Coke discharging and crushing device

A crushing device and coke technology, which is applied in the direction of grain processing, etc., can solve the problems of inability to absorb thermal expansion and deformation of the coke tower, reduce the probability of stalling and poor feeding, reduce the amount of crushing, and reduce the possibility of ineffective feeding sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing.

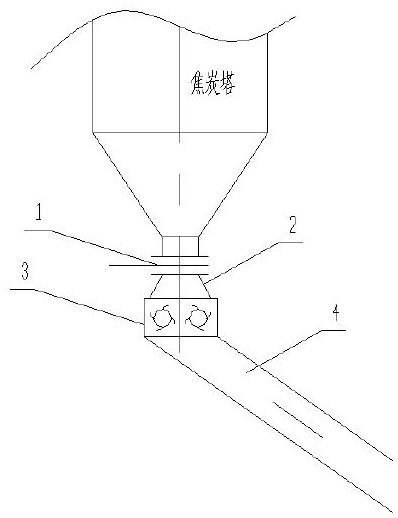

[0021] Such as figure 1 As shown, it includes a bottom cover machine 1, a flexible connection section 2, a crusher 3, and an inclined chute 4; after the petroleum coke is output from the coke tower, it passes through the bottom cover machine 1, passes through the flexible connection section 2, and enters the screening crusher 3 for crushing. The flexible coupling section 2 is connected directly below the bottom cover machine 1 and is connected to the upper surface of the crusher 3; the outlet of the lower surface of the crusher 3 is directly connected to the chute mouth of the inclined chute 4; the crusher 3 is installed on the bottom cover machine 1 and Between the inclined chute 4, the bottom cover machine 1 is connected with the crusher 3 through the flexible coupling section 2.

[0022] When decoking, a large amount of coke and water are mixed and freely fall from a hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com