Catalyst for producing synthesis gas and method for producing same

A catalyst, synthesis gas technology, applied in hydrogen/syngas production, chemical instruments and methods, catalyst activation/preparation, etc., can solve problems such as temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

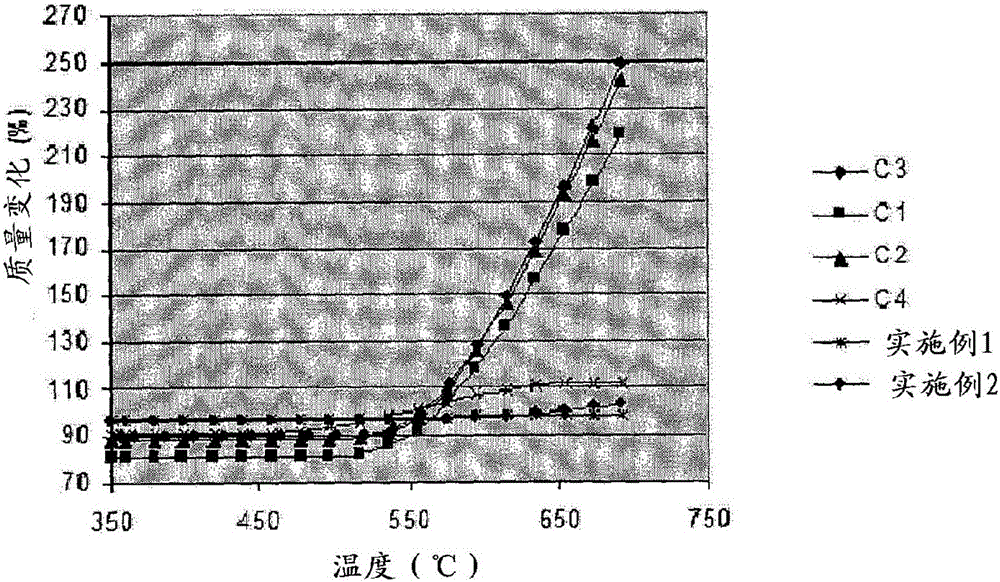

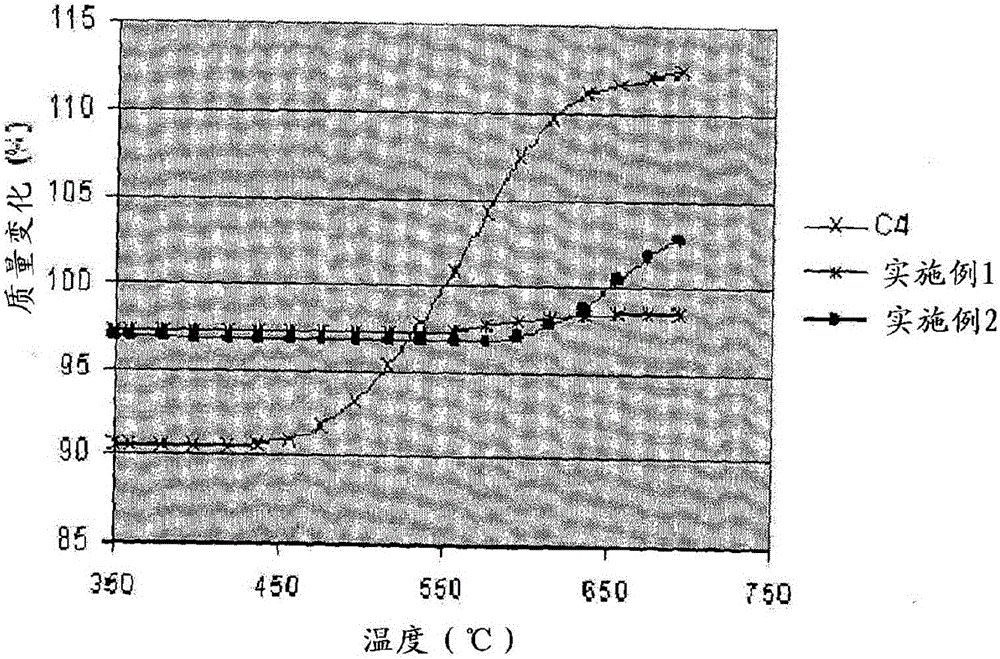

[0052] This example illustrates the preparation of a catalyst according to the invention based on nickel, lanthanum and cerium on an alumina type support and promoted with boron.

[0053] With 70mL containing 2.95 grams of La (NO 3 ) 3 .6H 2 O, 8.82 g Ce(NO 3 ) 3 .6H 2 O and 33.03 g Ni(NO 3 ) 2 .6H 2 One hundred grams of commercially available theta-alumina (Axens SP Pore volume is 0.7cm 3 / g, in the shape of a sphere with a diameter of 3 mm to 4 mm). The material was dried at 60 °C for 2 h, then heated in static air at a rate of 1 °C / min at a temperature ranging between 60 °C and 120 °C in the first step, and at 1.4 °C in the second step. Heat up to 250°C at a rate of °C / min. Then, the catalyst was calcined at 450°C for 4.5 hours. Thus obtaining a compound containing 7.6% (w / w) NiO, 1.0% (w / w) La 2 o 3 and 3% (w / w) Ce 2 o 3 Ni-Ce-La / θ-alumina catalyst. Then use 28mL containing 2.31 grams of boric acid (H 3 BO 4 ) in an aqueous solution wet spot impregnat...

Embodiment 2

[0055] This example illustrates the preparation of a catalyst according to the invention based on nickel, lanthanum and cerium on an alumina type support and promoted with silver.

[0056] With 70mL containing 2.95 grams of La (NO 3 ) 3 .6H 2 O, 8.82 g Ce(NO 3 ) 3 .6H 2 O and 33.03 g Ni(NO 3 ) 2 .6H 2 One hundred grams of commercially available theta-alumina (Axens SP Pore volume is 0.7cm 3 / g, in the shape of a sphere with a diameter of 3 mm to 4 mm). The material was dried at 60 °C for 2 h, then heated in static air at a rate of 1 °C / min at a temperature ranging between 60 °C and 120 °C in the first step, and at 1.4 °C in the second step. Heat up to 250°C at a rate of °C / min. Then, the catalyst was calcined at 450°C for 4.5 hours. Thus obtaining a compound containing 7.6% (w / w) NiO, 1.0% (w / w) La 2 o 3 and 3% (w / w) Ce 2 o 3 Ni-Ce-La / θ-alumina catalyst. Then use 28mL containing 2.31 grams of silver nitrate (AgNO 3 ) in an aqueous solution wet spot impregn...

Embodiment 3

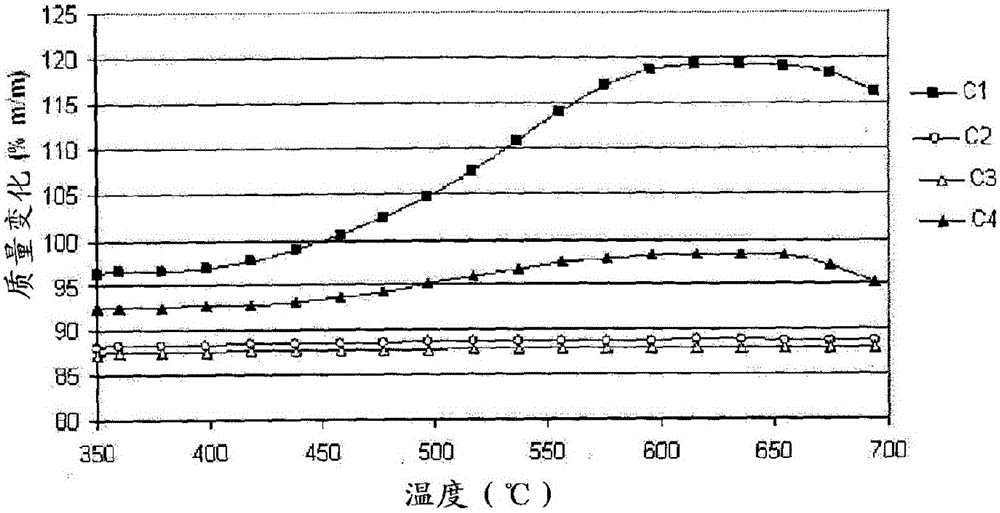

[0058] This example illustrates the performance of nickel-based commercially available catalysts for pre-reforming, which are known in the prior art, against carbon deposition under pre-reforming conditions for gas streams containing hydrocarbons, high in carbon monoxide, but free of olefins. Known in, with the symbols C1, C2, C3 and C4 said.

[0059] The catalysts were tested in a comparative manner in a thermogravimetric analysis apparatus (TGA Mettler Toledo TGA / SDTA851E). The test was carried out using 25 mg of catalyst which was crushed to obtain particles smaller than 0.088 mm (170 mesh). A pretreatment step was performed first by flowing 40 mL / min of a mixture containing 10% (v / v) hydrogen in argon-saturated water vapor at 15°C together with 40 mL / min of nitrogen (protective gas). The temperature was set in a value range between 100°C and 650°C at a heating rate of 10°C / min and maintained for 1 hour. The temperature was then lowered to 350°C by using a gas containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com