Method and system for recycling and purifying treatment of biogas slurry

A purification treatment and biogas slurry technology, which is applied in chemical instruments and methods, energy wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of biogas slurry not meeting environmental protection standards, failing to meet, polluting water quality, etc., to achieve Beautify the biogas station and factory environment, facilitate operation, and improve efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

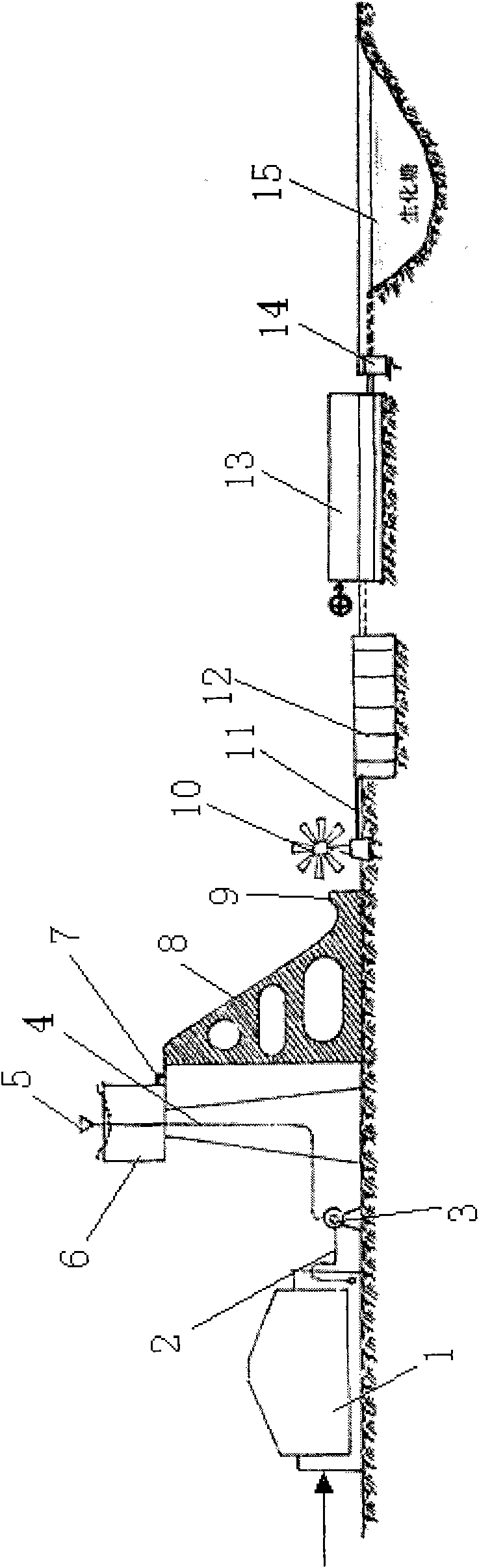

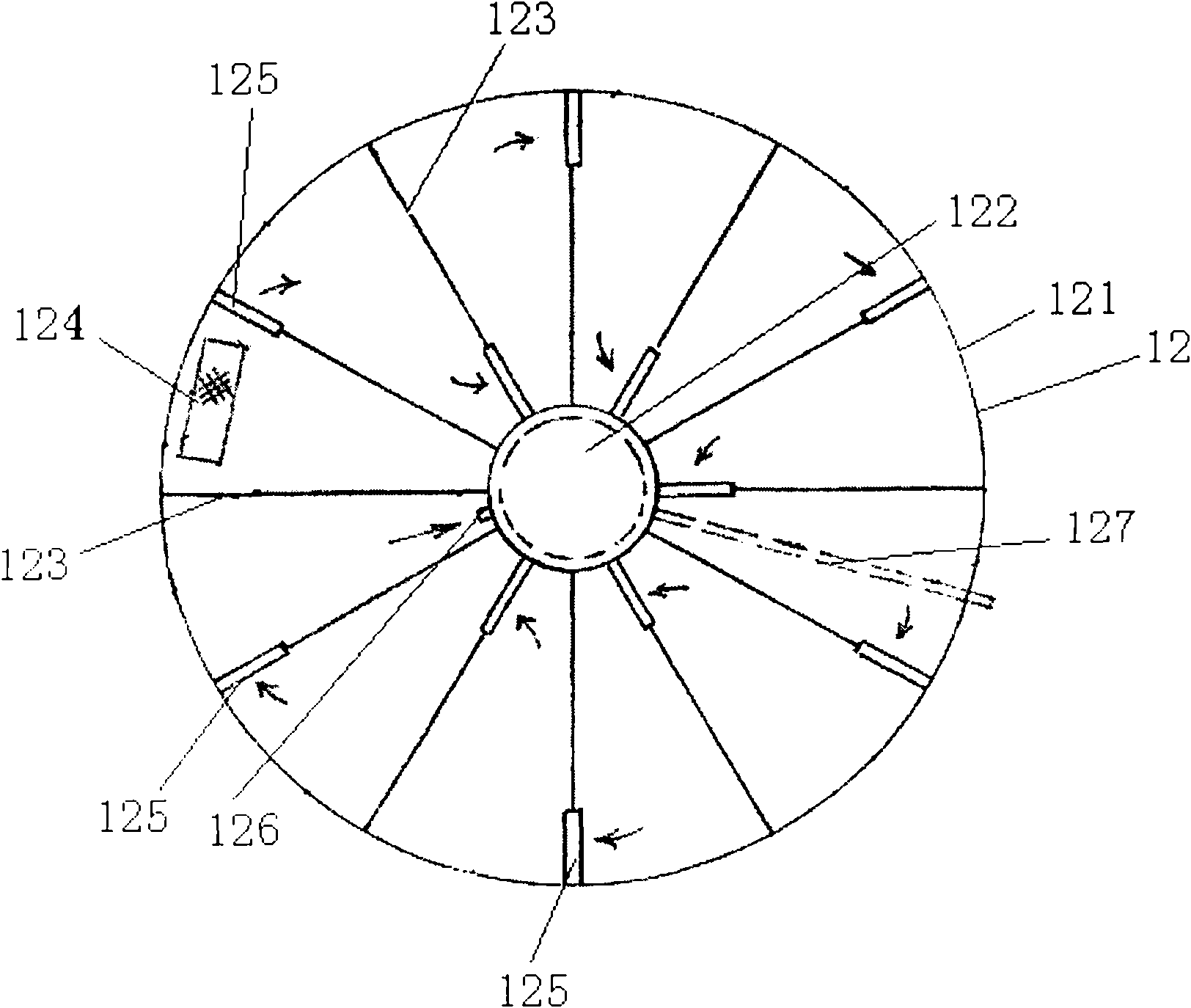

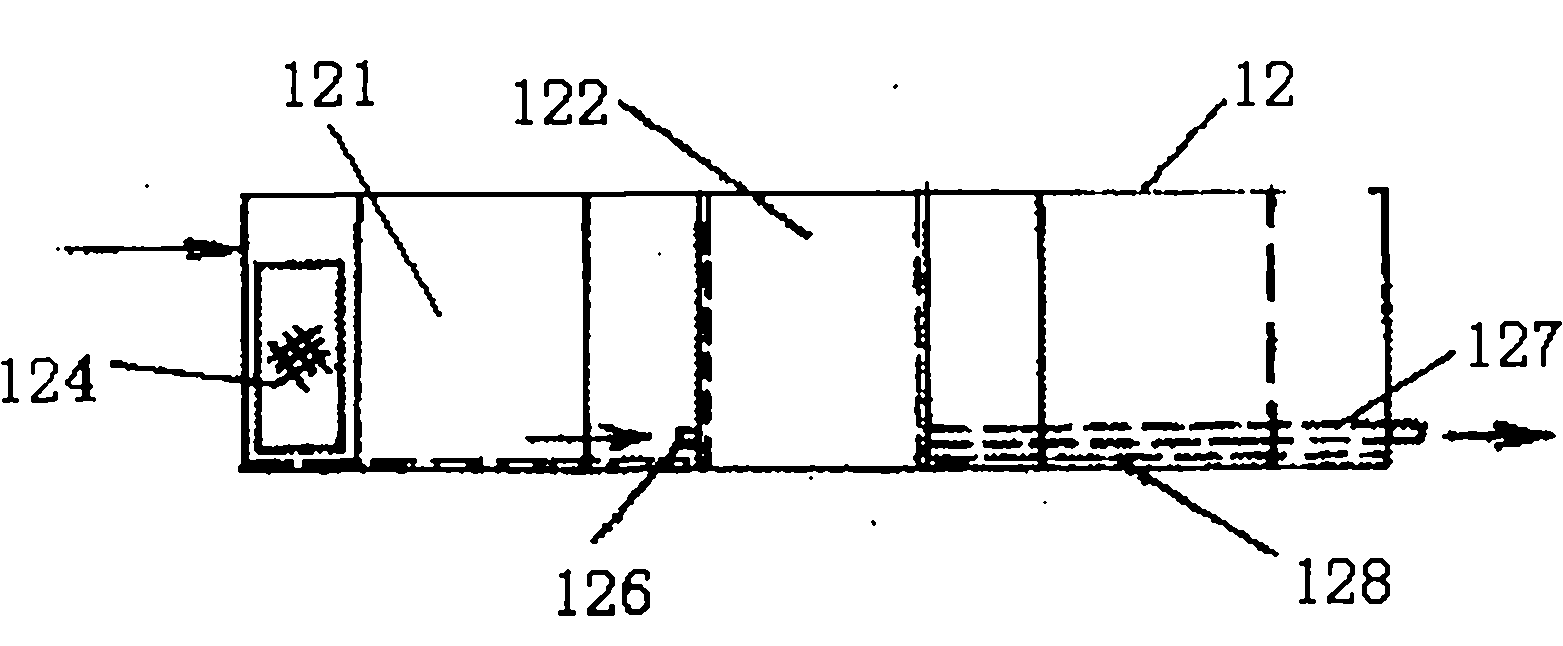

[0017] Such as figure 1 As shown, the device of the present invention includes a biogas slurry tank 1 for collecting biogas slurry, and a biogas slurry pipe 2 is arranged in the biogas slurry tank 1. The end of the biogas slurry pipe 2 is connected to a sewage pump 3, and the output end of the sewage pump 3 is connected to a Pressure pipe 4, the end of pressure pipe 4 is connected with a nozzle 5 located above the high water tower, below the nozzle 5 is the tower box 6 of the high water tower, a water outlet 7 is provided at the bottom of the tower box 6, and a vacuum overflow Flow weir 8, the lower end of the inclined plane of vacuum overflow weir 8 stirs upwards, forms a pick nose ridge 9. A waterwheel 10 is arranged behind the vacuum overflow weir 8 corresponding to the water falling position of the pick nose ridge 9, and a water diversion channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com