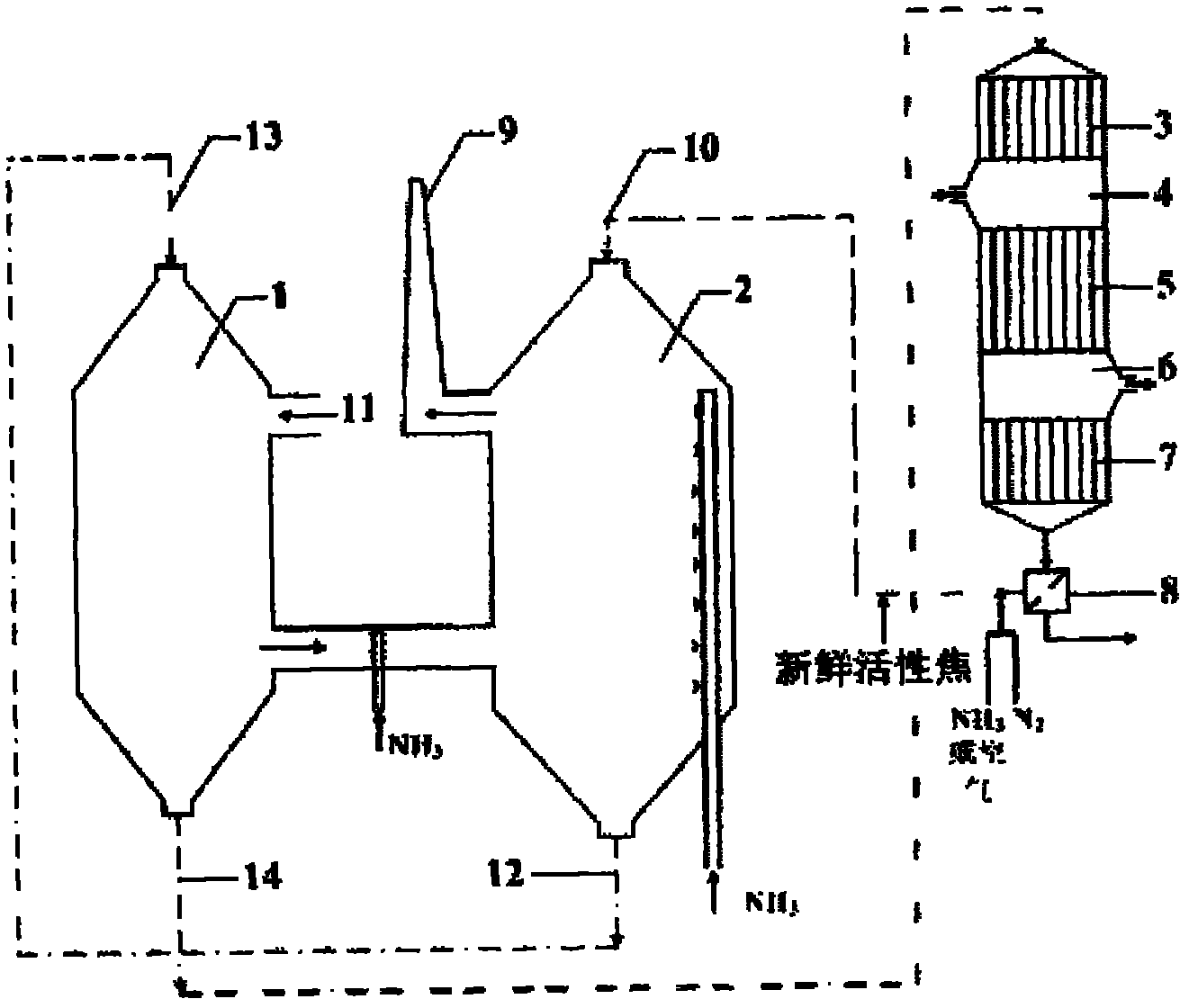

[0039] Example 2, flue gas combined desulfurization and denitrification device

[0040] The schematic diagram of the device is shown in figure 2 As shown, each mark in the figure is as follows: 1 desulfurization reactor, 2 denitrification reactor, 3 NO desorption zone, 4 NO enrichment zone, 5 SO 2 Desorption zone, 6 SO 2 Enrichment zone, 7 active coke cooling zone, 8 screening device, 9 flue gas outlet, 10 active coke denitrification reactor inlet, 11 flue gas inlet, 12 active coke denitrification reactor outlet, 13 active coke desulfurization reactor inlet, 14 Active coke desulfurization reactor outlet.

[0041] The flue gas combined desulfurization and denitration device of the present invention comprises a desulfurization reactor 1 and a denitration reactor 2, the desulfurization reactor 1 and the denitration reactor 2 are connected in series, and the volume of the denitration reactor 2 is 1.2 times the volume of the desulfurization reactor 1; Reactor 1 is located on th...

Embodiment 3

[0043] Embodiment 3, use the flue gas combined desulfurization and denitrification device of embodiment 1 to carry out desulfurization and denitrification

[0044] Add 500t of initial activated coke from the inlet 10 of the denitrification reactor to the denitrification reactor 2 in the combined flue gas desulfurization and denitrification device of Example 1. The active coke moves from top to bottom in the denitration reactor 2 by gravity and The NH spray installed in the adsorption denitrification reactor 2 3 NH emitted from the device 3 , remove NO and SO from flue gas 2 Then come out from the outlet 12 of the active coke denitrification reactor and enter the desulfurization reactor 1 through the inlet 13 of the active coke desulfurization reactor. The active coke moves from top to bottom in the desulfurization reactor 1 by gravity, absorbing NO and SO 2 ; Then come out from the outlet 14 of the active coke desulfurization reactor and enter the regeneration reactor throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com