Patents

Literature

66 results about "Coke deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

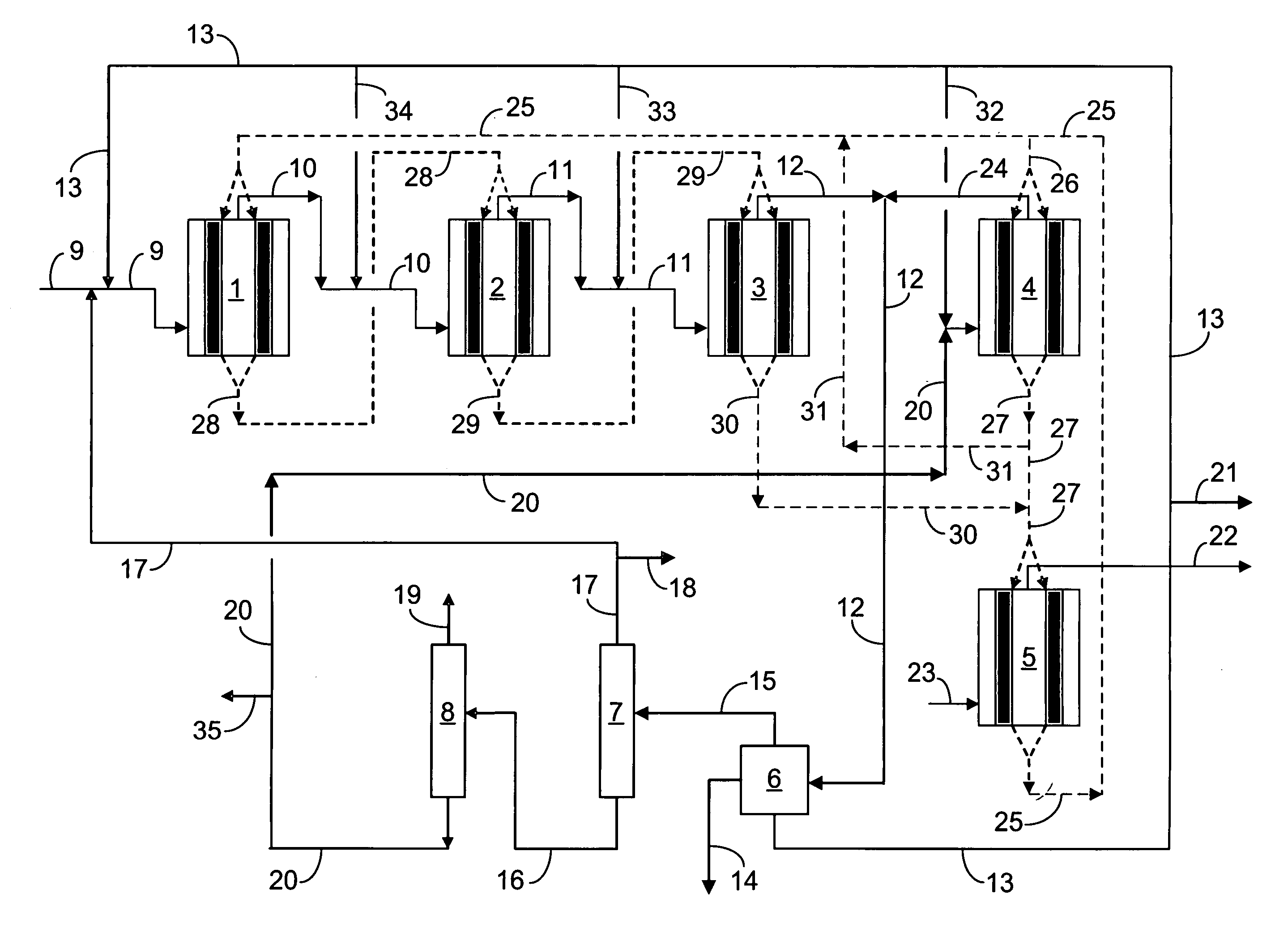

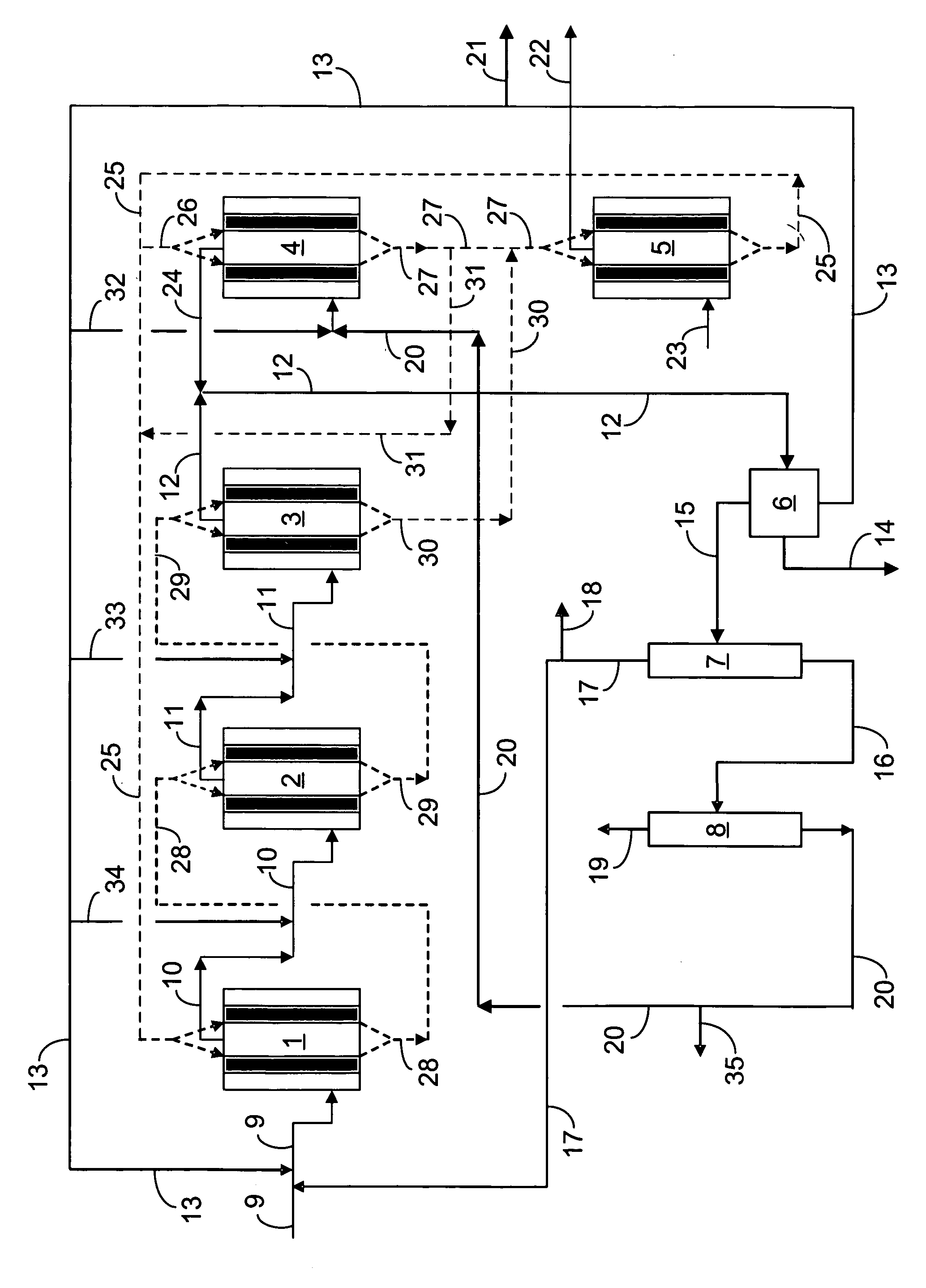

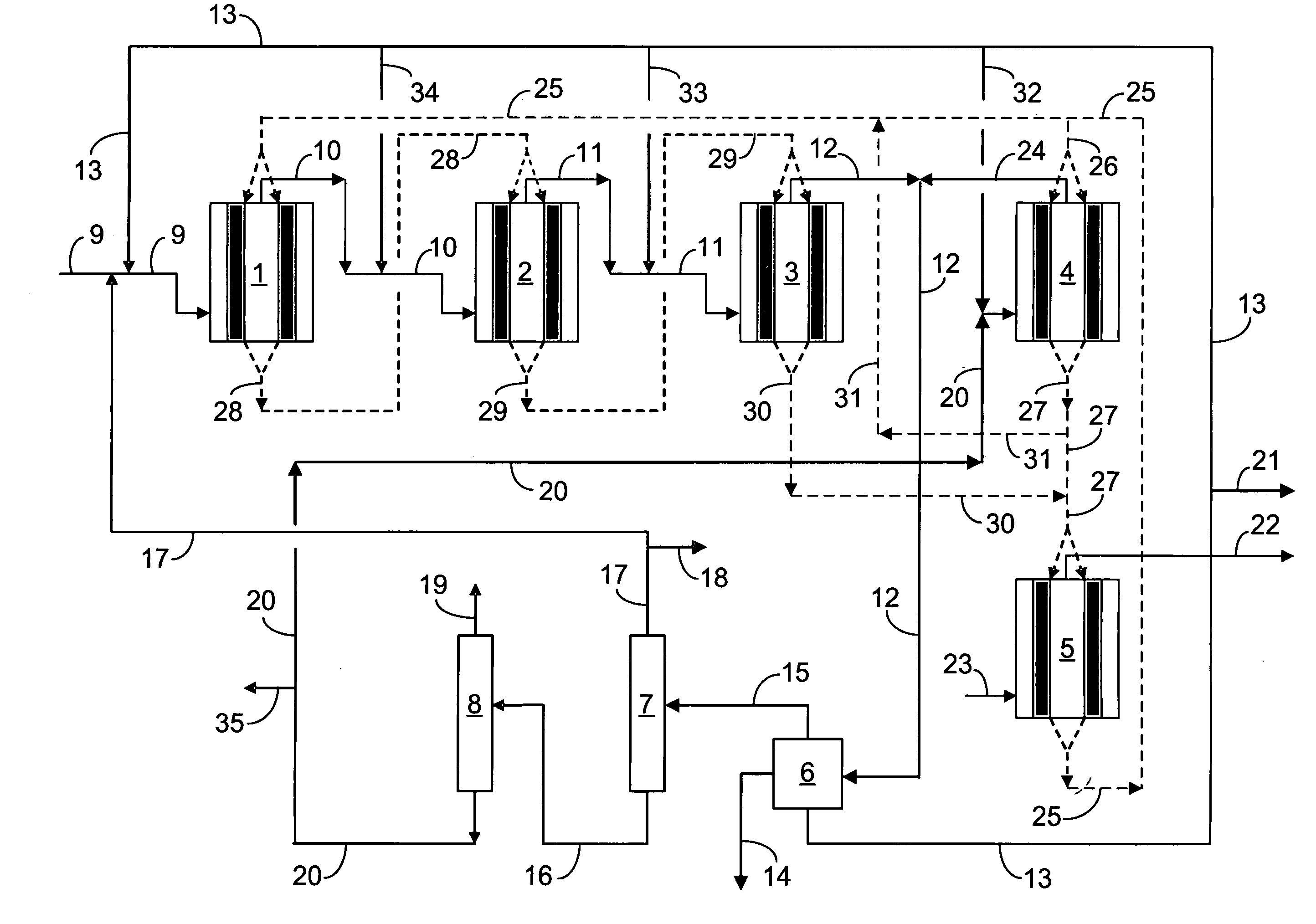

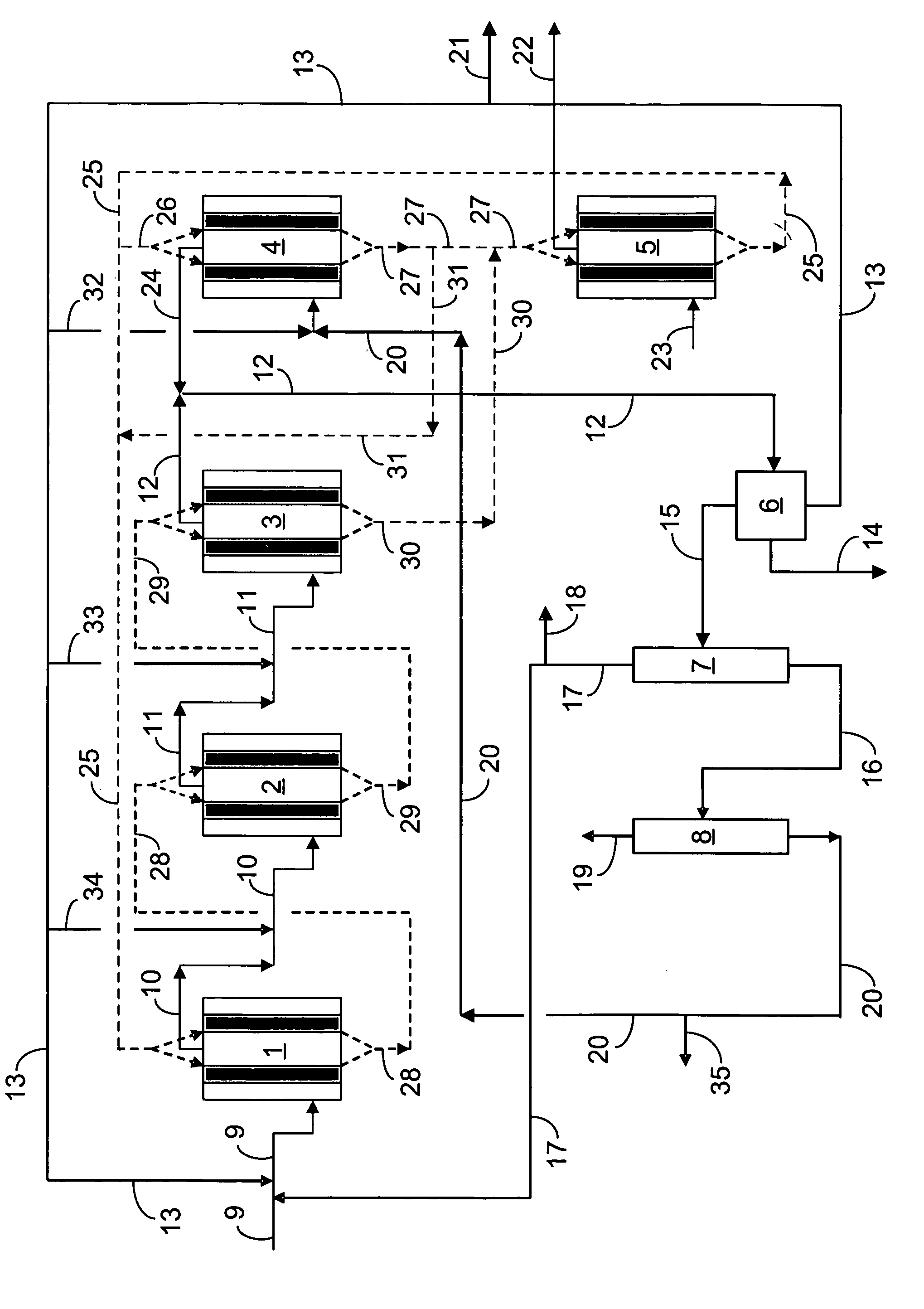

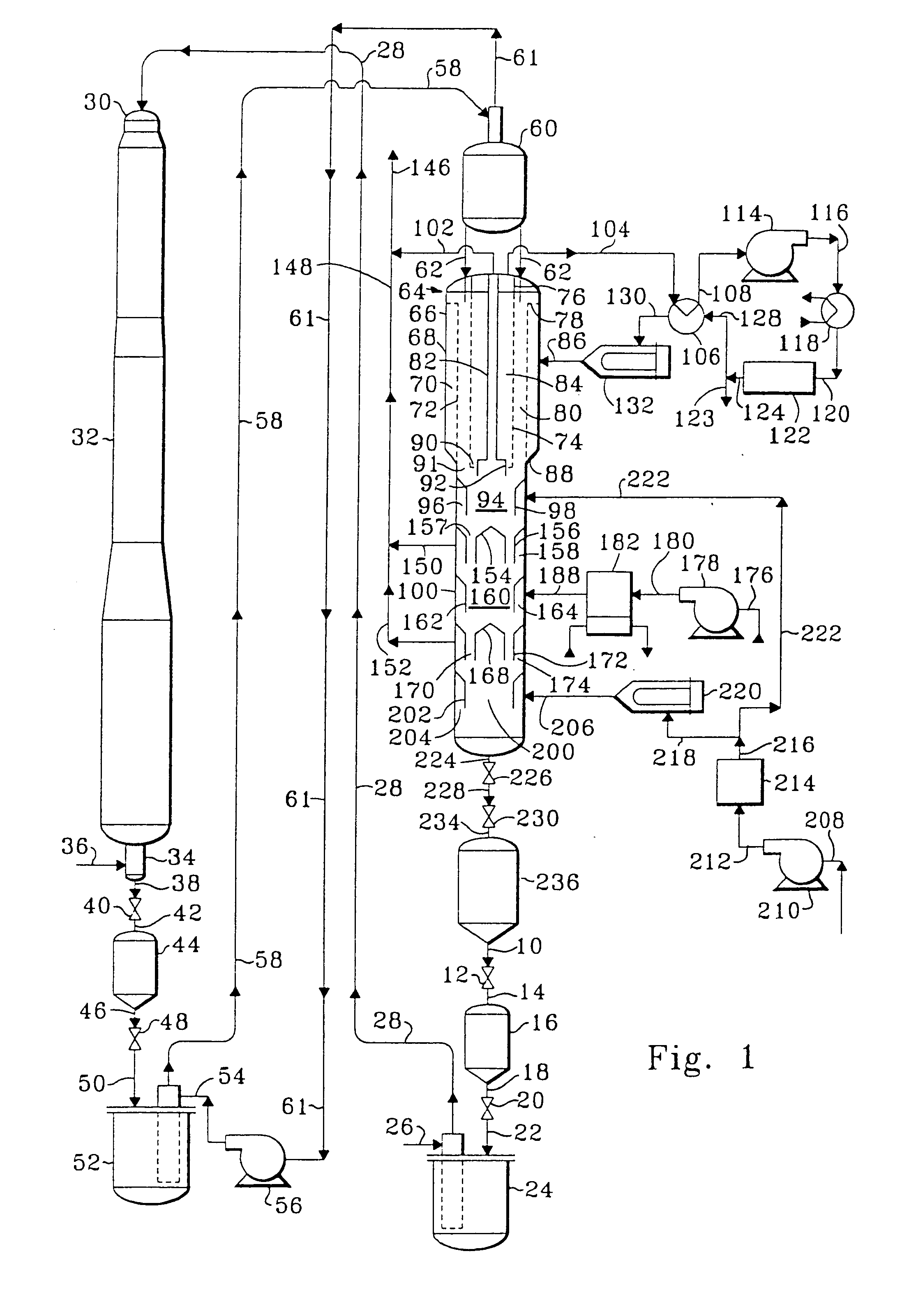

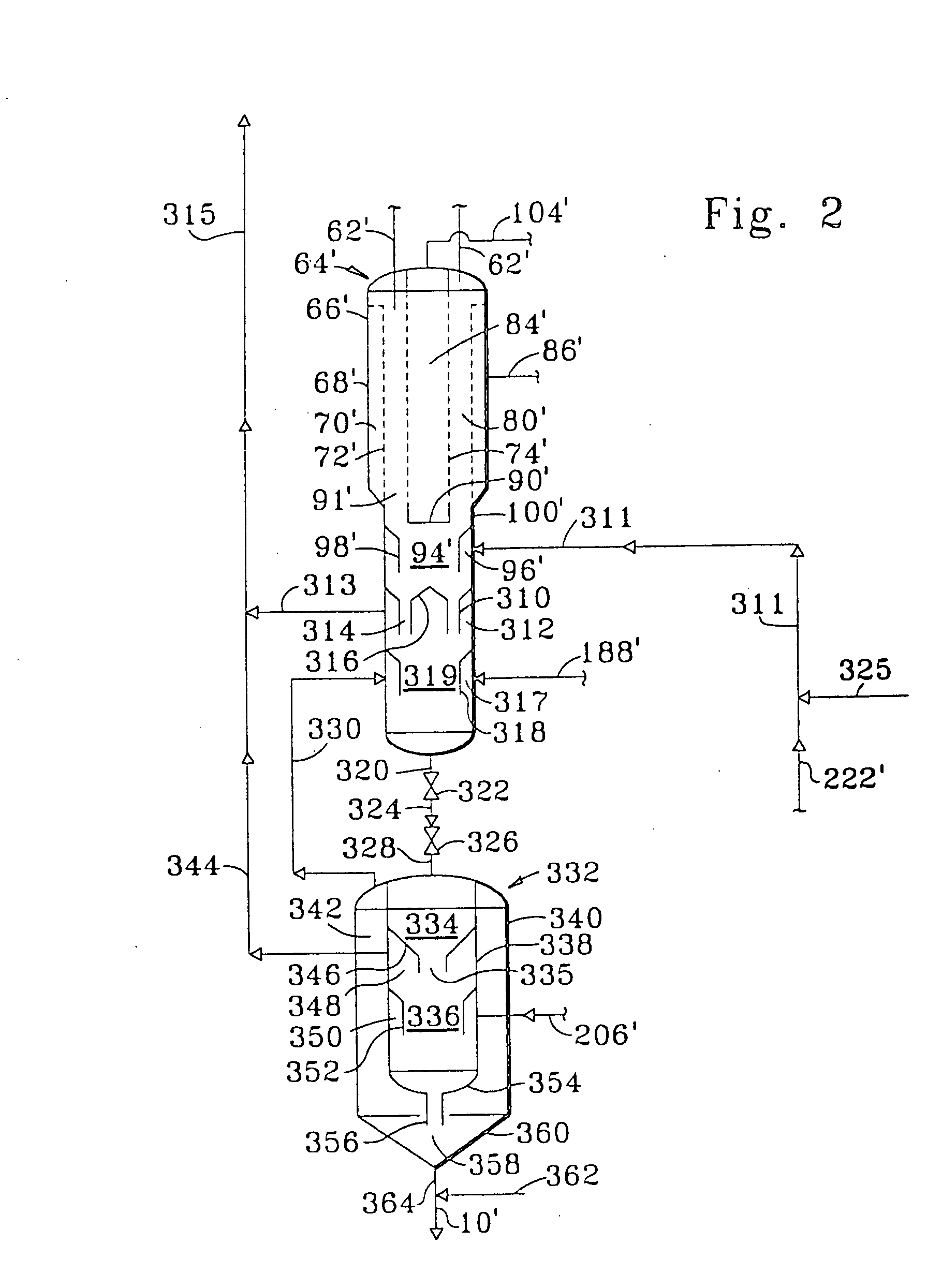

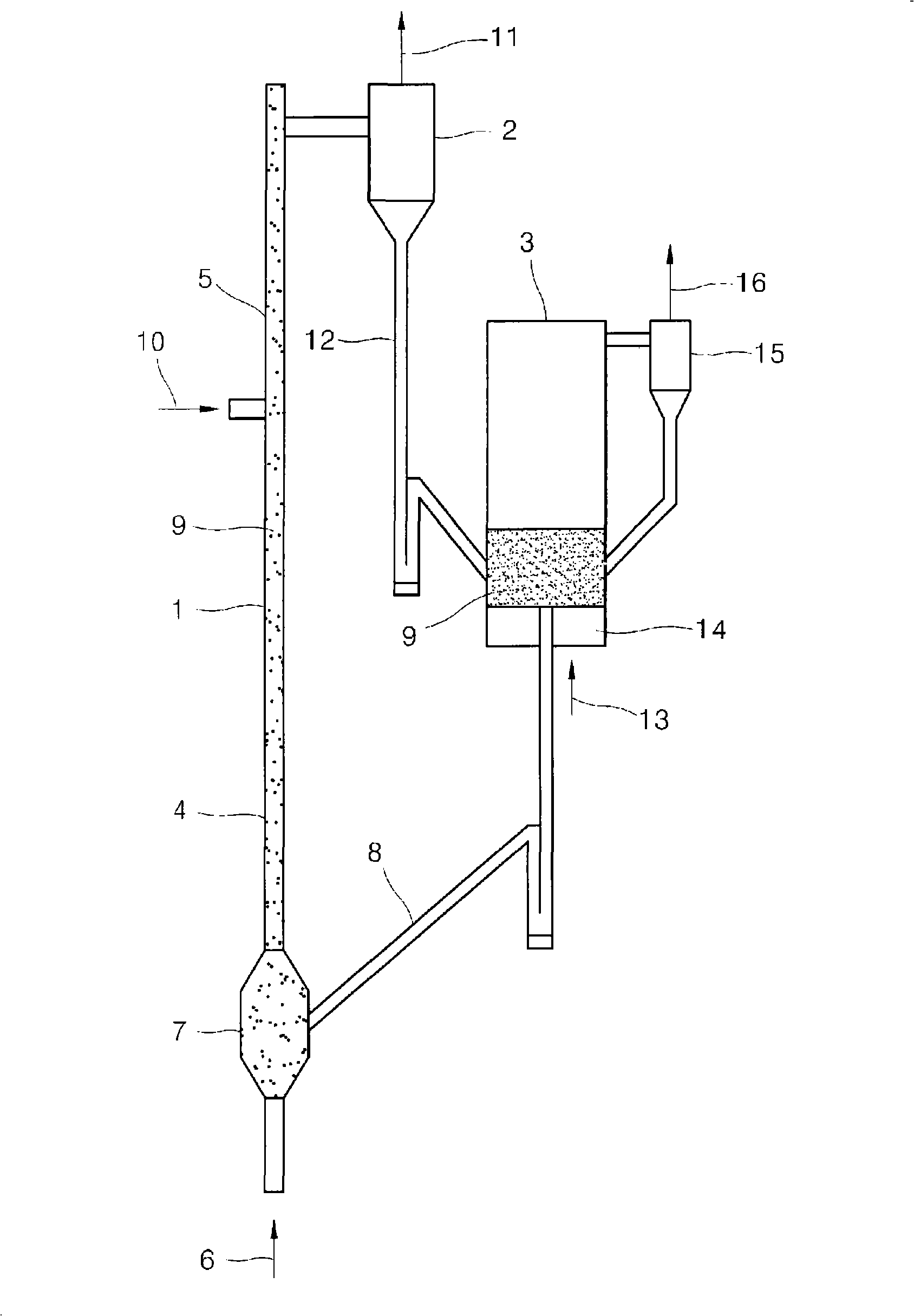

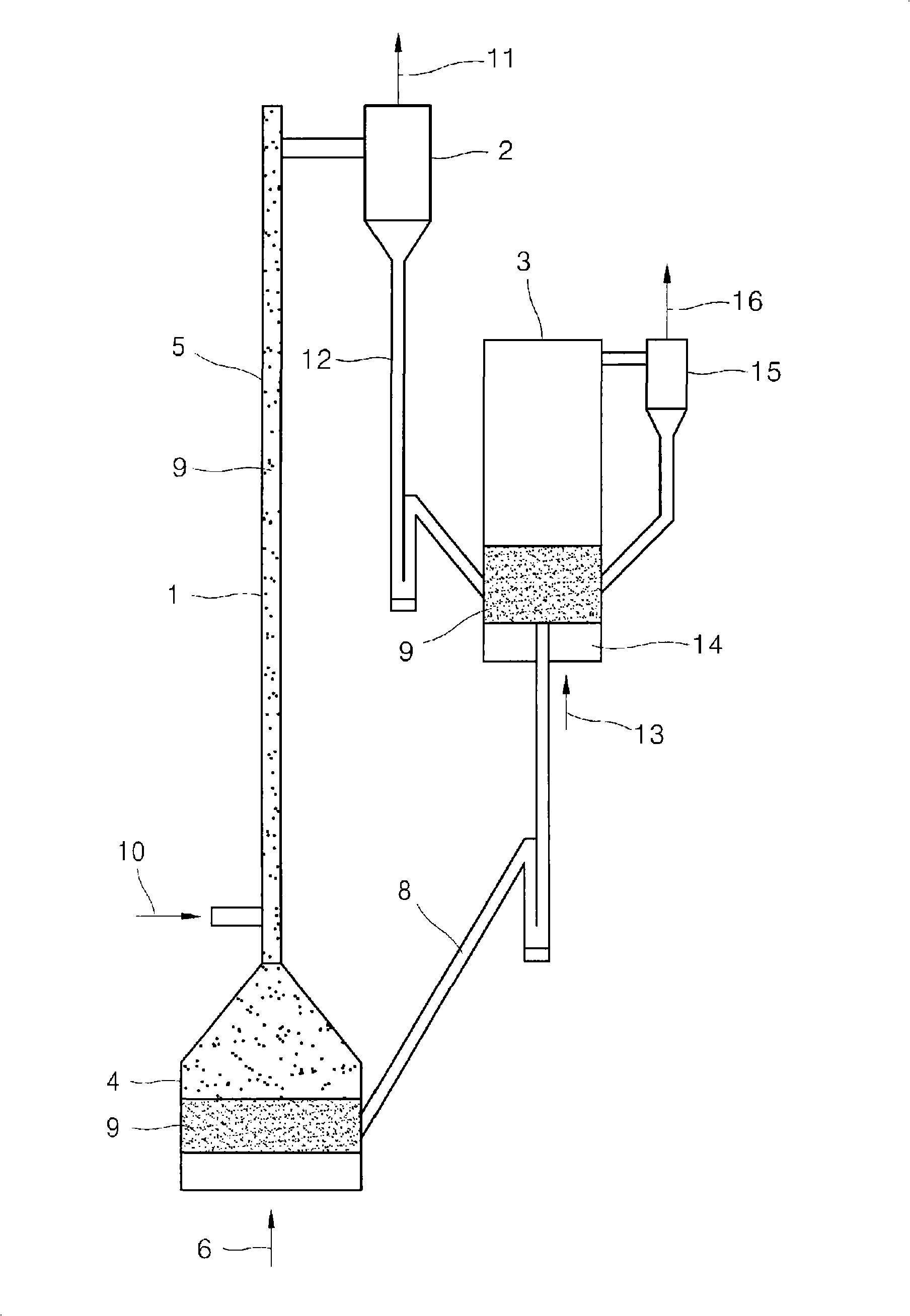

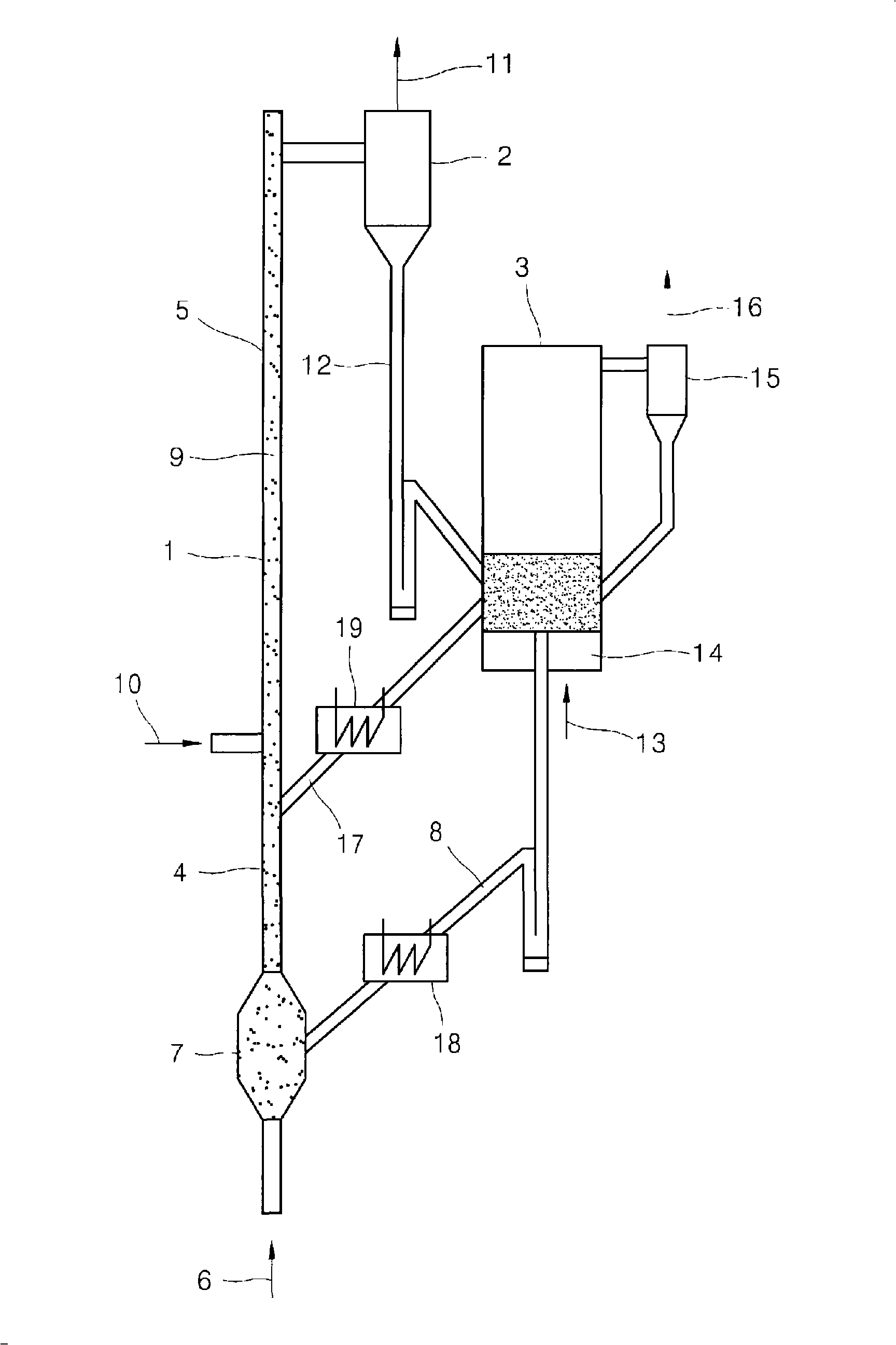

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

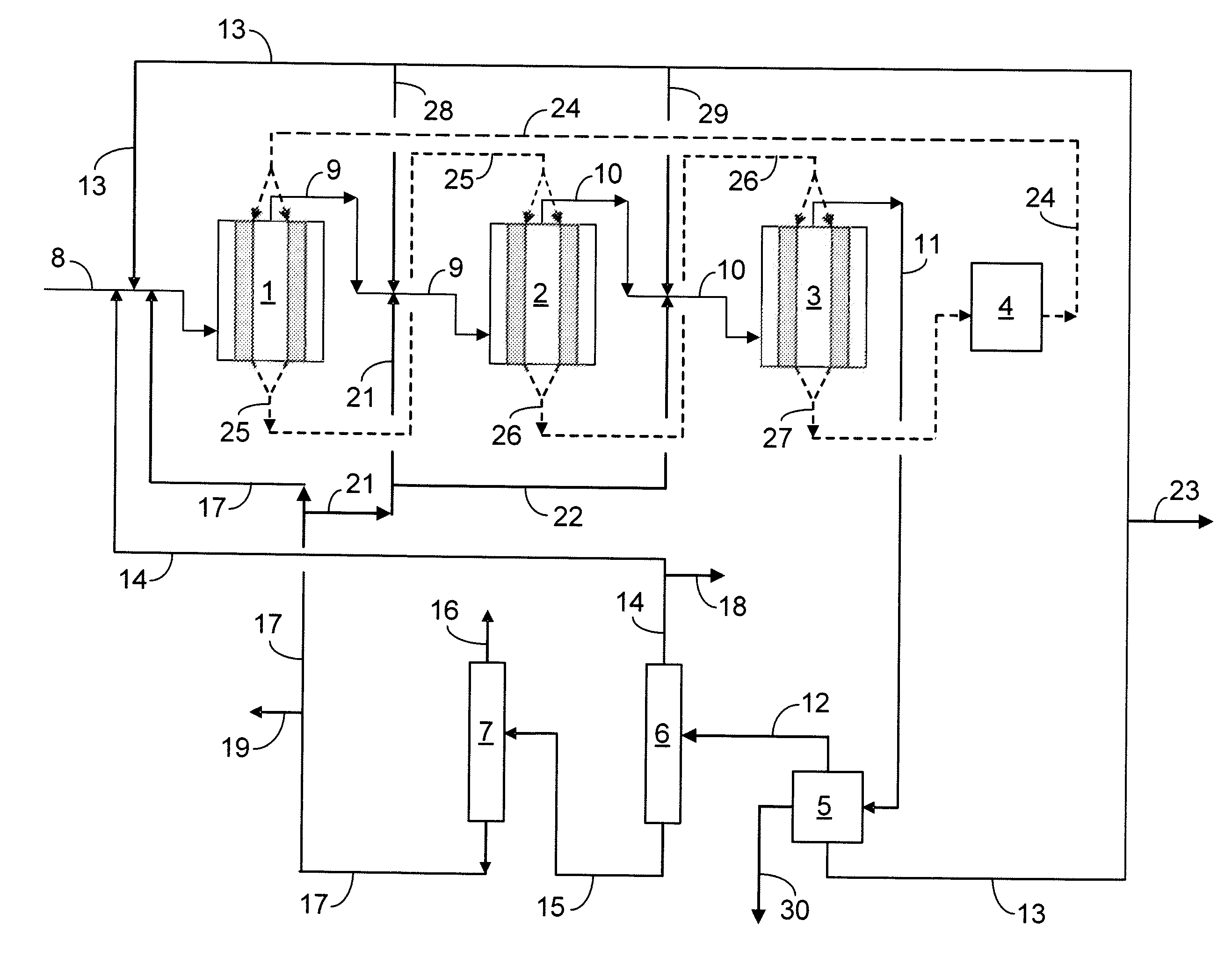

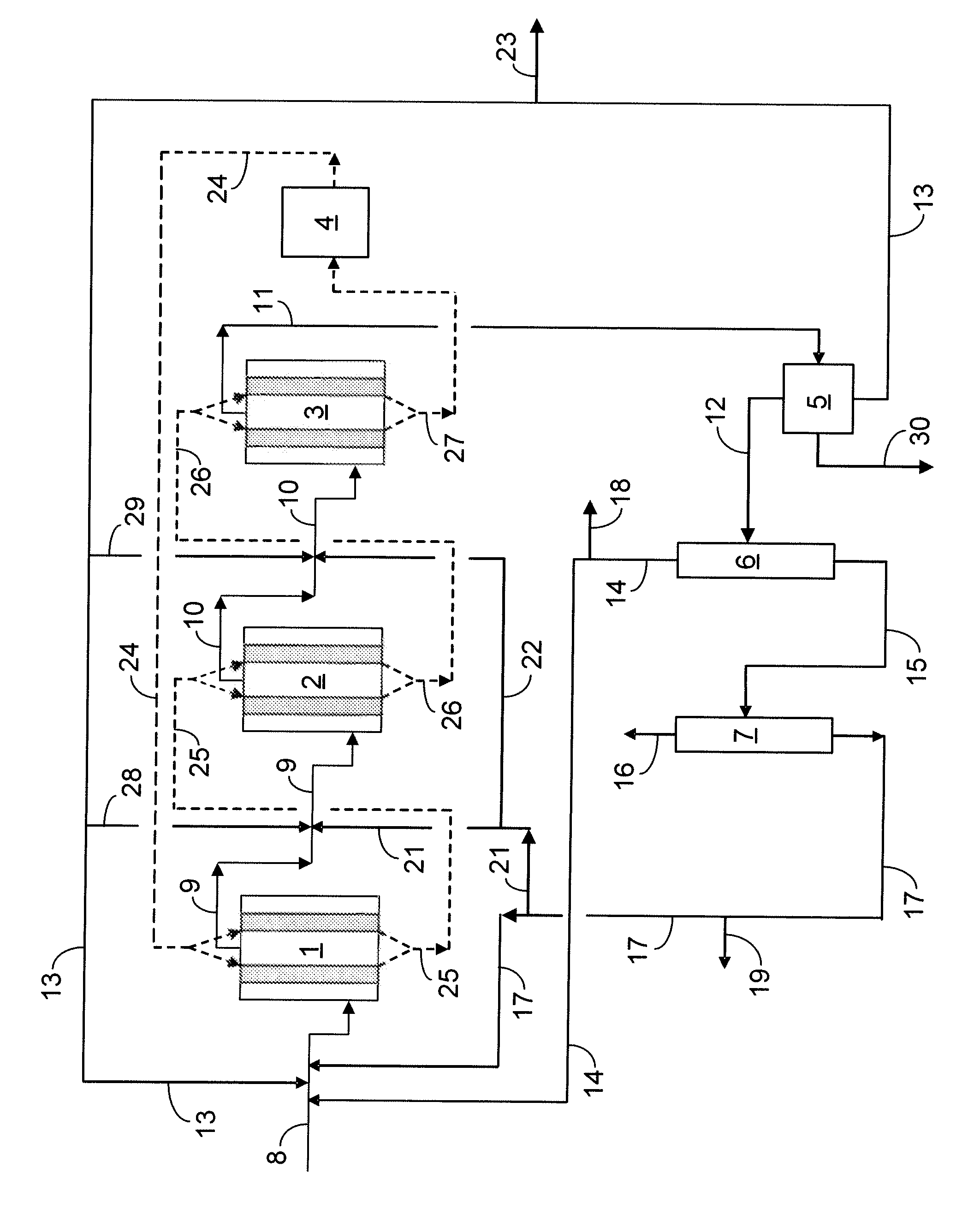

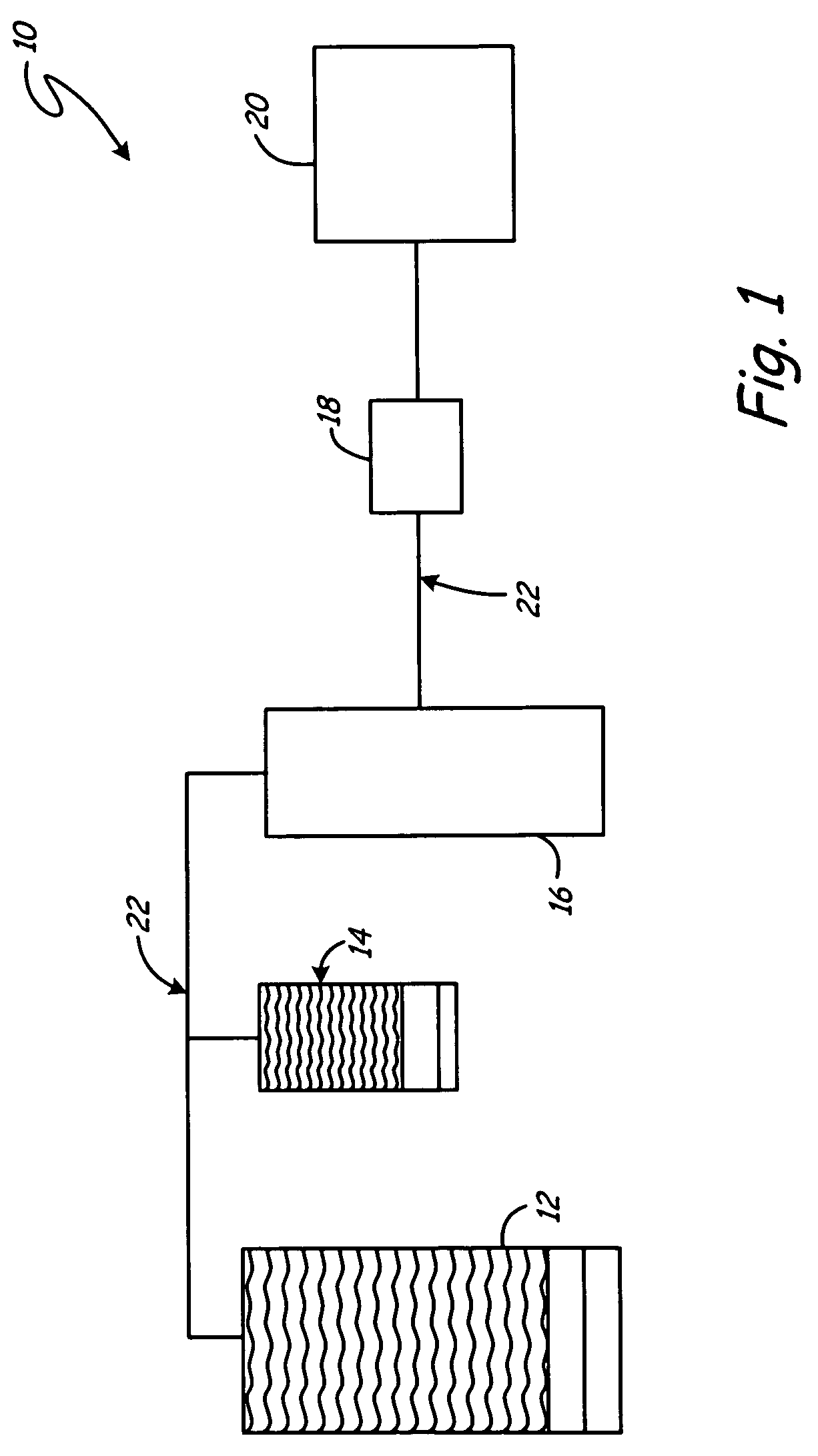

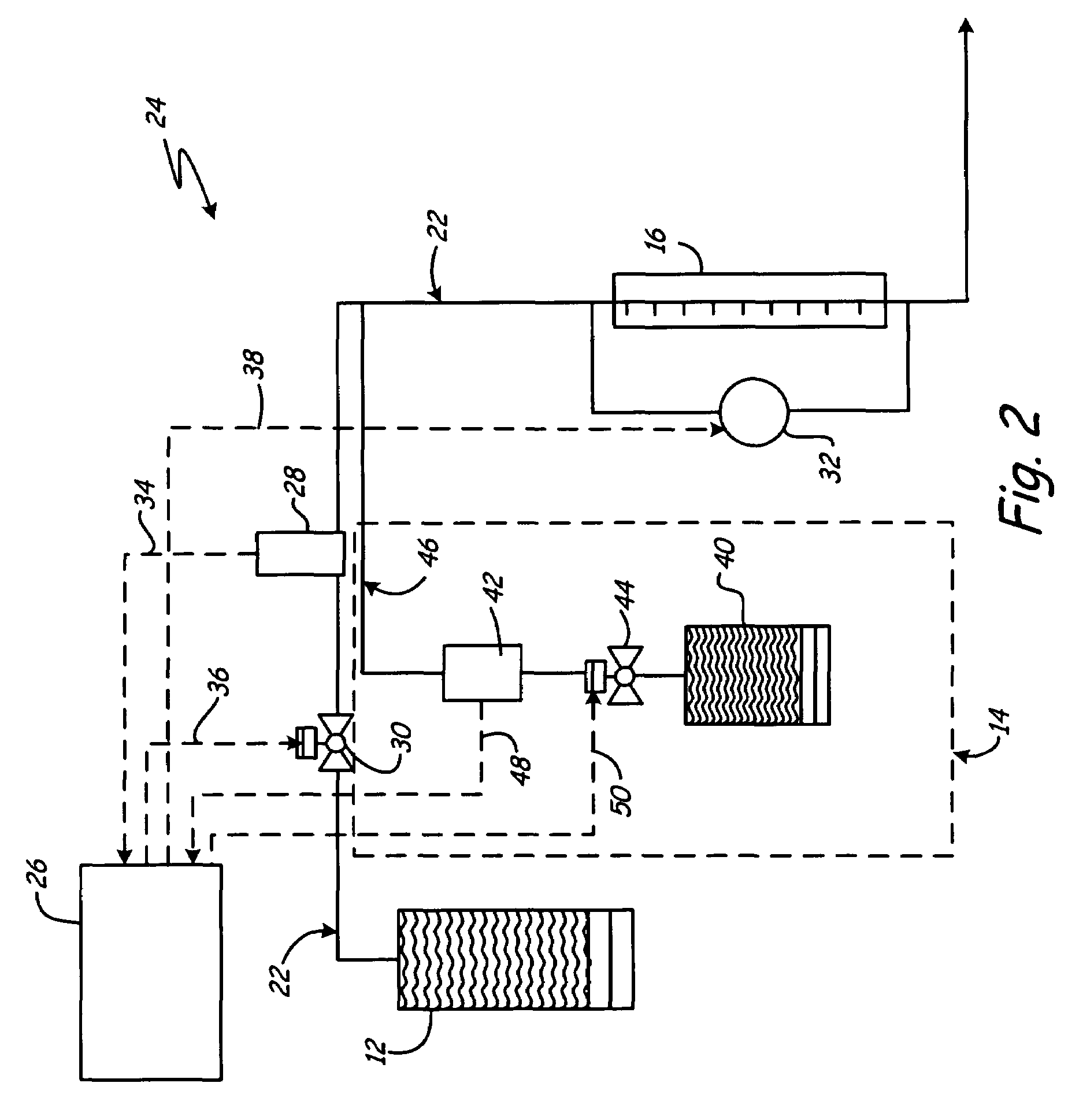

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

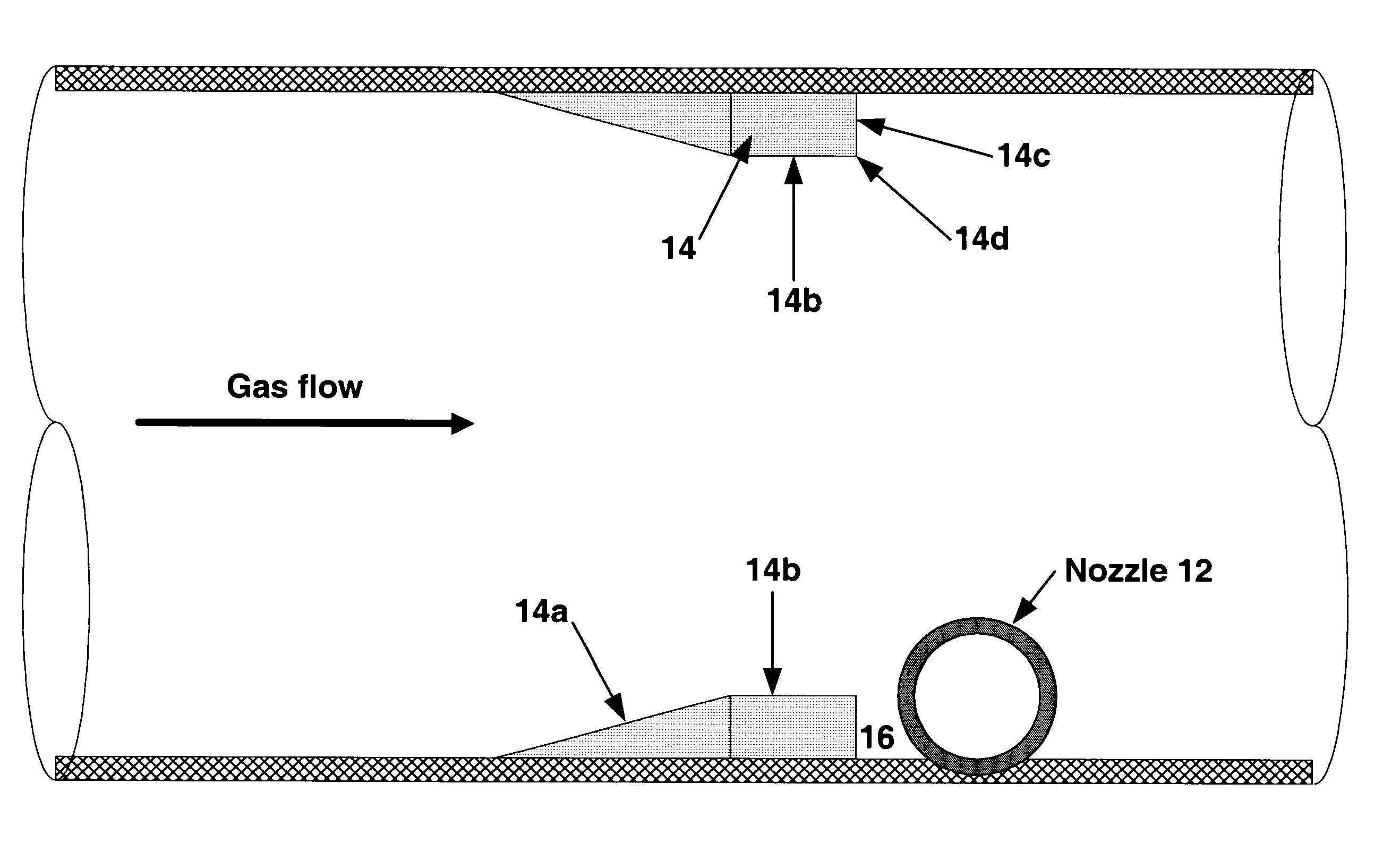

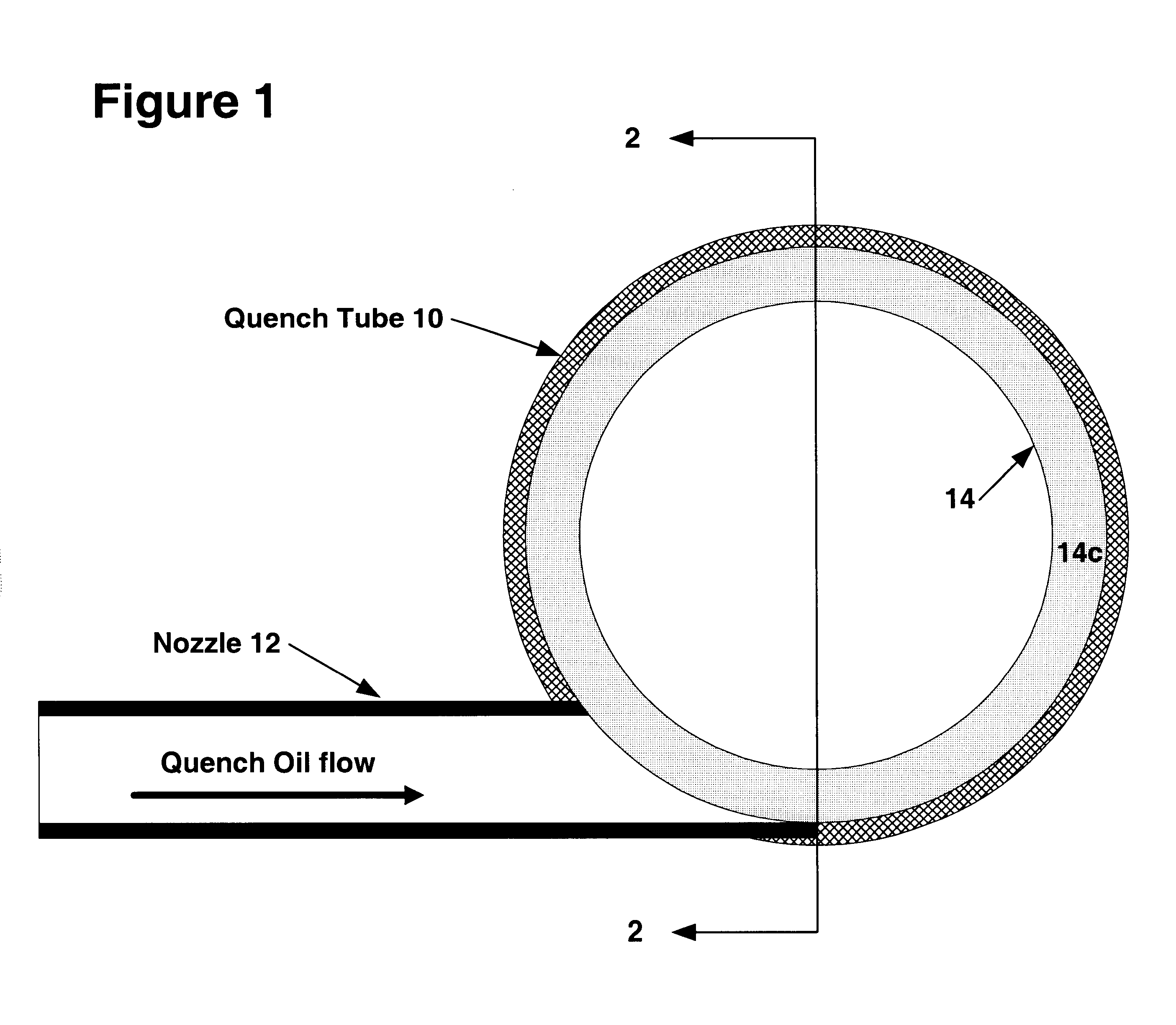

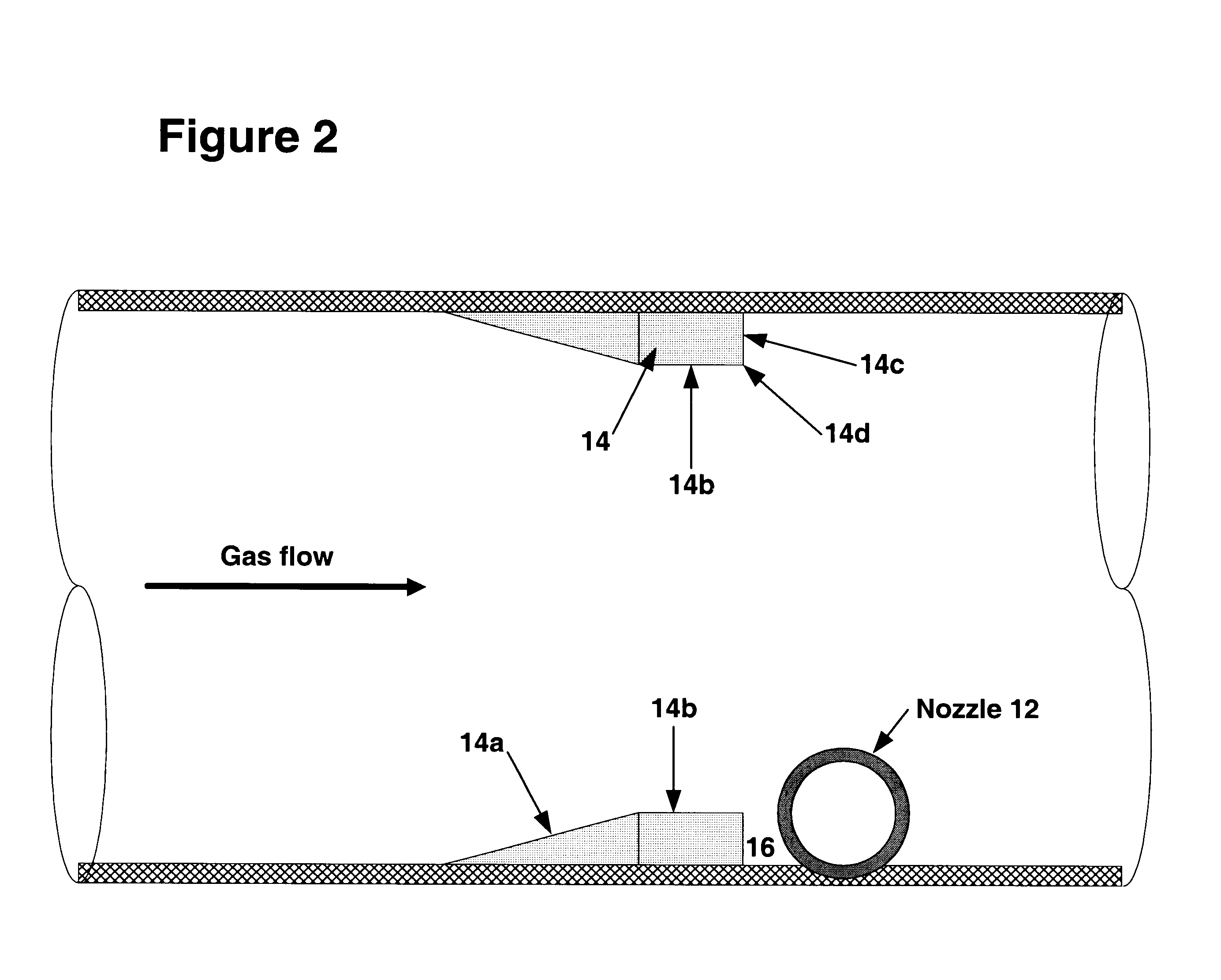

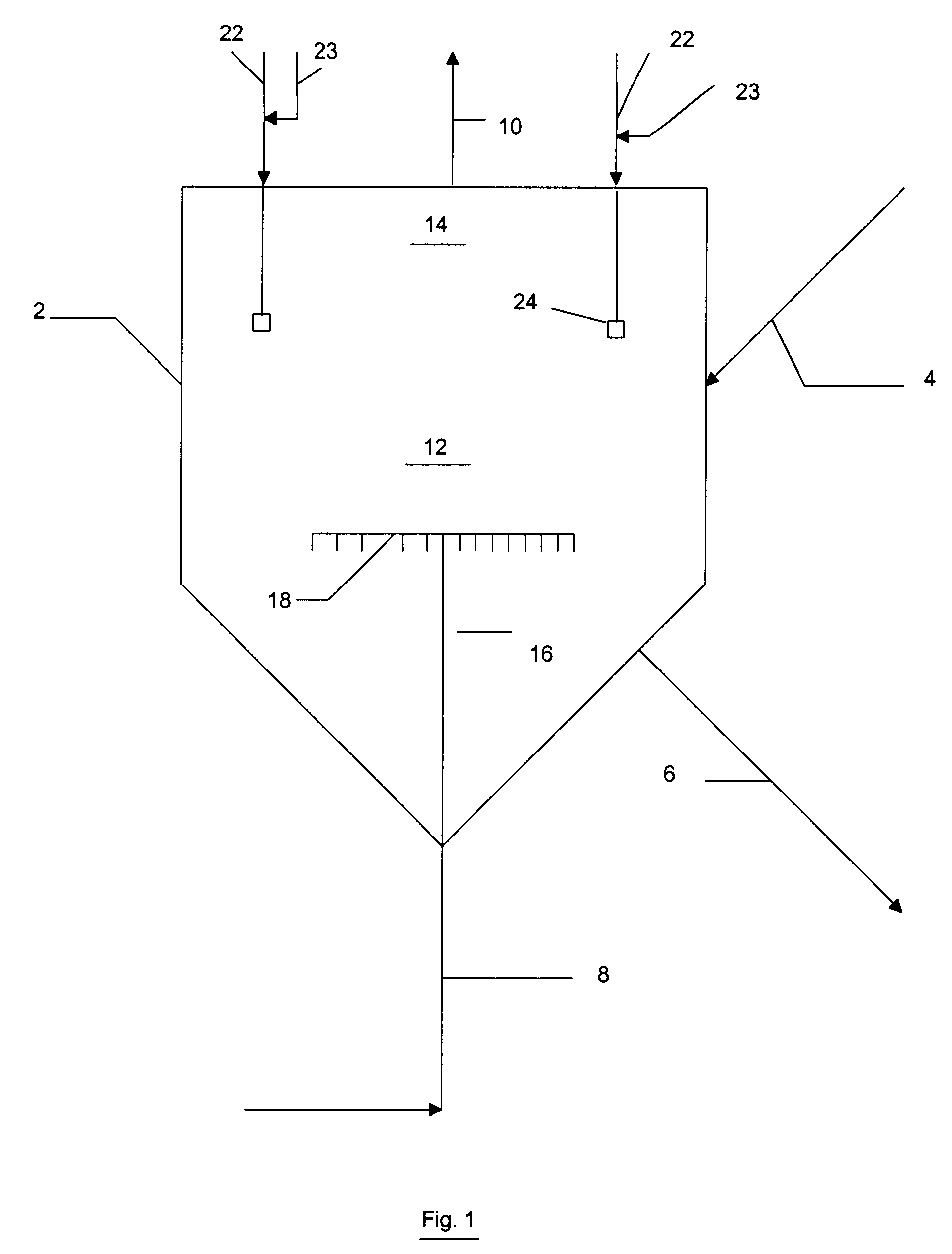

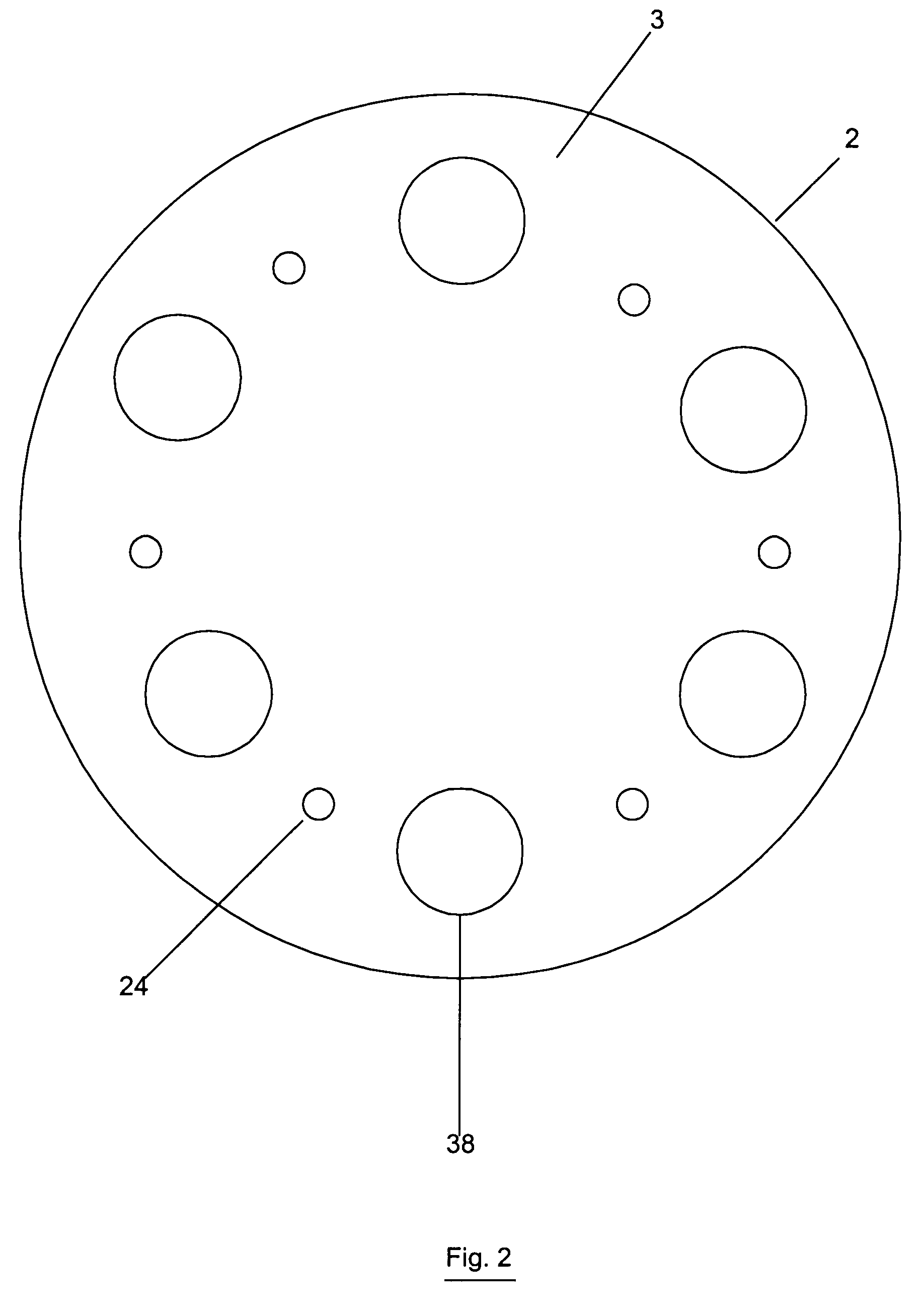

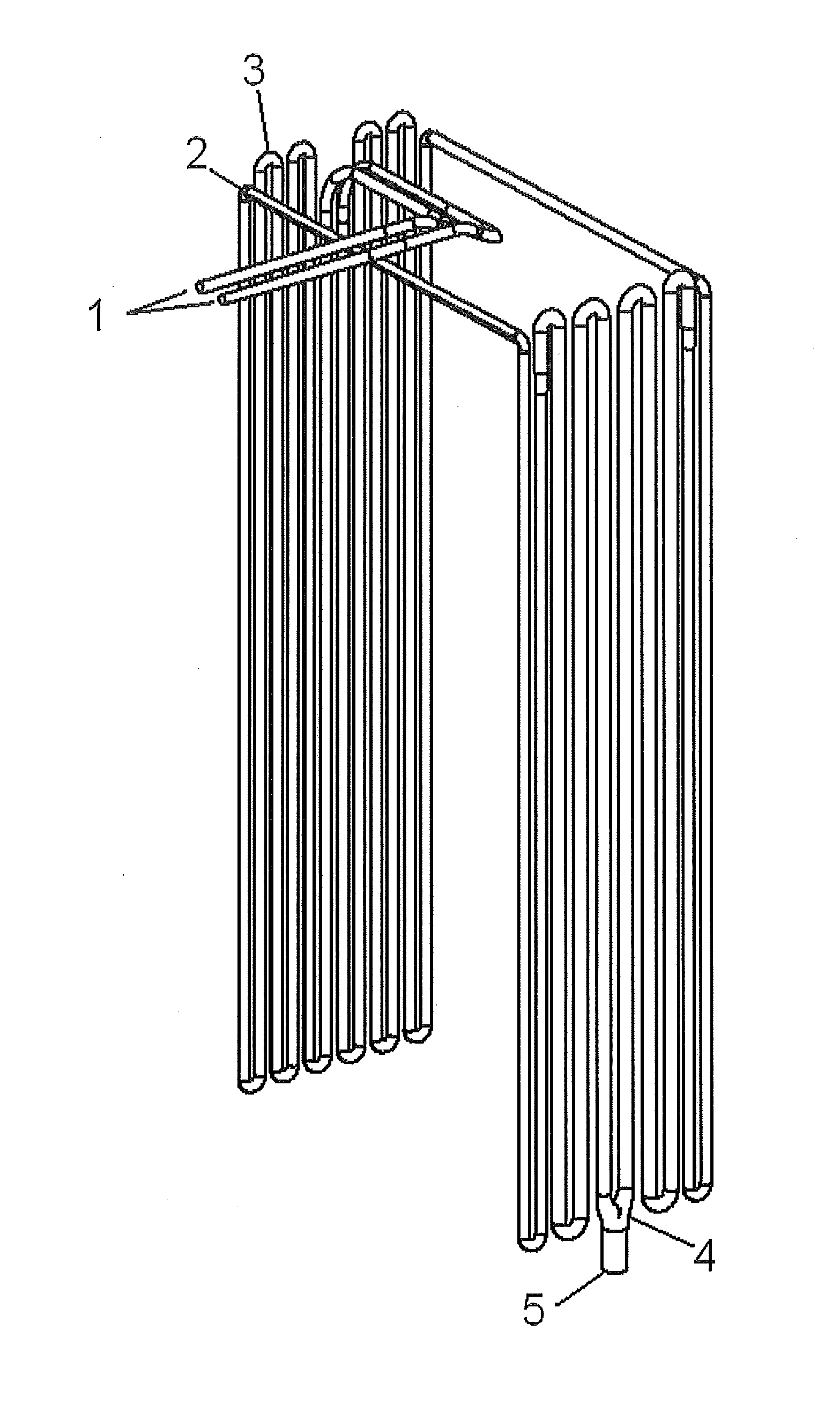

Quench nozzle

A quench nozzle design introduces quench oil tangentially into the quench tube which cools the hot gaseous pyrolysis products coming out of the hot radiant tubes in a pyrolysis furnace (in ethylene manufacture). Besides cooling the hot gases, the quench oil introduced into the quench tube by this nozzle design keeps the wall of the quench tube wetted, which is necessary to prevent coke deposition on the quench tube. The nozzle has one quench oil entry, which eliminates the need for any restriction orifice required to evenly distribute quench oil flows that would otherwise be required with several nozzle entries. Also, the one-nozzle oil introduction has a larger diameter than that required where more than one nozzle is employed in this service. The replacement of multiple nozzles with a single larger diameter nozzle eliminates plugging problems caused by coke solids or, coke solid precursors, present in the quench oil.

Owner:SHELL OIL CO

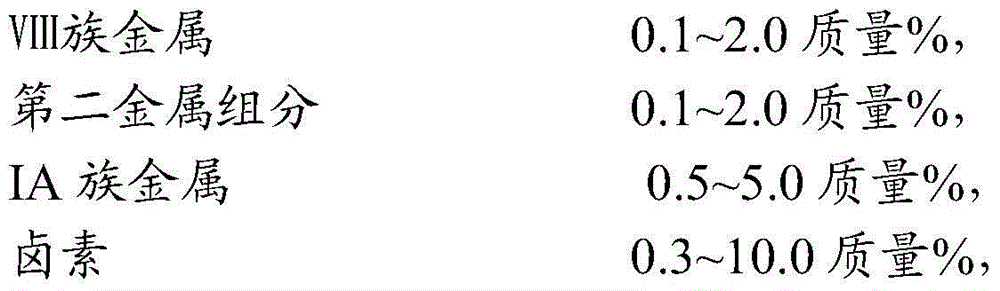

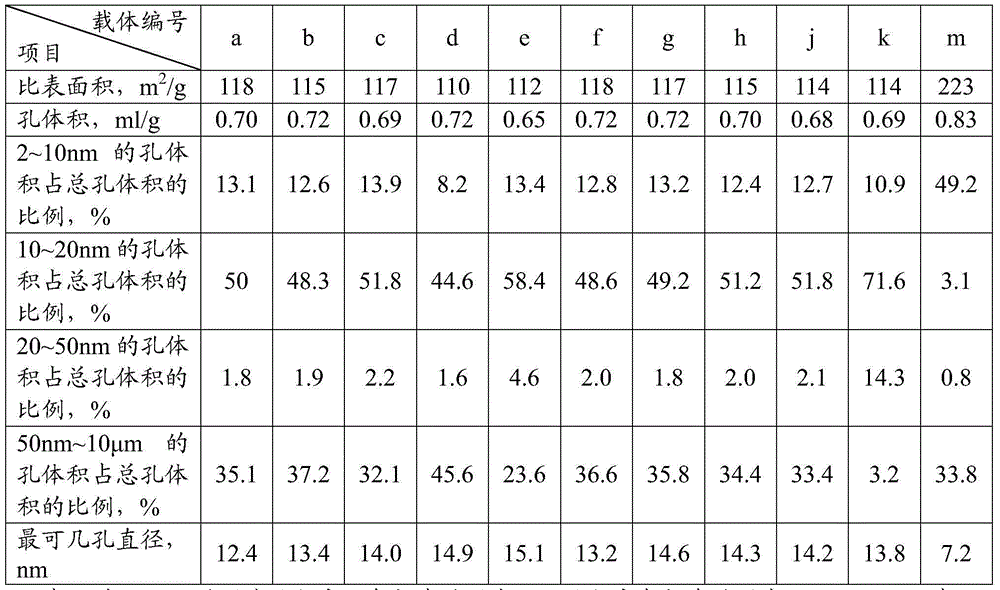

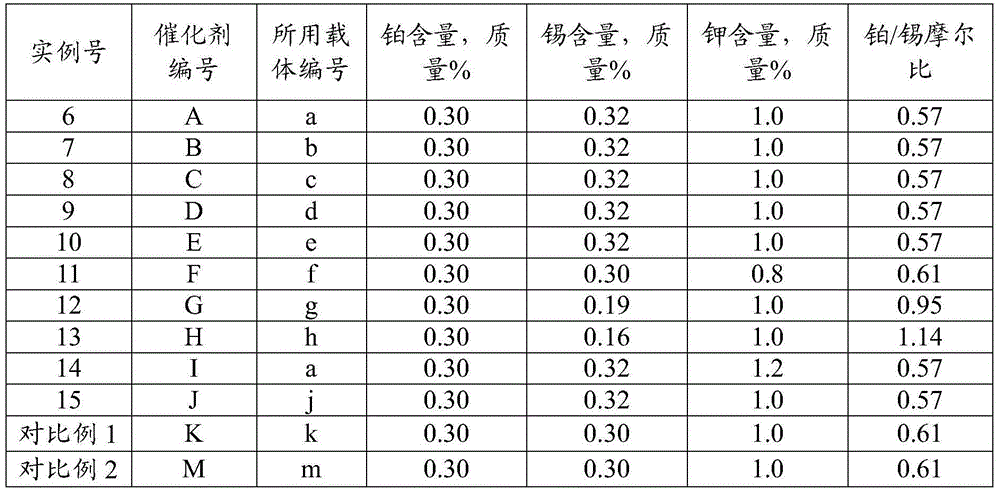

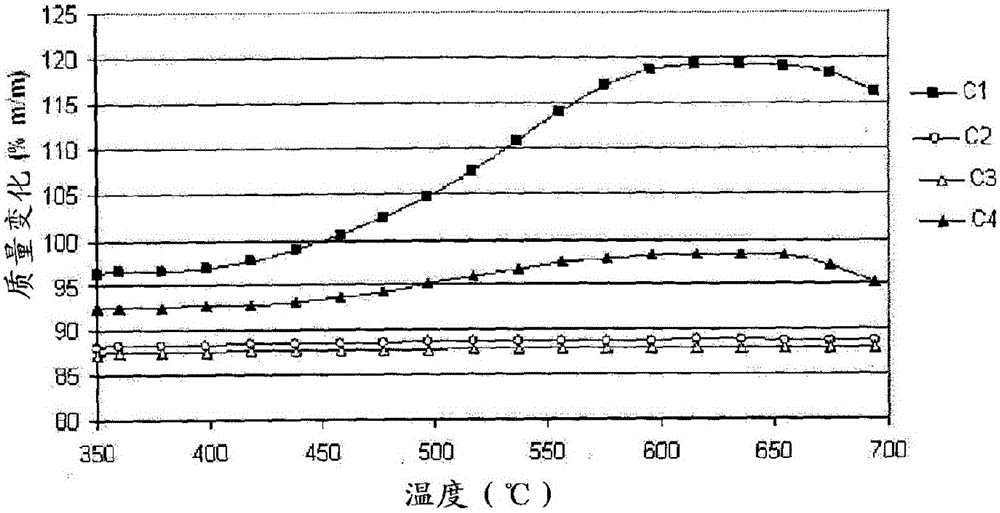

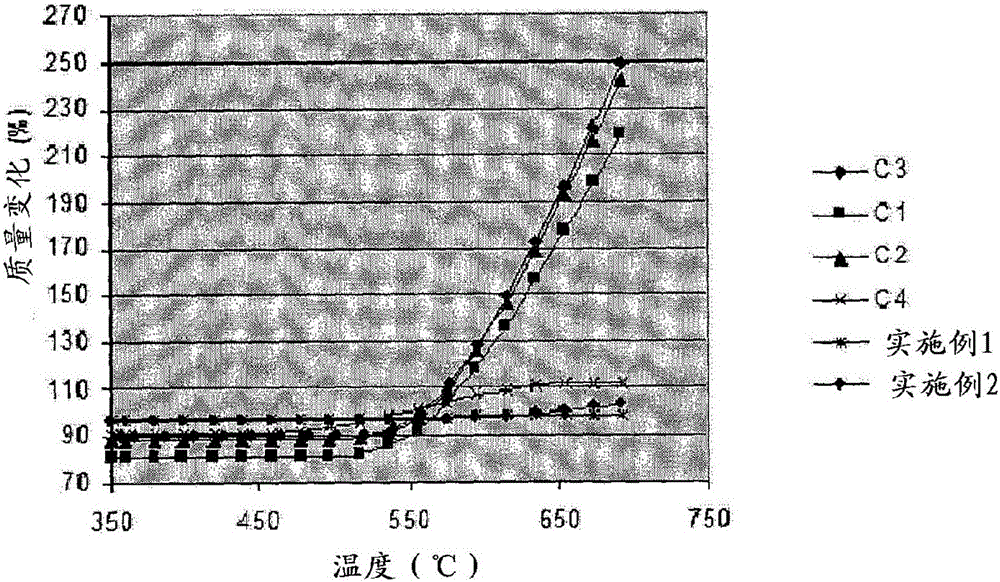

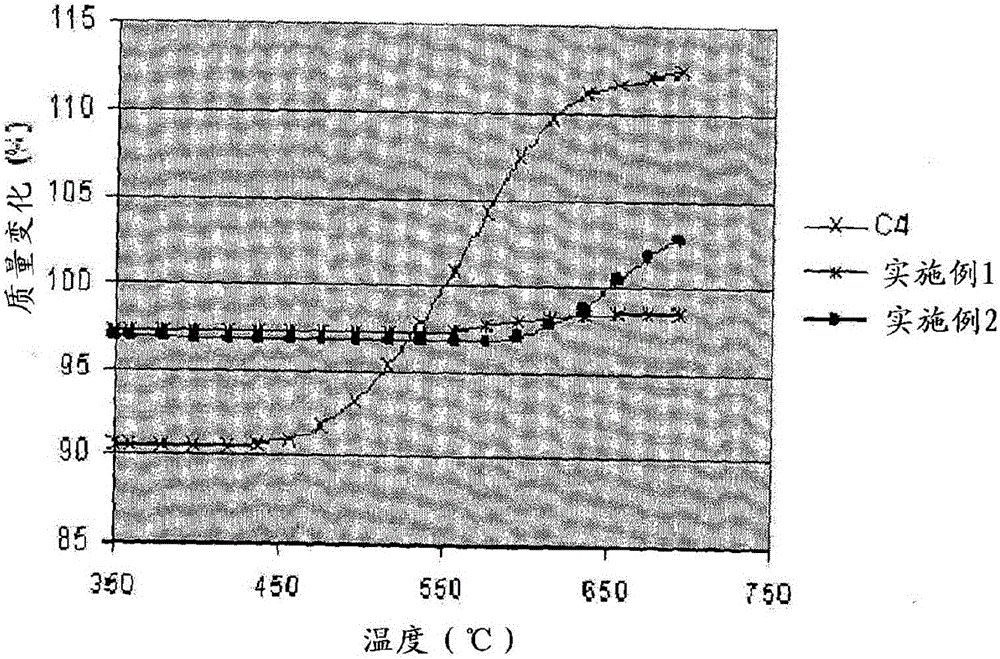

Catalyst for preparing olefin from low-carbon alkane by dehydrogenation and preparation method of catalyst

ActiveCN105214657AImprove carbon storage capacityImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkaneIndium

The invention provides a catalyst for preparing olefin from low-carbon alkane by dehydrogenation. The catalyst comprises an aluminum oxide carrier and the following active components with the carrier as datum by mass: 0.1 to 2.0% of a group-VIII metal, 0.1 to 2.0% of a second metal component, 0.5 to 5.0% of a group-IA metal and 0.3 to 10.0% of halogen, wherein the aluminum oxide carrier has a pore volume of pores with a diameter of 2 to 10 nanometers accounting for 4 to 15% of a total pore volume, a pore volume of pores with a diameter of 10 to 20 nanometers accounting for 40 to 60% of the total pore volume, a pore volume of pores with a diameter of 20 to 50 nanometers accounting for 1.0 to 5.0% of the total pore volume, and a pore volume of pores with a diameter of more than 50 nanometers and less than 10 microns accounting for 20 to 50% of the total pore volume; and the second metal component is selected from the group consisting of tin, germanium, lead, indium, gallium or thallium. The catalyst is applied to preparation of propylene from propane by dehydrogenation and has high activity and selectivity and low coke deposition rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

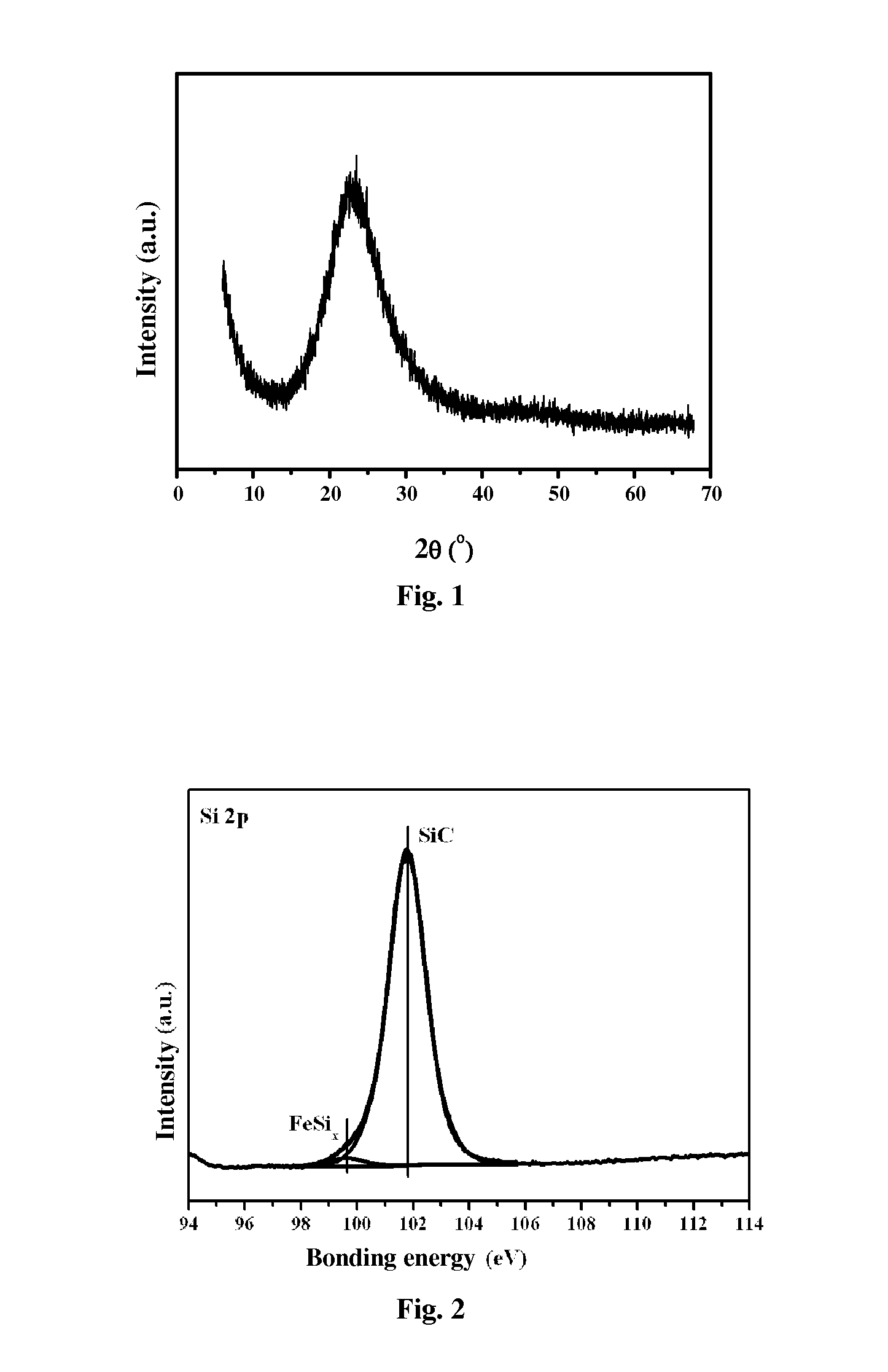

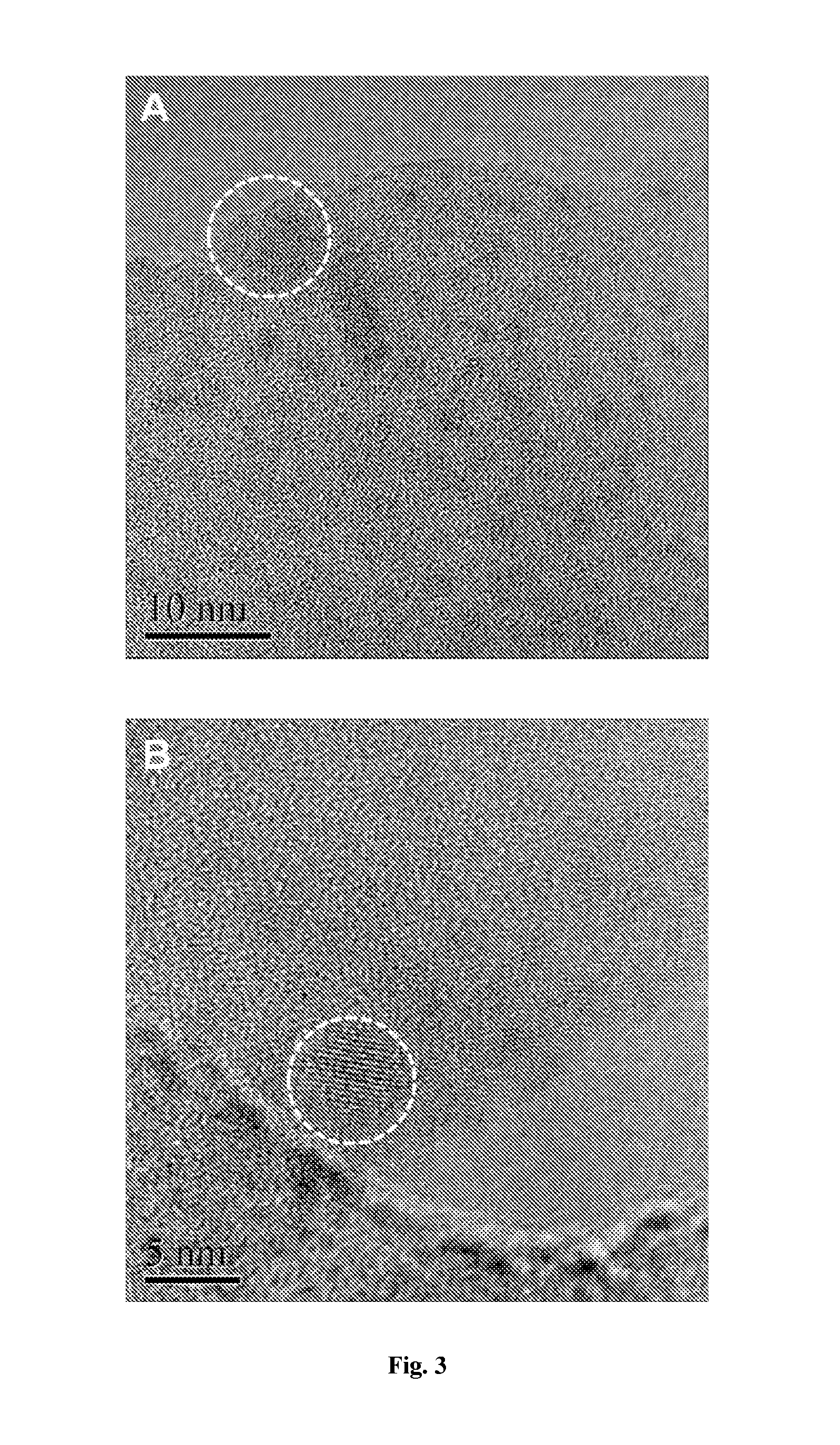

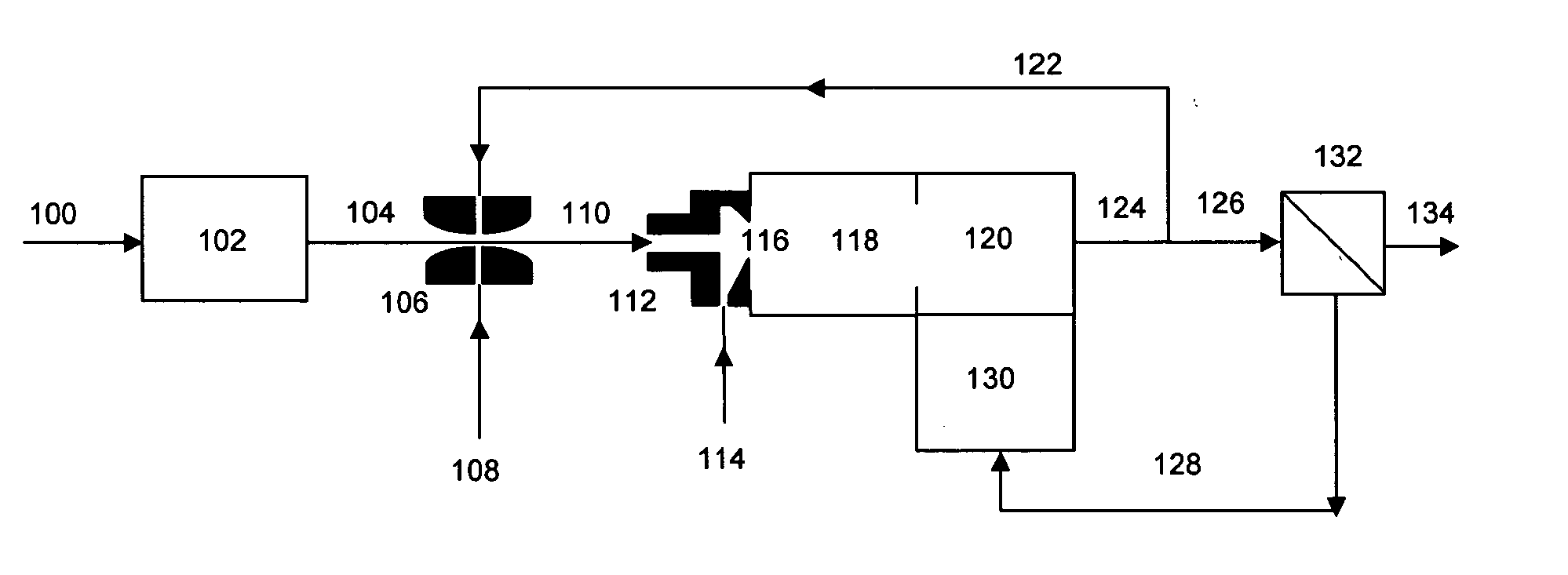

Synthesis of olefins from oxygen-free direct conversion of methane and catalysts thereof

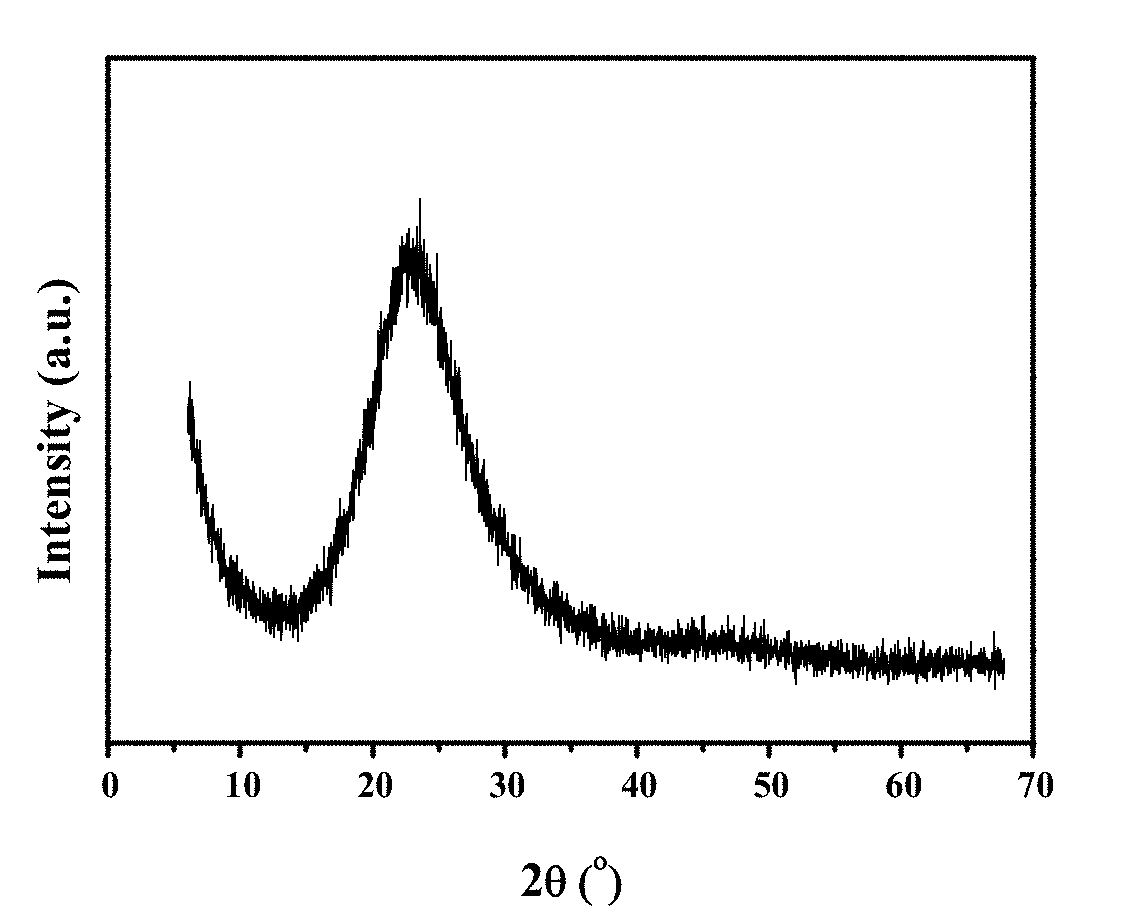

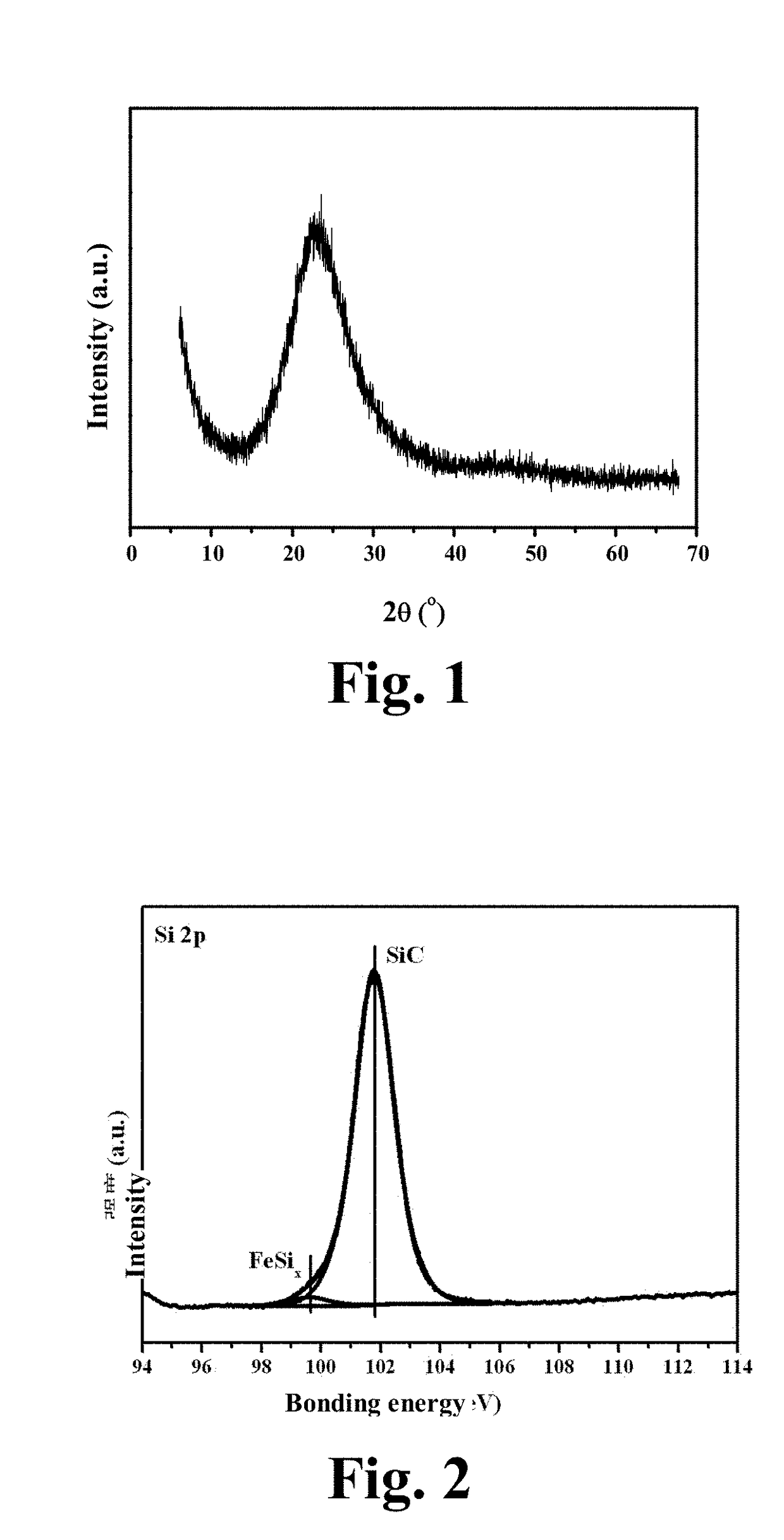

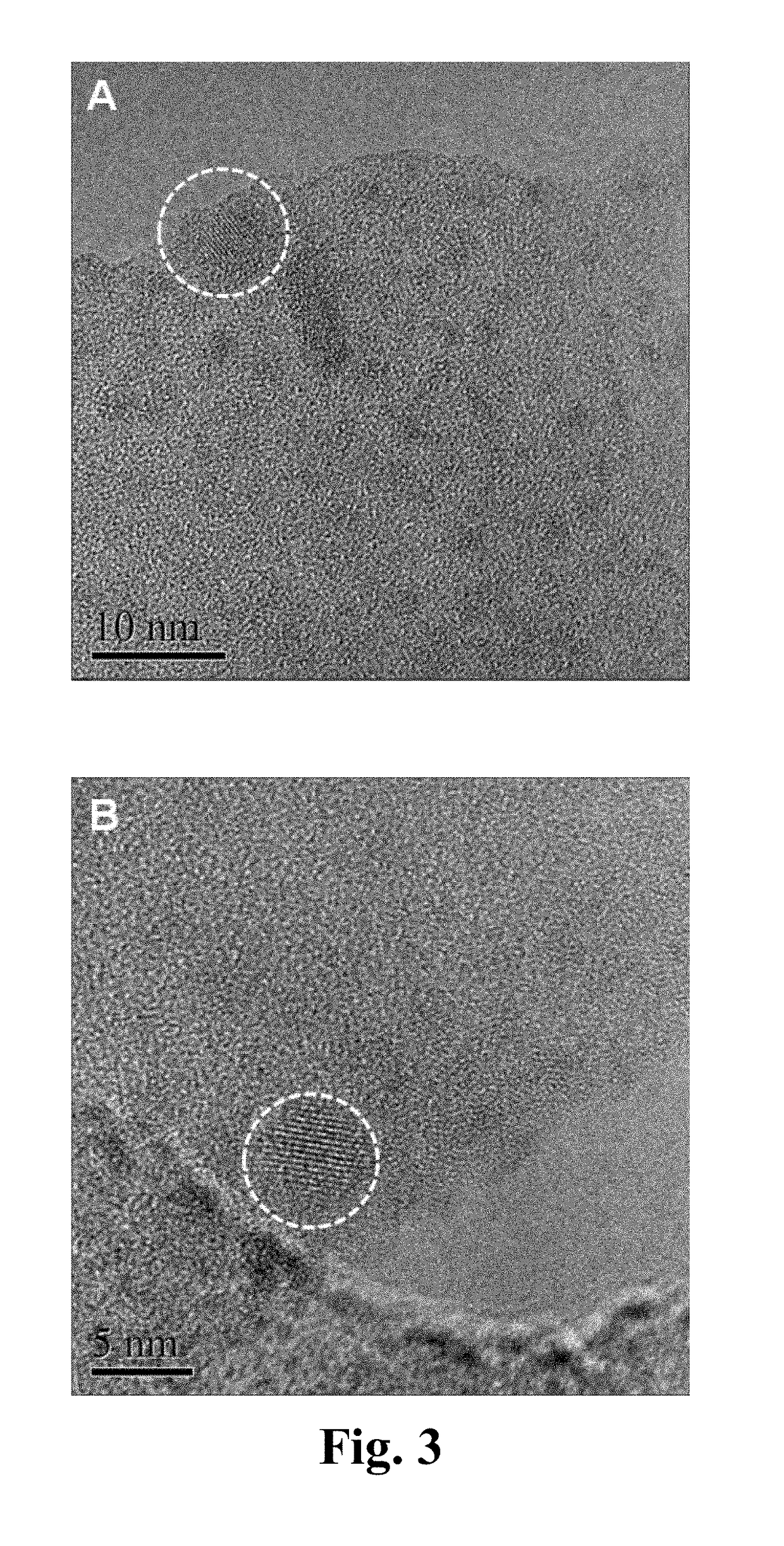

ActiveUS20140336432A1Specific performanceGood dispersionOrganic-compounds/hydrides/coordination-complexes catalystsCatalystsPtru catalystFixed bed

The present invention is related to the preparation of a metal lattice-doping catalyst in an amorphous molten state, and the process of catalyzing methane to make olefins, aromatics, and hydrogen using the catalyst under oxygen-free, continuous flowing conditions. Such a process has little coke deposition and realizes atom-economic conversion. Under the conditions encountered in a fixed bed reactor (i.e. reaction temperature: 750˜1200° C.; reaction pressure: atmospheric pressure; the weight hourly space velocity of feed gas: 1000˜30000 ml / g / h; and fixed bed), conversion of methane is 8-50%. The selectivity of olefins is 30˜90%. And selectivity of aromatics is 10˜70%. There is no coking. The reaction process has many advantages, including a long catalyst life (>100 hrs), high stability of redox and hydrothermal properties under high temperature, high selectivity towards target products, zero coke deposition, easy separation of products, good reproducibility, safe and reliable operation, etc., all of which are very desirable for industrial application.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

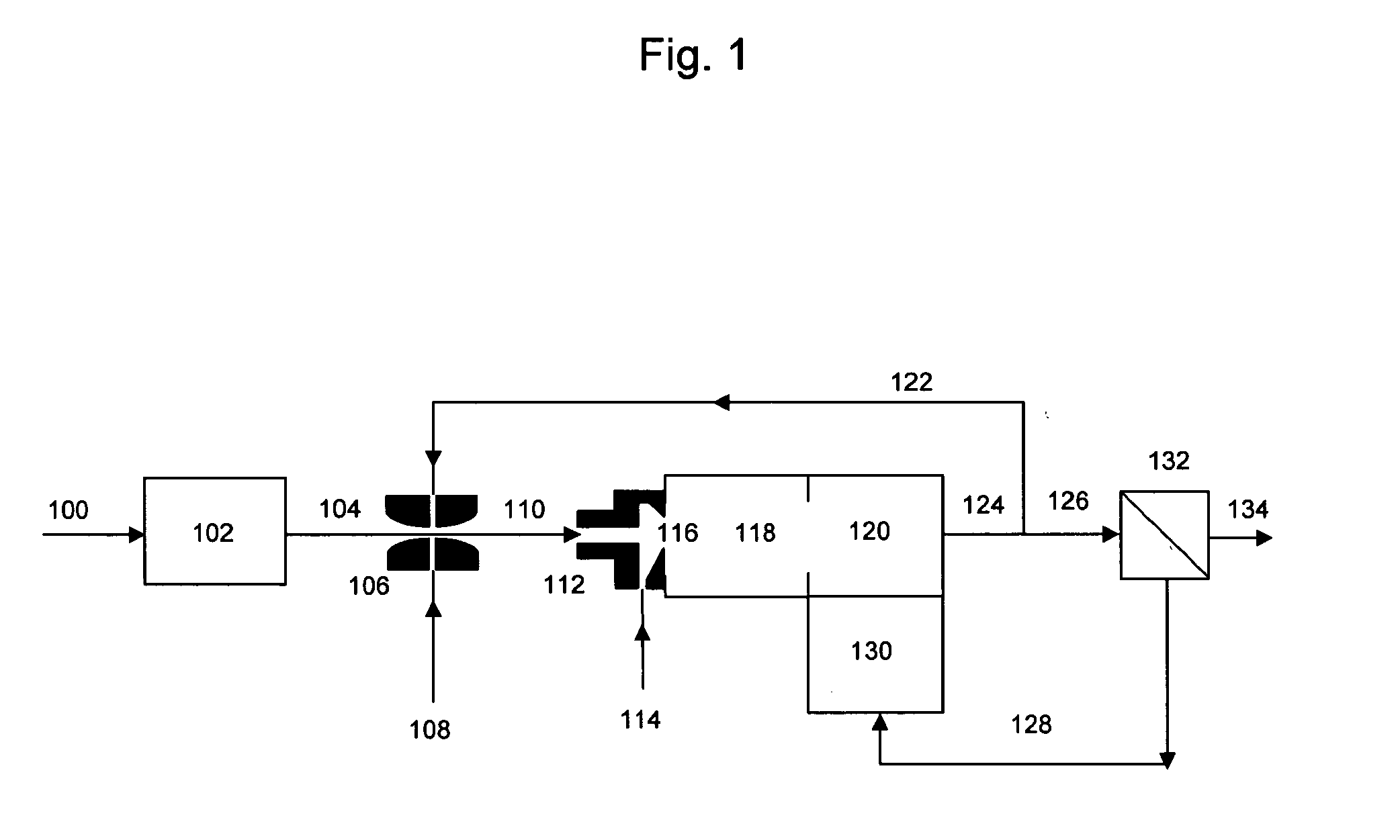

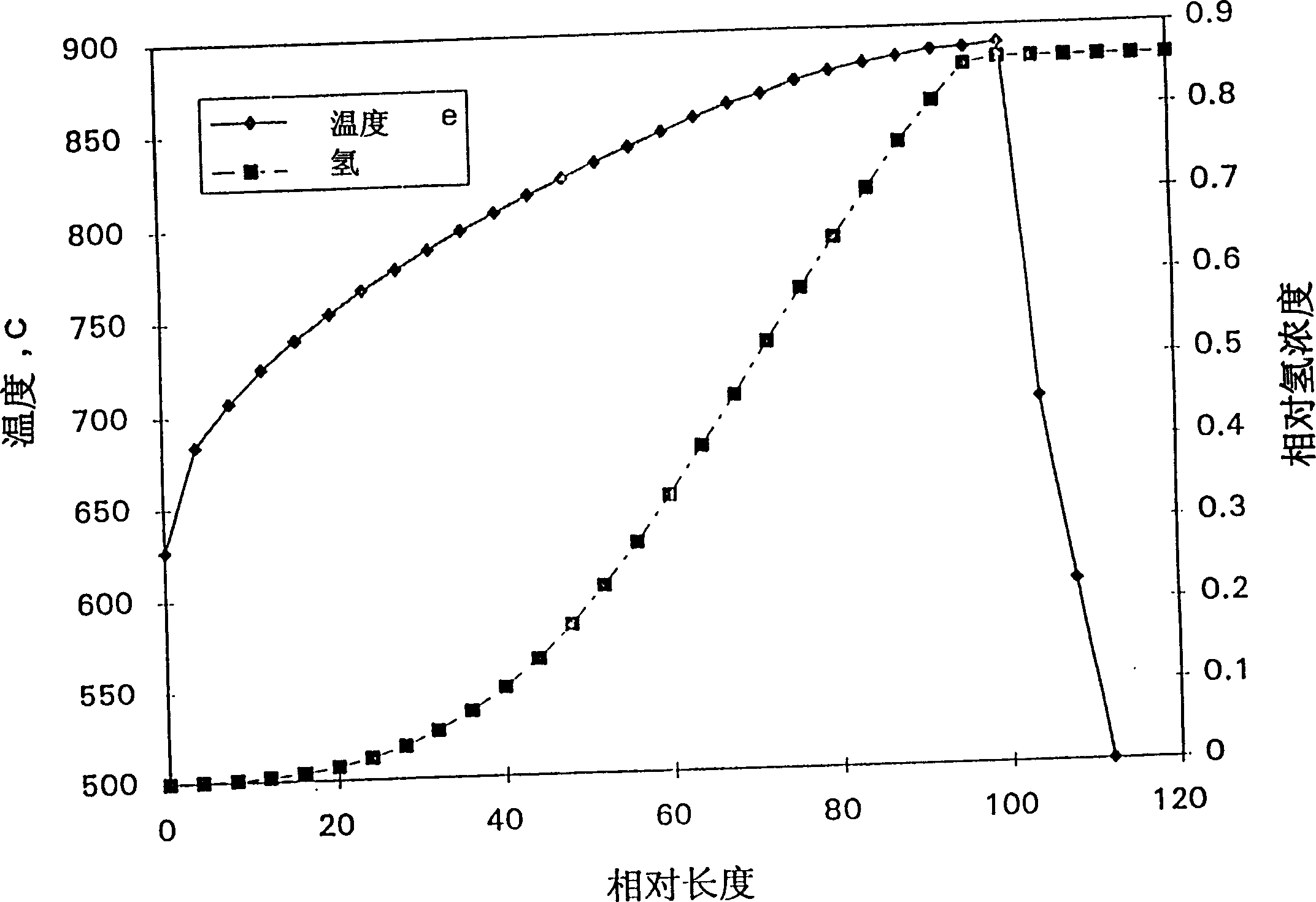

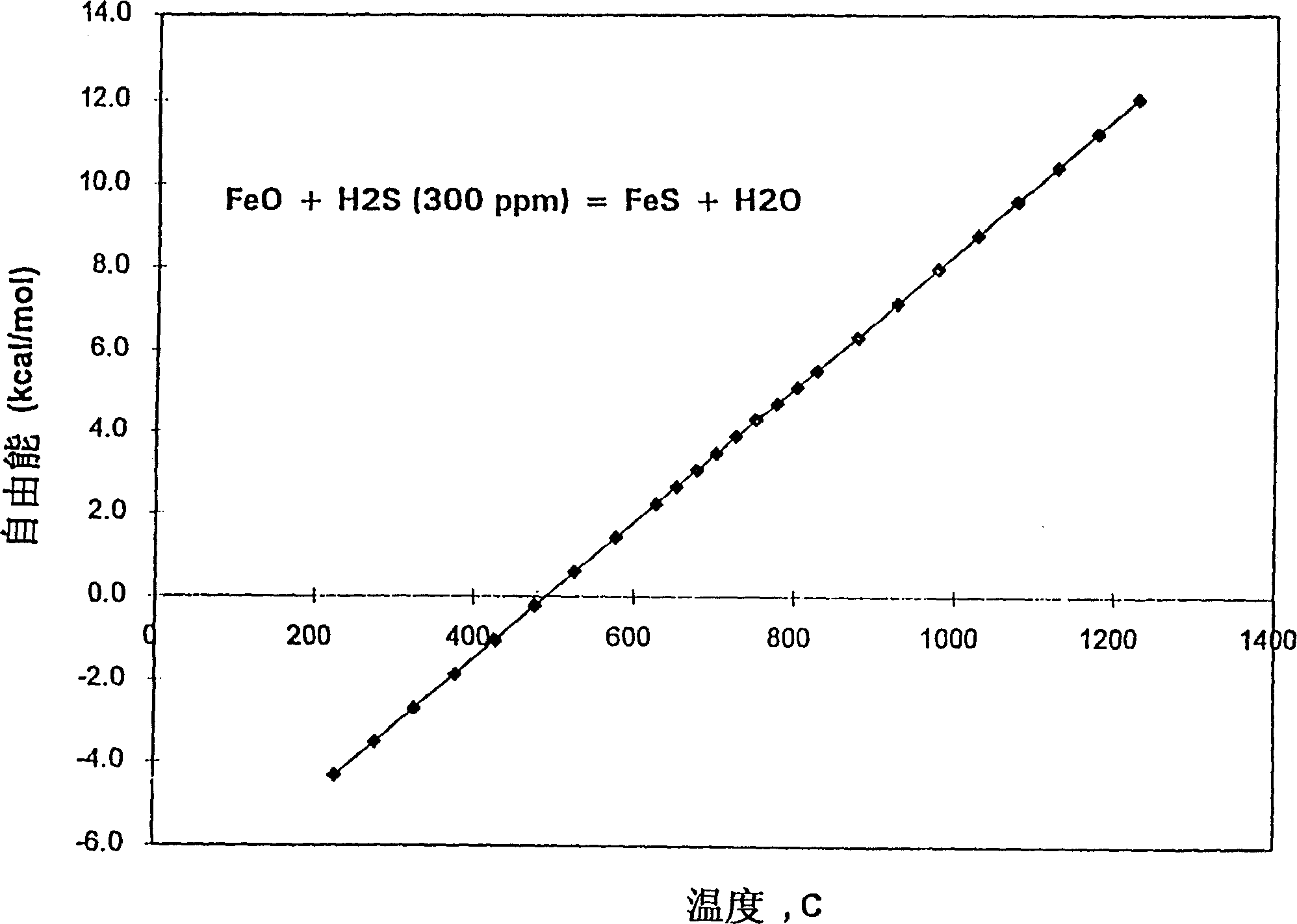

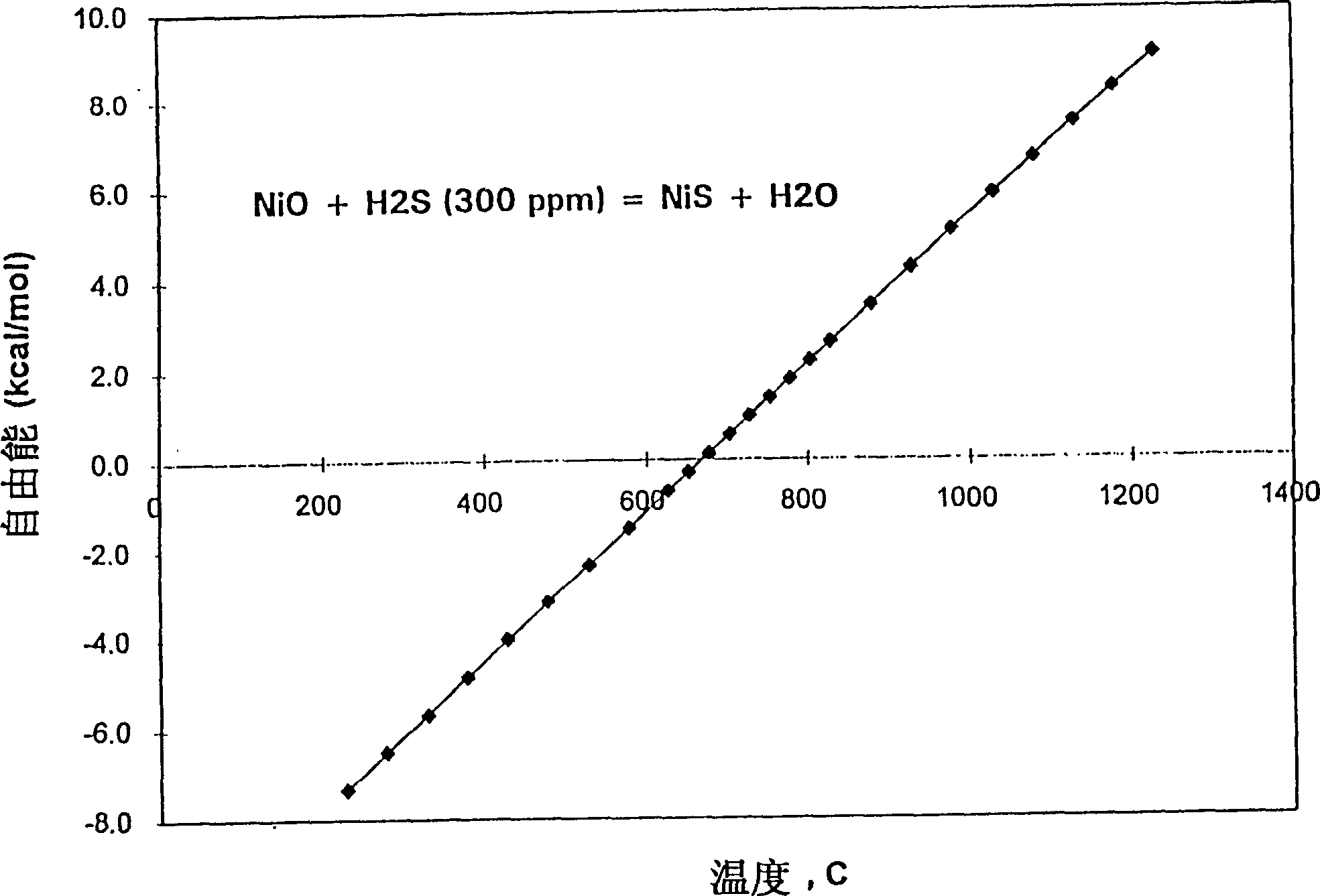

Systems and methods for generating hydrogen from hycrocarbon fuels

InactiveUS20050229491A1Hydrogen separation using solid contactHydrogen/synthetic gas productionPtru catalystThermodynamics

The present invention provides a system and a method to reform hydrocarbon fuels, including sulfur-laden liquid fuels, to produce a reformate stream containing hydrogen. The system comprises a reforming reactor using a hydrocarbon stream and a water stream as reactants. The water stream is mixed with a hydrogen-rich stream prior to mixing with the hydrocarbon stream and fed to the reforming reactor, which contains a precious metal based catalyst. In one embodiment of the present invention, the temperature of the catalyst is lower at the inlet to prevent formation of coke by pre-reforming heavy hydrocarbons to methane, and higher at the outlet for efficient production of hydrogen. In another embodiment, air is introduced periodically into the system to burn off any metal sulfides and coke deposits that could form. In another embodiment, pure hydrogen is separated from the reformate stream using a hydrogen selective, sulfur-tolerant membrane or by pressure swing adsorption. Thus, the system and method of the present invention can be used to process sulfur-laden, heavy hydrocarbons to produce PEM fuel-cell quality hydrogen.

Owner:NU ELEMENT

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS7414167B2Improve economyEfficient processingMolecular sieve catalystCatalystsPtru catalystFixed bed

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

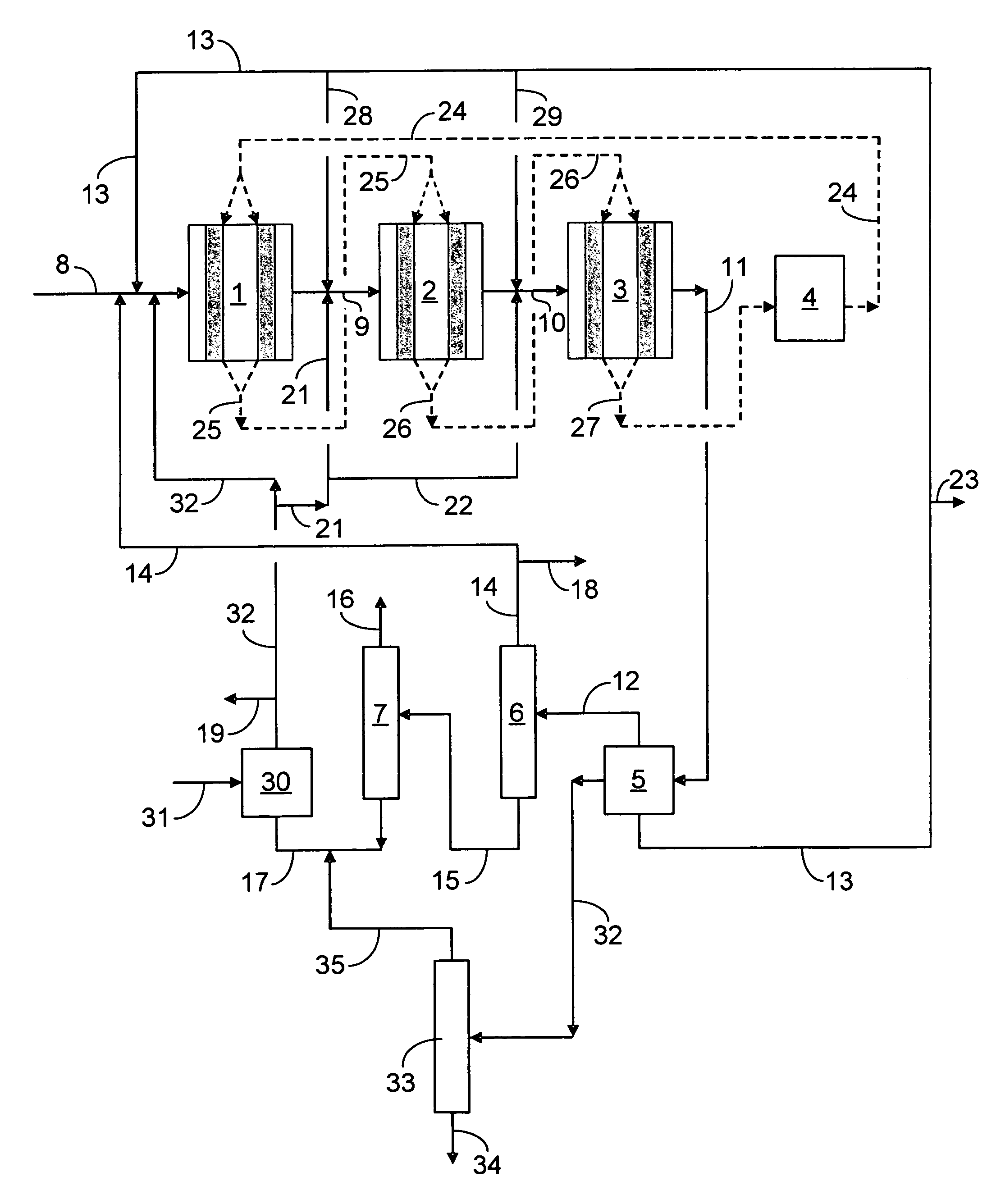

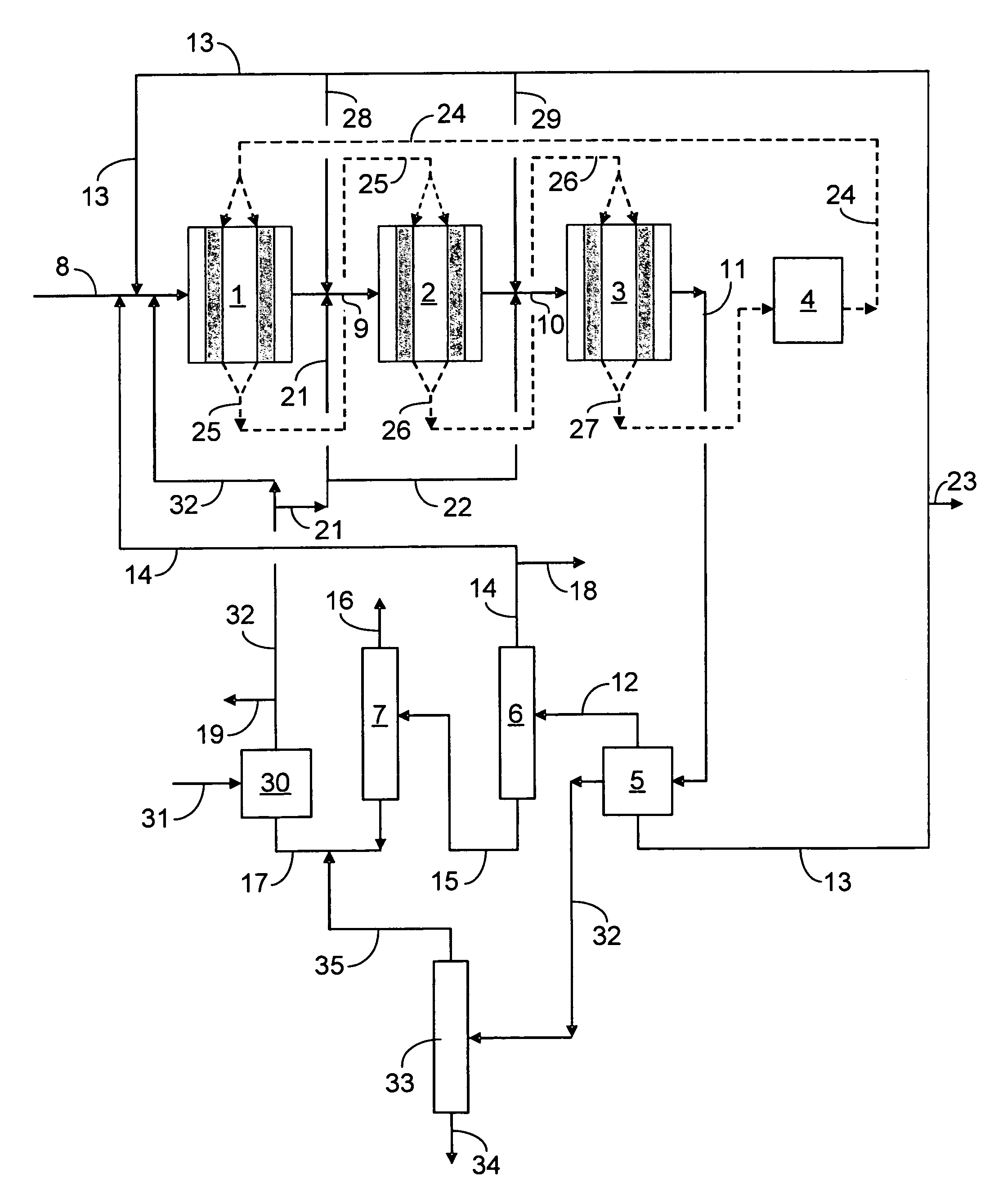

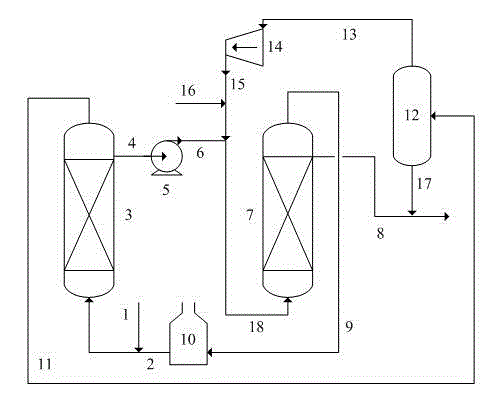

Conversion of oxygenate to propylene with selective hydrogen treatment of heavy olefin recycle stream

ActiveUS7405337B2Improve economyMinimize severityMolecular sieve catalystHydrocarbons from unsaturated hydrocarbon additionOxygenateHydrogen treatment

The average cycle propylene selectivity of an oxygenate to propylene (OTP) process using one or more fixed or moving beds of a dual-function oxygenate conversion catalyst with recycle of one or more C4+ olefin-rich fractions is substantially enhanced by the use of selective hydrotreating technology on these C4+ olefin-rich recycle streams to substantially eliminate detrimental coke precursors such as dienes and acetylenic hydrocarbons. This hydrotreating step helps hold the build-up of detrimental coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling a substantial improvement in propylene average cycle yield. The propylene average cycle yield improvement enabled by the present invention over that achieved by the prior art using the same or a similar catalyst system but without the use of the hydrotreating step on the C4+ olefin-rich recycle stream is of the order of about 1.5 to 5.5 wt-% or more.

Owner:UOP LLC

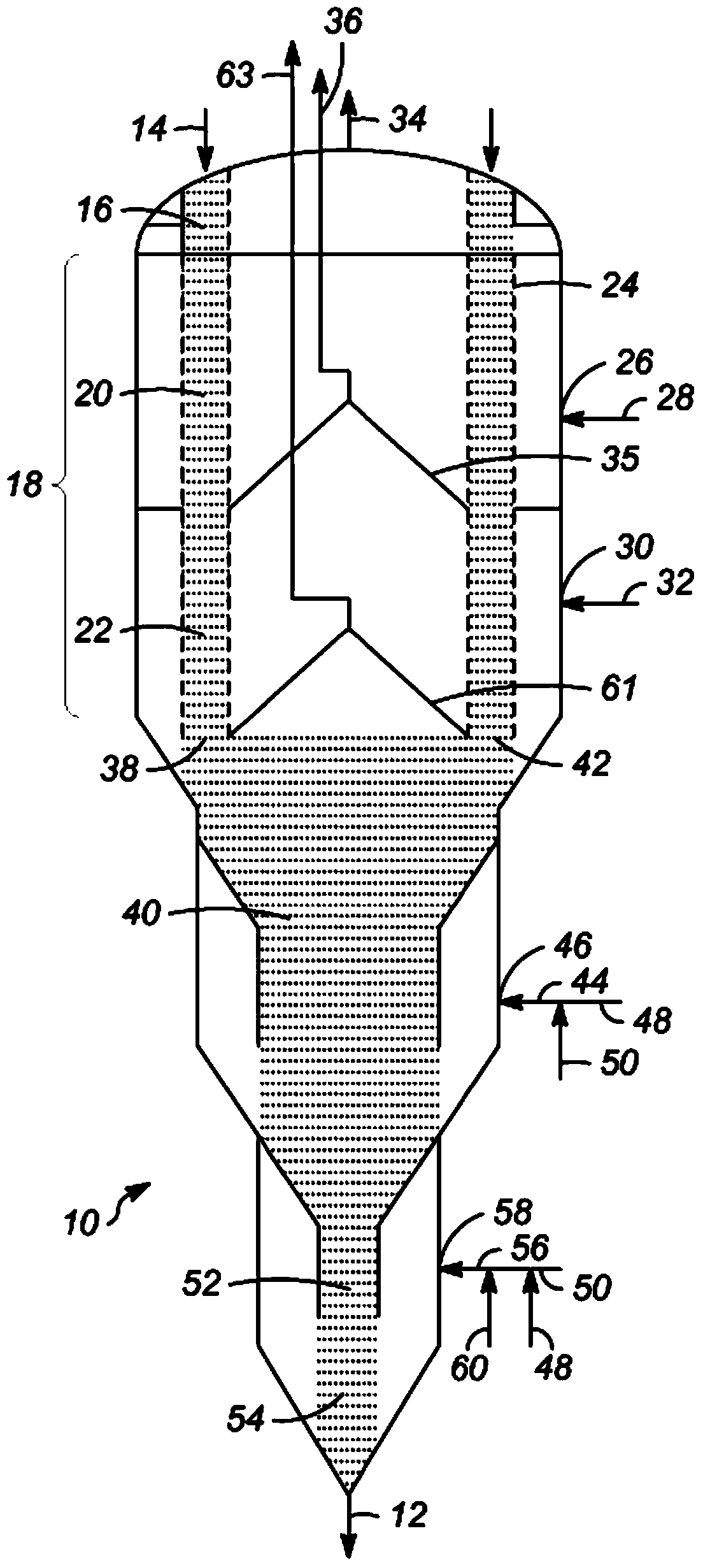

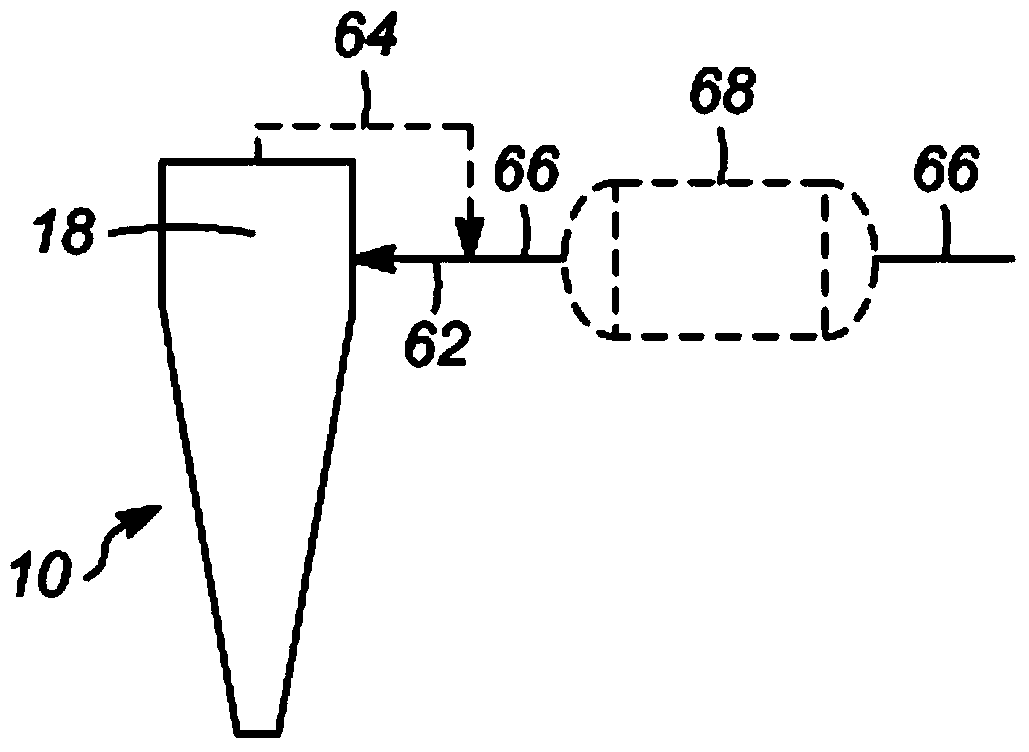

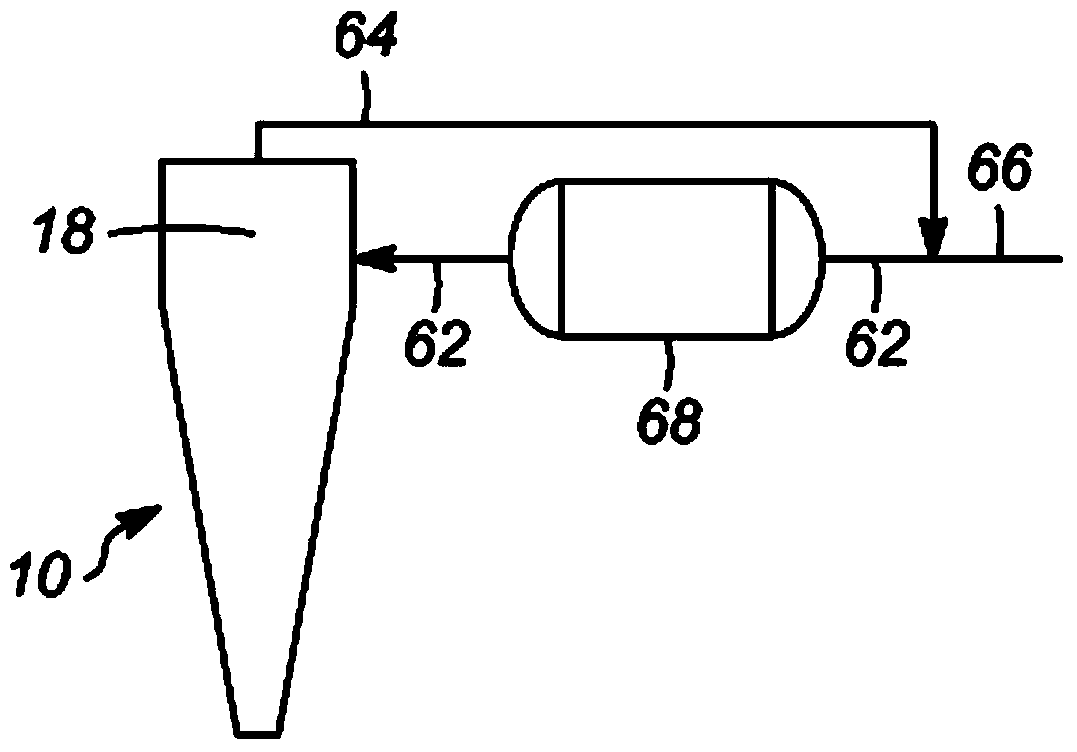

Processes and apparatuses for regenerating catalyst particles

InactiveCN103517761ARuthenium/rhodium/palladium/osmium/iridium/platinum compoundsCatalyst regeneration/reactivationPtru catalystMetallurgy

Processes and apparatuses for regenerating catalyst particles are provided. The processes include introducing spent catalyst particles to a burn zone in a continuous catalyst regenerator. When introduced, the catalyst particles, which contain a platinum group metal, carry coke deposits. In the process, a combustion gas at a temperature of at least 490 DEG C with an oxygen content of at least 0.5 mol% is fed to the burn zone. There, the coke deposits on the catalyst particles are combusted with the combustion gas. The catalyst particles are passed from the burn zone to a halogenation zone in the continuous catalyst regenerator and the catalyst particles are oxyhalogenated to redisperse the platinum group metal to form regenerated catalyst particles.

Owner:UOP LLC

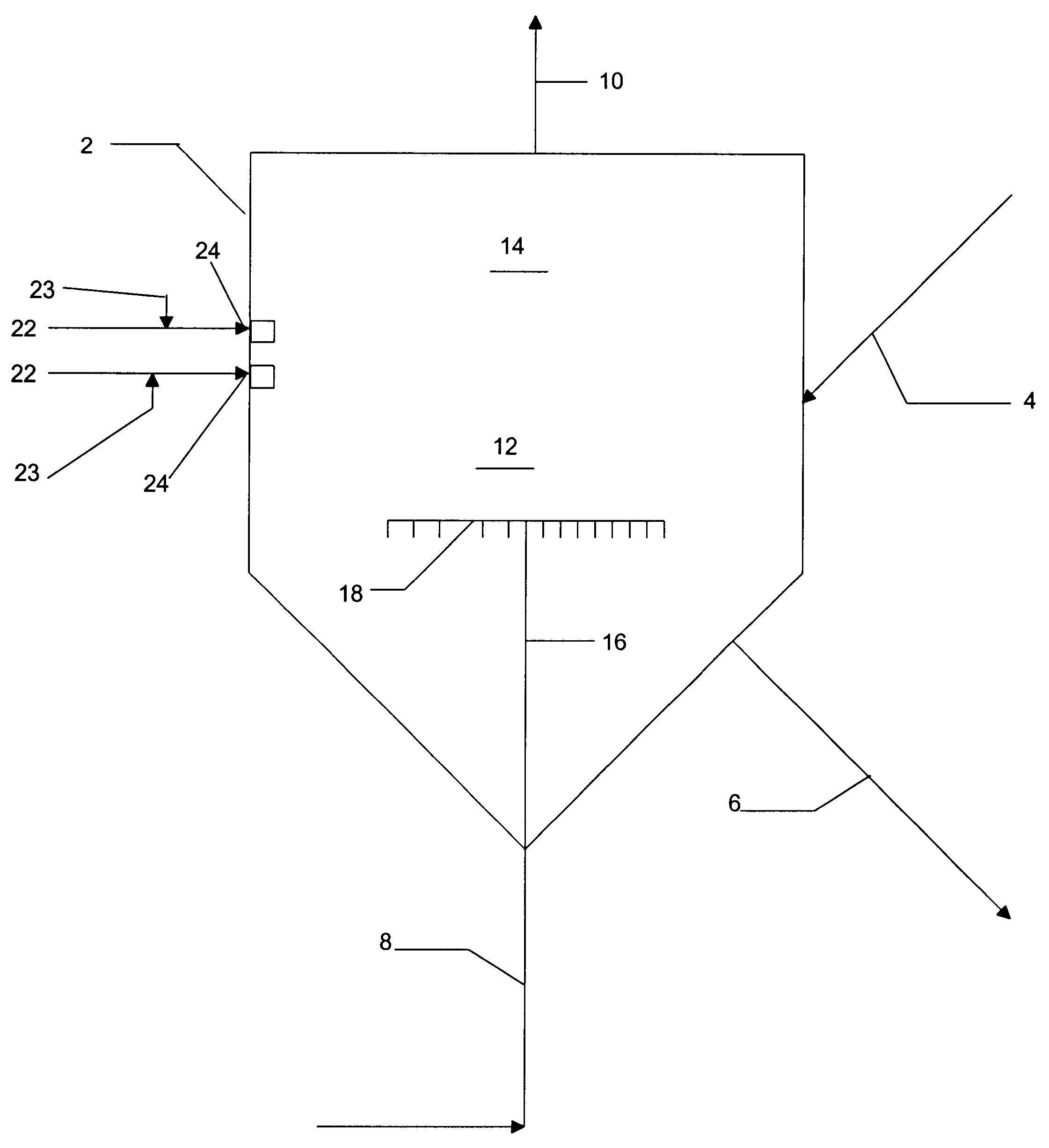

Reactor modifications for NOx reduction from a fluid catalytic cracking regeneration vessel

InactiveUS6579820B2Reduce nitrogen oxide emissionsReduce temperature riseNitrous oxide captureCombination devicesCombustionShielding gas

A process for regenerating a spent catalyst having coke deposits thereon in a catalyst regeneration vessel having a dense phase and a dilute phase, wherein the process comprises the steps of: (a) contacting the spent catalyst with a primary oxygen-containing gas in the dense phase, thereby combusting the coke, resulting in the formation of a combustion gas comprising nitrogen oxides and carbon monoxide which further reacts, thus reducing a majority of the nitrogen oxides to form elemental nitrogen; and (b) contacting the combustion gas with a secondary oxygen-containing gas, and typically a shield gas, at a location just above the interface between the dense phase and the dilute phase and also in the dilute phase, thereby oxidizing the remaining CO to CO2 without significant temperature rise in the dilute phase due to the after burn.

Owner:BOC GRP INC

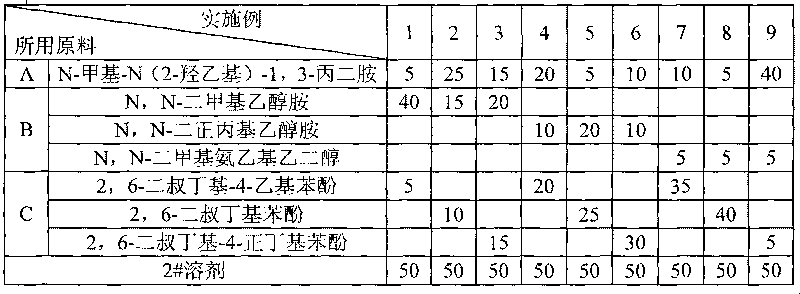

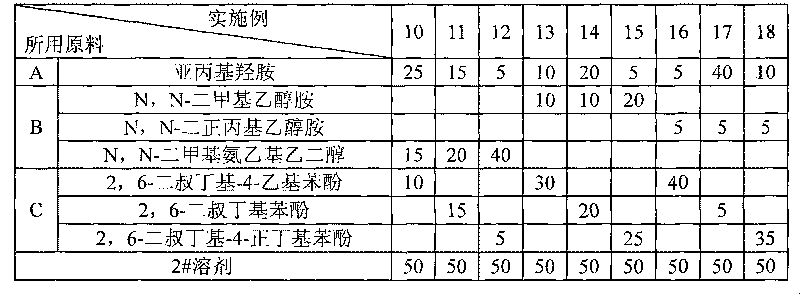

Efficient scale inhibitor of tail-gas compressor of styrene device and application method thereof

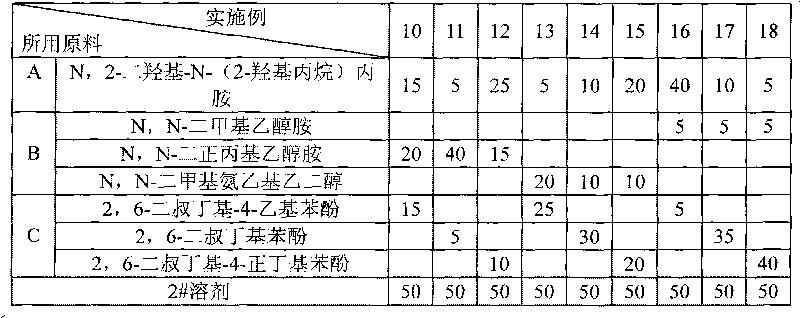

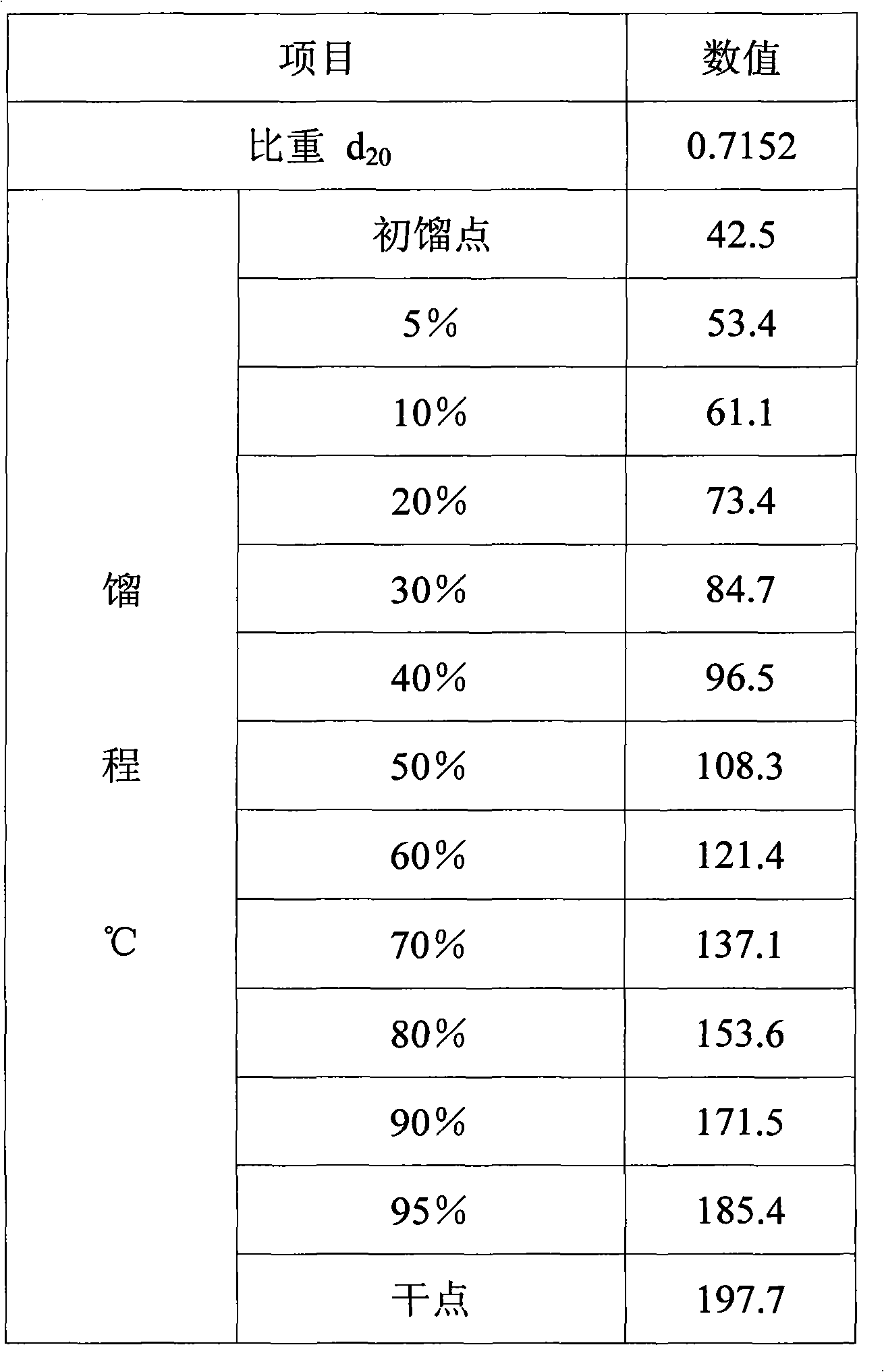

InactiveCN101700991AEasy to disperseNot easy to disperseHydrocarbonsHydrocarbon preparationGas compressorHydroxylamine Hydrochloride

The invention relates to an efficient scale inhibitor of a tail-gas compressor of a styrene device and an application method thereof, comprising hydroxylamine compounds, alcohol amine compounds and phenol compounds. The invention overcomes the disadvantages that the generation of polymer dirt in the tail-gas compressor can not be effectively inhibited by using an ethylbenzene physical spraying method, can thoroughly inhibit and suppress the radical polymerization of the styrene, alpha-methyl styrene, phenyl ethylene and the other activated alkenes in the styrene tail-gas compressor, and has the functions of metallic catalytic coke deposition suppression and detergency and dispersancy. The invention has the advantages of safety and environment protection, energy conservation and low energy consumption and simple use, has no influence on downstream processes, can effectively promote the operational cycle and working load of the styrene tail-gas compressor, reduce energy and material consumption of the styrene device, and can improve the economical and social effects of the whole styrene device.

Owner:北京斯伯乐科技发展有限公司

Anti-coking anti-carburizing cracking furnace tube and manufacturing method thereof

ActiveCN102399572AEasy to industrializeReduce depositionThermal non-catalytic crackingCarbon numberNi cr alloy

The invention relates to an anti-coking anti-carburizing cracking furnace tube and a manufacturing method thereof. The inner surface of the cracking furnace tube of the invention has a layer which comprises an oxide membrane which comprises at least one of Cr, Ni, Fe, Mn, La, Ce and Y. The manufacturing method comprises the following steps: Ni-Cr alloy containing elements of Cr, Ni, Fe, Mn and C is directly added to at least one element selected from La, Ce or Y in a routine cracking furnace tube manufacturing process to prepare a tube; and the tube is subjected to heat treatment in low oxygen partial pressure atmosphere to generate a layer of the metal oxide membrane on the inner surface. The coke deposition on the inner surface of the radiant section furnace tube can be reduced by more than 60% when the cracking furnace tube of the invention is used in a petroleum hydrocarbon cracking furnace to produce low carbon number olefins.

Owner:CHINA PETROLEUM & CHEM CORP +2

Heavy aromatic solvents for catalyst reactivation

ActiveUS20210155858A1Hydrotreatment operations starting-upCatalyst regeneration/reactivationAromatic solventPtru catalyst

Compositions and methods for restoring catalytic activity by dissolving soft coke with a solvent, one method including detecting soft coke deposition on a catalyst composition; preparing an aromatic bottoms composition with a Hildebrand solubility parameter of at least about 20 SI to remove the soft coke from the catalyst composition; and washing the catalyst composition with the aromatic bottoms composition until at least a portion of the soft coke deposition is removed.

Owner:SAUDI ARABIAN OIL CO

Conversion of Dimethylether to Propylene using Moving Bed Technology

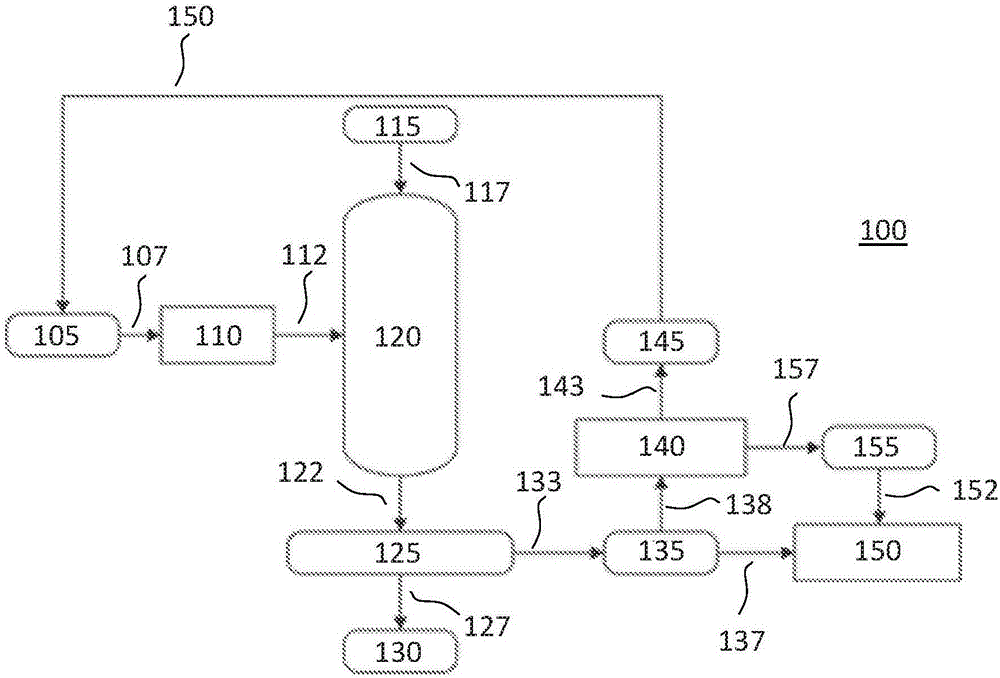

ActiveUS20080242910A1Improved economicsReduce amountMolecular sieve catalystCatalystsOxygenateDimethyl ether

The average cycle propylene selectivity of an oxygenate to propylene (OTP) process using one or more fixed beds of a dual-function oxygenate conversion catalyst is substantially enhanced by the use of moving bed reactor technology in the hydrocarbon synthesis portion of the OTP flow scheme in lieu of fixed bed technology coupled with the selection of a catalyst on-stream cycle time of 200 hours or less. Those provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of propylene average cycle yield at essentially start-of-cycle levels. The propylene average cycle yield improvement enabled by the present invention over that achieved by the fixed bed system of the prior art using the same or a similar catalyst system is of the order of about 1.5 to 5.5 wt-% or more.

Owner:UOP LLC

Oxygen-free direct conversion of methane and catalysts therefor

ActiveUS20180169621A1Efficient removalImprove stabilityCatalystsHydrocarbon preparation catalystsDopantHydrogen

A process of methane catalytic conversion produces olefins, aromatics, and hydrogen under oxygen-free, continuous flowing conditions. Such a process has little coke deposition and realizes atom-economic conversion. Under the conditions encountered in a fixed bed reactor (i.e. reaction temperature: 750-1200° C.; reaction pressure: atmospheric pressure; the weight hourly space velocity of feed gas: 1000-30000 ml / g / h; and fixed bed), conversion of methane is 8-50%. The selectivity of olefins is 30-90%. And selectivity of aromatics is 10-70%. The catalyst for this methane conversion has a SiO2-based matrix having active species that are formed by confining dopant metal atoms in the lattice of the matrix.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

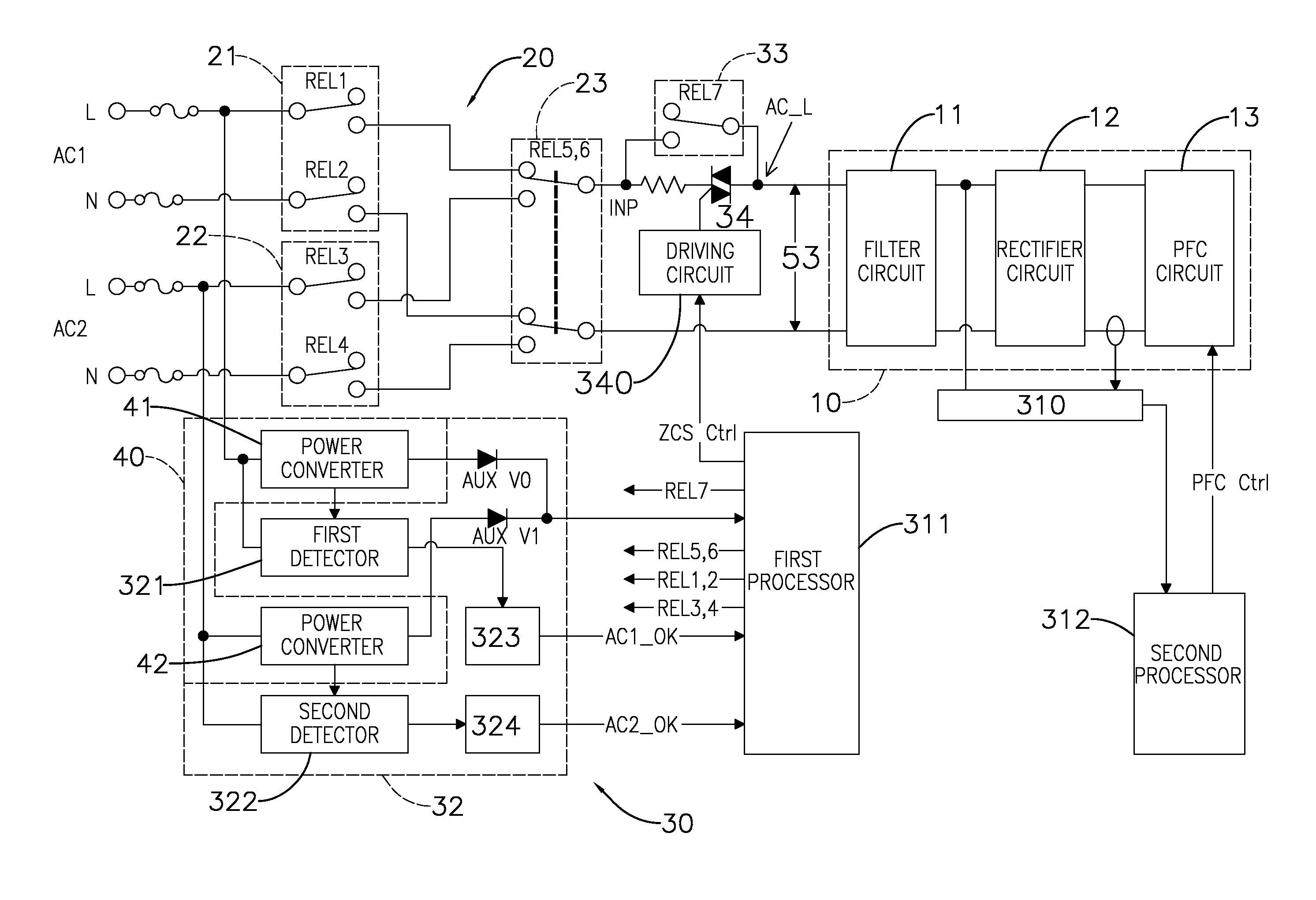

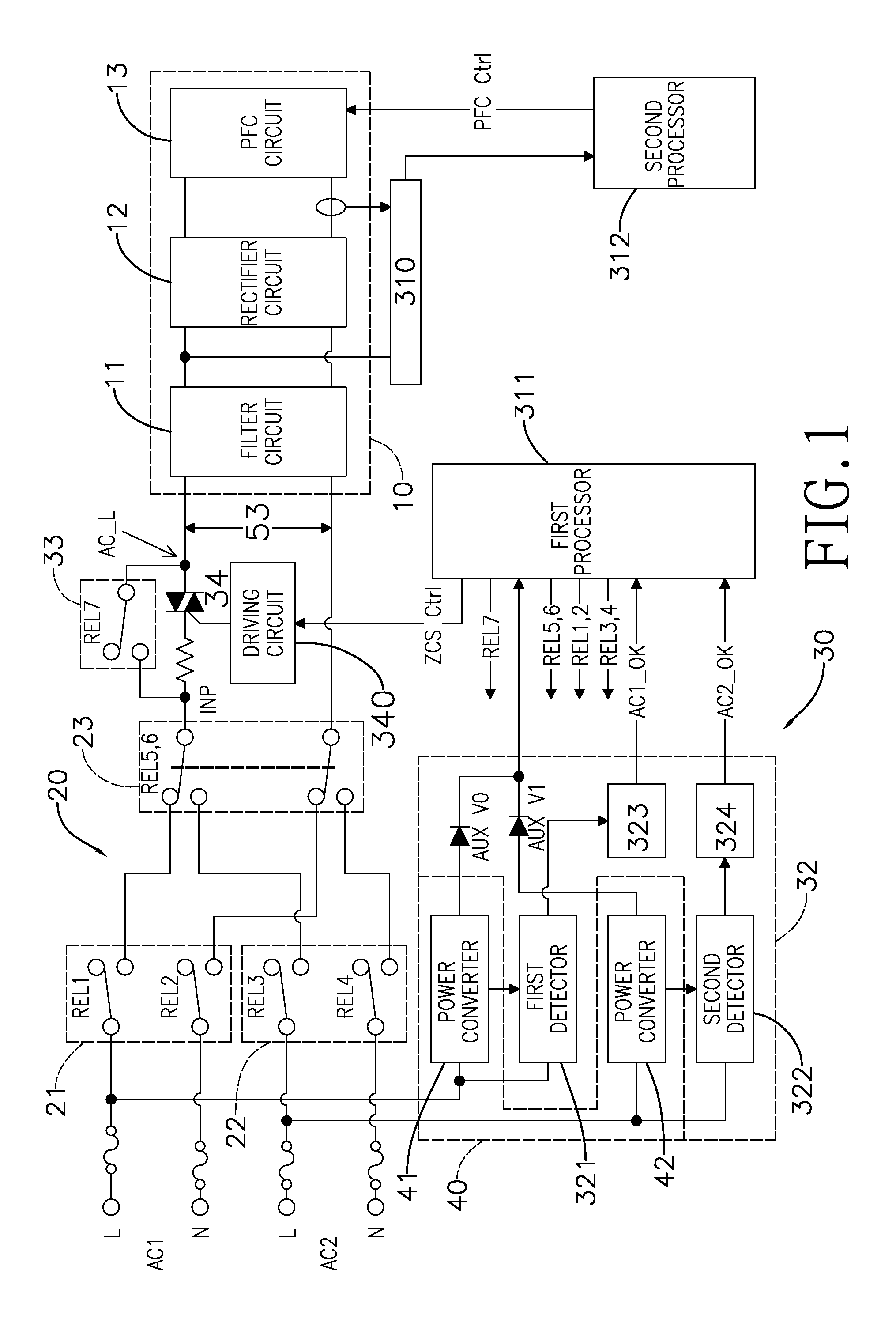

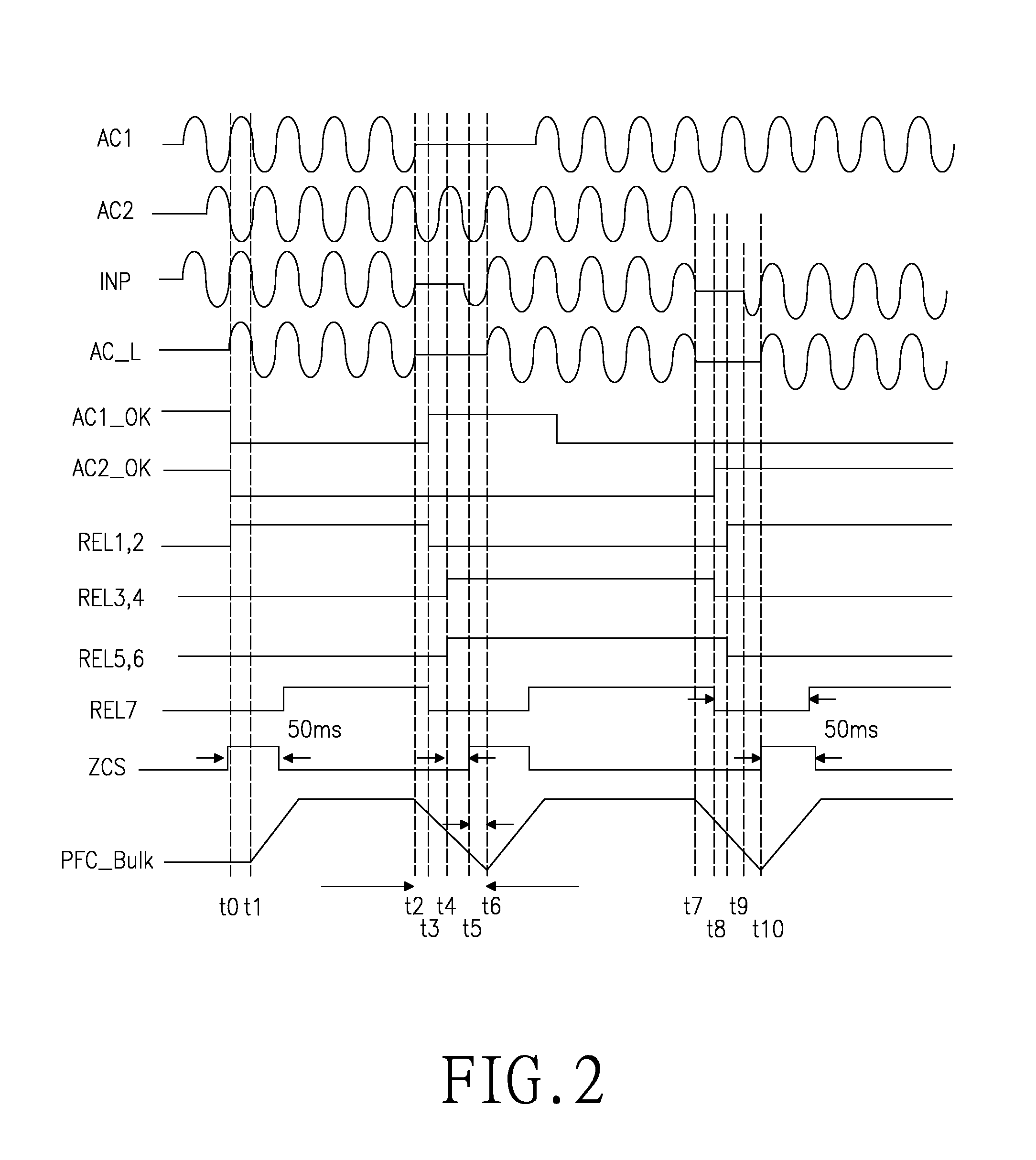

AC backup power system

ActiveUS9112376B2Avoid problemsElectric signal transmission systemsEmergency power supply arrangementsStandby powerAC power

An AC backup power system controls a power supply to selectively connect to a primary AC power source or a backup AC power source through a switching module. The switching module is controlled by a monitoring module. The monitoring module has a power monitoring unit, a first circuit switch, a second circuit switch, and a first processor. When the power monitoring unit detects an interruption of primary AC current, the first circuit switch that is normally closed is immediately turned off. The first processor then drives the switching module to connect to the backup AC power source. Once the backup AC power source reaches the zero-crossing point, the second circuit switch is turned on so that the backup AC power source provides power to the power supply. The power supply receives power at the zero-crossing point to avoid problems of sparks and coke deposition.

Owner:ACBEL POLYTECH INC

Method of inhibiting coke deposition in pyrolysis furnaces

A method is disclosed for reducing coke deposition in a pyrolysis furnace which comprises treating the pyrolysis furnace with a combination of sulfur- and phosphorus-containing compounds having a total sulfur to phosphorus atomic ratio of at least 5.

Owner:NALCOEXXON ENERGY CHEM

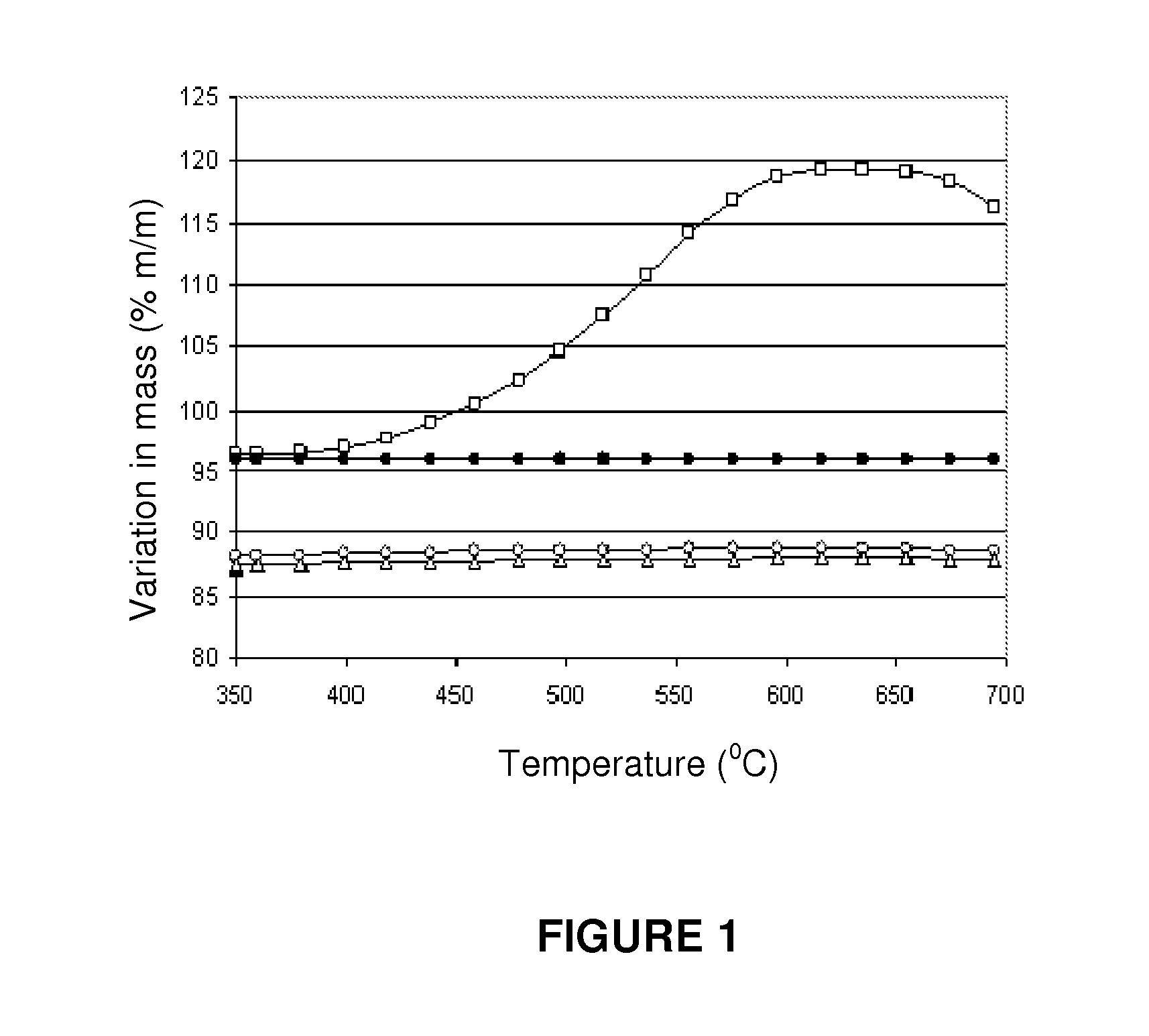

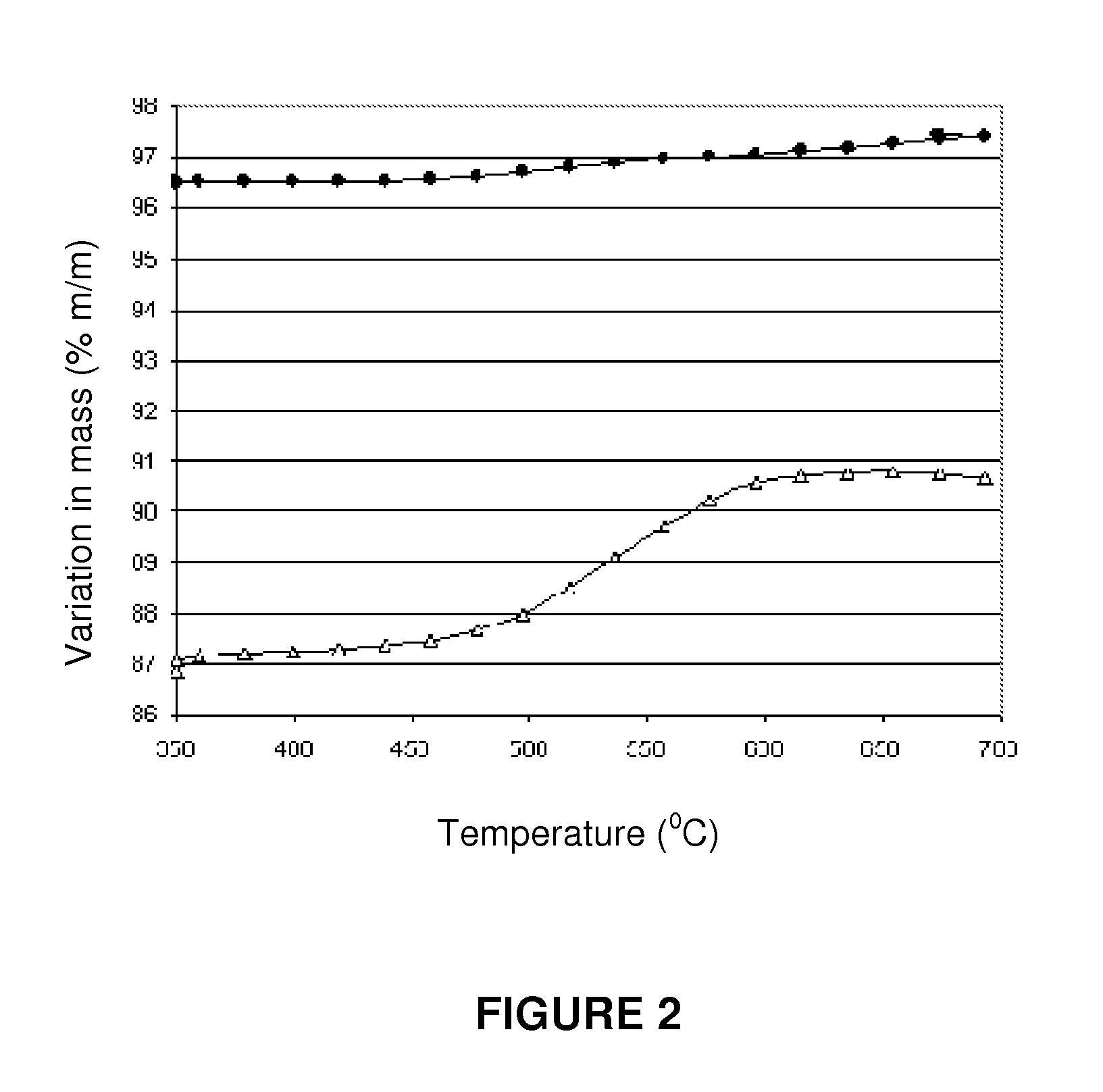

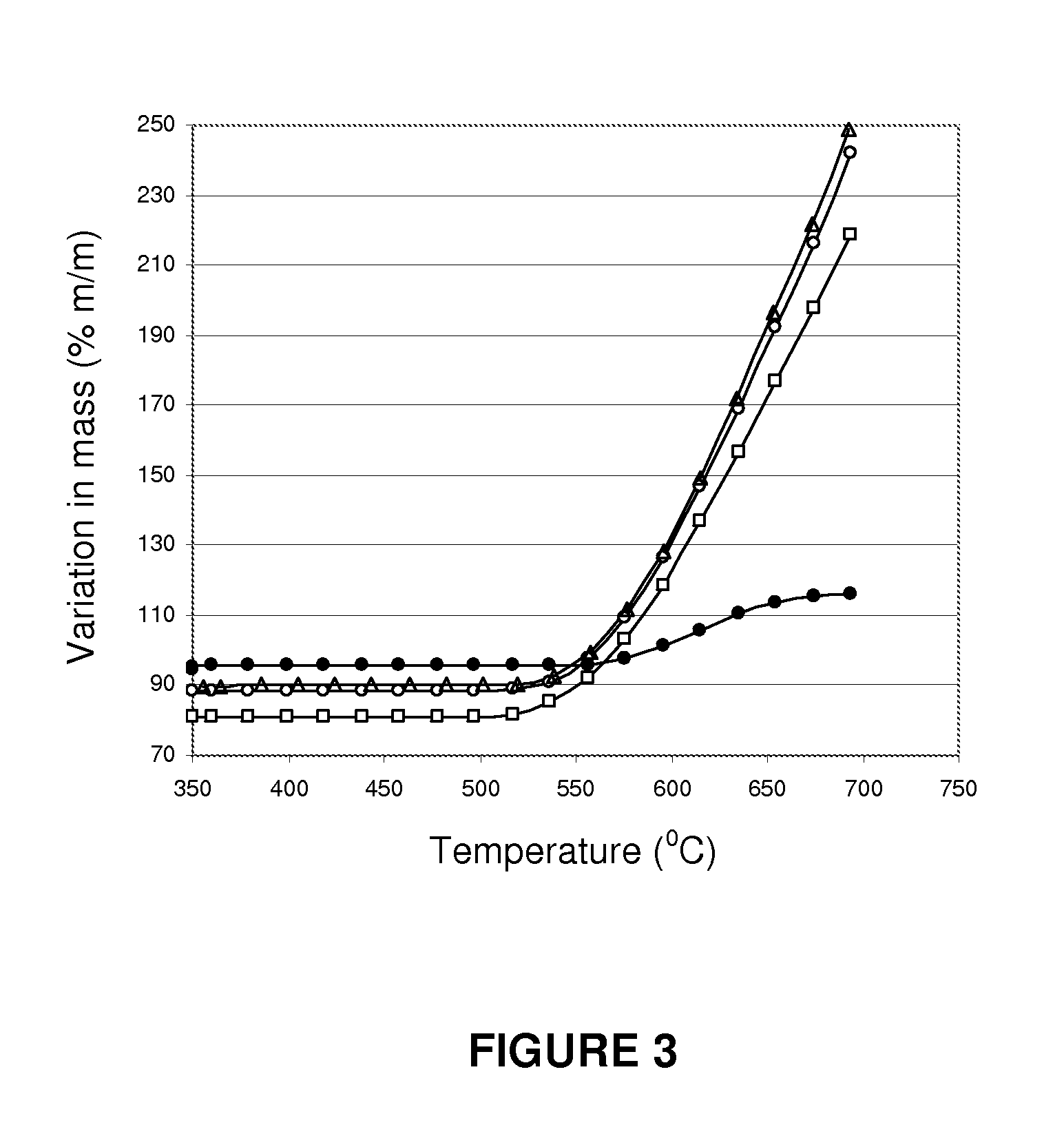

A process for pre-reforming hydrocarbon streams containing olefins, pre-reforming catalyst and a process for preparing said catalyst

The present invention relates to a catalyst for steam pre-reforming of hydrocarbons, containing in its formulation nickel and rare earths supported on alumina or magnesium or calcium aluminates, so as to increase the resistance to coke deposition, and the process for preparing said catalyst. Additionally the present invention relates to a process for manufacturing hydrogen or syn gas through steam pre-reforming olefin-containing hydrocarbons in the presence of the catalyst obtained according to the present invention.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

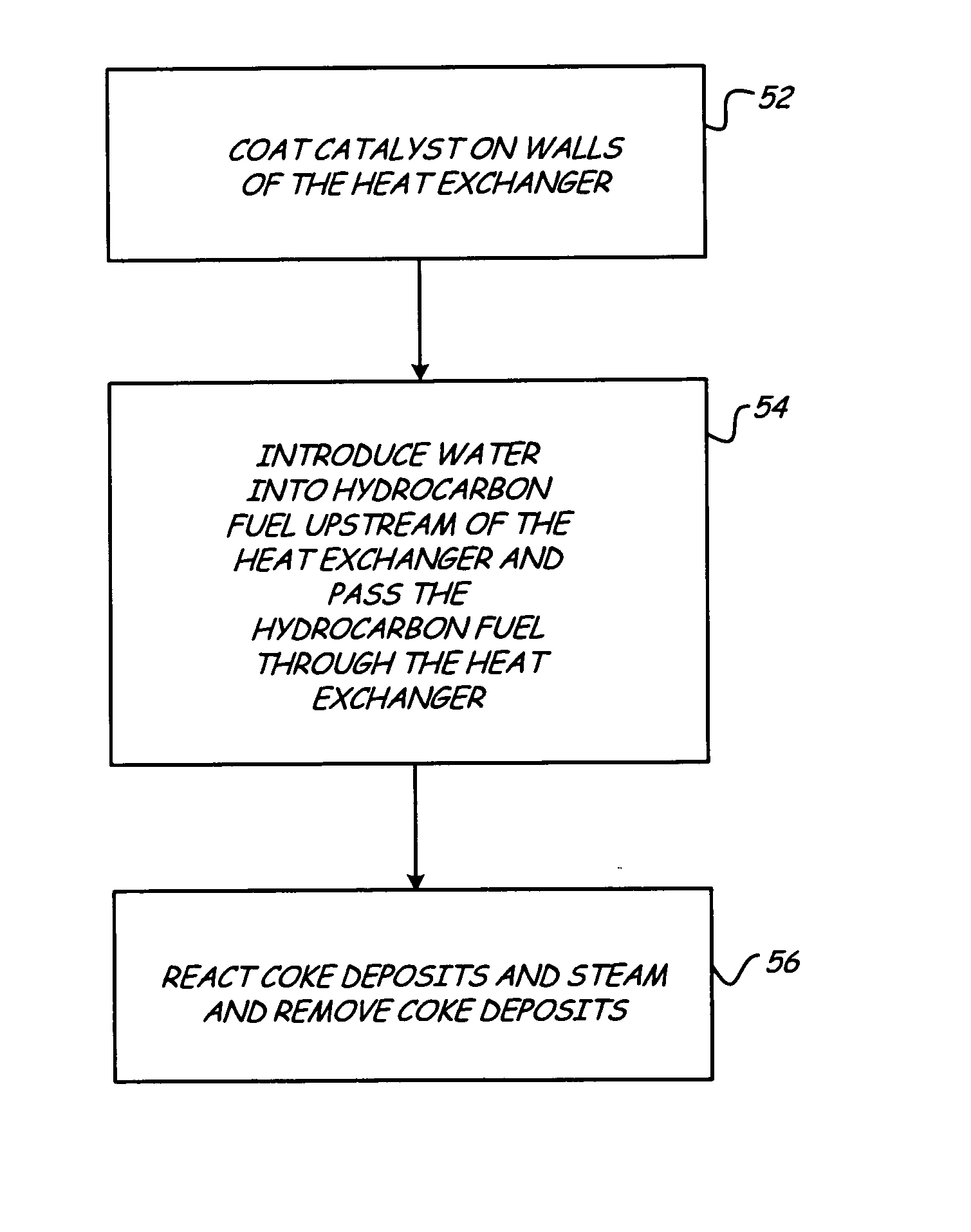

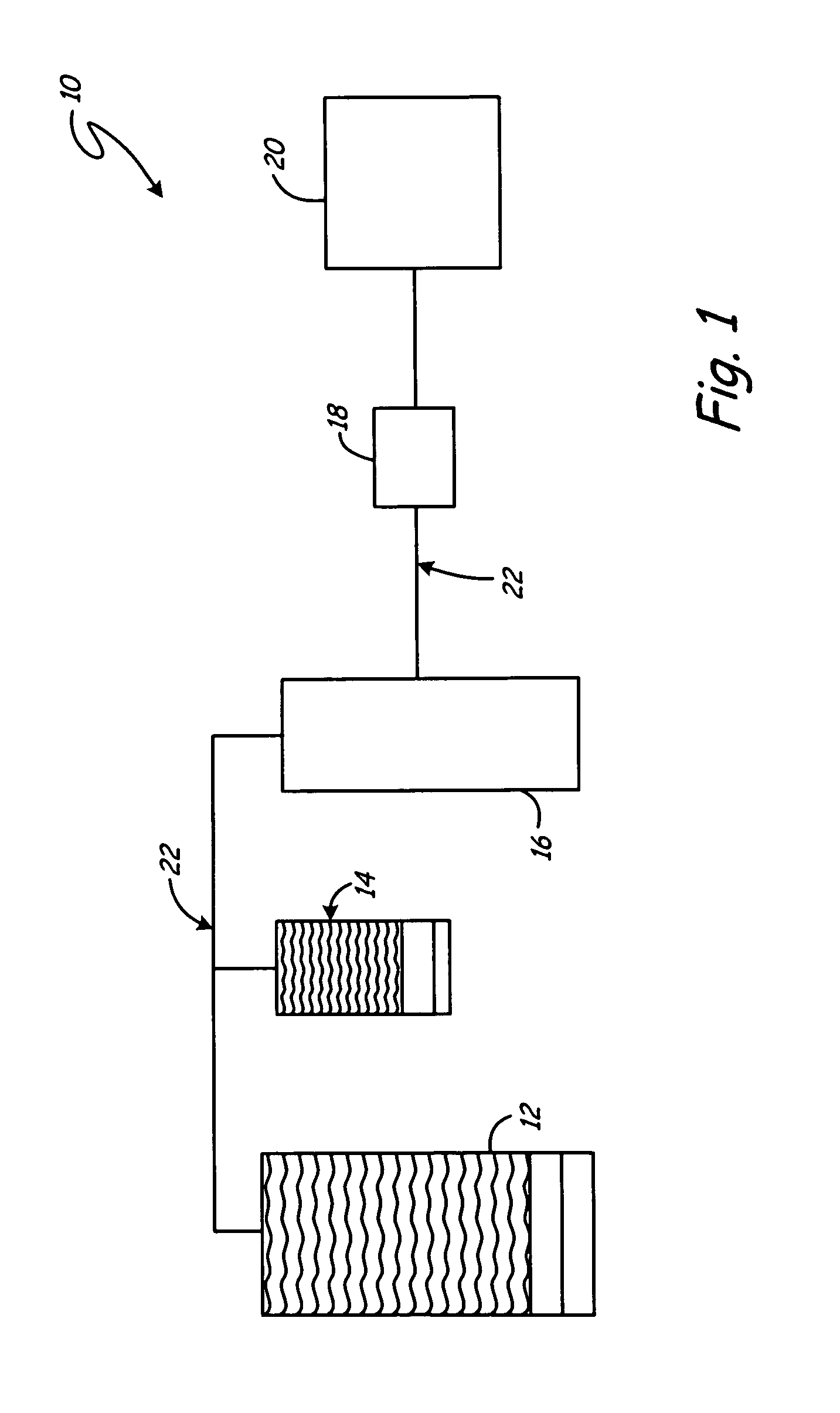

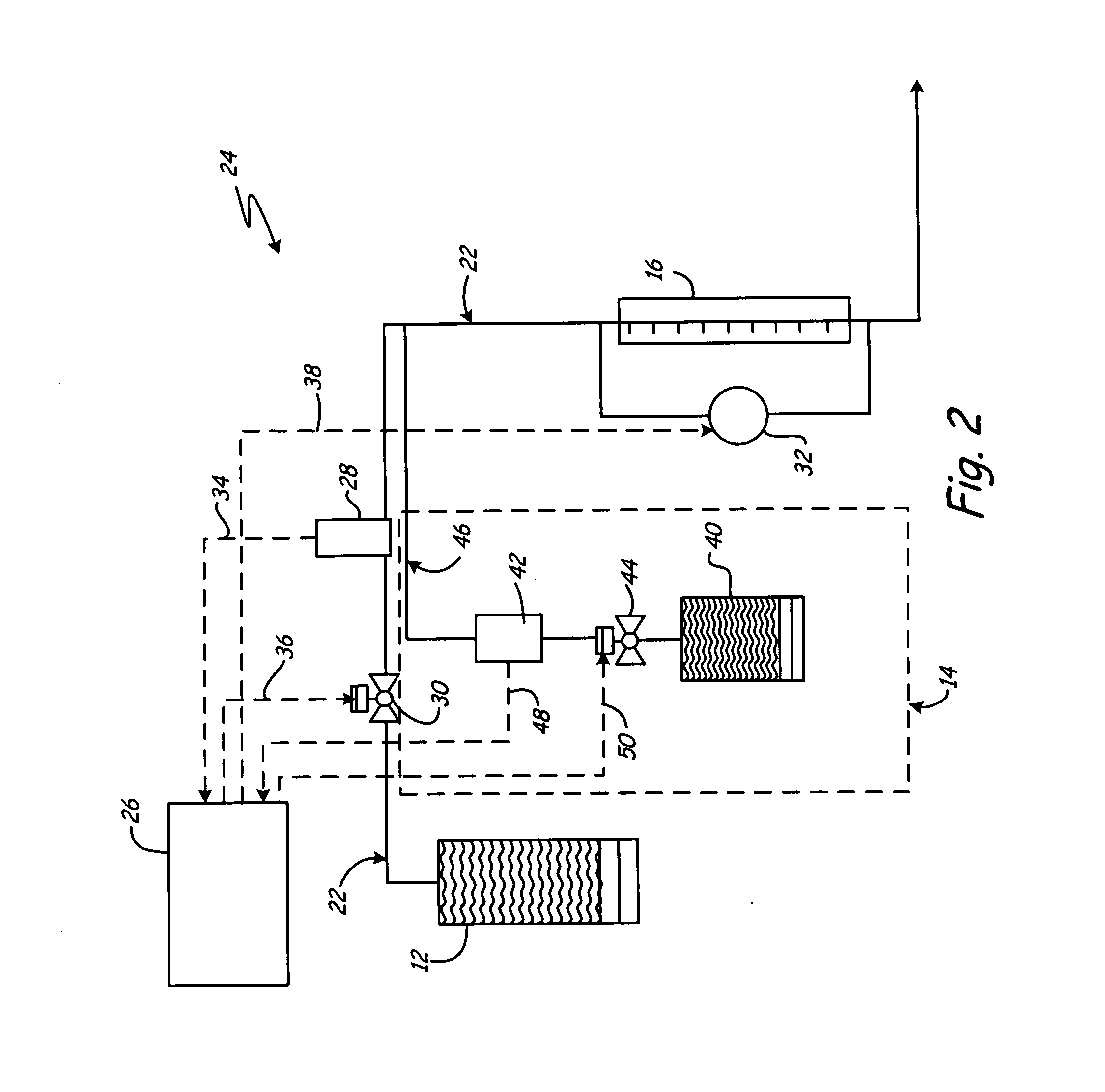

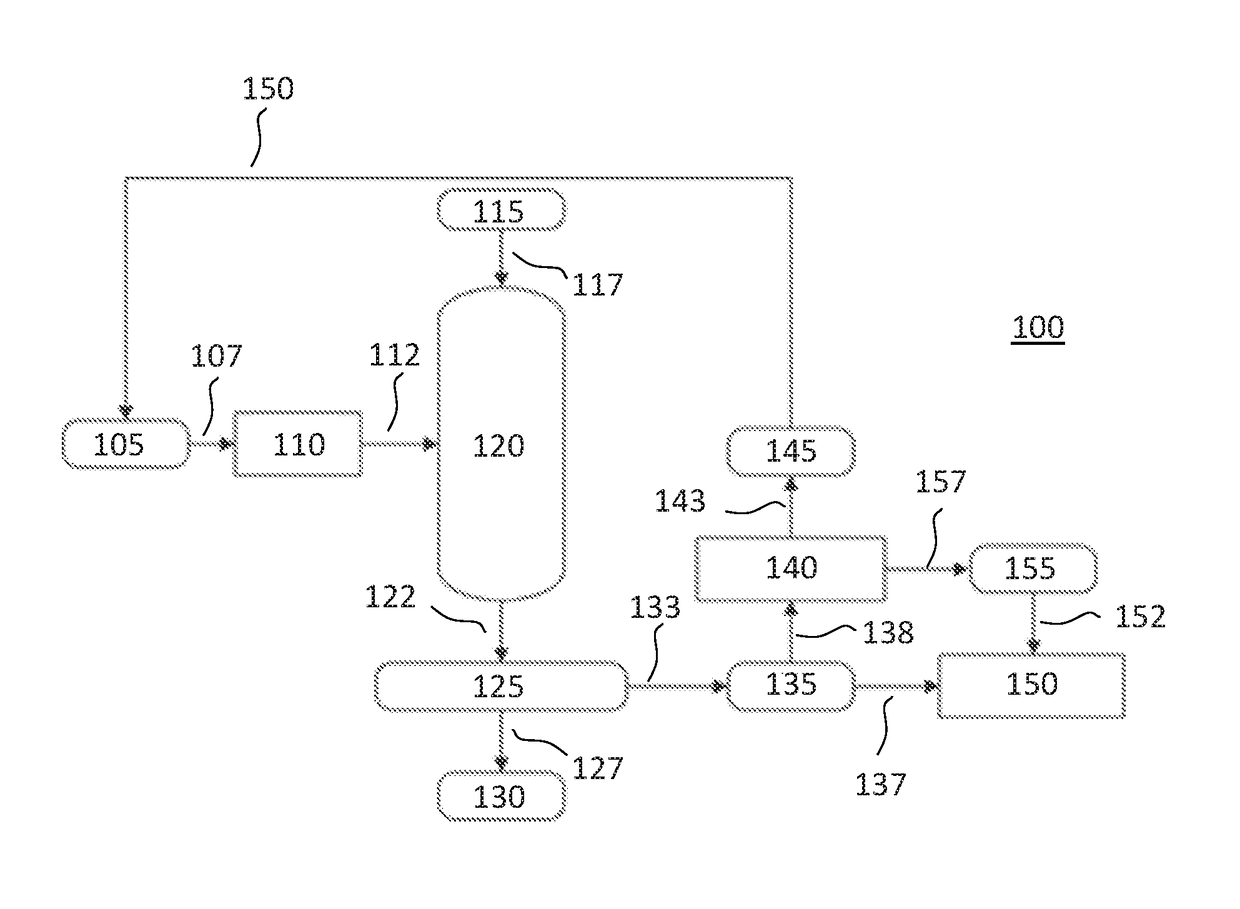

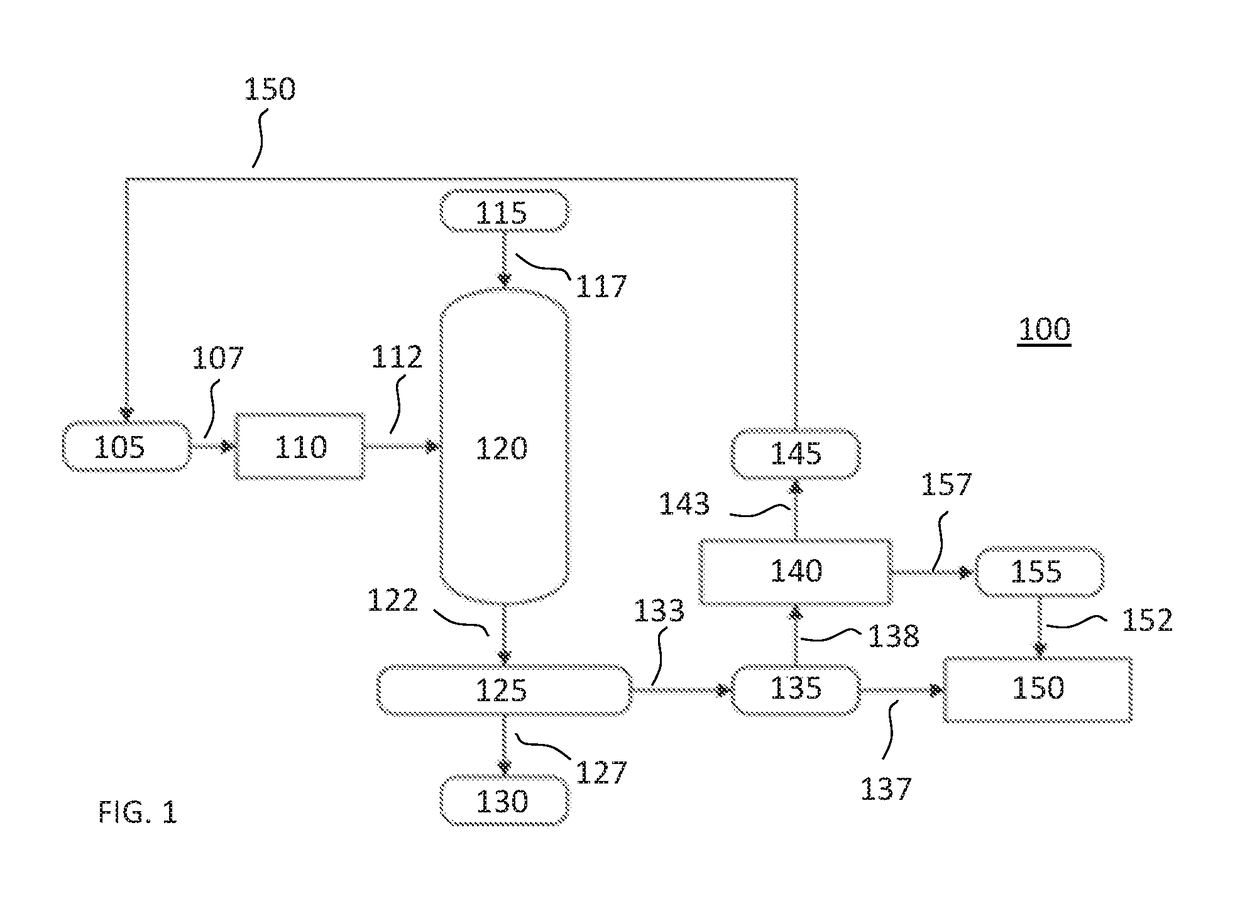

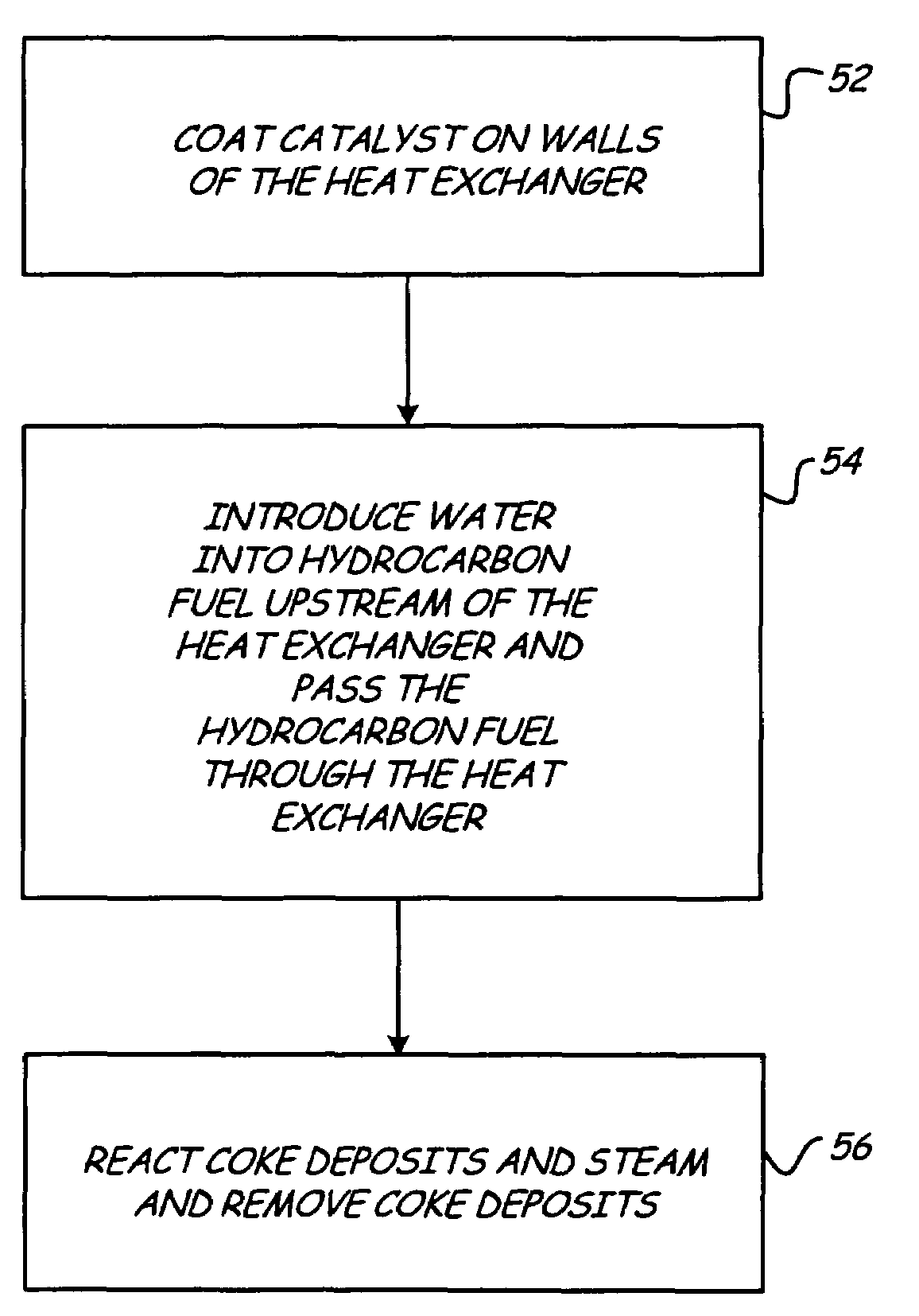

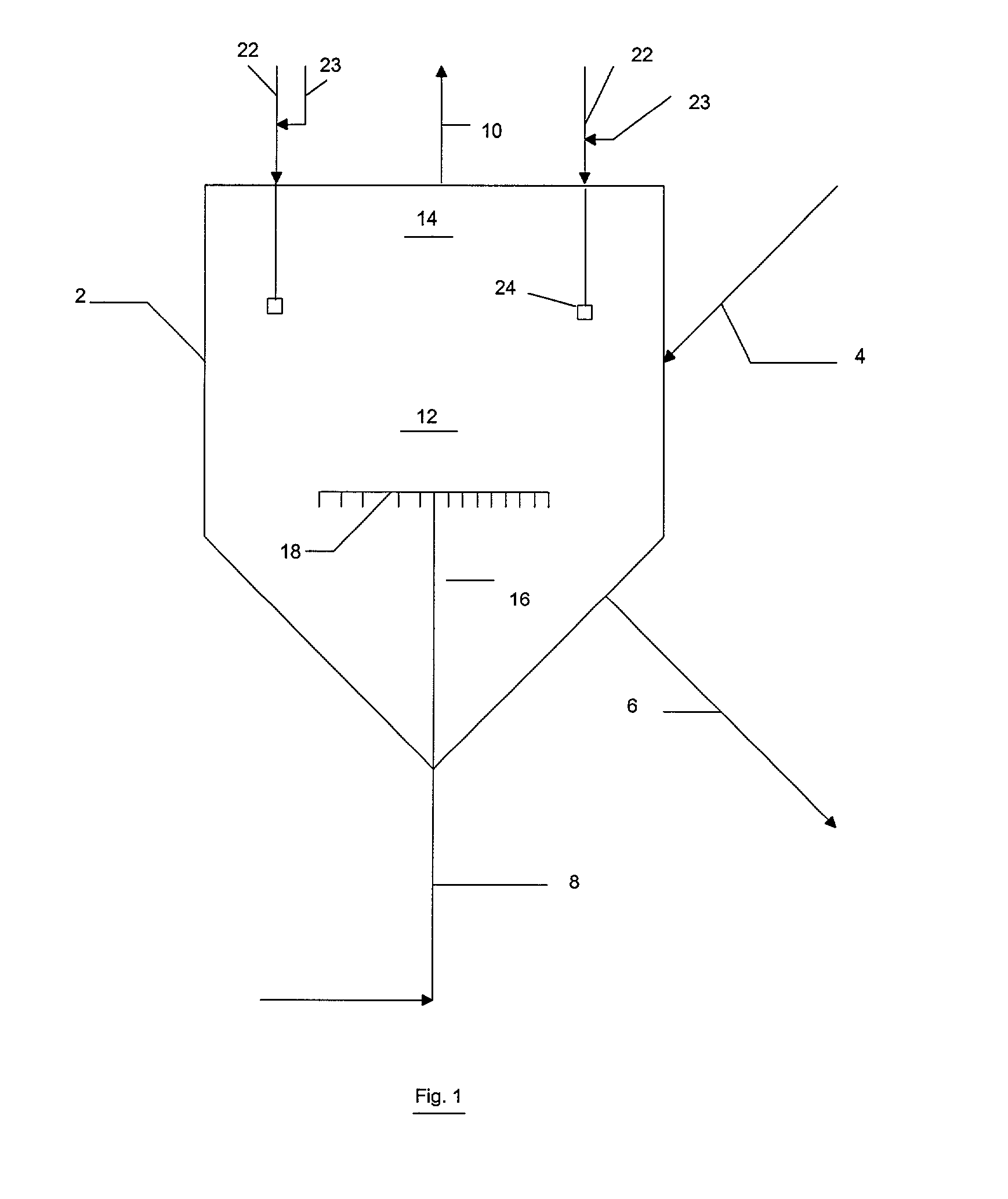

In-situ continuous coke deposit removal by catalytic steam gasification

InactiveUS20070261714A1Thermal non-catalytic crackingCatalytic crackingWater sourceProcess engineering

A coke removal system removes coke deposits from the walls of a high temperature passage in which hydrocarbon fuel is present. The system includes a carbon-steam gasification catalyst and a water source. The carbon-steam gasification catalyst is applied to the walls of the high temperature passage. The water reacts with the coke deposits on the walls of the high temperature passage to remove the coke deposits from the walls of the high temperature passage by carbon-steam gasification in the presence of the carbon-steam gasification catalyst.

Owner:RAYTHEON TECH CORP

Method for preparing dehydrocyclodimerization catalyst

InactiveUS20050059544A1Easily employedEasy to incorporateMolecular sieve catalystsCatalyst regeneration/reactivationPtru catalystPhysical chemistry

This invention relates to a process for reactivating a dehydrocyclodimerization catalyst. Dehydrocyclodimerization catalysts which contain an aluminum phosphate binder can be deactivated when they are exposed to hydrogen at temperatures above 500° C. The instant process restores substantially all of the catalyst's lost activity. The process involves treating the catalyst with a fluid comprising water and drying the catalyst. The process is employed particularly advantageously in combination with coke removal for reactivating catalysts that contain coke deposits and that have also been hydrogen deactivated. This invention also relates to a method of producing a dehydrocyclodimerization catalyst that is resistant to hydrogen deactivation.

Owner:UOP LLC

Catalyst for producing synthesis gas and method for producing same

InactiveCN105813737AHave economic benefitsReduce manufacturing costHydrogenHeterogenous catalyst chemical elementsSteam reformingSyngas

The present invention aims at providing a catalyst and a method for producing same which, besides withstanding coke deposition on the surface of the catalyst better, does not introduce limitations to the process variables, retains acceptable activity thresholds during the entire steam reforming process, and has a lower production cost. This objective is achieved by means of a catalyst formed by an inorganic oxide support, a mixture of nickel, lanthanum and cerium, and a promoter element.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Method and apparatus for preparing vinyl chloride using ethane and 1,2-dichloroethane

ActiveCN101356139AInhibitionAvoid accumulationPreparation by hydrogen halide split-offChemical/physical processesSolid particleEthane Dichloride

Provided are a method of preparing vinyl chloride including: supplying chlorine gas and ethane to an ethane chlorination reaction region disposed in a lower portion of a pyrolysis reactor in which solid particles exist; performing an ethane chlorination reaction by contacting the chlorine gas and ethane with solid particles such that a product of the ethane chlorination reaction and the solid particles rise toward an upper portion of the pyrolysis reactor at the same time, and depositing coke produced during the ethane chlorination reaction on the solid particles; supplying 1,2-dichloroethane to a pyrolysis reaction region disposed in an upper portion of the pyrolysis reactor; ; performing a pyrolysis reaction in the pyrolysis reaction region by contacting a product of the ethane chlorination reaction and 1,2-dichloroethane with the solid particles such that the product of the ethane chlorination reaction , the 1,2-dichloroethane and the solid particles rise up at the same time, and depositing coke produced during the pyrolysis reaction on the solid particles; regenerating the solid particles by burning coke deposited on the solid particles in a regeneration reactor; and resupplying the solid particles that collect heat generated by burning coke to the pyrolysis reactor, and an apparatus for preparing the same. When vinyl chloride monomer is prepared using the above-described method, yield is improved, and coke production is inhibited.

Owner:LG CHEM LTD

Coking full-distillate oil hydrocracking method

ActiveCN104611028AAddress uneven distributionRealize separation operationTreatment with hydrotreatment processesHydrocarbon oils treatment productsGas phaseFractionation

The present invention discloses a coking full-distillate oil hydrocracking method. According to the method, coking full-distillate and a hydrocracking gas phase heated by a heating furnace are mixed and then enter an upflow type reactor, and the hydrorefining product is separated on the upper portion of the reactor to obtain a gas phase and a liquid phase; the gas phase enters a separator to separate to obtain gas and a liquid phase; the pressure-increasing hydrorefining liquid and hydrogen gas are mixed and then enter a hydrocracking reactor from the bottom portion of the reactor, and the cracking reaction product is separated in the reactor; the obtained cracking gas phase is heated and then is mixed with raw material oil; and the obtained cracking liquid phase is mixed with the liquid phase obtained through the separator, and then fractionation is performed to obtain the hydrocracking product. With the method of the present invention, the problem of the non-uniform material distribution is well solved, the problem that the direct mixing heat exchange of the raw material oil and the hydrocracking gas phase heated by the heating furnace at the low temperature causes the sharply-increased pressure drop due to the coking deposition of the unsaturated hydrocarbon in the equipment is solved, the operating period is effectively prolonged, and the energy consumption of the equipment is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

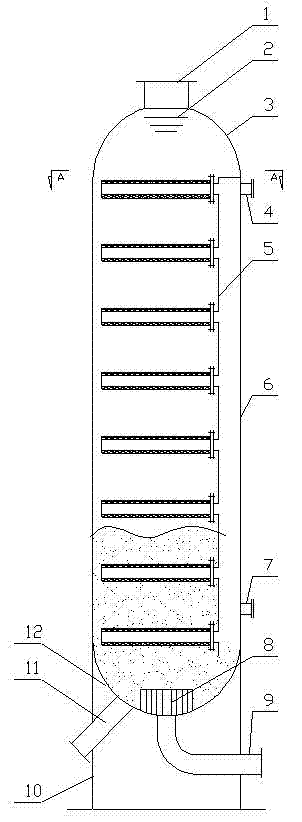

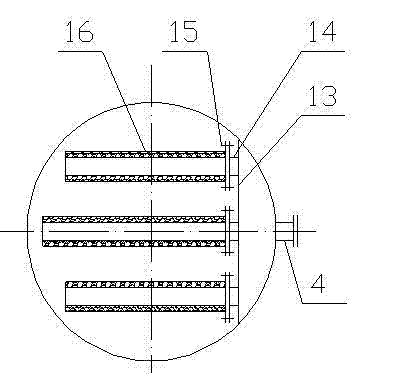

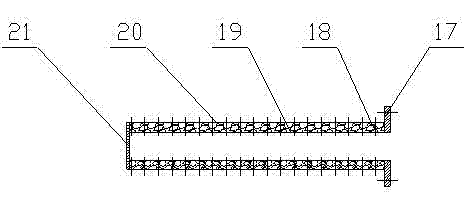

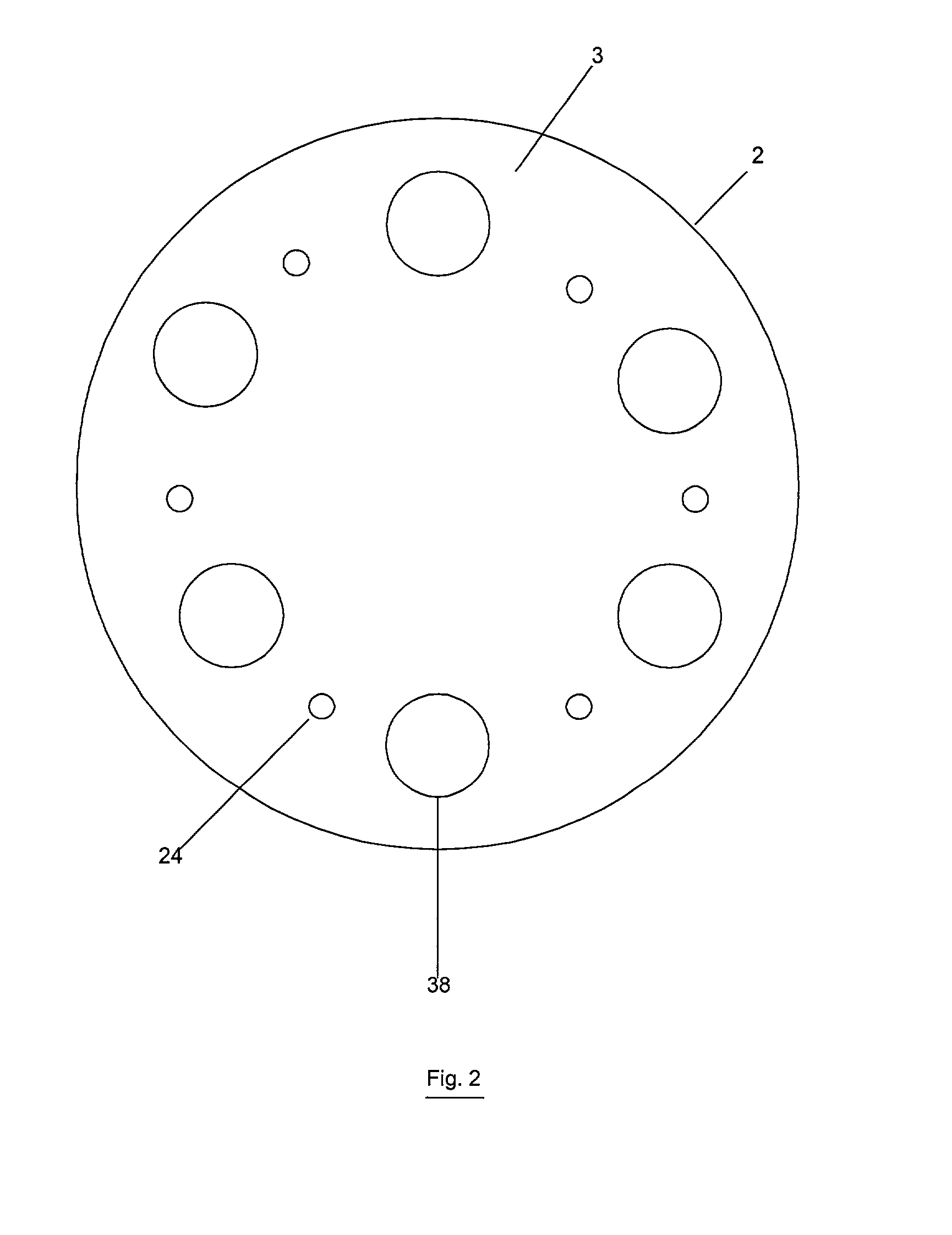

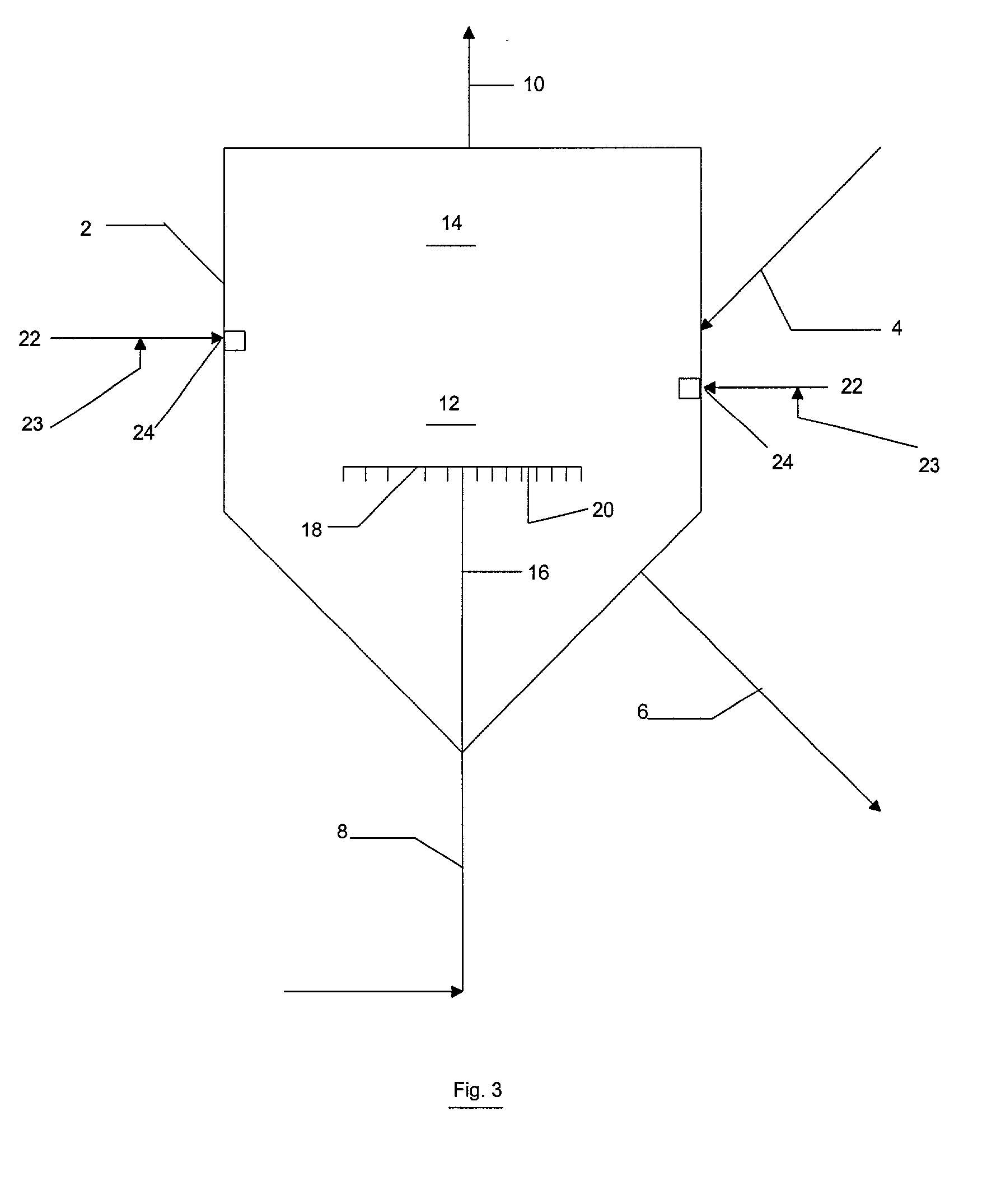

Naphtha hydrogenation method and decoking tank

ActiveCN102732309ASimple structureSmall footprintDispersed particle filtrationTreatment with hydrotreatment processesNaphthaHydrogenation reaction

The invention discloses a naphtha hydrogenation method and a decoking tank. The naphtha hydrogenation method comprises the following steps of heating a mixture of a naphtha feedstock and hydrogen in a heating surface to a temperature required by hydrofining, then carrying out decoking by the decoking tank, and then feeding the decoked mixture into a fixed bed hydrogenation reactor. The decoking tank comprises a cylindrical body, an upper head, a lower head and a separator. The separator comprises a box plate and multiple separation pipe assemblies fixed to the box plate. The decoking tank is divided into two parts by the box plate, wherein one part is a channel for outflow of filtered materials and the other part is a coke deposition zone. Compared with the prior art, the naphtha hydrogenation method and the decoking tank can effectively and economically prolong a naphtha hydrogenation device running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Serpentine Fluid Reactor Components

ActiveUS20140178256A1Thermal non-catalytic crackingWeather/light/corrosion resistanceErosion rateProcess engineering

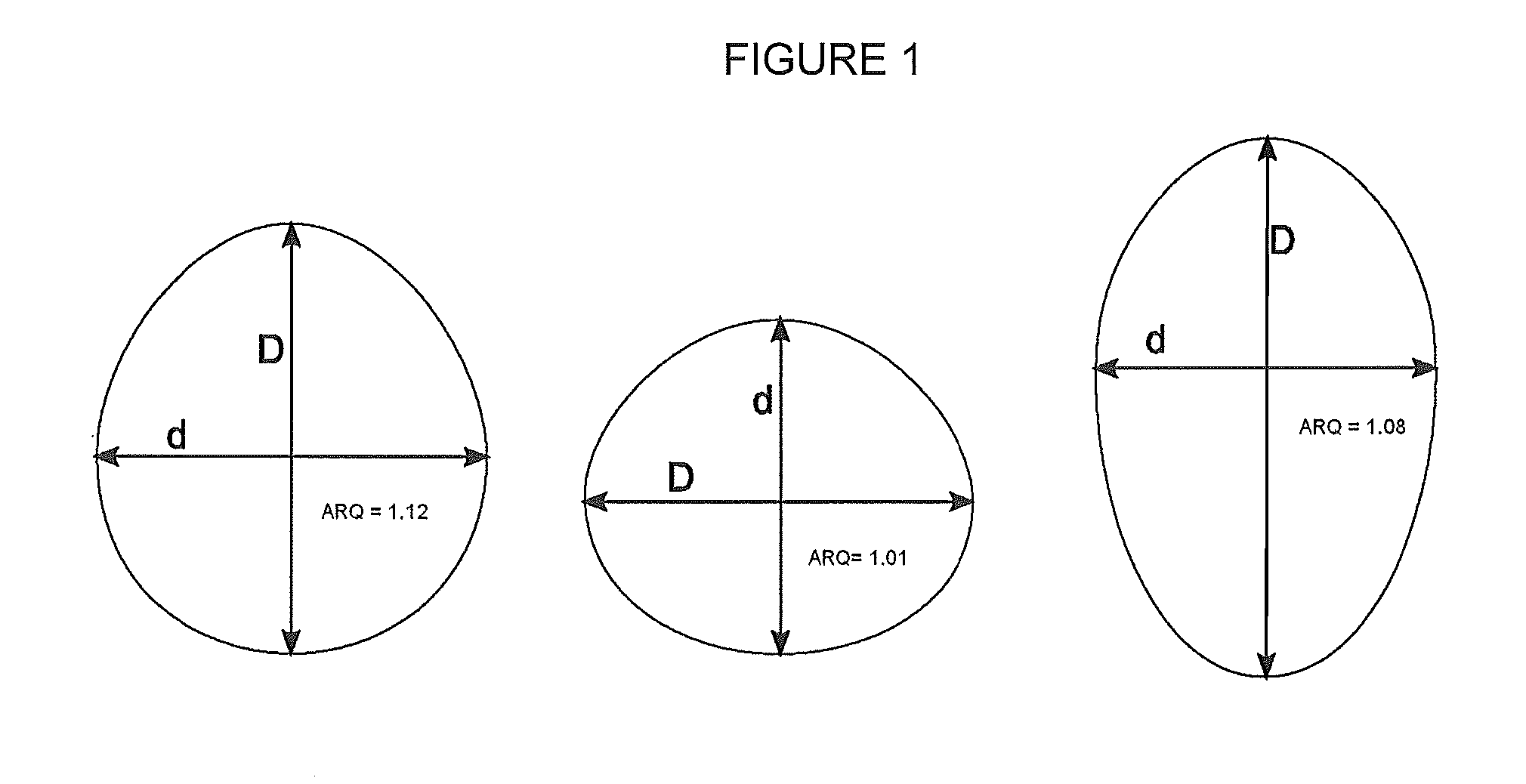

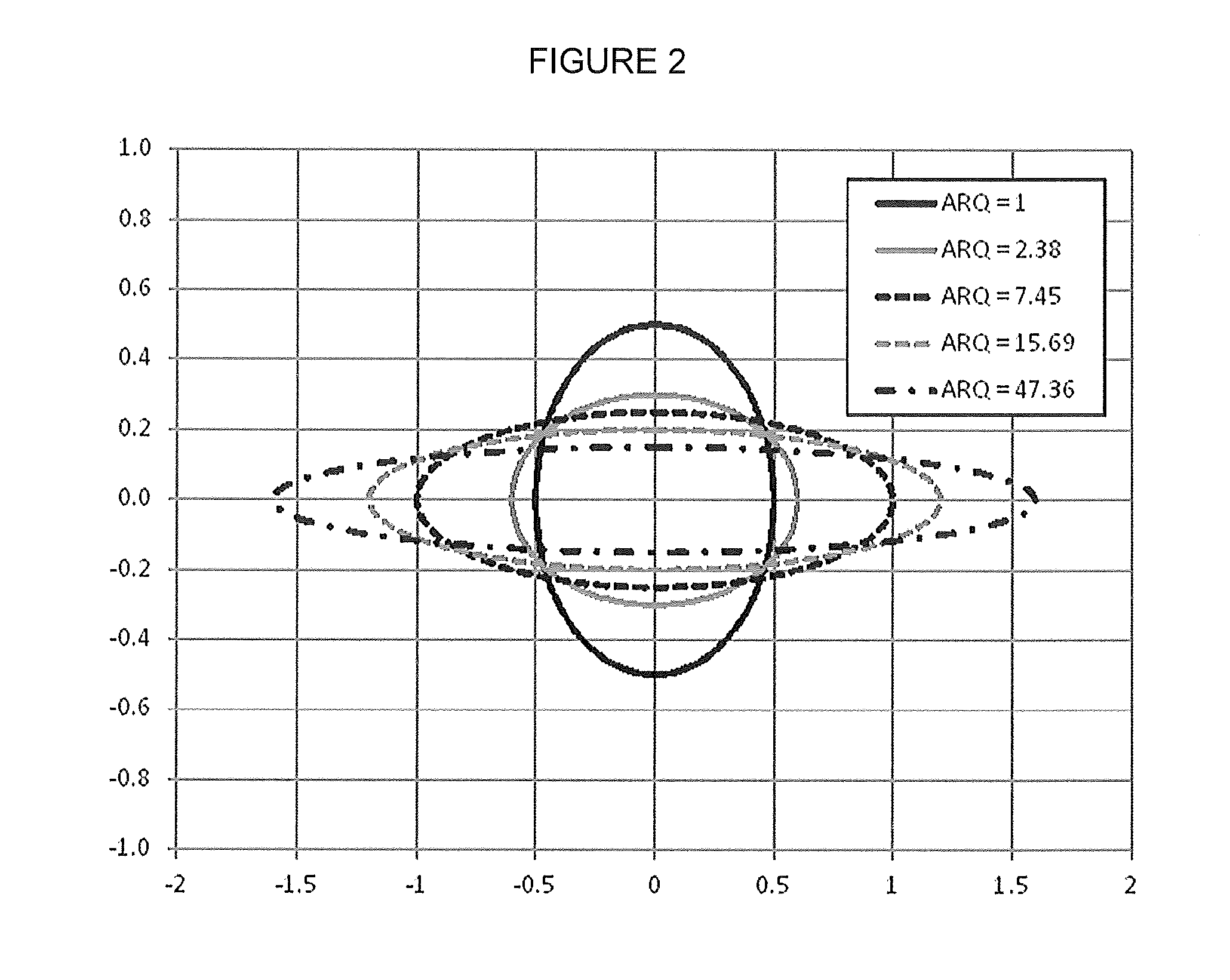

Some embodiments of the present invention provide components for a serpentine fluid reactor which is optimized for one or more objective functions of interest such as pressure drop, erosion rate, fouling, coke deposition and operating costs. The components are designed by computer modeling the components individually and collectively in which the cross section of flow path is substantially circular under industrial conditions to validate the model design and its operation. Then iteratively the component designs are deformed and the operation of the deformed part(s) is modeled and compared to values obtained with other deformed models until the value of the objective function is optimized (e.g. at an extreme) or the change in the objective function is approaching zero.

Owner:NOVA CHEM (INT) SA

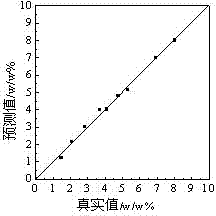

Method for detecting coke deposition of catalyst by utilizing nuclear magnetic resonance

InactiveCN103196938AHigh precisionCancel noiseAnalysis using nuclear magnetic resonanceNMR - Nuclear magnetic resonanceCoke deposition

The invention discloses a method for detecting coke deposition of a catalyst by utilizing nuclear magnetic resonance. The method comprises the following steps of acquiring a carbon nuclear magnetic resonance spectrum of samples of certain quantity with known coke deposition, correlating and modeling a carbon spectrum peak area set and a coke deposition set of the known samples after being pretreated, and calculating the coke deposition of an unknown sample by predicting the carbon nuclear magnetic resonance spectrum of the model and the unknown sample. The method is fast, accurate and stable, can be used for offline detecting the coke deposition on a solid acid catalyst in the industry and is significant for optimizing a catalyst reaction-renewable system.

Owner:ZHEJIANG UNIV

Enhanced performance of the dehydrogenation by the reduction of coke formation using pre-activated co2

The present disclosure addresses the deficiencies described above by providing systems and methods for enhancing the efficiency and yield of alkene production. The methods and systems provide for the use of activated CO2 in a dehydrogenation reactor along with an alkane stream. Through the use of the methods and systems of the invention, catalyst deactivation by coke deposition is reduced and the selectivity and efficiency of the dehydrogenation reaction is improved.

Owner:SABIC GLOBAL TECH BV

In-situ continuous coke deposit removal by catalytic steam gasification

A coke removal system removes coke deposits from the walls of a high temperature passage in which hydrocarbon fuel is present. The system includes a carbon-steam gasification catalyst and a water source. The carbon-steam gasification catalyst is applied to the walls of the high temperature passage. The water reacts with the coke deposits on the walls of the high temperature passage to remove the coke deposits from the walls of the high temperature passage by carbon-steam gasification in the presence of the carbon-steam gasification catalyst.

Owner:RTX CORP

Enhanced performance of the dehydrogenation by the reduction of coke formation using pre-activated co2

The present disclosure addresses the deficiencies described above by providing systems and methods for enhancing the efficiency and yield of alkene production. The methods and systems provide for the use of activated CO2 in a dehydrogenation reactor along with an alkane stream. Through the use of the methods and systems of the invention, catalyst deactivation by coke deposition is reduced and the selectivity and efficiency of the dehydrogenation reaction is improved.

Owner:SABIC GLOBAL TECH BV

Reactor modifications for NOx reduction from a fluid catalytic cracking regeneration vessel

InactiveUS20030021737A1Reduce nitrogen oxide emissionsReduce temperature riseNitrous oxide captureCombination devicesCombustionShielding gas

A process for regenerating a spent catalyst having coke deposits thereon in a catalyst regeneration vessel having a dense phase and a dilute phase, wherein the process comprises the steps of: (a) contacting the spent catalyst with a primary oxygen-containing gas in the dense phase, thereby combusting the coke, resulting in the formation of a combustion gas comprising nitrogen oxides and carbon monoxide which further reacts, thus reducing a majority of the nitrogen oxides to form elemental nitrogen; and (b) contacting the combustion gas with a secondary oxygen-containing gas, and typically a shield gas, in the dilute phase, thereby oxidizing the remaining CO to CO2 without significant temperature rise in the dilute phase due to the after bum.

Owner:BOC GRP INC

Process for pre-reforming hydrocarbon streams containing olefins, pre-reforming catalyst and a process for preparing said catalyst

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com