Anti-coking anti-carburizing cracking furnace tube and manufacturing method thereof

A technology of cracking furnace tube and manufacturing method, applied in cracking, non-catalytic thermal cracking, petroleum industry and other directions, can solve the problems of high cost, many steps, complicated coating preparation process, etc., and achieve the effect of reducing deposition and achieving remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

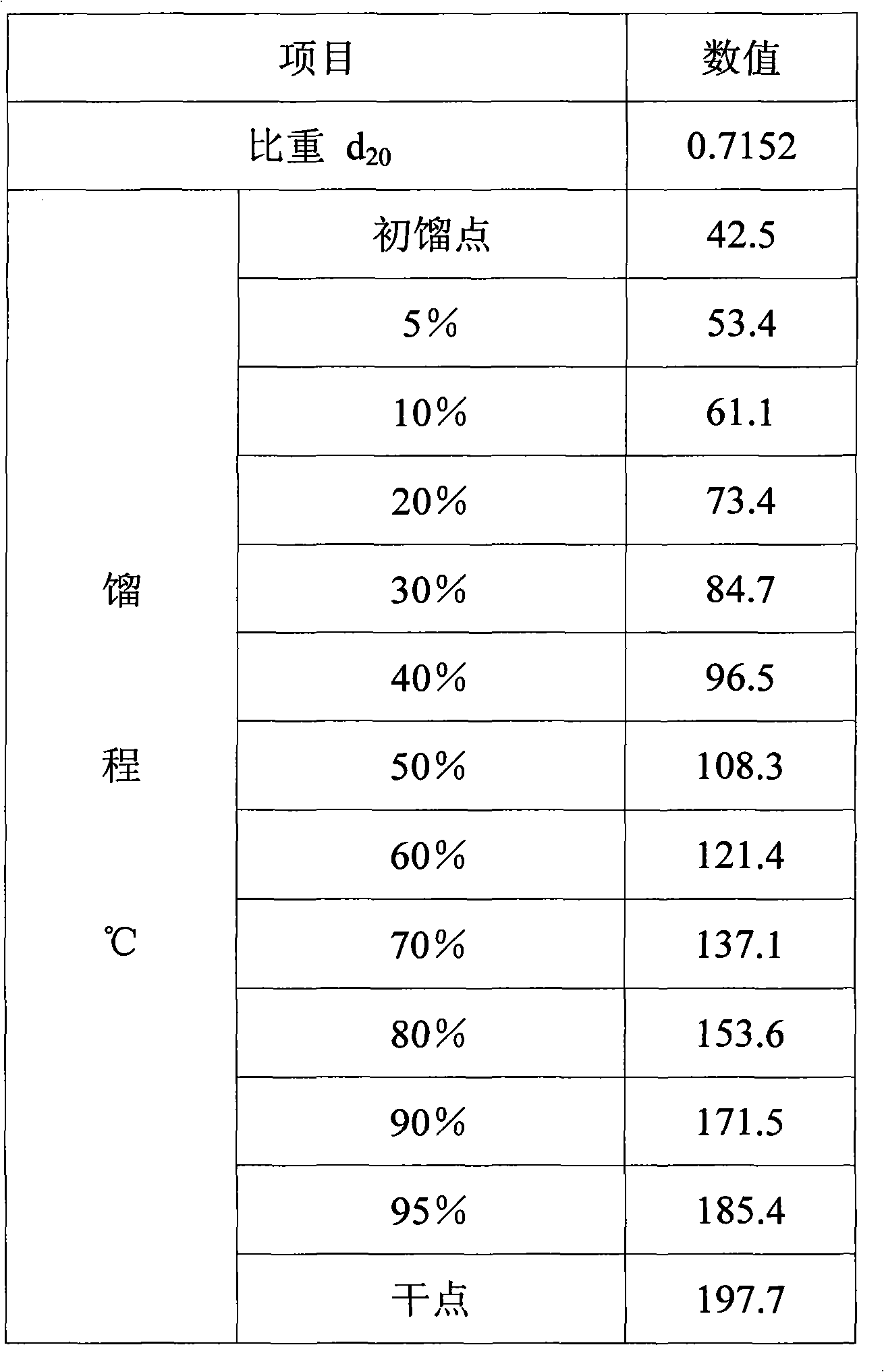

[0049] In the smelting process of HK-40 nickel-chromium alloy, 1.0% of rare earth metal elemental lanthanum is added to the total weight of the alloy, and it is made by centrifugal casting method After machining, the inner surface of the furnace tube is bright and free of scale, and the oxygen content is 3.09%. The surface composition of the furnace tube is analyzed by X-ray energy dispersive spectrometer (Energy Dispersive Spectrometer, referred to as EDS). The results are shown in Table 1.

[0050] use this The furnace tube was treated in a low oxygen partial pressure atmosphere on a self-made laboratory device with a feed rate of 200g / h. Use H 2 and H 2 A gas mixture of O is used as a low oxygen partial pressure atmosphere treatment gas, where H 2 O accounts for H 2 and H 2 The volume percentage of the O gas mixture is 2.0%, and the specific treatment conditions are as follows:

[0051] Furnace tube size:

[0052] Oxidation temperature: 900°C

[0053] Oxidation ...

Embodiment 2

[0072] In the smelting process of HP-40 nickel-chromium alloy, 0.5% of rare earth metal elemental yttrium is added to the total weight percentage of the alloy, and it is made by centrifugal casting method After machining, the inner surface of the furnace tube is bright, free of scale, and the oxygen content is 0.15%. The surface composition of the furnace tube is analyzed by X-ray energy dispersive spectrometer (Energy Dispersive Spectrometer, referred to as EDS). The results are shown in Table 3.

[0073] use this The furnace tube was treated in a low oxygen partial pressure atmosphere on a self-made laboratory device with a feed rate of 200g / h. Using CO and H 2 A gas mixture of O is used as a low oxygen partial pressure atmosphere treatment gas, where H 2 O accounts for CO and H 2 The volume percent of the O gas mixture is 8.0%, and the specific treatment conditions are as follows:

[0074] Furnace tube size:

[0075] Oxidation temperature: 950°C

[0076] Oxidation...

Embodiment 3

[0087] In the smelting process of 35Cr45Ni nickel-chromium alloy (referred to as 3545 nickel-chromium alloy steel), 0.8% of rare earth metal elemental yttrium and 0.5% of rare earth metal elemental lanthanum are added to the total weight percentage of the alloy, and it is made by centrifugal casting method After mechanical processing, the inner surface of the furnace tube is bright, free of scale, and the oxygen content is zero. The surface composition of the furnace tube is analyzed by X-ray energy dispersive spectrometer (Energy Dispersive Spectrometer, referred to as EDS). The results are shown in Table 4.

[0088] use this The furnace tube was treated in a low oxygen partial pressure atmosphere on a self-made laboratory device with a feed rate of 200g / h. Using CO 2 The gas mixture with CO is used as a low oxygen partial pressure atmosphere to treat the gas, and the specific treatment conditions are as follows:

[0089] Furnace tube size:

[0090] Oxidation temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com