Method for reducing coke and oligomer formation in a furnace

a technology of oligomer formation and furnace, which is applied in the direction of thermal non-catalytic cracking, cracking process, petroleum industry, etc., can solve the problems of bending of pipe down stream, affecting the operation of furnace, and affecting the efficiency of furnace operation,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

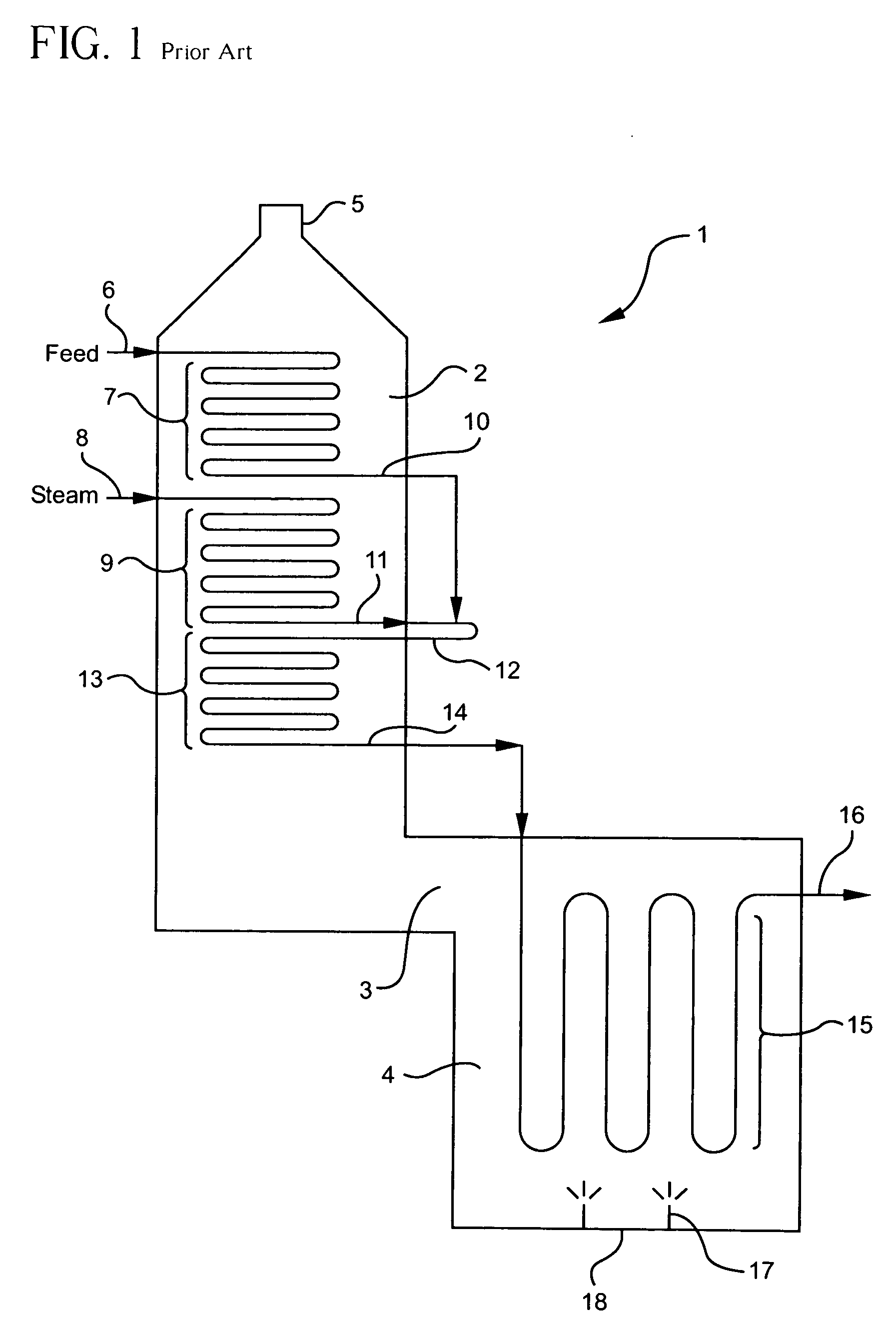

[0039]A liquid hydrocarbonaceous feed 6 comprising Algerian condensate is fed into furnace 1 at a temperature of about 250 F and pre-heated to a temperature of about 400 F in coils 7. The total operating amount of dilution steam employed in the cracking process is about 35 pounds per hour (pph).

[0040]Pursuant to the prior art, the full amount of this total operating amount of dilution steam would be supplied by way of conduit 11.

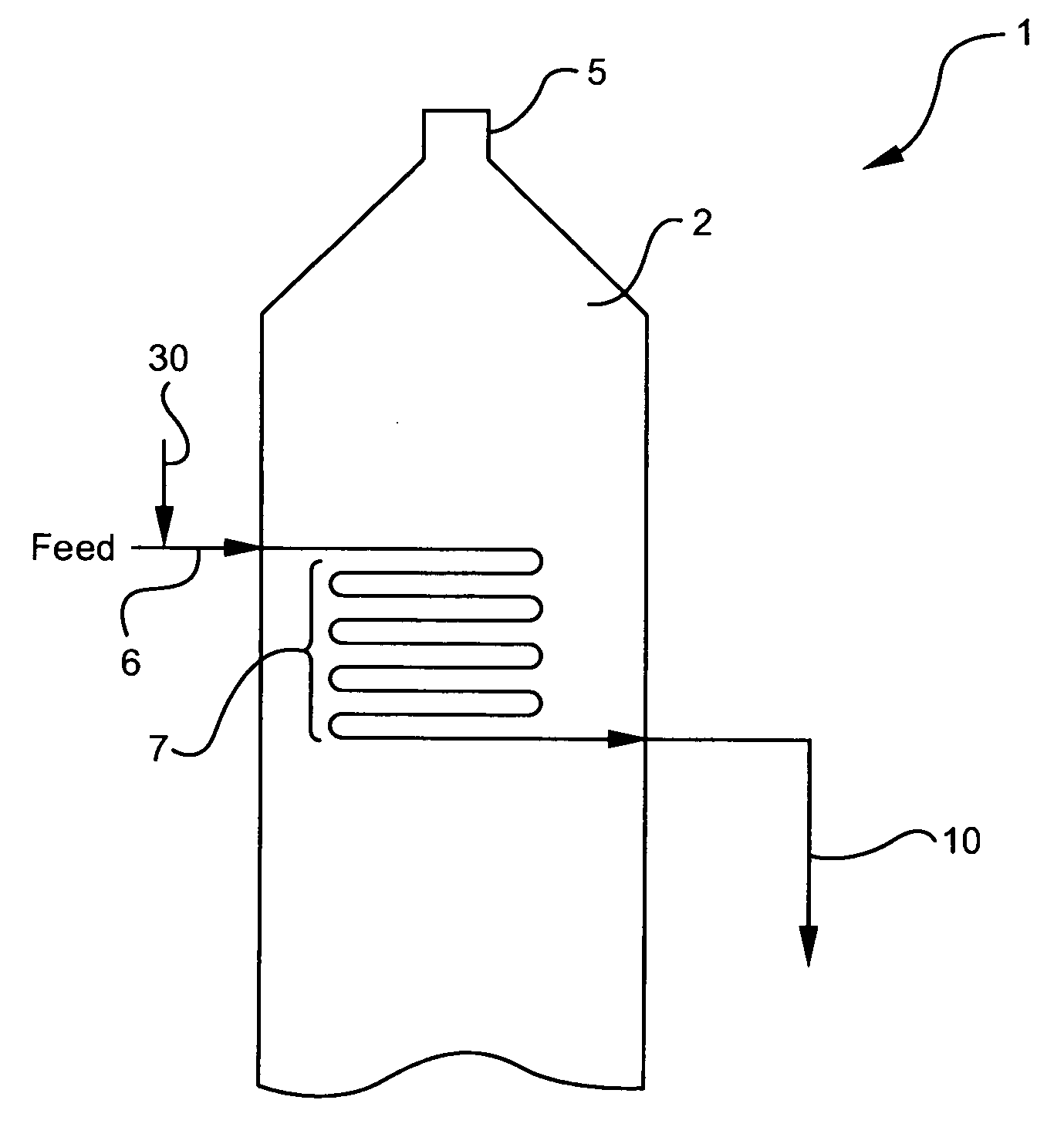

[0041]Pursuant to this invention, about 10 pph of the total operating amount of dilution steam is mixed with feed 6 by way of line 30 as feed 6 enters the interior of furnace 1 for pre-heating of that feed in coils 7, and only about 25 pph of the total operating dilution steam is added by way of line 11.

[0042]The 10 pph of dilution steam, added by way of conduit 30 before the addition of the preponderance (25 pph) of the total operating dilution steam by way of line 11, is an amount effective to reduce the formation of coke in coils 13 by at least half as co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| partial pressure | aaaaa | aaaaa |

| total weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com