Building waste smashing device with smashing rollers with extrusion rollers

A construction waste and crushing device technology, applied in non-rotational vibration suppression, grain processing and other directions, can solve the problems of unfavorable construction waste reuse, poor crushing quality, low crushing efficiency, etc., to reduce vibration and noise, reduce crushing costs, Guaranteed effect of crushing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

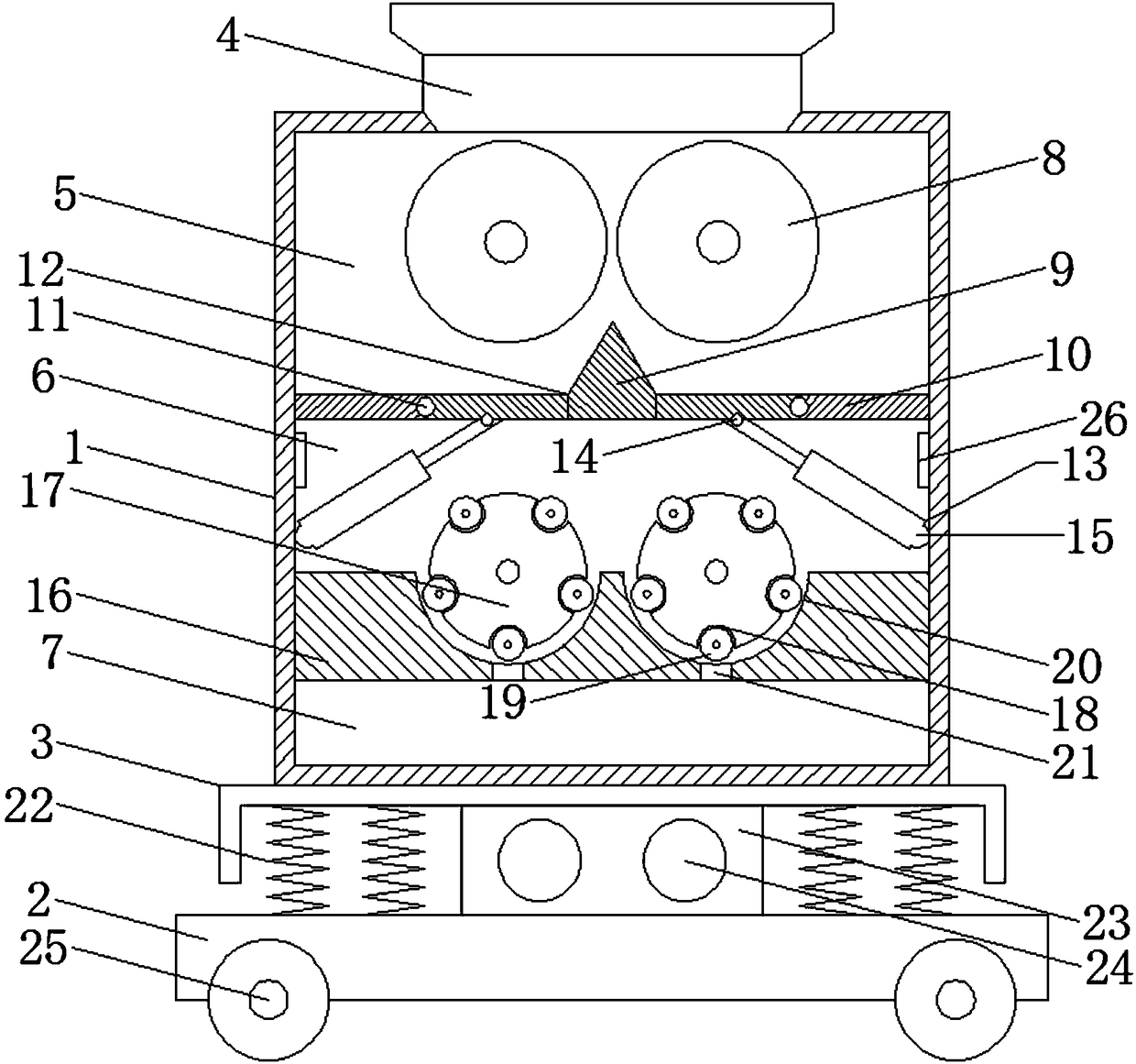

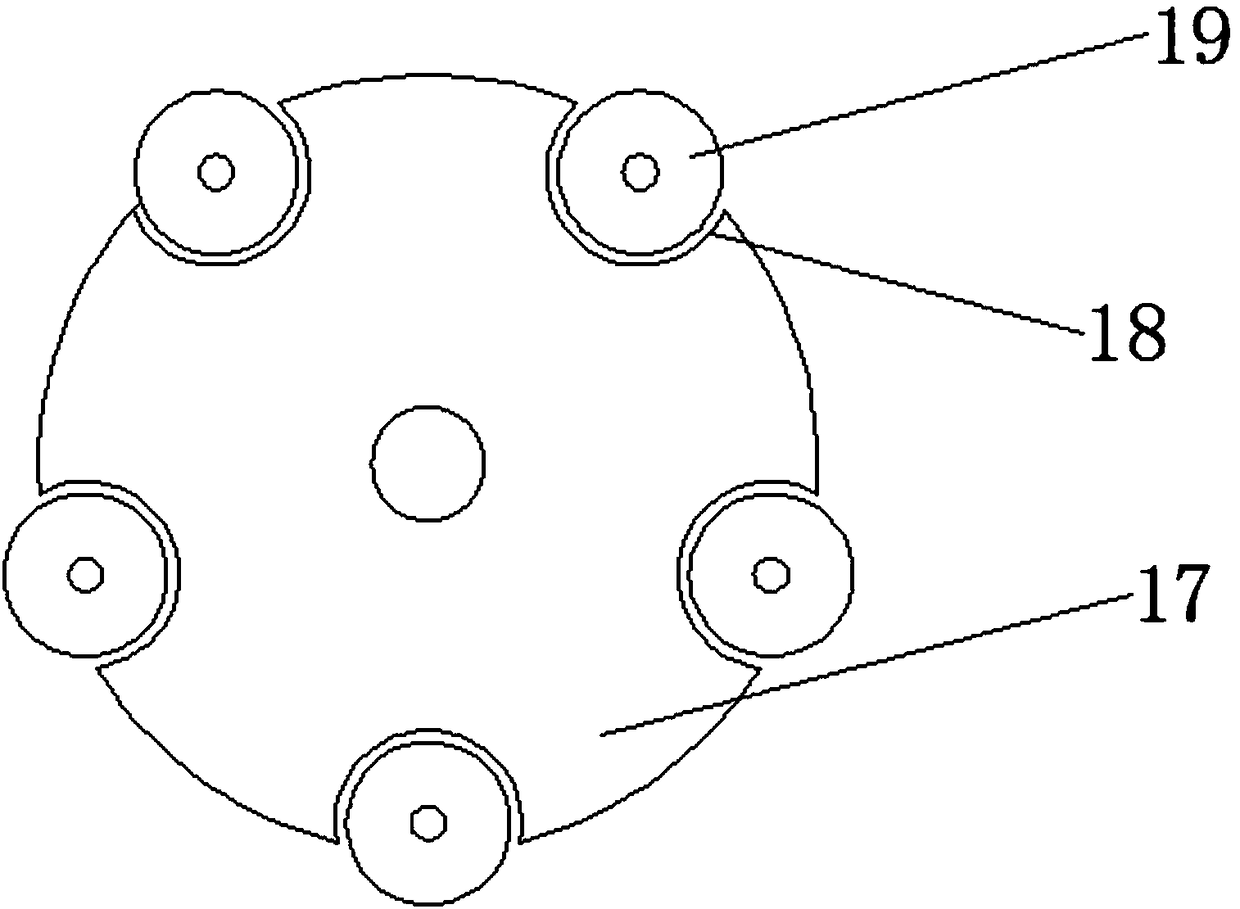

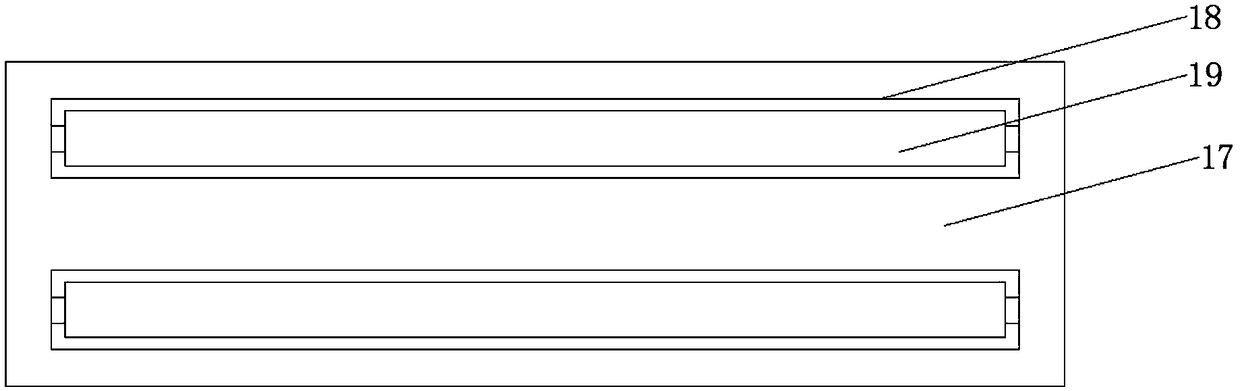

[0019] Please refer to the figure, in the embodiment of the present invention, a construction waste crushing device with a crushing roller and a squeezing roller includes a housing 1, a base 2, a support plate 3 and a feed hopper 4; The roller 25 makes the device move conveniently and is convenient to use flexibly on the construction site; the support plate 3 is located above the base 2, and several support springs 22 and a shock absorber 23 are fixedly connected between the support plate 3 and the base 2, The upper end of the support spring 22 is fixed on the support plate 3, the lower end is fixed on the base 2, the support plate 3 is supported by the support spring 22, the material of the shock absorber 23 is rubber, and the inside of the shock absorber 23 is provided with a plurality of cavities 24 , the cavity 24 makes the interior of the shock absorbing block 23 hollow, which facilitates the deformation of the shock absorbing block 23 and plays a role of shock absorbing a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com