Raw bauxite secondary crushing device for manufacturing brown fused alumina

A technology for secondary crushing and raw bauxite, applied in grain processing and other directions, can solve the problems of increasing factory production costs, unfavorable industrial production, and troublesome transportation, and achieves the effects of reducing the amount of crushing, simple structure, and convenient production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

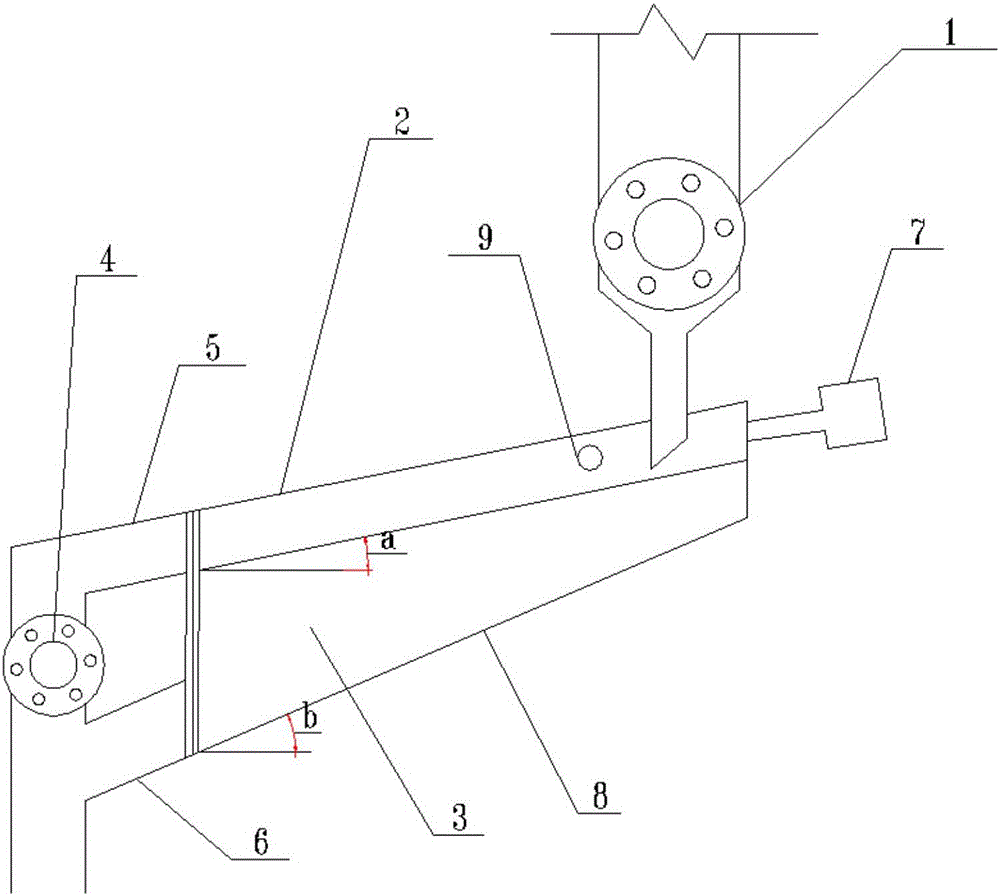

[0013] The embodiment of the present invention: a raw bauxite secondary crushing device for making brown steel jade, as shown in the figure, includes a raw bauxite crusher 1 for the first damage, and a raw bauxite crusher 1 A screen 2 is set below 1, and the upper end of the screen 2 is aligned with the discharge port of the raw bauxite crusher 1. A storage box 3 is set below the screen 2, and the output end of the screen 2 is connected to the raw bauxite crusher 1. The second 4 bauxite crusher and the storage box 3 are connected to the output end of the second 4 raw bauxite crusher through the second pipe 6 so that the raw bauxite in the screen 2 and the storage box 3 can be combined to flow into the next process.

[0014] The screen 2 is placed obliquely, and the inclination angle a is 30-75 degrees. A vibrator 7 is provided at the front end of the screen 2 to realize the vibrator 7 to drive the screen 2 to vibrate. The bottom of the storage box 3 is an inclined slide 8. The an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com