Gas heat carrier low-temperature pyrolyzing furnace and gas heat carrier low-temperature pyrolyzing method

A gas heat carrier and low-temperature pyrolysis technology, which is used in the field of low-temperature tar, gas and semi-coke, can solve the problems of large energy consumption and increase the processing burden of the gas cooling system, so as to reduce dust content, reduce sewage treatment capacity, and reduce losses. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

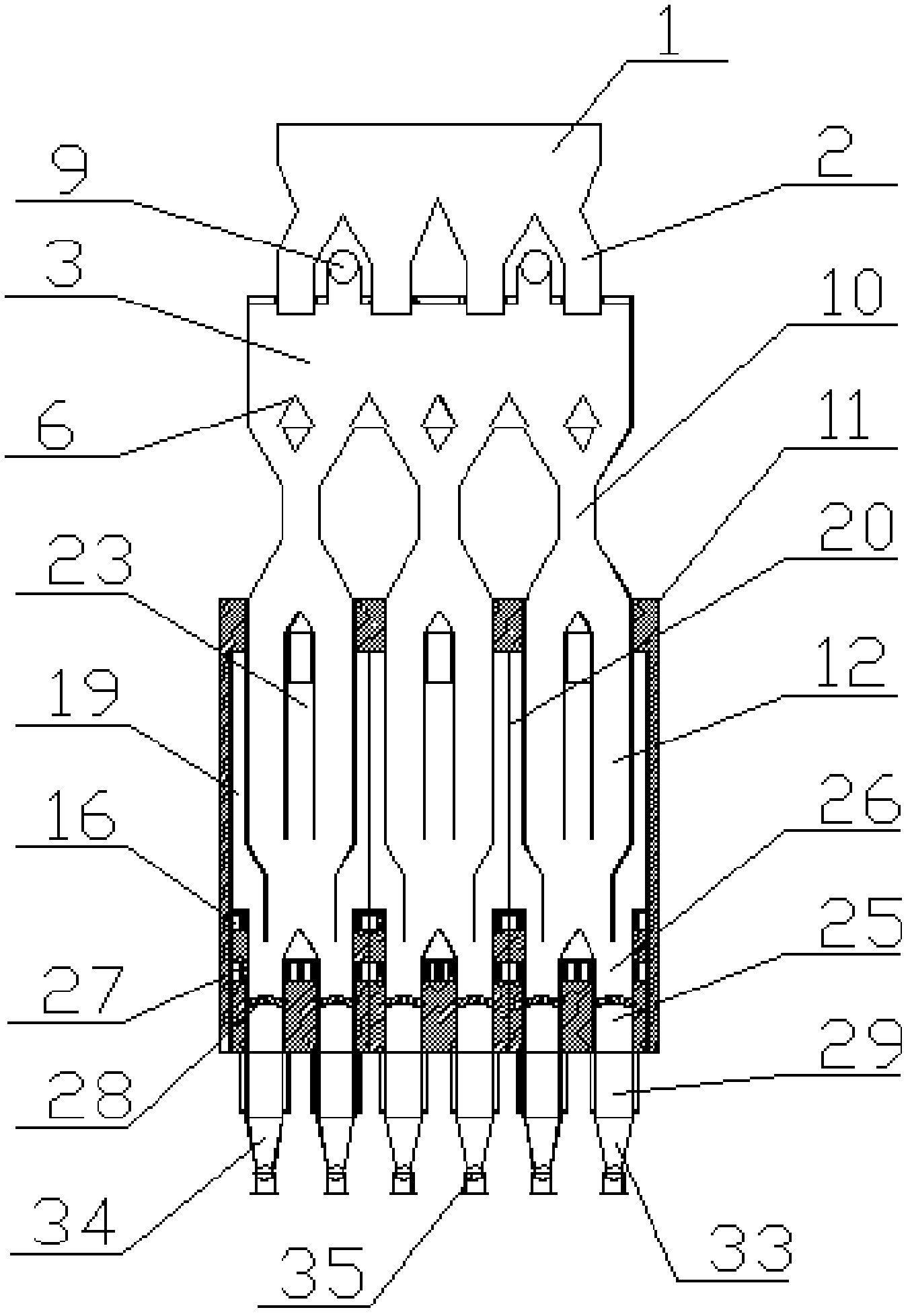

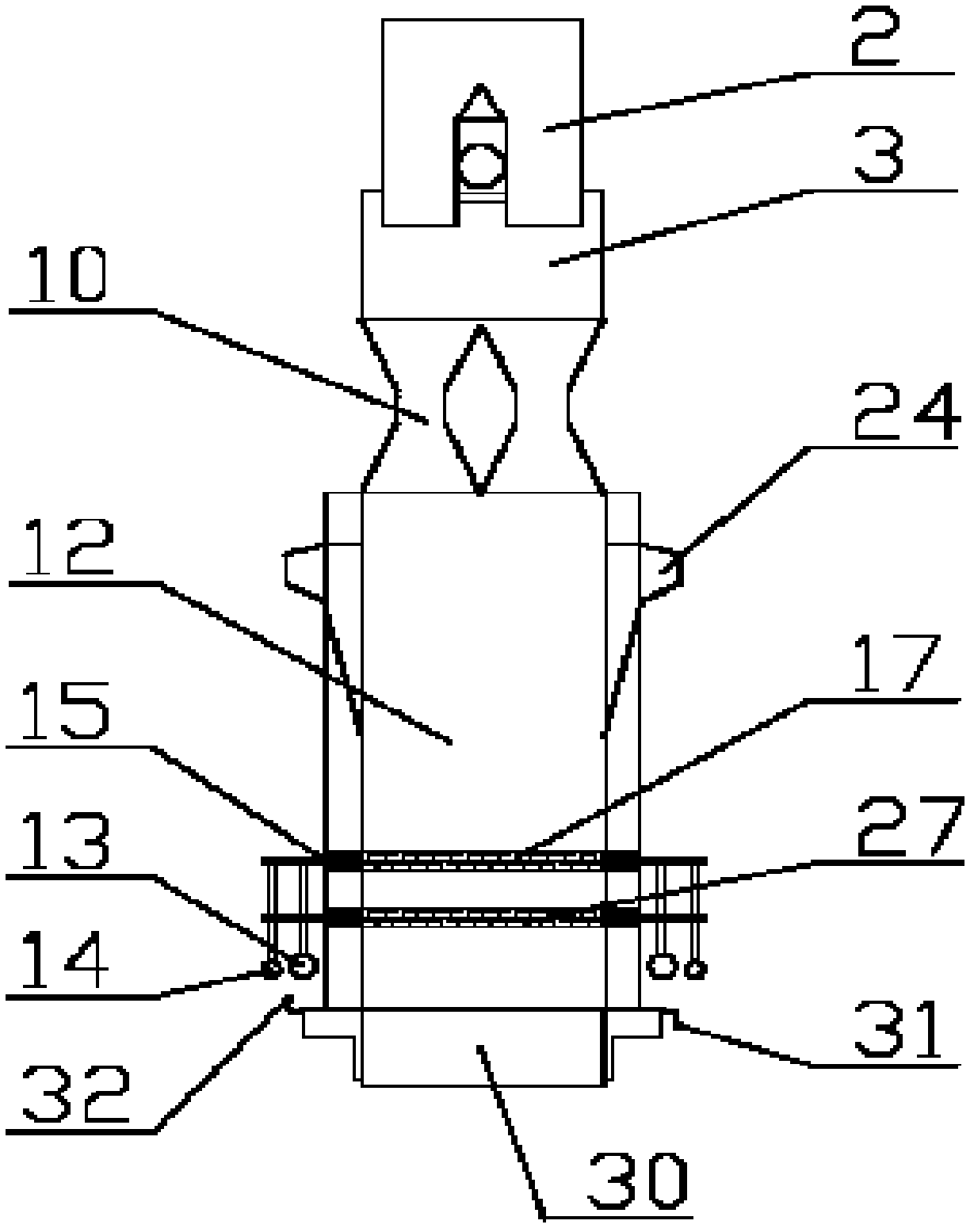

[0036] Embodiment 1: as figure 1 , figure 2 and image 3 As shown, a gas heat carrier low-temperature pyrolysis furnace for high-moisture non-viscous or weak-viscosity solid fuels includes a furnace body 11, a furnace top bunker 1, a furnace top distributor 2, a raw material drying section 3, Gas separation section 10, pyrolysis section 12, combined coke quenching section 25, semi-coke exporting device 33.

[0037] The raw material drying section 3 includes a main dry gas pipeline 4 , a dry gas branch pipe 5 , an air distribution umbrella 6 , a gas distribution bottom plate 7 , a dry gas outlet pipe 9 , and a gas barrier pipe 10 . The drying section adopts a steel structure; the drying air distribution air array umbrella adopts a triangular structure, and may also adopt a circular structure.

[0038] The pyrolysis section 12 includes a gas pipeline 13, an air pipeline 14, a gas-air mixed burner 15, a combustion chamber 16, a combustion chamber distribution flower wall 17, ...

Embodiment 2

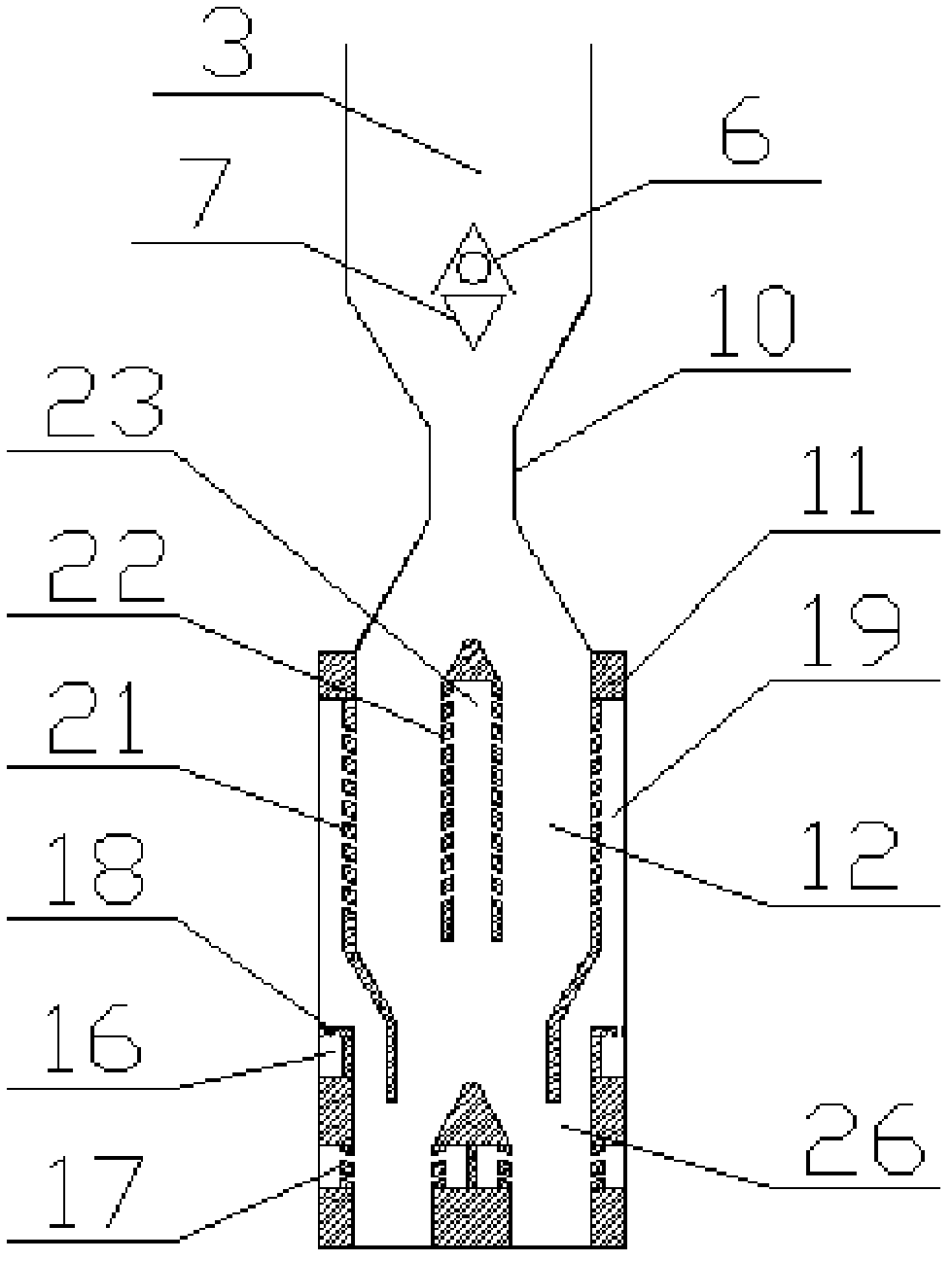

[0042] Embodiment 2: as Figure 4 , Figure 5 As shown, this embodiment is a form of drying gas distribution structure of the basic structural unit drying section 3, and the described drying gas distribution structure adopts a steel structure. The drying gas distribution structure is located at the bottom of the drying section, and at the top of the gas barrier area between the drying section and the pyrolysis section. The hot gas is evenly distributed into the air distribution umbrella 6 from the dry gas main pipeline 4 through the dry gas branch pipe 5. The cut surface of the air distribution umbrella is in the form of a triangle. There is a gap, and the dry gas enters the furnace from the bottom gap space.

Embodiment 3

[0043] Embodiment 3: as Image 6 , Figure 7 As shown, this embodiment is a form of drying gas distribution structure of the basic structural unit drying section 3, and the described drying gas distribution structure adopts a steel structure. The dry gas distribution structure is located in the middle and upper part of the gas barrier area between the drying section and the pyrolysis section. The hot gas is evenly distributed into the air distribution umbrella 6 from the dry gas main pipeline 4 through the dry gas branch pipe 5. The cut surface of the air distribution umbrella is a fan-shaped structure. The bottom of the air distribution umbrella is open, and the dry gas enters the furnace through the open space at the bottom. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com