Patents

Literature

36 results about "Hildebrand solubility parameter" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

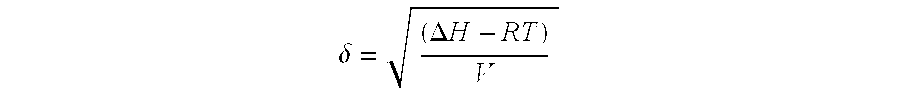

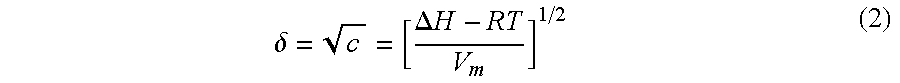

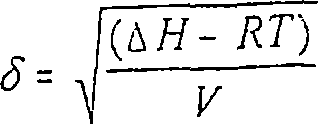

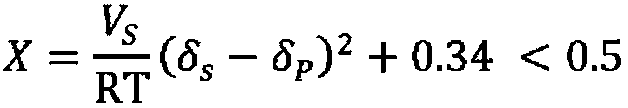

The Hildebrand solubility parameter (δ) provides a numerical estimate of the degree of interaction between materials and can be a good indication of solubility, particularly for nonpolar materials such as many polymers. Materials with similar values of δ are likely to be miscible.

Solvent inkjet ink receptive films

InactiveUS6589636B2Decorative surface effectsDuplicating/marking methodsPolymer scienceSolvent based

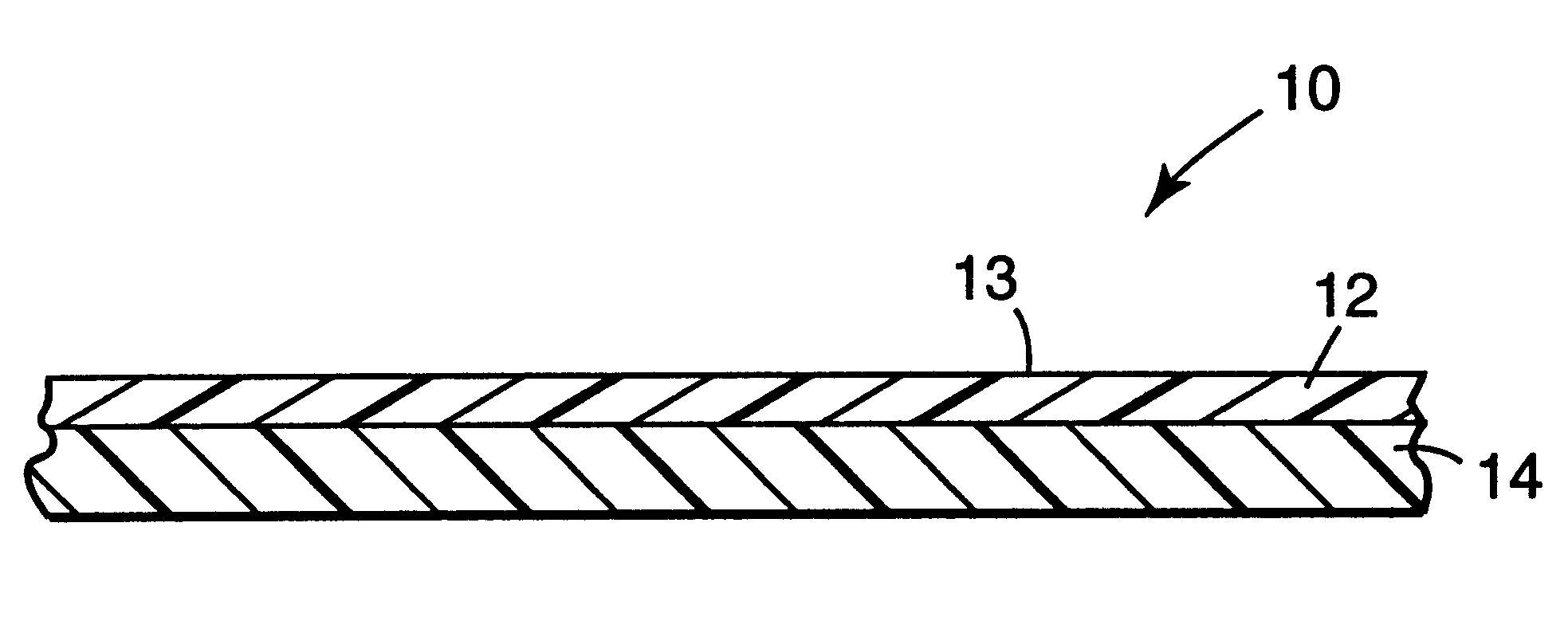

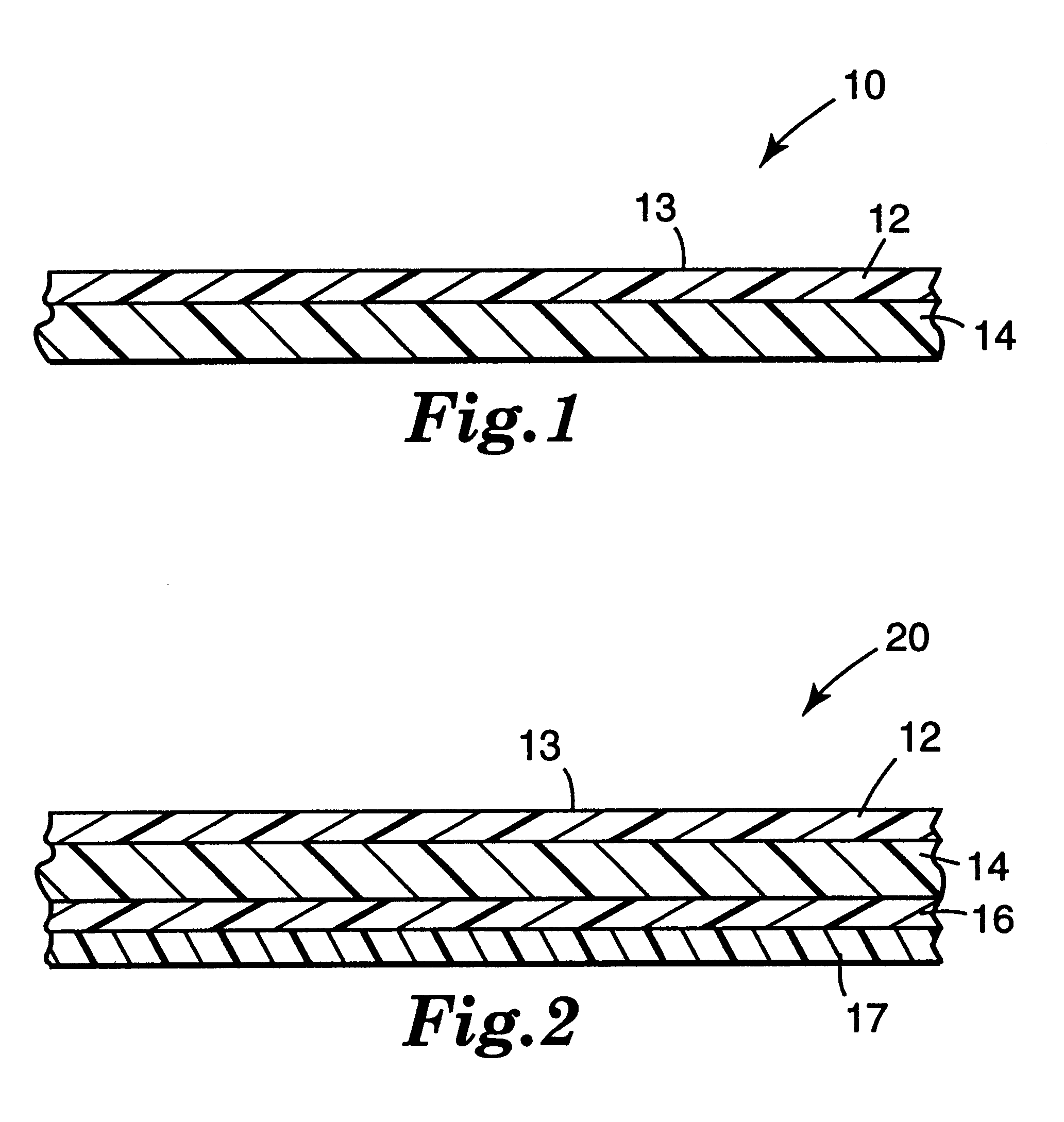

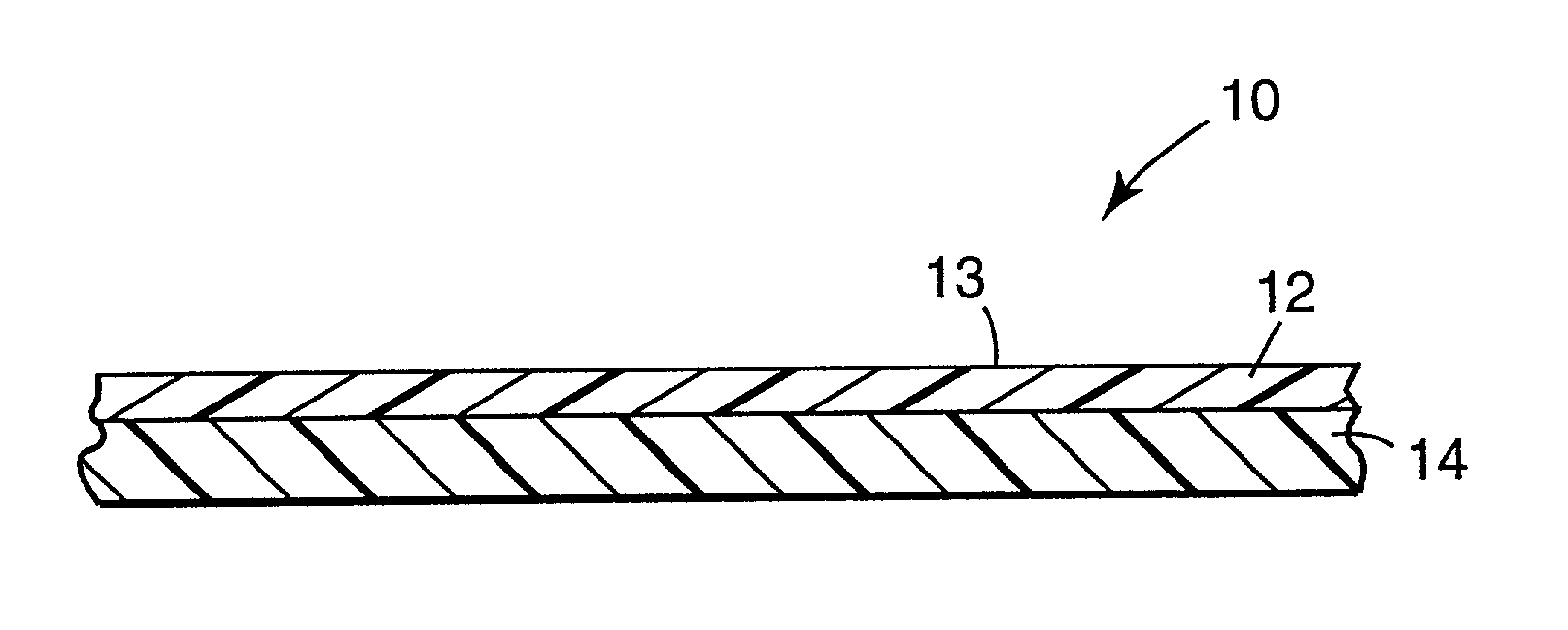

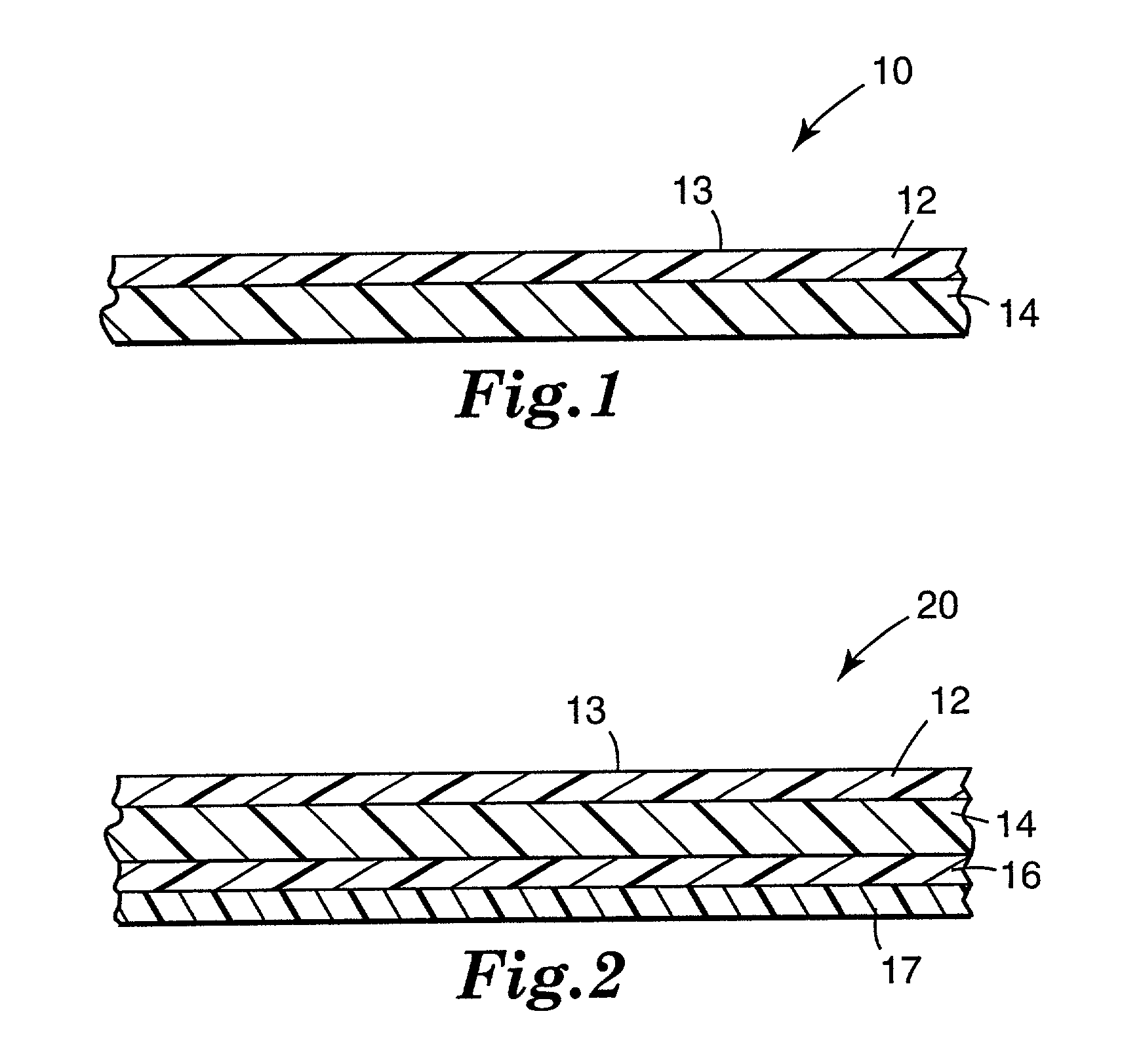

In one aspect, the invention provides an image receptor medium which comprises an extruded image receptive layer that is receptive to solvent-based inkjet ink. Image receptive layers of the invention comprise a blend of an ink absorptive resin and a carrier resin. The ink absorptive resin is compatible with the carrier resin and had a Hildebrand Solubility Parameter within about 3.1 (MPa)1 / 2 of that of the solvent of the ink. In another aspect, the invention provides an image receptor medium which comprises a coextruded or extrusion coated image receptive layer and a core layer bonded together. In other aspects, the invention provides methods of printing images and methods of making an extrusion coated or coextruded image receptor medium.

Owner:3M INNOVATIVE PROPERTIES CO

Biologically-active adhesive articles and methods of manufacture

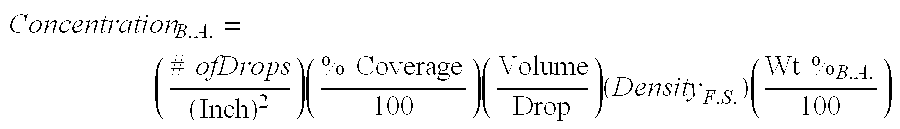

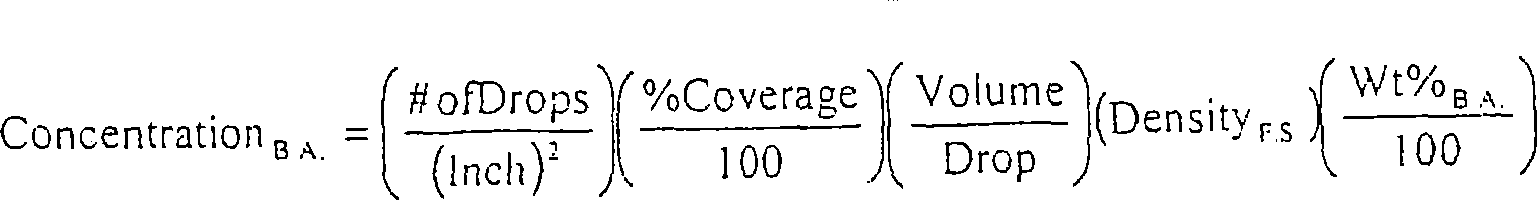

The present invention is a method of coating an adhesive layer. The method includes non-contact depositing a fluid solution onto the adhesive layer and allowing the fluid solution to substantially dry, where the fluid solution comprising a biological active. The fluid solution exhibits a Hildebrand solubility parameter of at least about 3.7 MegaPascals1 / 2 greater than a Hildebrand solubility parameter of the adhesive layer.

Owner:3M INNOVATIVE PROPERTIES CO

Solvent inkjet ink receptive films

InactiveUS20030107635A1Decorative surface effectsDuplicating/marking methodsSolvent basedPolymer chemistry

In one aspect, the invention provides an image receptor medium which comprises an extruded image receptive layer that is receptive to solvent-based inkjet ink. Image receptive layers of the invention comprise a blend of an ink absorptive resin and a carrier resin. The ink absorptive resin is compatible with the carrier resin and had a Hildebrand Solubility Parameter within about 3.1 (MPa)½ of that of the solvent of the ink. In another aspect, the invention provides an image receptor medium which comprises a coextruded or extrusion coated image receptive layer and a core layer bonded together. In other aspects, the invention provides methods of printing images and methods of making an extrusion coated or coextruded image receptor medium.

Owner:3M INNOVATIVE PROPERTIES CO

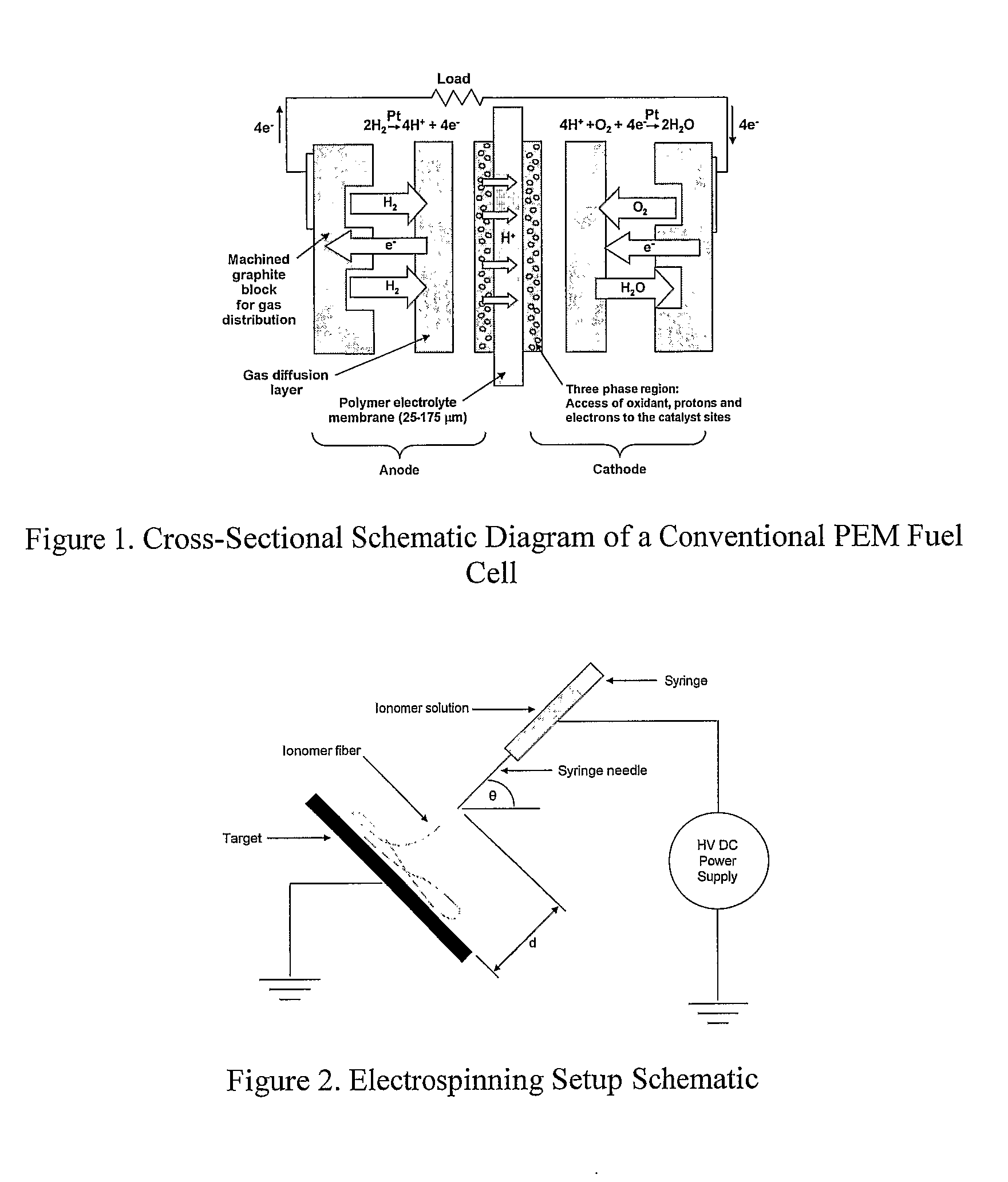

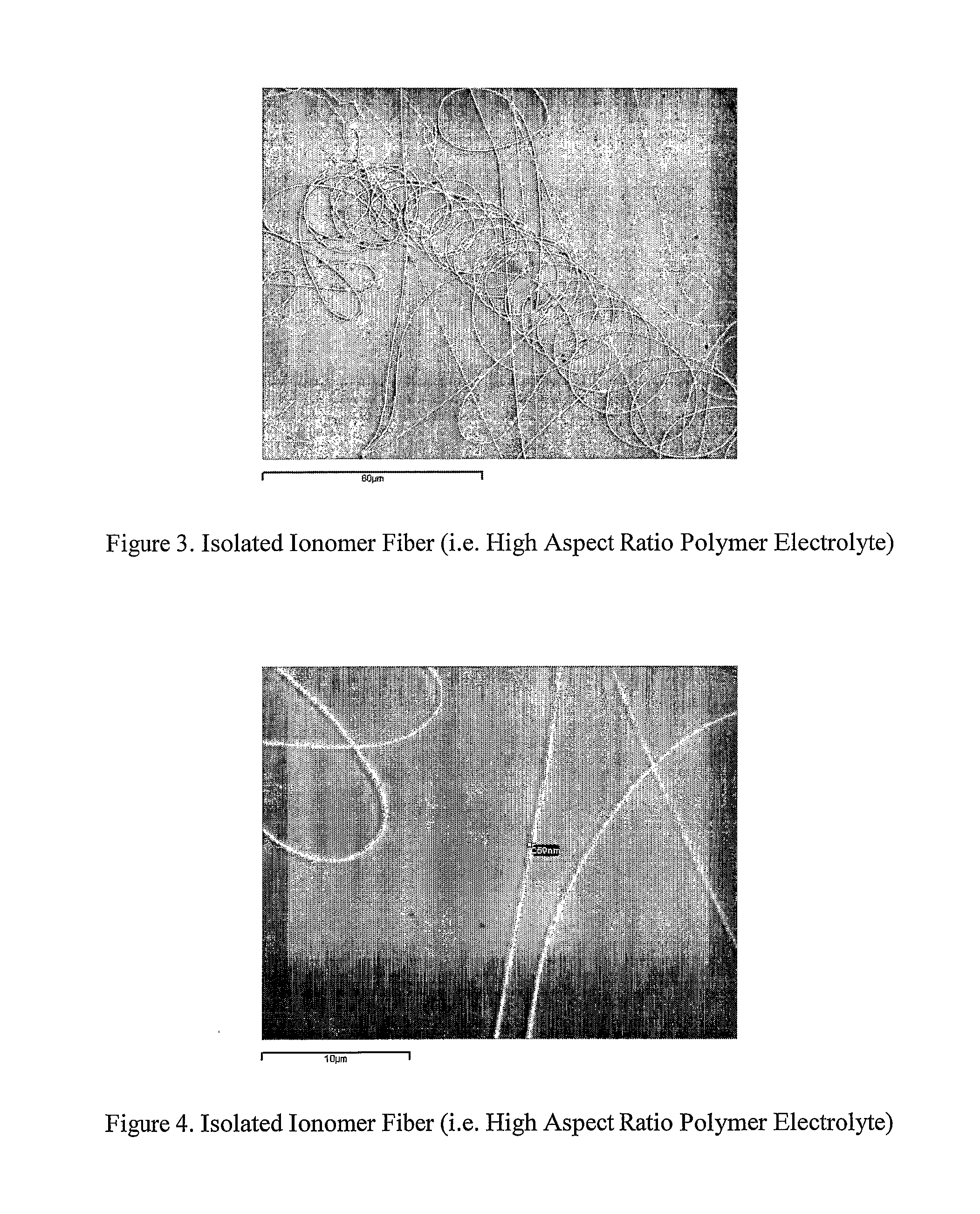

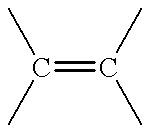

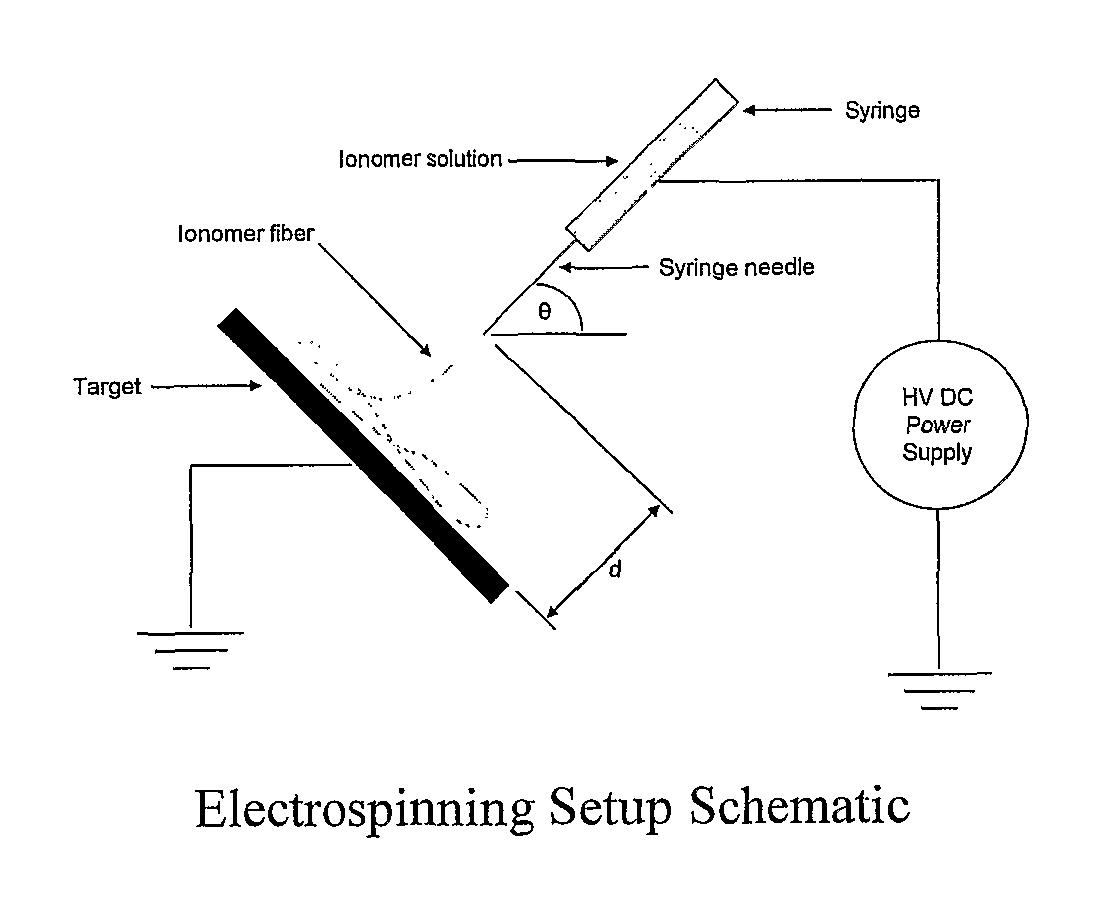

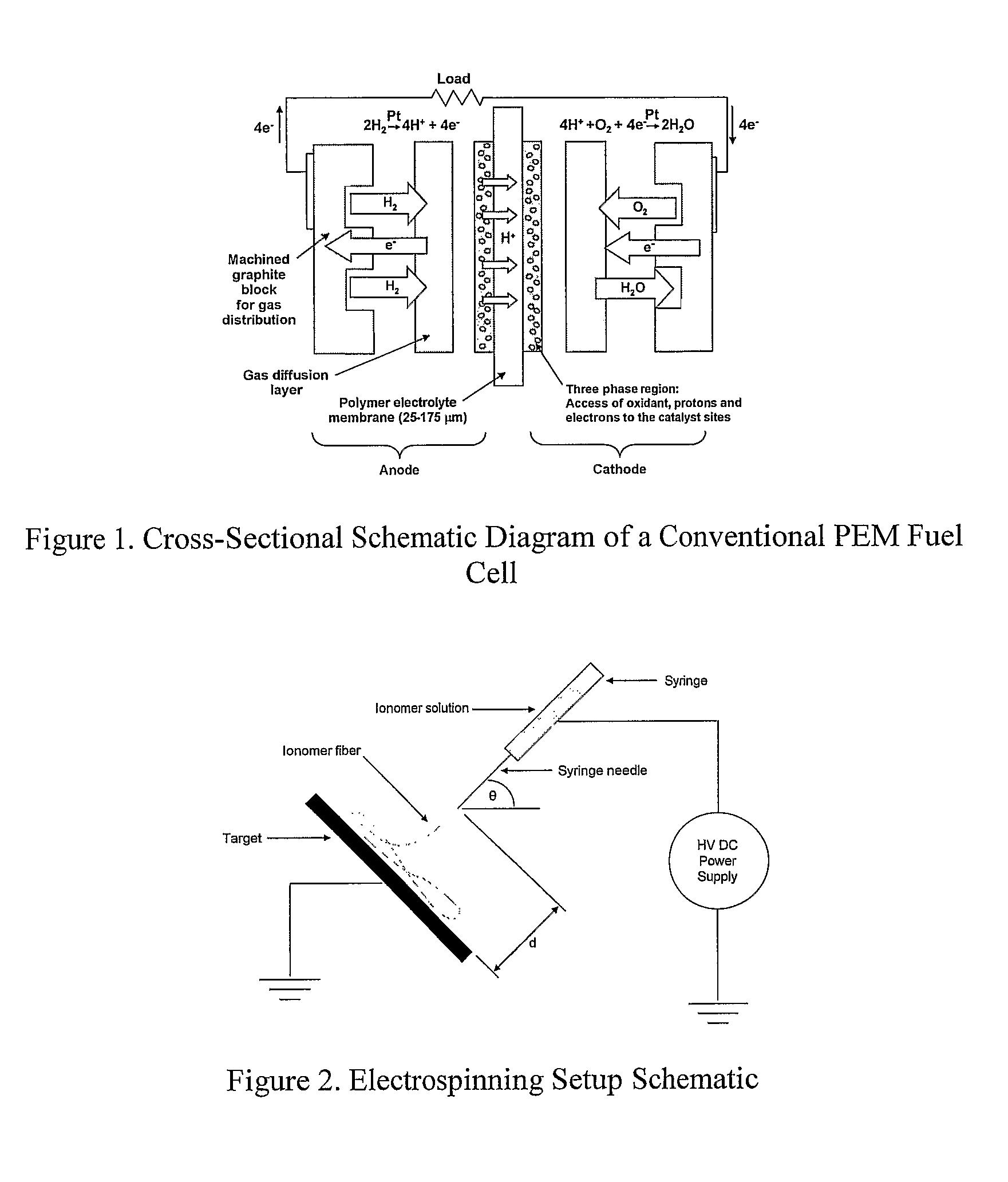

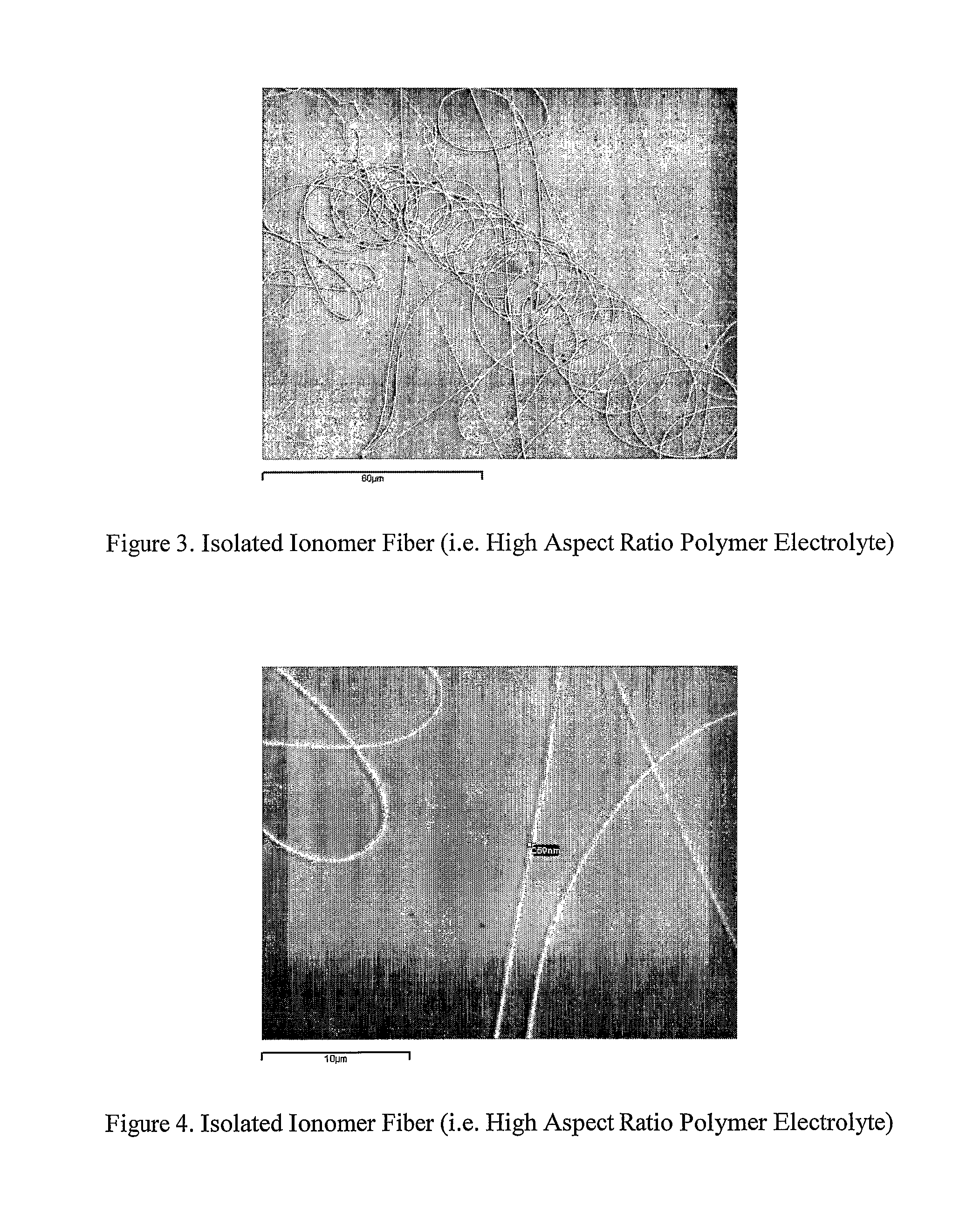

Solution Based Enhancements of Fuel Cell Components and Other Electrochemical Systems and Devices

ActiveUS20080248362A1Improve propertiesFinal product manufactureCell electrodesPolymer scienceFuel cells

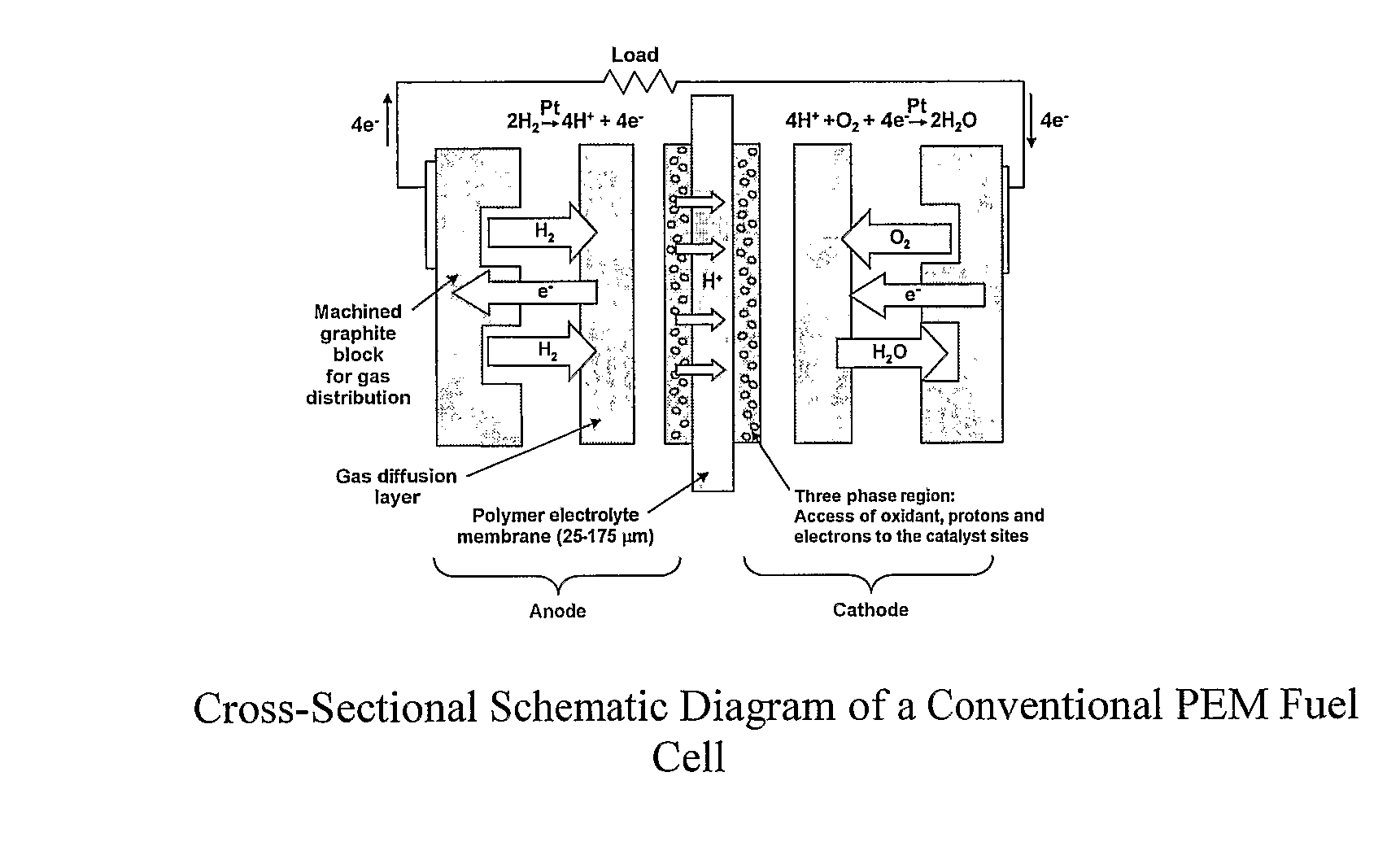

This invention relates in general to components of electrochemical devices, and to methods of preparing the components. The components and methods include the use of a composition comprising an ionically conductive polymer and at least one solvent, where the polymer and the solvent are selected based on the thermodynamics of the combination. In one embodiment, the invention relates to a component for an electrochemical device which is prepared from a composition comprising a true solution of an ionically conductive polymer and at least one solvent, the polymer and the at least one solvent being selected such that |δ solvent−δ solute|<1, where δ solvent is the Hildebrand solubility parameter of the at least one solvent and where δ solute is the Hildebrand solubility parameter of the polymer. In another embodiment, the invention relates to a method of improving at least one property of a component for an electrochemical device or at least one property of the electrochemical device, the method comprising preparing the component from a composition comprising a true solution of an ionically conductive polymer and at least one solvent, the polymer and the at least one solvent being selected such that |δ solvent−δ solute|<1, where δ solvent is the Hildebrand solubility parameter of the at least one solvent and where δ solute is the Hildebrand solubility parameter of the polymer.

Owner:BATTELLE MEMORIAL INST

Thermosettable pressure sensitive adhesive

InactiveUS20020007910A1Improve adhesionImprove mechanical propertiesLayered productsPhotomechanical apparatusEpoxyPhotoinitiator

The invention refers to a photopolymerizable precursor of a pressure-sensitive thermosettable adhesive, said precursor comprising: (i) from about 30% to about 80% by weight with respect to the mass of the precursor of a photopolymerizable component, comprising a monomeric or prepolymeric syrup, said component exhibiting an overall solubility parameter of between 10 and 11 and comprising (A) at least 30% by weight with respect to the mass of the photopolymerizable component (i) of one or more ethylenically unsaturated monomers with a solubility parameter of between 10 and 11.5 and less than 10% by weight with respect to the mass of component (i) of one or more ethylenically unsaturated compounds with a solubility parameter of more than 11.5, or (B) at least 50% by weight with respect to the mass of the photopolymerizable compound (i) of one or more ethylenically unsaturated monomers with a solubility parameter of between 9.5 and 11.5 and 10-30% by weight with respect to the mass of the photopolymerizable component (i) of one or more ethylenically unsaturated compounds with a solubility parameter of between 11.5 and 12.5 provided that in case (B) the precursor comprises between 3-15% by weight with respect to the mass of the precursor of one or more polymers with a solubility parameter of 10-12.5; (ii) from about 20 to about 70% by weight with respect to the mass of the precursor of one or more epoxy resins and / or monomers; (iii) an effective amount of a photoinitiator; and (iv) an effective amount of one or more nucleophilic latent hardeners for the epoxy resins and / or epoxy-containing monomers which are selected to provide an onset temperature of the epoxy curing reaction of between 40-100° C. when subjecting the adhesive to a DSC scan at a rate of 20° C. / min. The invention furthermore refers to thermosettable adhesives which are obtainable by photopolymerization of said precursor and to thermoset adhesives which are obtainable by thermal curing of said thermosettable adhesives. The thermosettable adhesive of the invention is particularly useful for bonding a plastic substrate to other substrates such as metal, glass, ceramic, wood and plastics.

Owner:MINNESOTA MINING & MANUACTURING

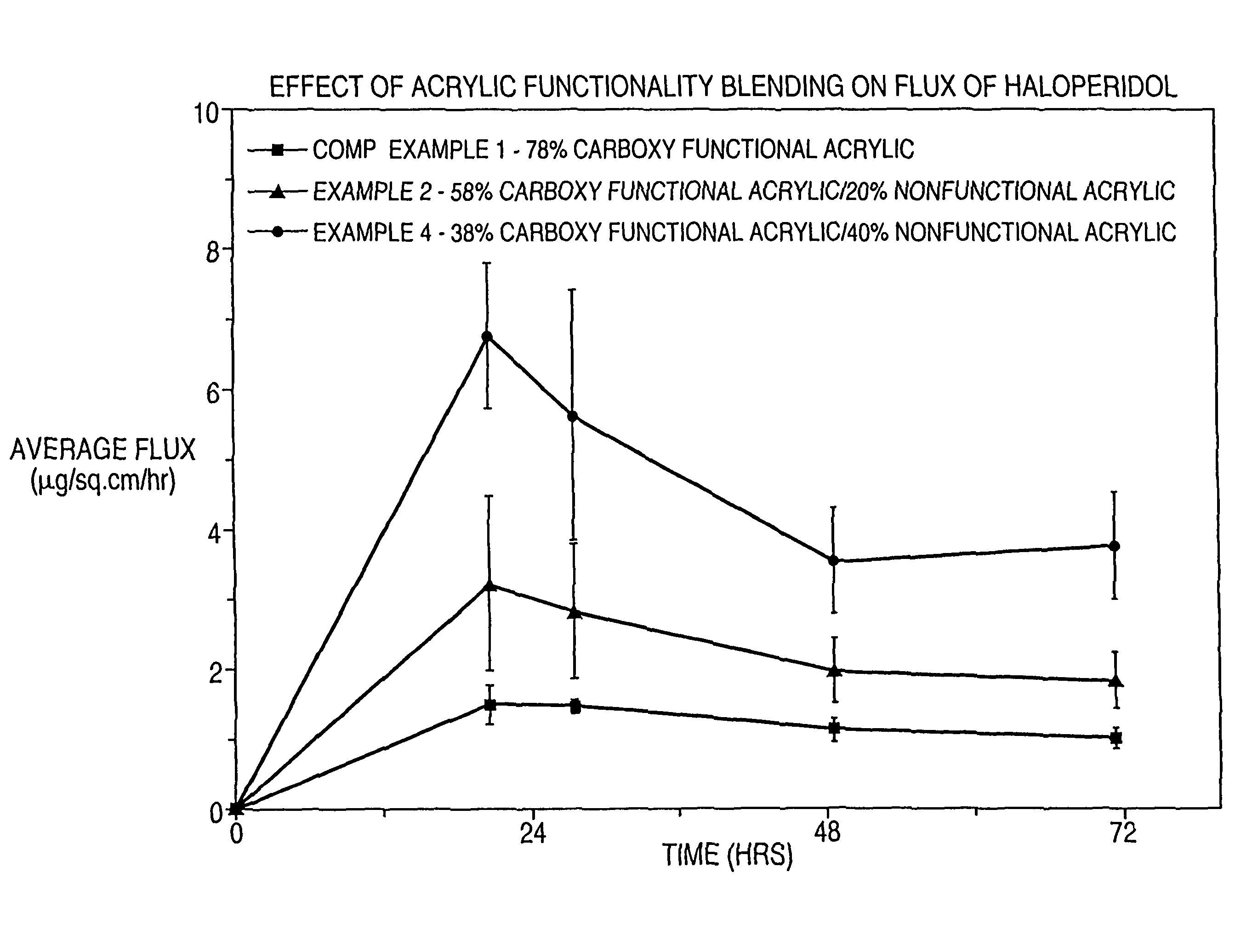

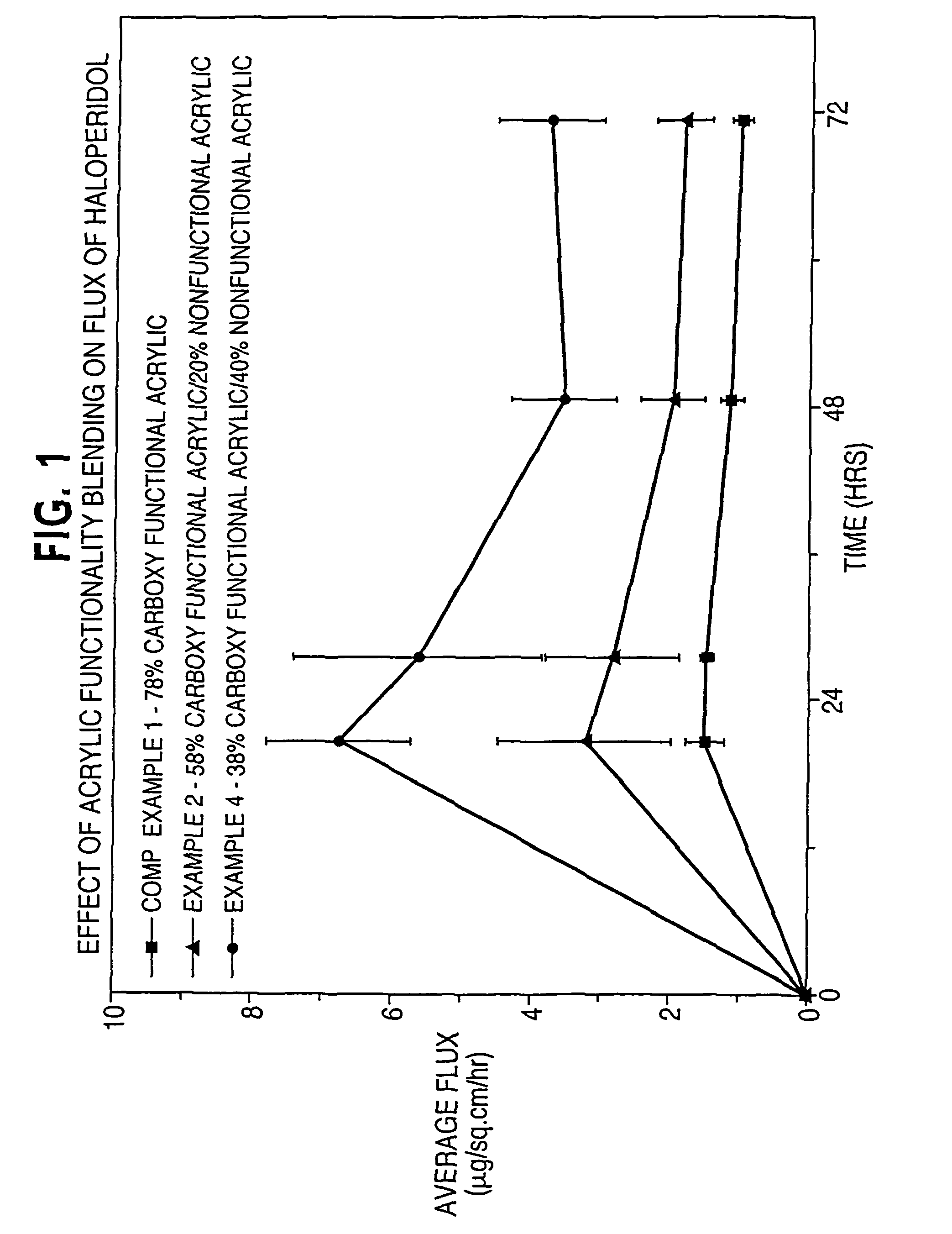

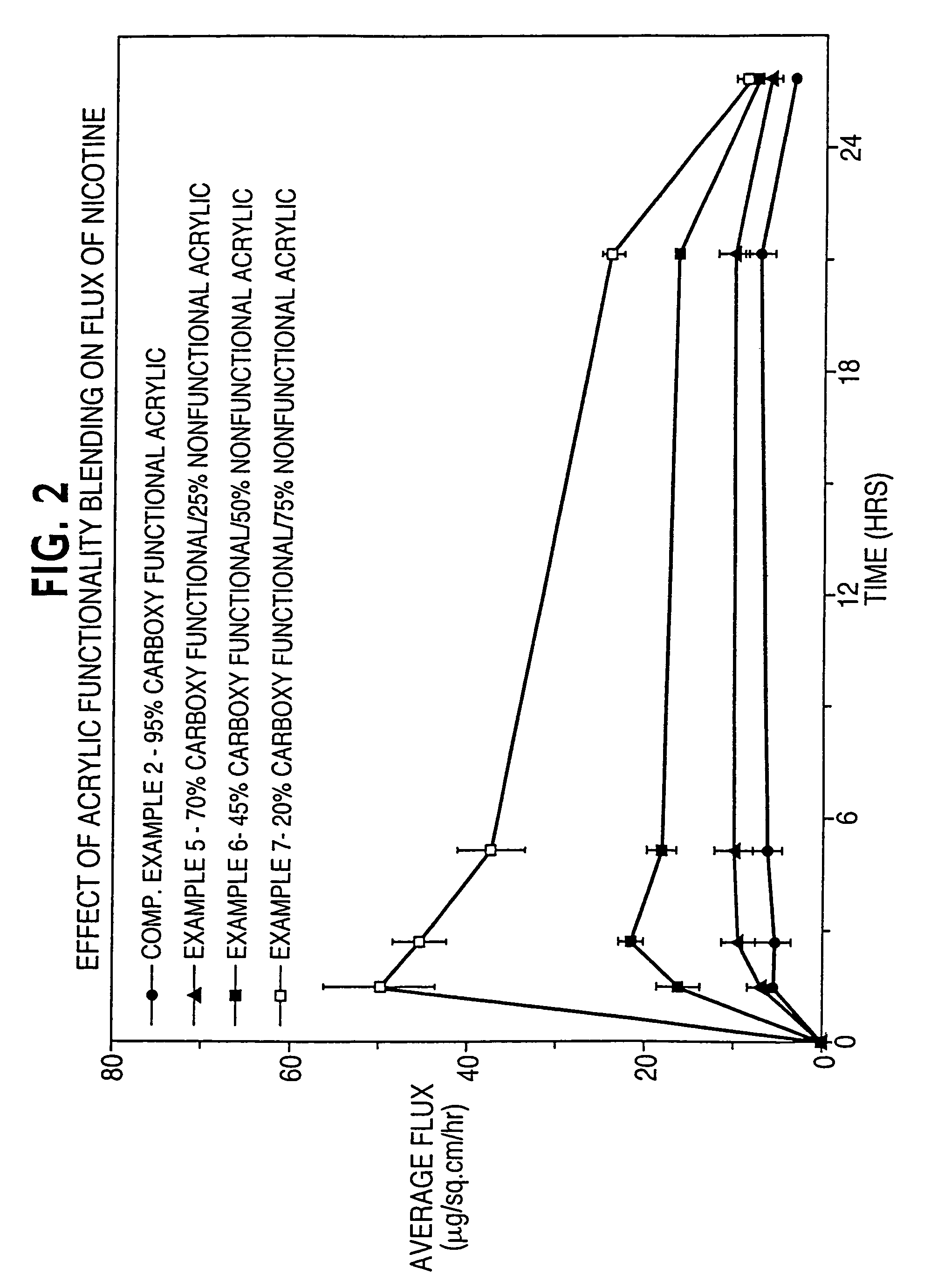

Dermal composition for controlling drug flux comprising two acrylic adhesive polymers having different functionalities and different solubility parameters

InactiveUS8187628B2Simple and inexpensiveDesirable in adhesiveCosmetic preparationsBiocideControlled drugsAmphetamine

A dermal composition for administration of an amphetamine drug comprising a blend of two or more acrylic-based polymers having differing functionalities so as to modulate the drug solubility in the polymer matrix and the delivery rate of the drug, and methods therefor.

Owner:NOVEN PHARMA

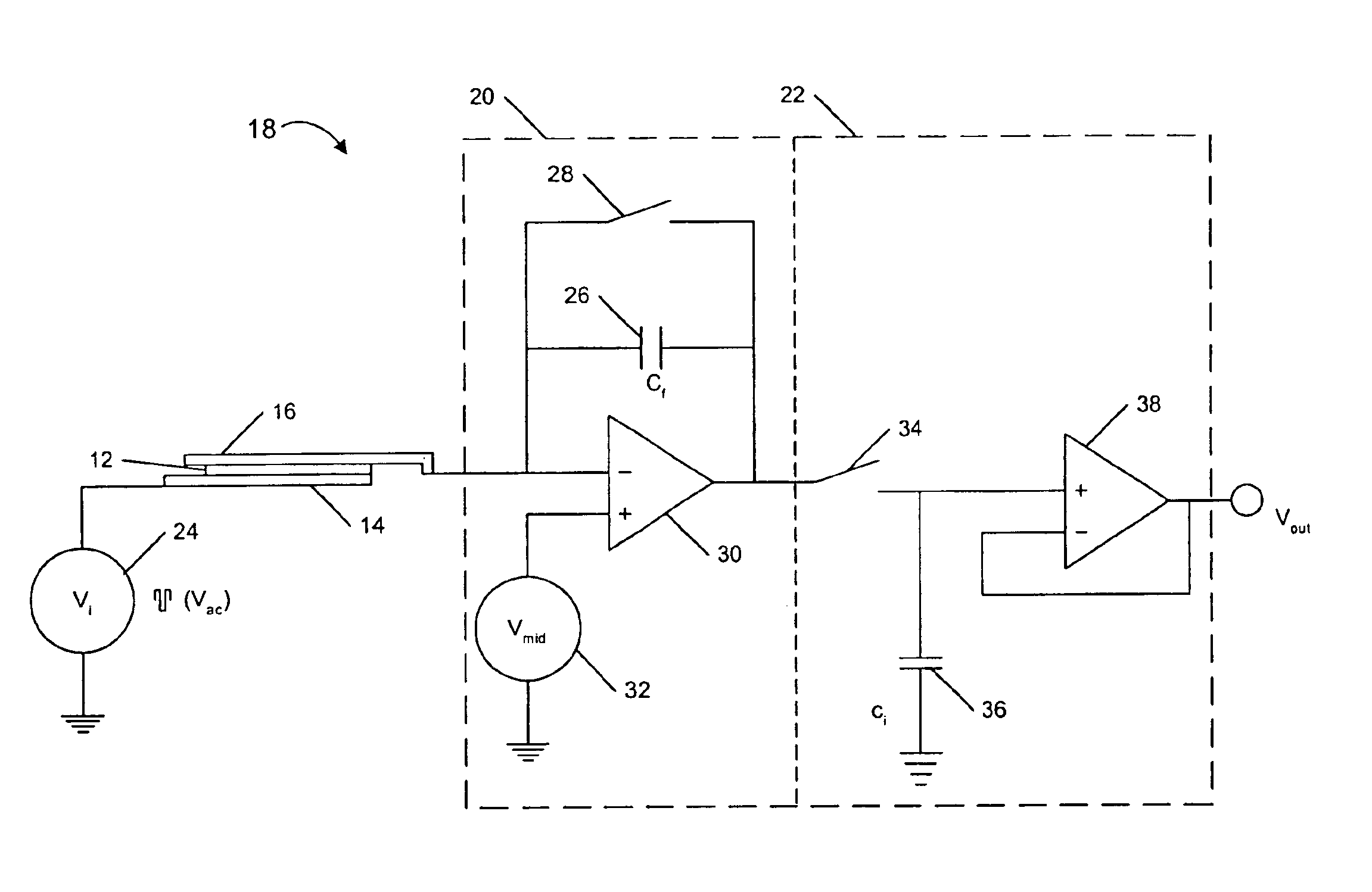

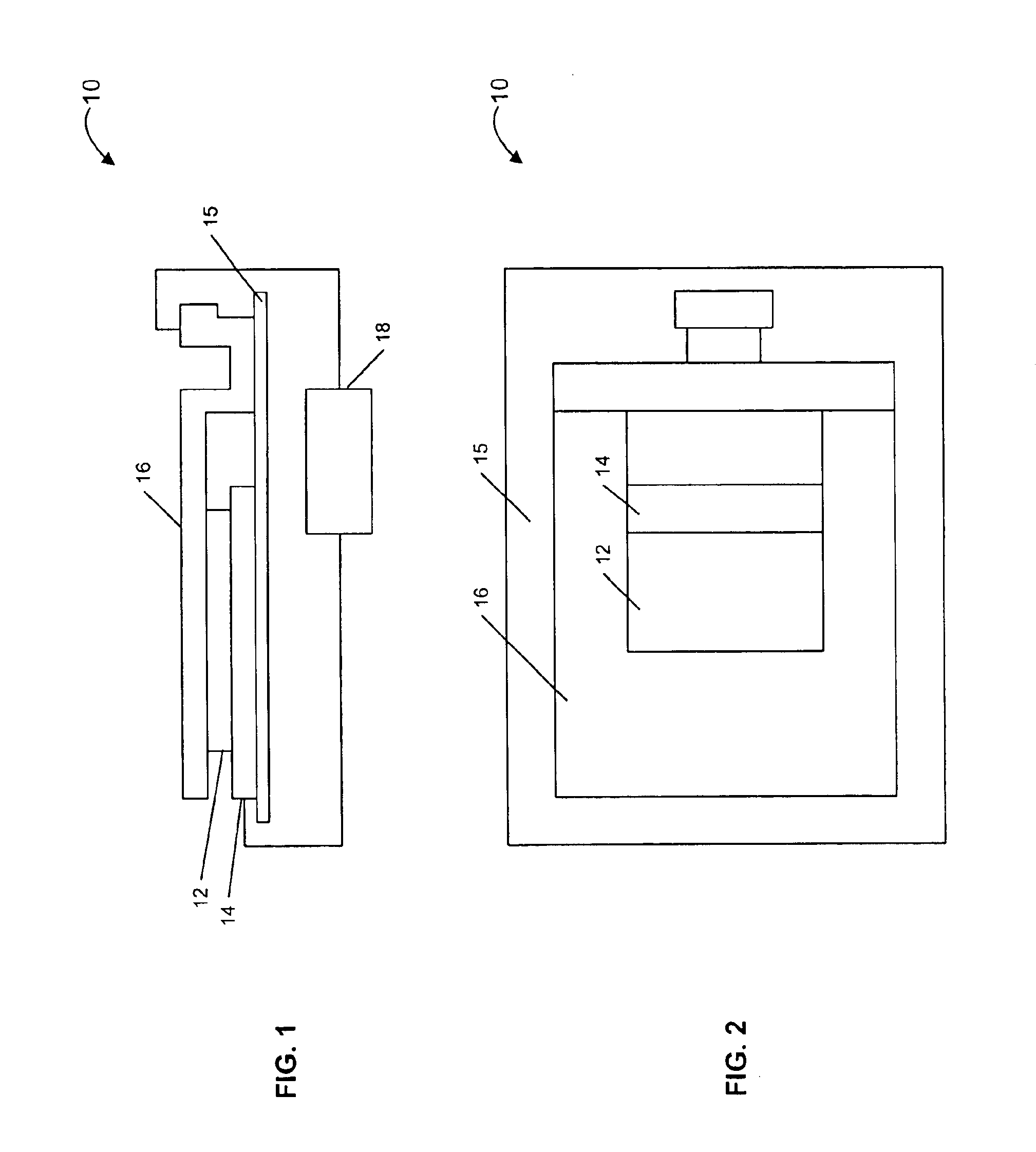

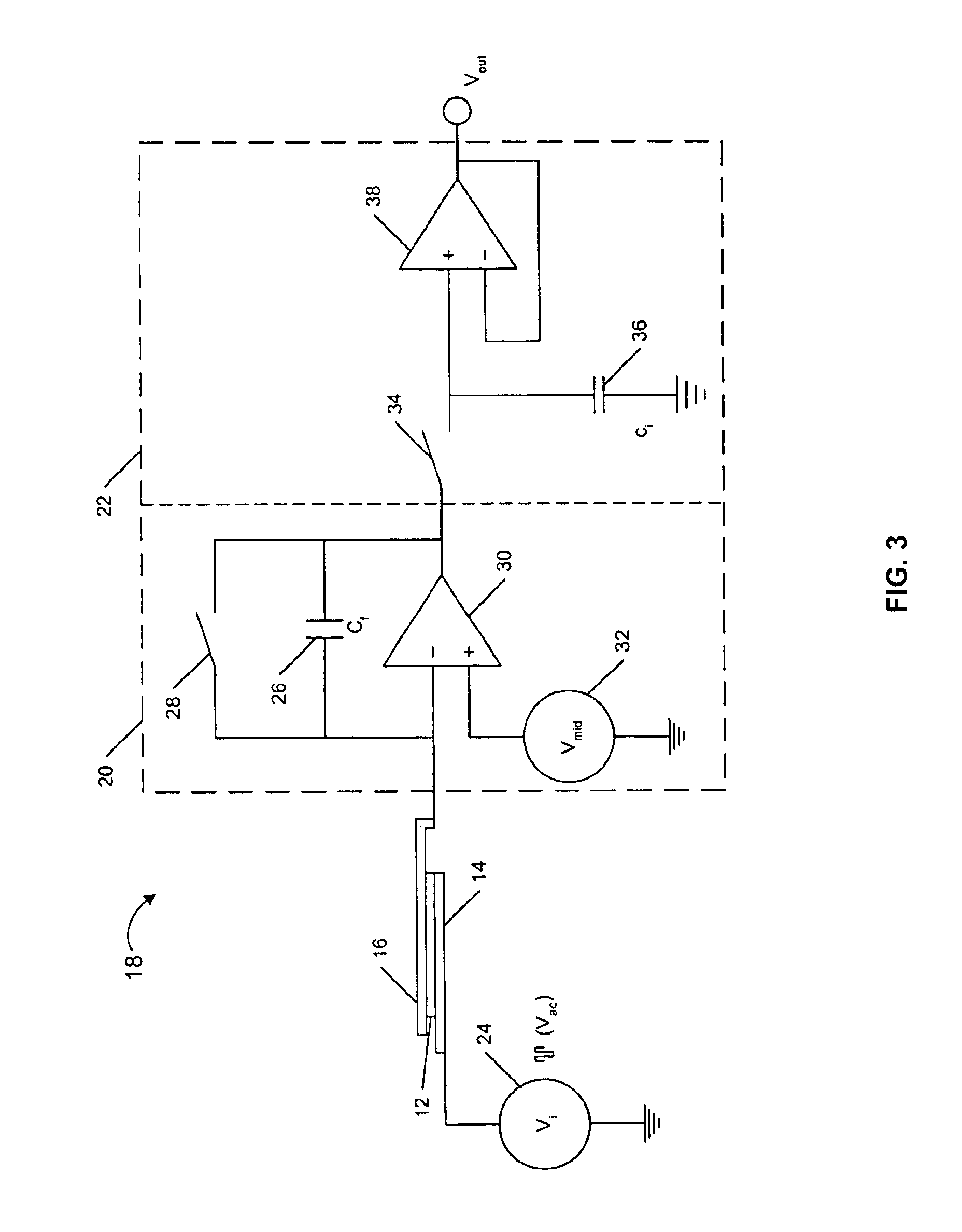

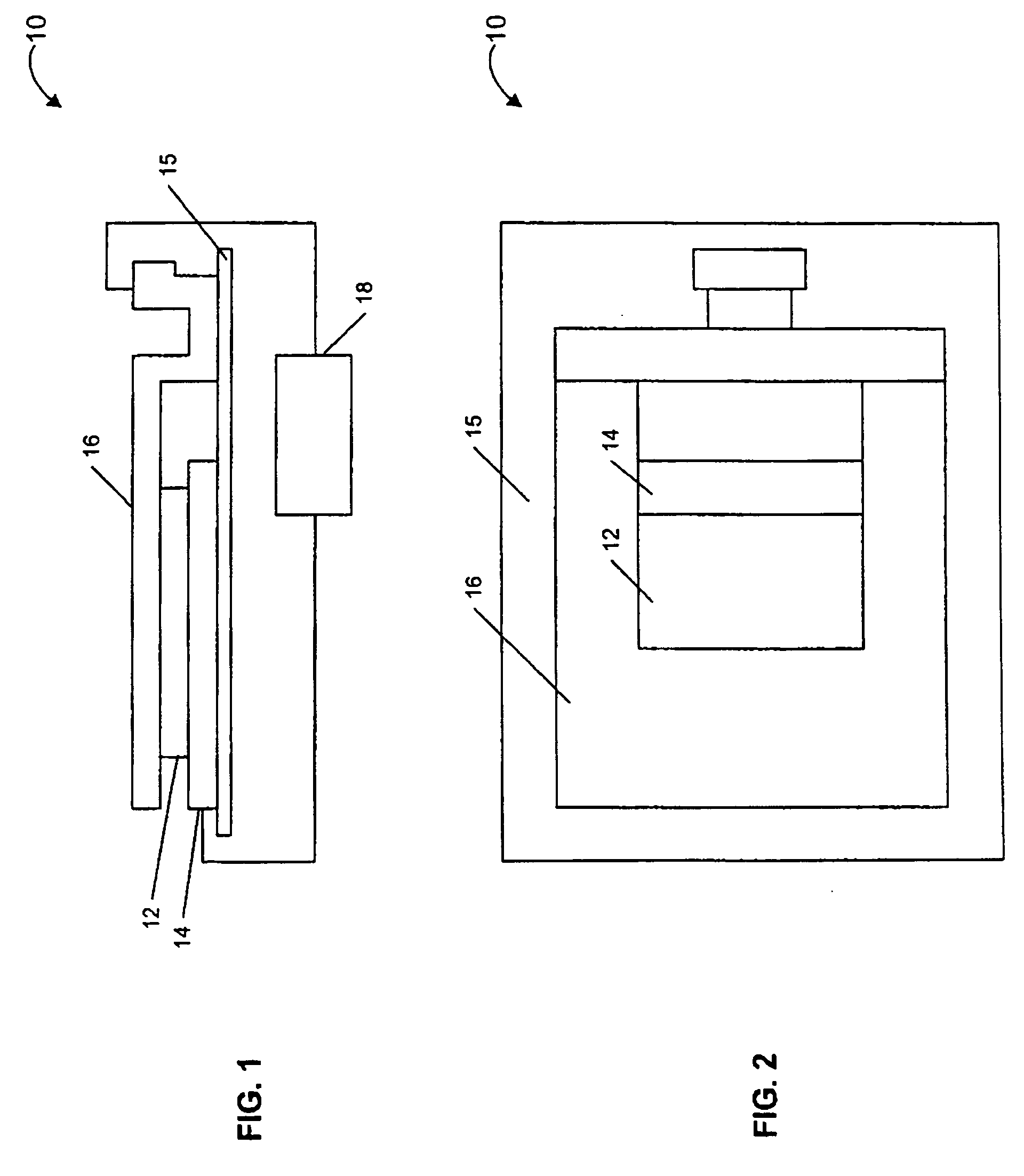

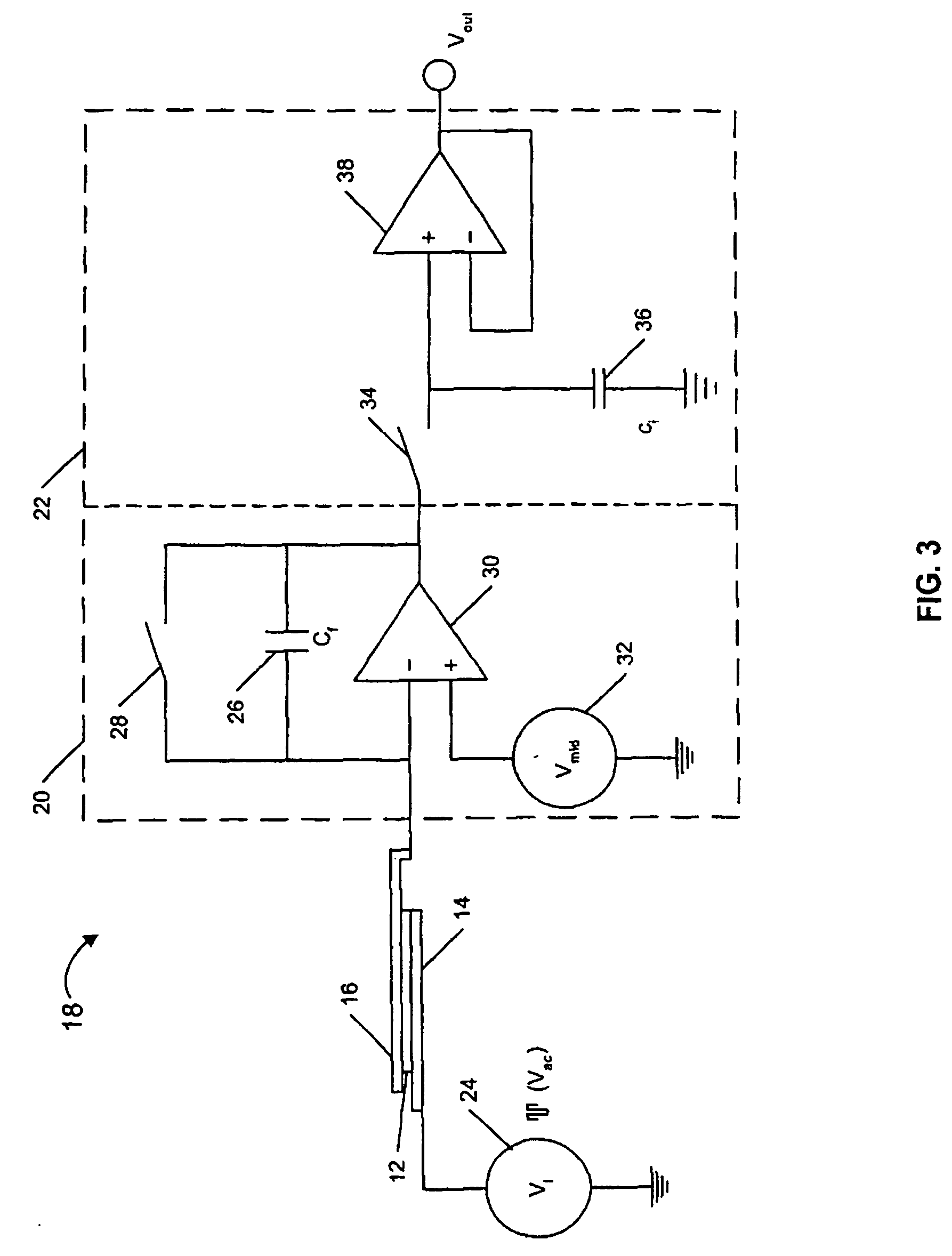

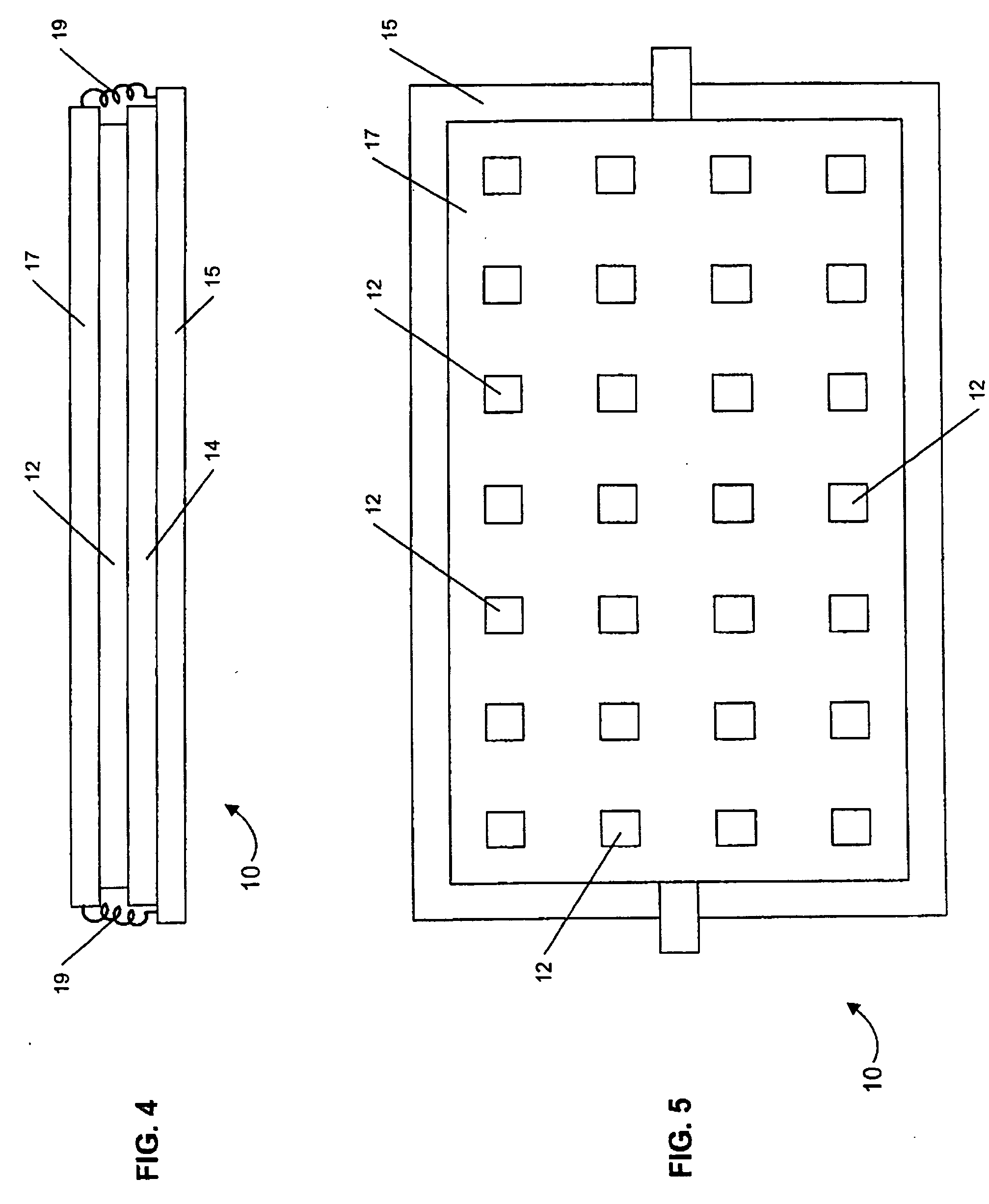

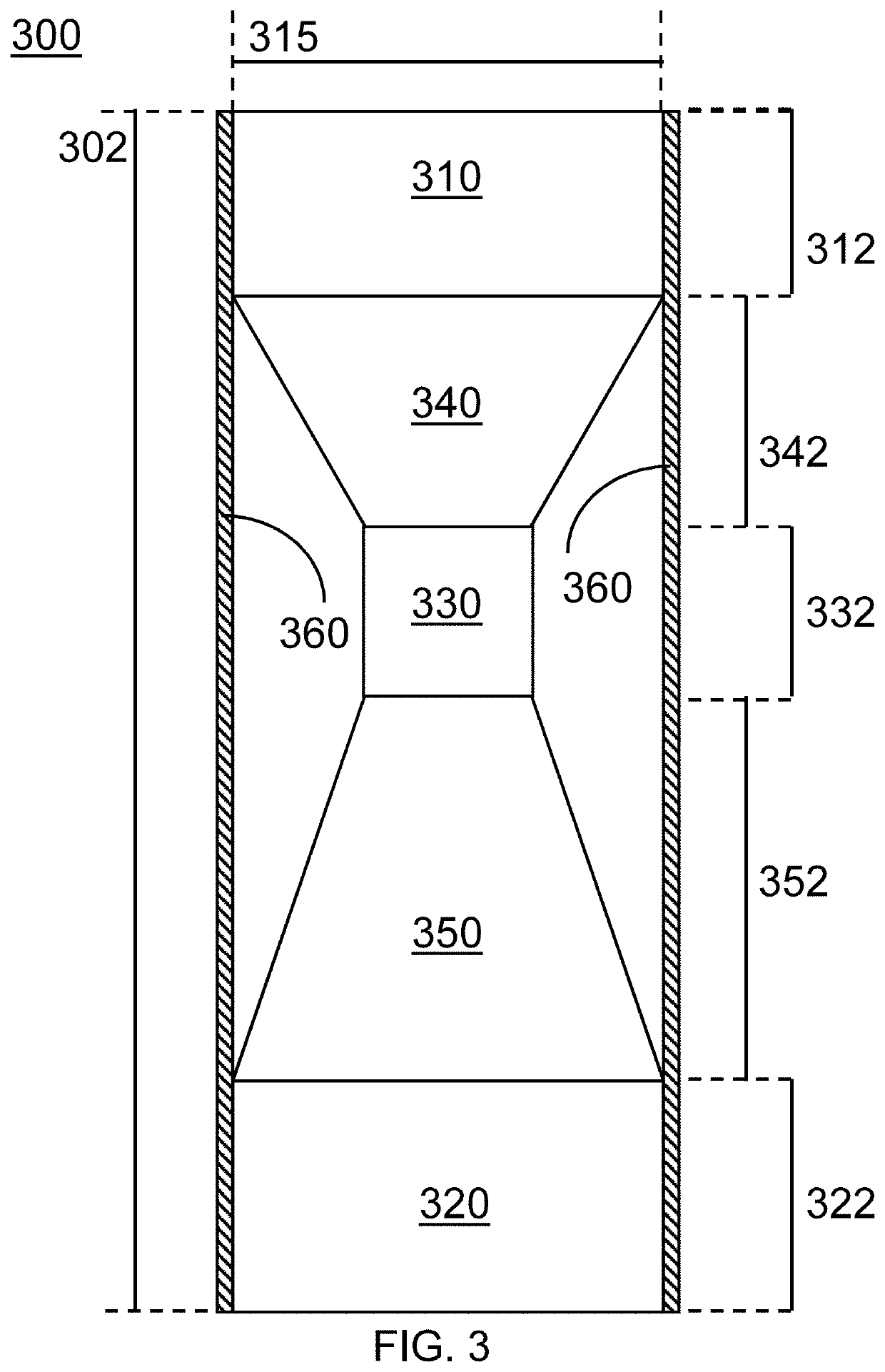

Sensor having improved selectivity

InactiveUS6864692B1High sensitivityAccurately determineMechanically variable capacitor detailsResistance/reactance/impedenceCapacitanceAnalyte

A sensor for determining the presence of an analyte is disclosed comprising a reactive layer disposed between a base plate and a movable plate. The reactive layer is configured to interact with an analyte effecting a change in capacitance between the base plate and movable plate. When the analyte has a polarity or overall Hildebrand solubility parameter that is similar to the reactive layer, the change in capacitance is caused by a swelling of the reactive layer as analyte is absorbed into the reactive layer. This results in a decrease in capacitance. When the analyte has a solubility parameter not near the reactive layer, the absorbed analyte causes the reactive layer's total polarity to increase, an effect that dominates swelling. This causes an increase in capacitance. A capacitive sensing circuit is included for measuring the change in capacitance which is indicative of the analyte exposed to the sensor.

Owner:KRATOS TECH & TRAINING SOLUTIONS

Compositions Useful For Tooth Whitening

The present invention provides tooth whitening compositions in the form of a liquid crystal or a microemulsion that includes a tooth whitening agent in an amount effective to whiten teeth, a hydrophilic phase including water, a hydrophobic phase including at least one oil, at least one anionic, nonionic, amphoteric or zwitterionic surfactant, and a water soluble co-solvent having a Hildebrand solubility parameter above 12 (cal / cm3)1 / 2, as well as methods for whitening teeth including applying the liquid crystal or microemulsion composition to the teeth for a period of time and under conditions effective to whiten the teeth.

Owner:MCNEIL PPC INC

Impermeable Capsules

InactiveUS20080292692A1High solubility parameterReduce free spaceDigestive systemOral carePolymer scienceWater soluble

A capsule comprising a core and a shell surrounding and enclosing the core, the shell comprising at least one first polymer having a first water solubility parameter, and at least one second polymer having a water solubility parameter higher than the first water solubility parameter, wherein the second polymer is crosslinked, and / or all of the at least one second polymer is present in an amount that is less than all of the at least one first polymer. Upon exposure to an aqueous medium, the first polymer begins to swell, and water begins to leak into the capsule. Also, the second polymer is attracted to the entering water. As the second polymer absorbs water and swells, the mean free space in the shell decreases and the tortuous pathway for materials crossing the boundary of the wall increases. As a result, leakage rates across the capsule wall decrease.

Owner:COLGATE PALMOLIVE CO

Heavy aromatic solvents for catalyst reactivation

ActiveUS20210155858A1Hydrotreatment operations starting-upCatalyst regeneration/reactivationAromatic solventPtru catalyst

Compositions and methods for restoring catalytic activity by dissolving soft coke with a solvent, one method including detecting soft coke deposition on a catalyst composition; preparing an aromatic bottoms composition with a Hildebrand solubility parameter of at least about 20 SI to remove the soft coke from the catalyst composition; and washing the catalyst composition with the aromatic bottoms composition until at least a portion of the soft coke deposition is removed.

Owner:SAUDI ARABIAN OIL CO

Sensor and sensor array having improved selectivity

InactiveUS20050164285A1High selectivityIncrease the gapBioreactor/fermenter combinationsBiological substance pretreatmentsSensor arrayCapacitance

A sensor for determining the presence of an analyte is disclosed comprising a reactive layer disposed between a base plate and a movable plate. The reactive layer is configured to interact with an analyte effecting a change in capacitance between the base plate and movable plate. When the analyte has a polarity or overall Hildebrand solubility parameter that is similar to the reactive layer, the change in capacitance is caused by a swelling of the reactive layer as analyte is absorbed into the reactive layer. This results in a decrease in capacitance. When the analyte has a solubility parameter not near the reactive layer, the absorbed analyte causes the reactive layer's total polarity to increase, an effect that dominates swelling. This causes an increase in capacitance. A capacitive sensing circuit is included for measuring the change in capacitance which is indicative of the analyte exposed to the sensor.

Owner:XSILOGY

Compositions useful for tooth whitening

The present invention provides tooth whitening compositions in the form of a liquid crystal or a microemulsion that includes a tooth whitening agent in an amount effective to whiten teeth, a hydrophilic phase including water, a hydrophobic phase including at least one oil, at least one anionic, nonionic, amphoteric or zwitterionic surfactant, and a water soluble co-solvent having a Hildebrand solubility parameter above 12 (cal / cm3)1 / 2, as well as methods for whitening teeth including applying the liquid crystal or microemulsion composition to the teeth for a period of time and under conditions effective to whiten the teeth.

Owner:JOHNSON & JOHNSON CONSUMER COPANIES

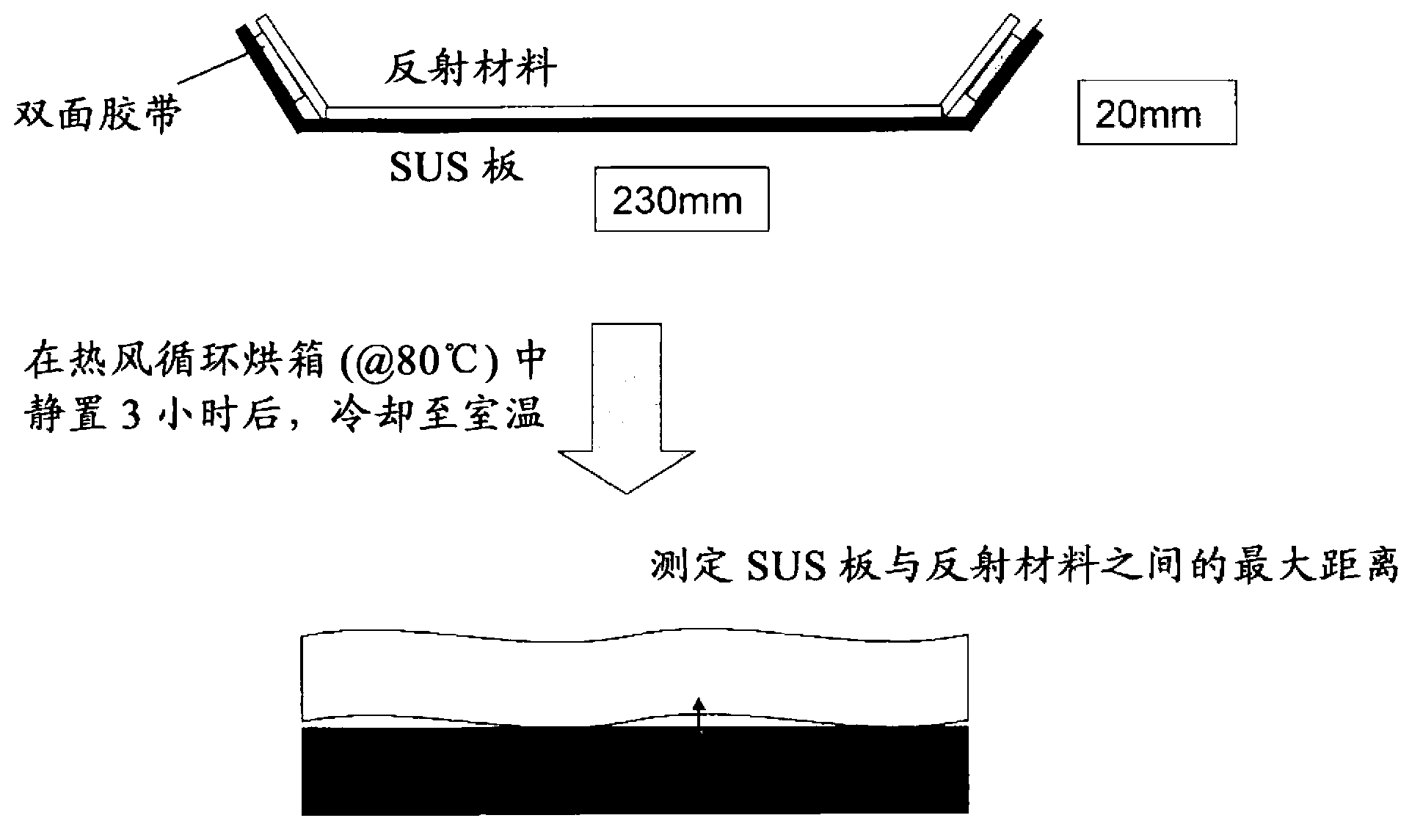

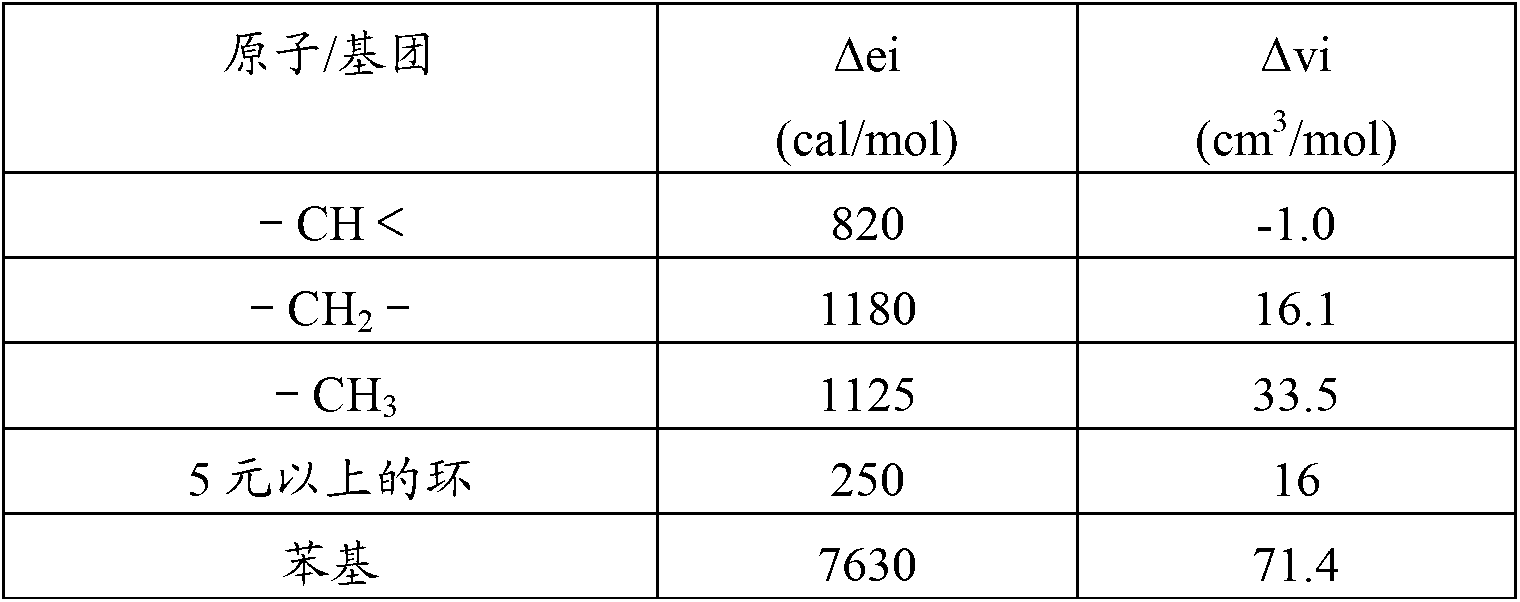

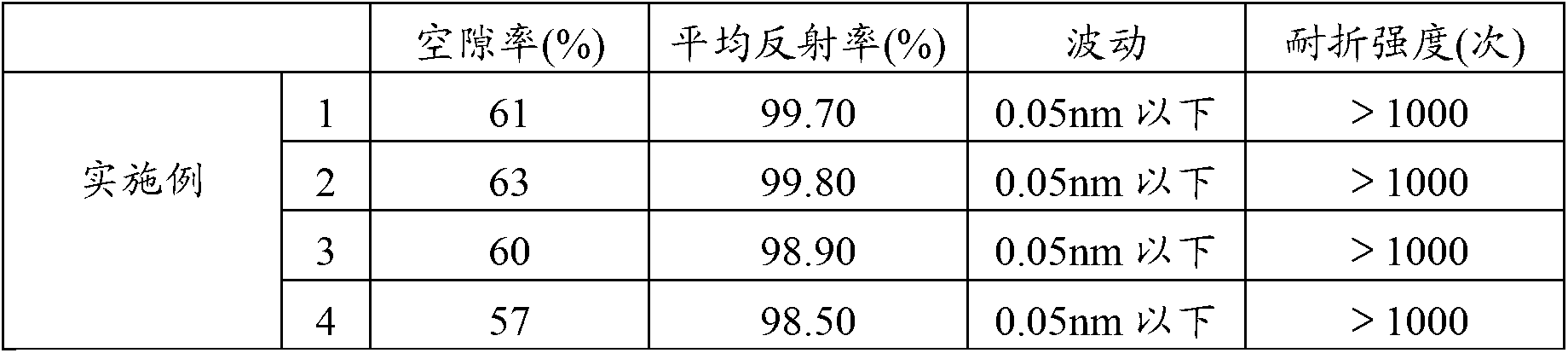

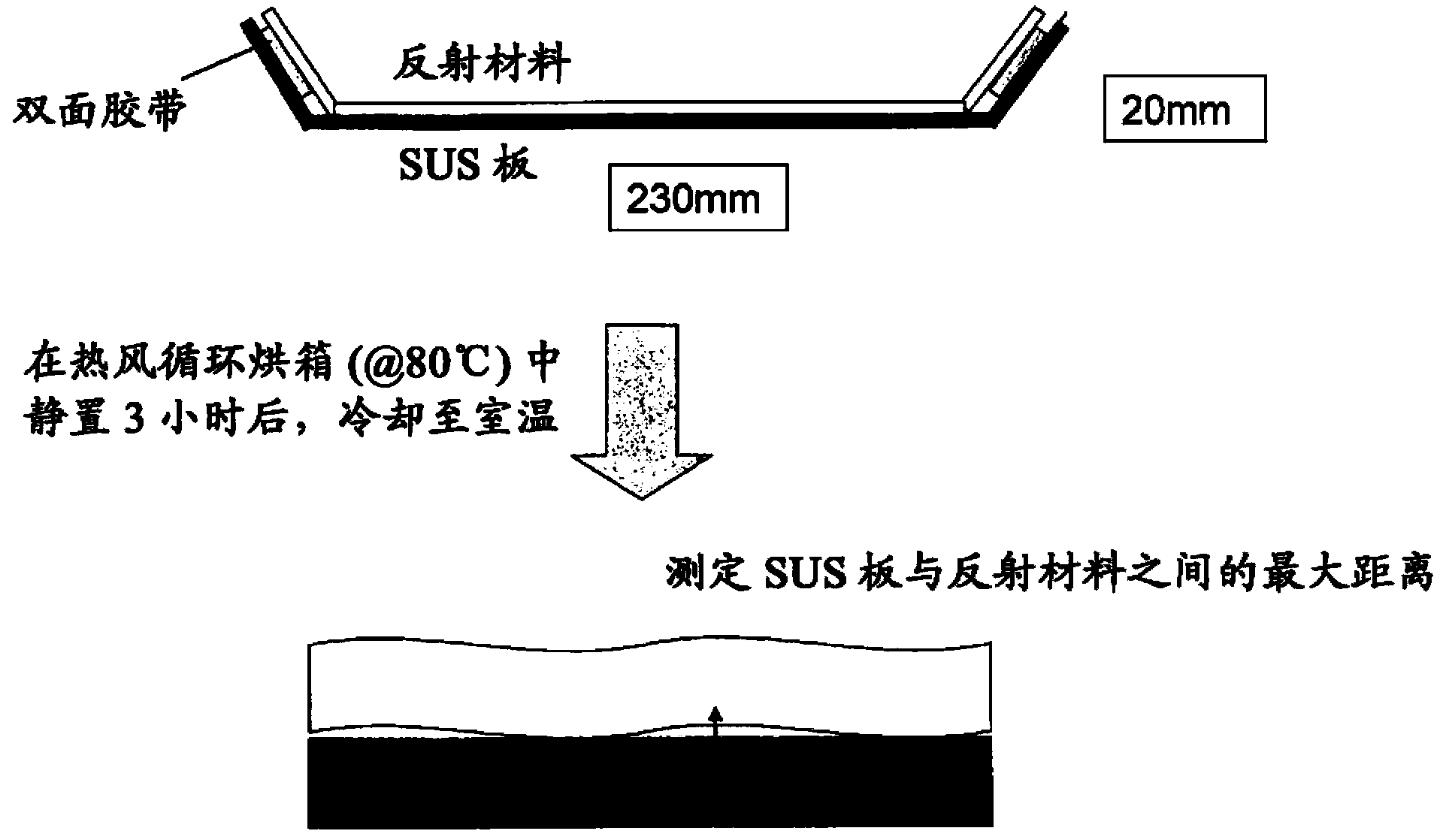

Reflective material

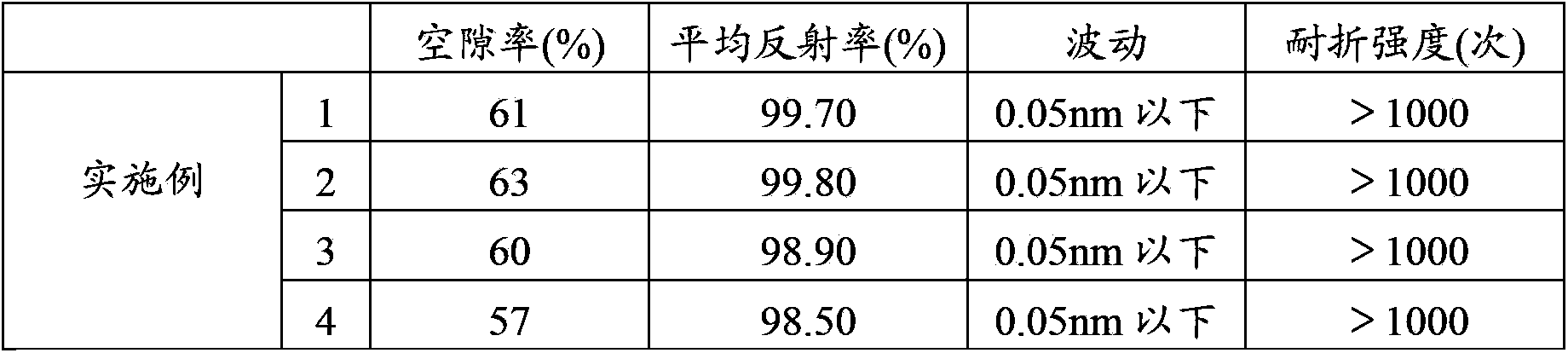

ActiveCN103003067AGood light diffusion effectIncrease brightnessMirrorsSynthetic resin layered productsSurface roughnessReflective layer

Disclosed is a novel reflective material which exhibits excellent reflection properties and particularly excellent light diffusing properties. The disclosed reflective material is provided with a resin layer (B) that contains at least two kinds of thermoplastic resin having different solubility parameters (SP values) on at least one surface of a resin layer (A) having internal voids. The reflective material is characterized in that, due to the combination of the thermoplastic resins having different solubility parameters (SP values), the arithmetic mean roughness (Sa) of the three-dimensional surface roughness of the resin layer (B) is at least 0.5[mu]m.

Owner:MITSUBISHI CHEM CORP

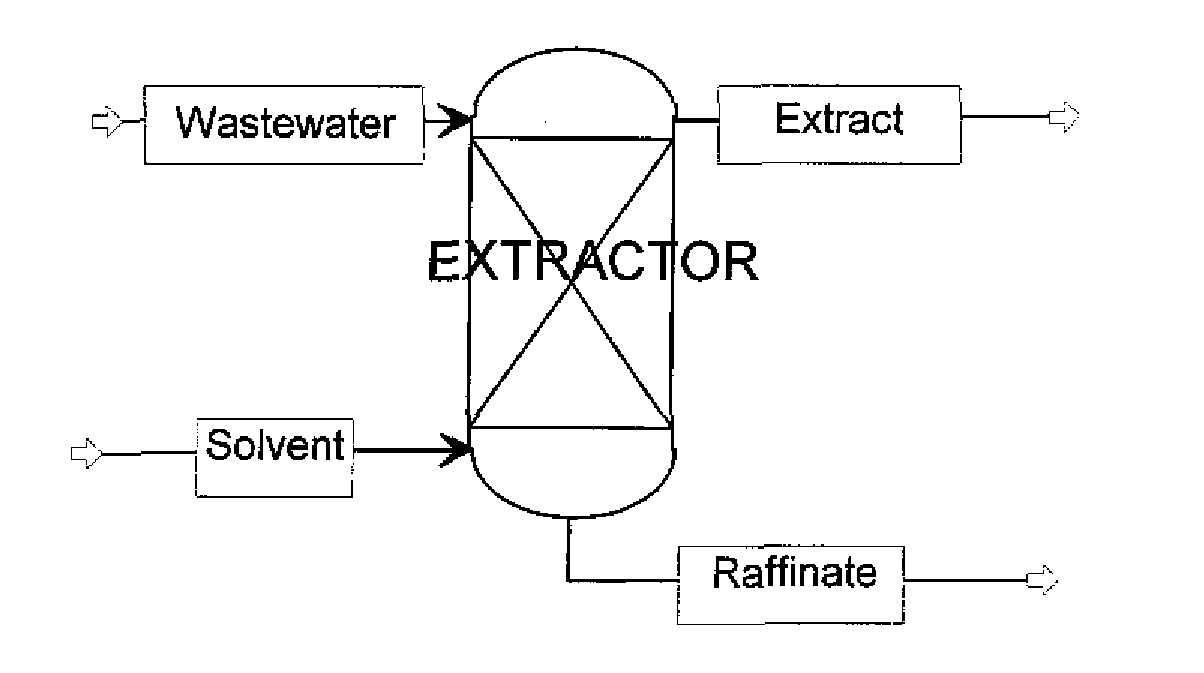

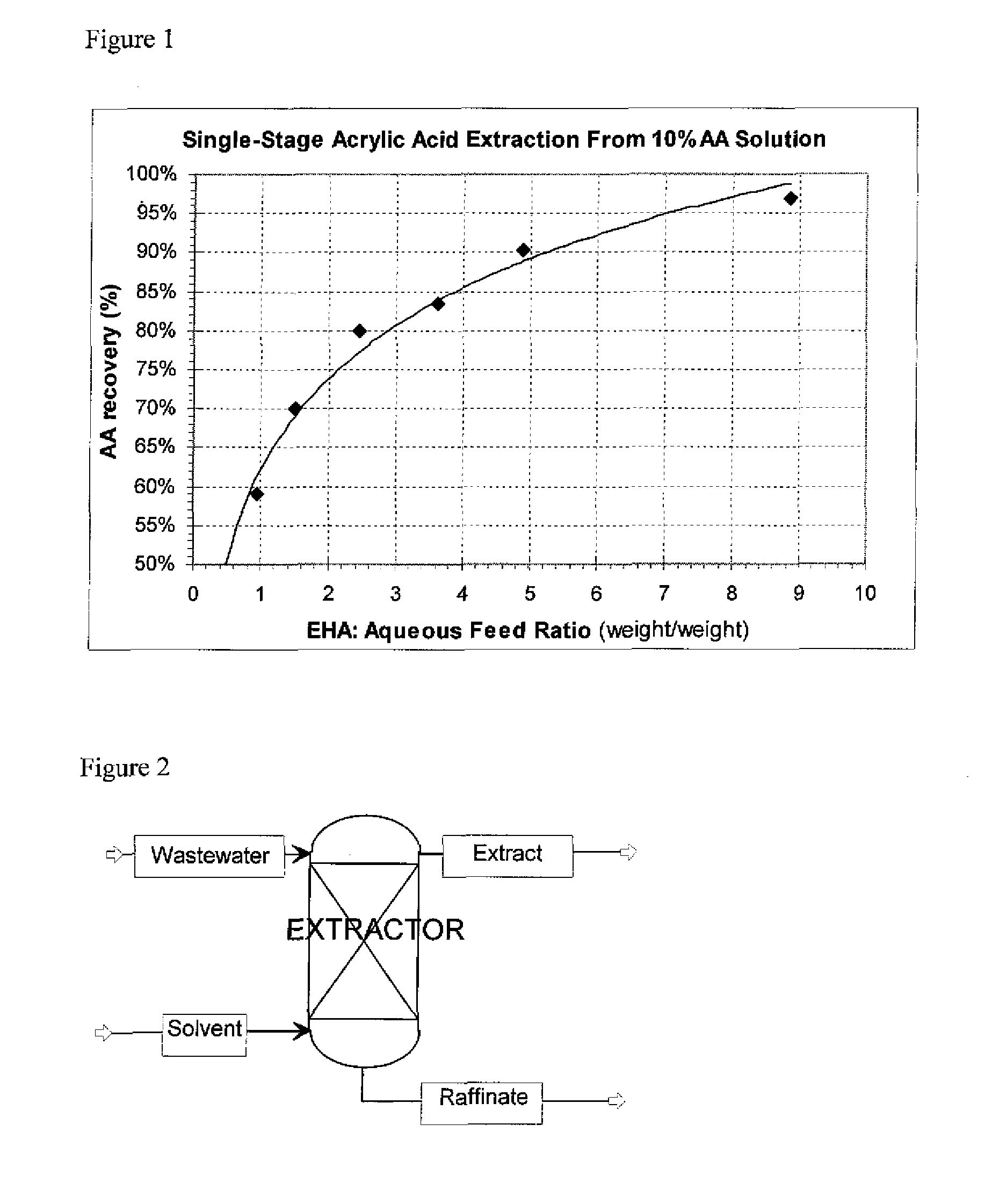

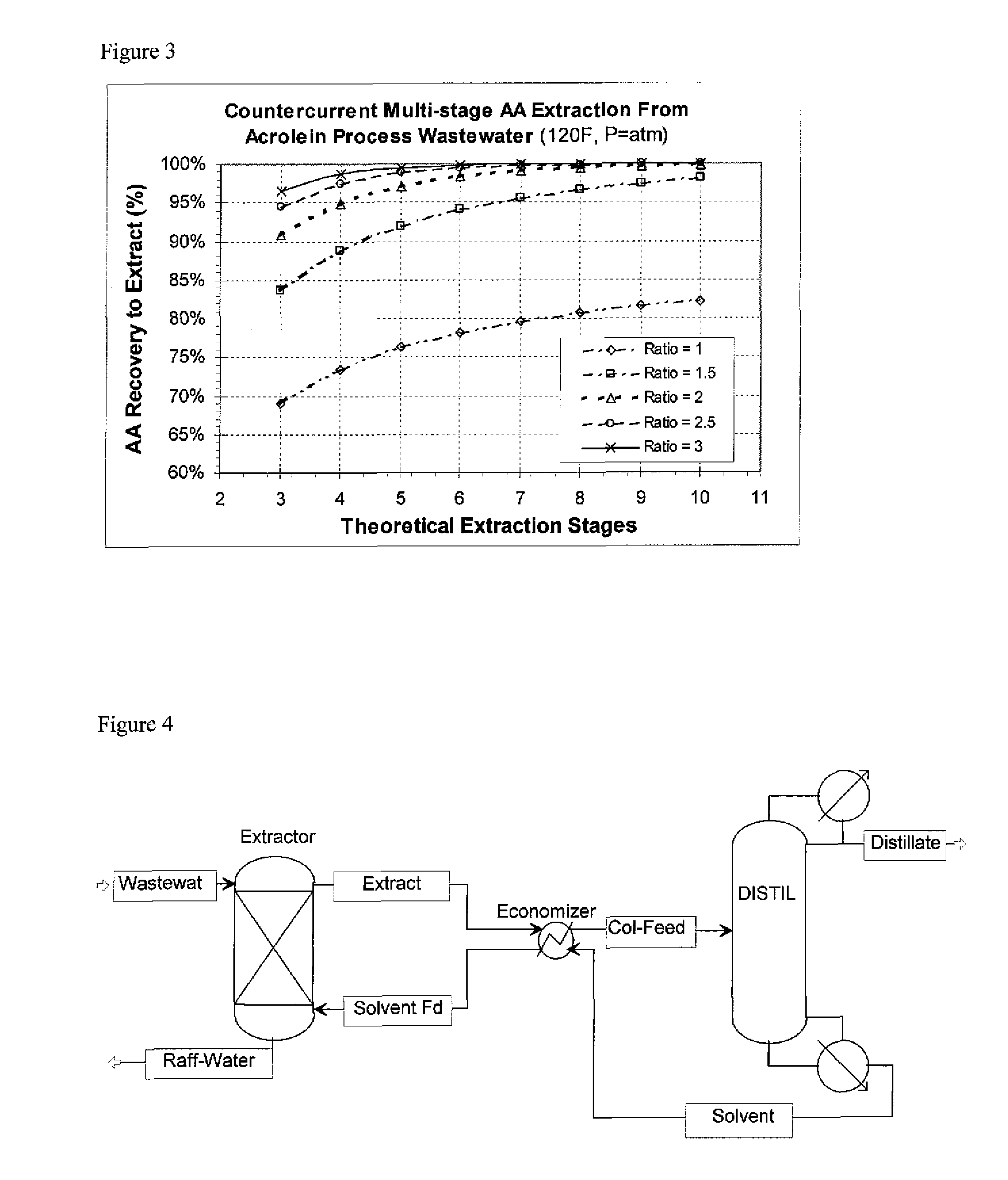

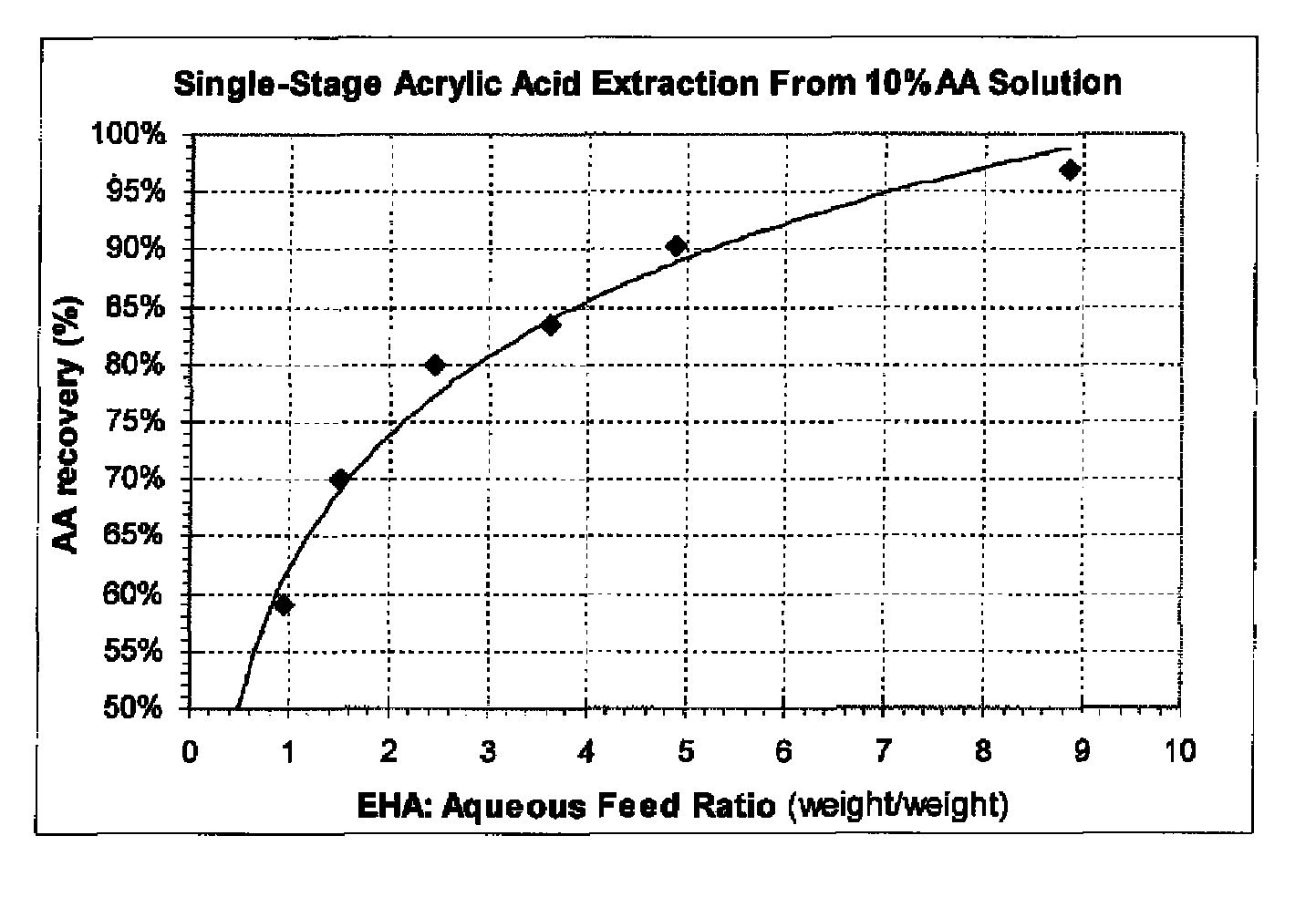

Method for recovering carboxylic acids from dilute aqueous streams

InactiveUS20110147307A1Inhibition of polymerizationSolid sorbent liquid separationWater/sewage treatment bu osmosis/dialysisOrganic acidBoiling point

Improvement in separating lower, C2 saturated and / or C3, and / or C4, saturated and / or unsaturated mono carboxylic acids from aqueous streams via extraction by using as the extractant an organic acid or ester or mixtures thereof with a melting point below 10° C., a normal boiling point between 190 and 280° C. and a Hildebrand solubility parameter between 8 and 11 cal1 / 2 cm−3 / 2.

Owner:ARKEMA INC

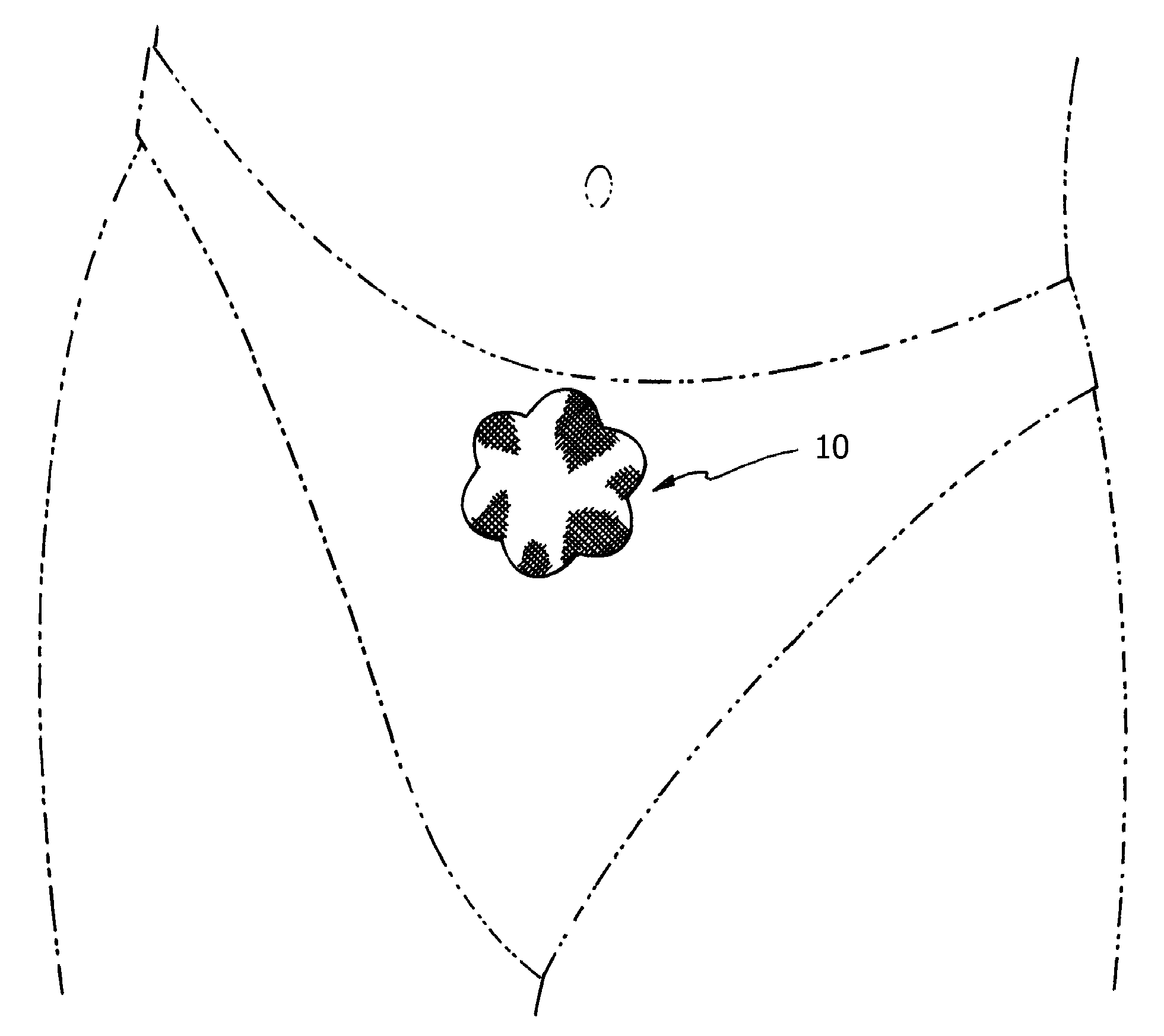

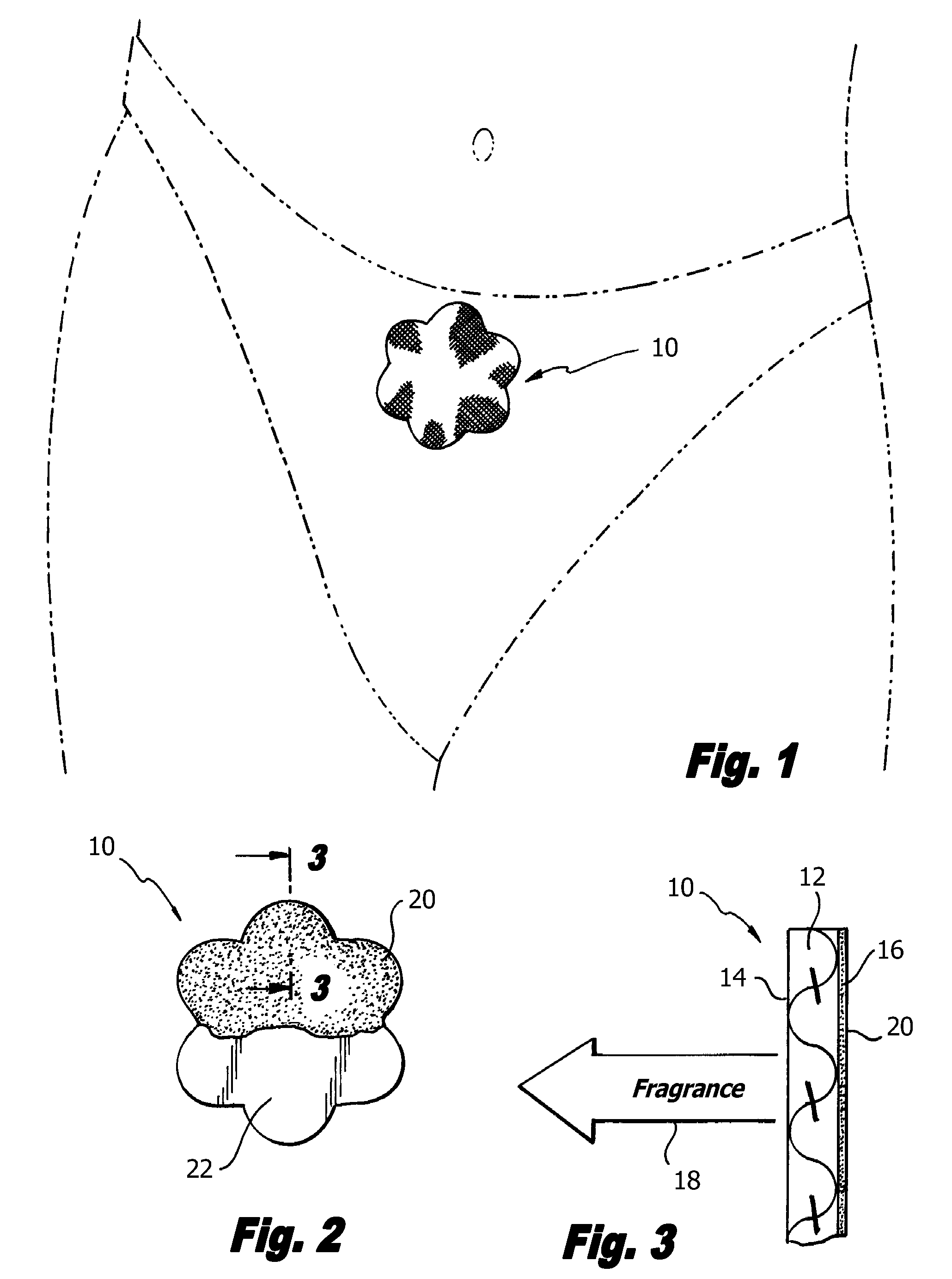

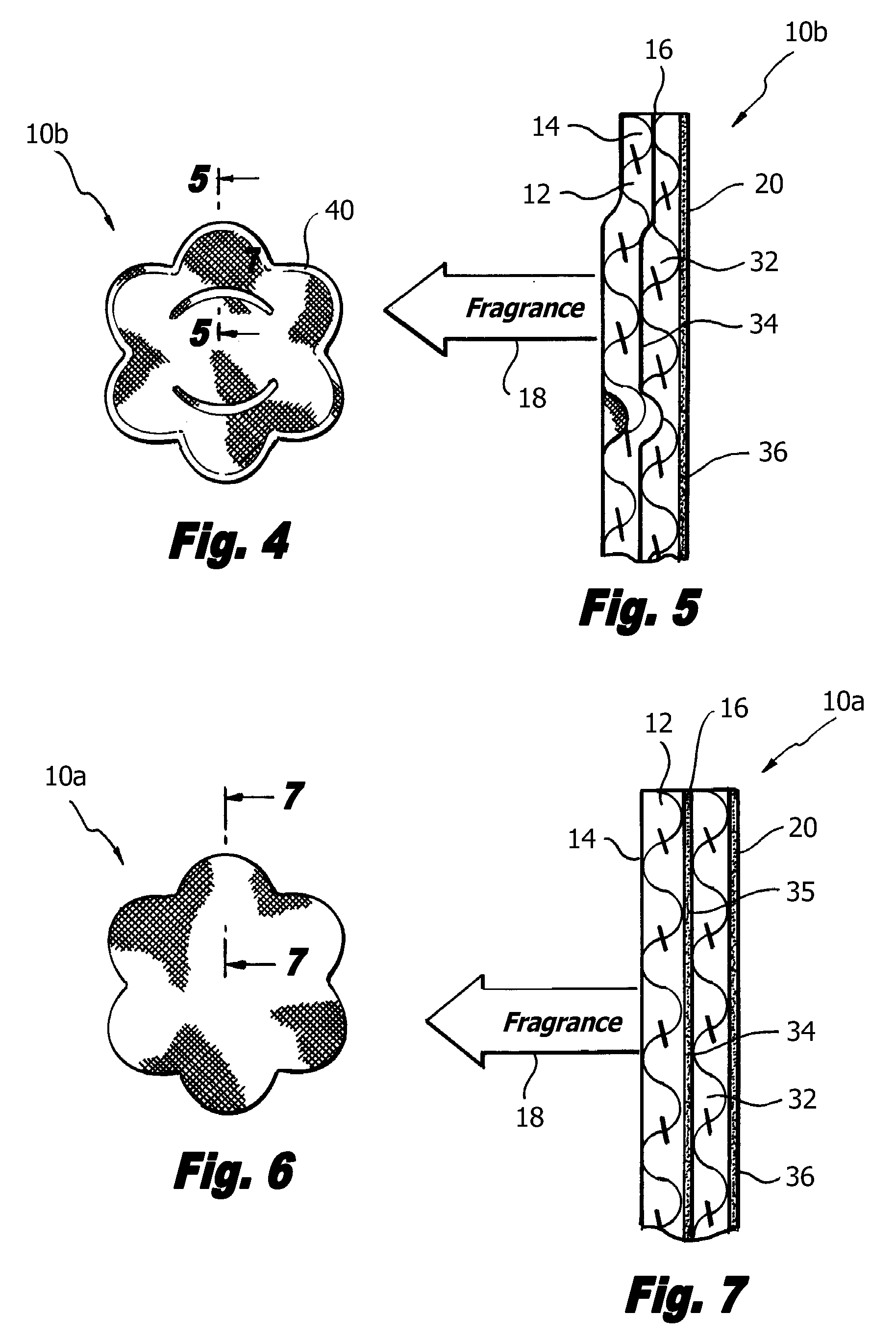

Fragrance emitting patch

A fragrance emitting patch including a primary porous layer having a top and a bottom surface, a secondary layer having a top and a bottom surface, a construction adhesive arranged between the primary layer and the secondary layer for securing the primary and secondary layers to one another, the primary layer being provided with a fragrance, and an absolute difference of a Hildebrand solubility parameter of the construction adhesive and the Hildebrand solubility parameter of the fragrance is greater than 1.5.

Owner:MCNEIL PPC INC

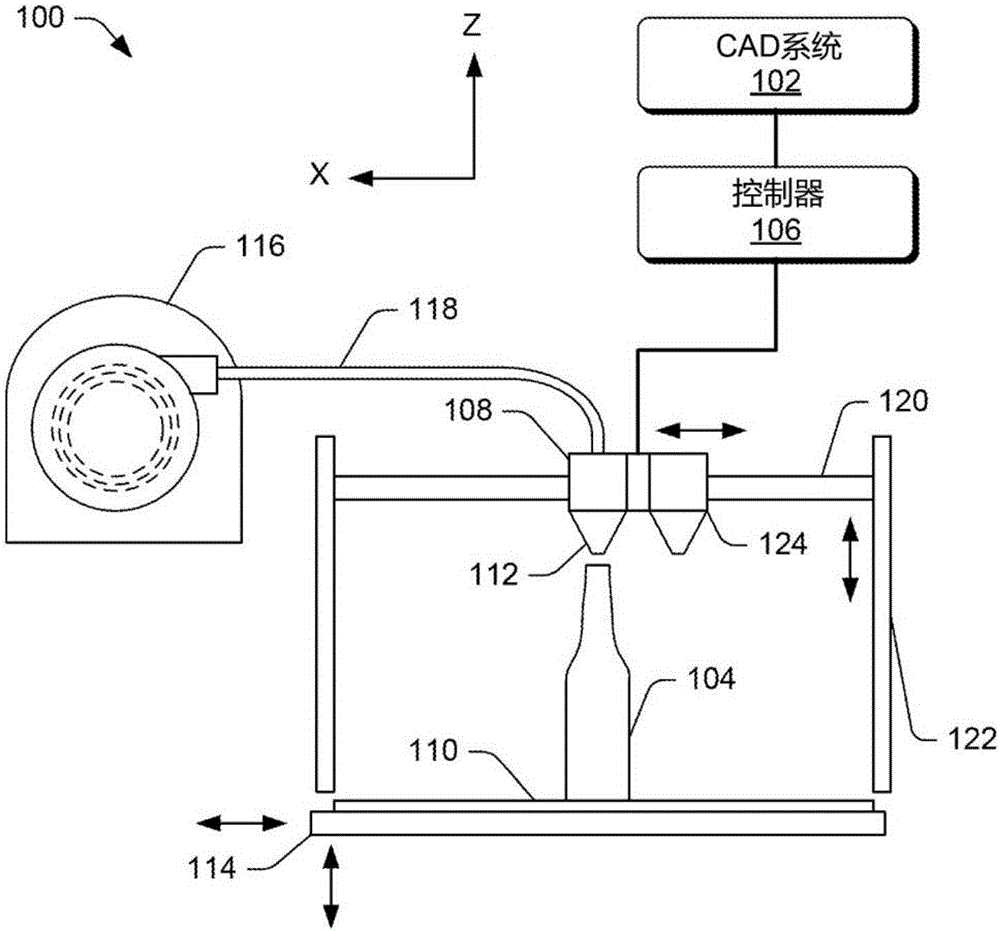

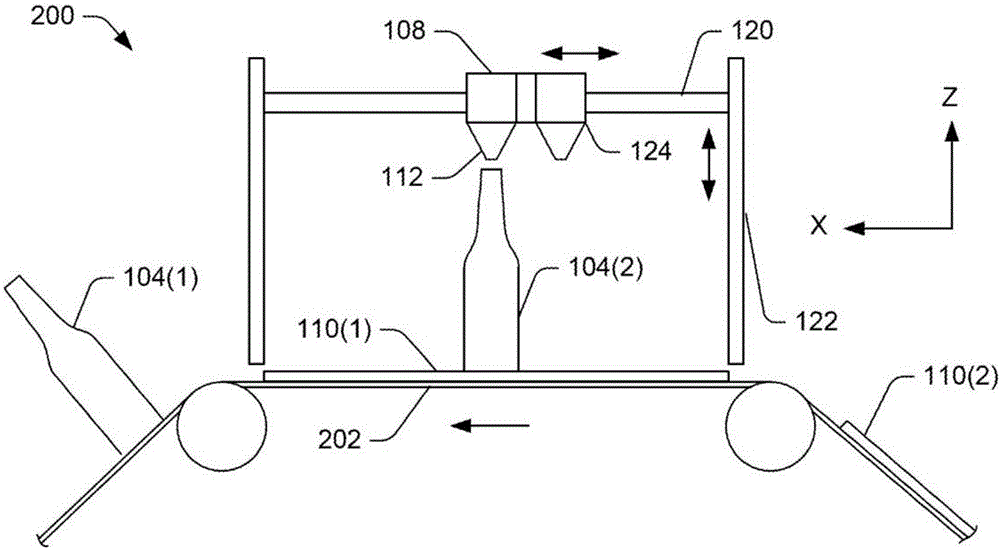

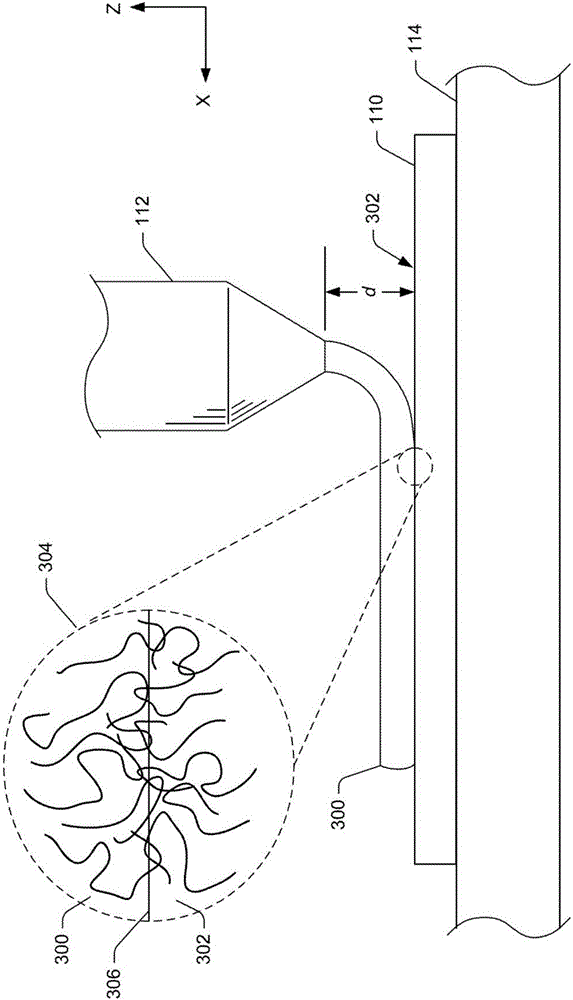

Additive manufacturing using miscible materials

An object can be formed in an additive manufacturing process, such as FDM, by providing a substrate having at least a surface that is made of a first material, and forming one or more layers of a second material on the surface of the substrate. A Hildebrand solubility parameter of the second material is within about 5% of a Hildebrand solubility parameter of the first material. In this manner, the object part formed by the one or more layers of the second material may be incorporated into the object. In an example, the object includes a first portion and a second portion, the first portion comprises the one or more layers of the second material, the second portion comprises the substrate, the first portion has a first haze value, and the second portion has a second haze value, wherein a percent difference between the first haze value and the second haze value is equal to or greater than about 165%.

Owner:EASTMAN CHEM CO

Solution based enhancements of fuel cell components and other electrochemical systems and devices

This invention relates in general to components of electrochemical devices, and to methods of preparing the components. The components and methods include the use of a composition comprising an ionically conductive polymer and at least one solvent, where the polymer and the solvent are selected based on the thermodynamics of the combination. In one embodiment, the invention relates to a component for an electrochemical device which is prepared from a composition comprising a true solution of an ionically conductive polymer and at least one solvent, the polymer and the at least one solvent being selected such that |δ solvent−δ solute|<1, where δ solvent is the Hildebrand solubility parameter of the at least one solvent and where δ solute is the Hildebrand solubility parameter of the polymer. In another embodiment, the invention relates to a method of improving at least one property of a component for an electrochemical device or at least one property of the electrochemical device, the method comprising preparing the component from a composition comprising a true solution of an ionically conductive polymer and at least one solvent, the polymer and the at least one solvent being selected such that |δ solvent−δ solute|<1, where δ solvent is the Hildebrand solubility parameter of the at least one solvent and where δ solute is the Hildebrand solubility parameter of the polymer.

Owner:BATTELLE MEMORIAL INST

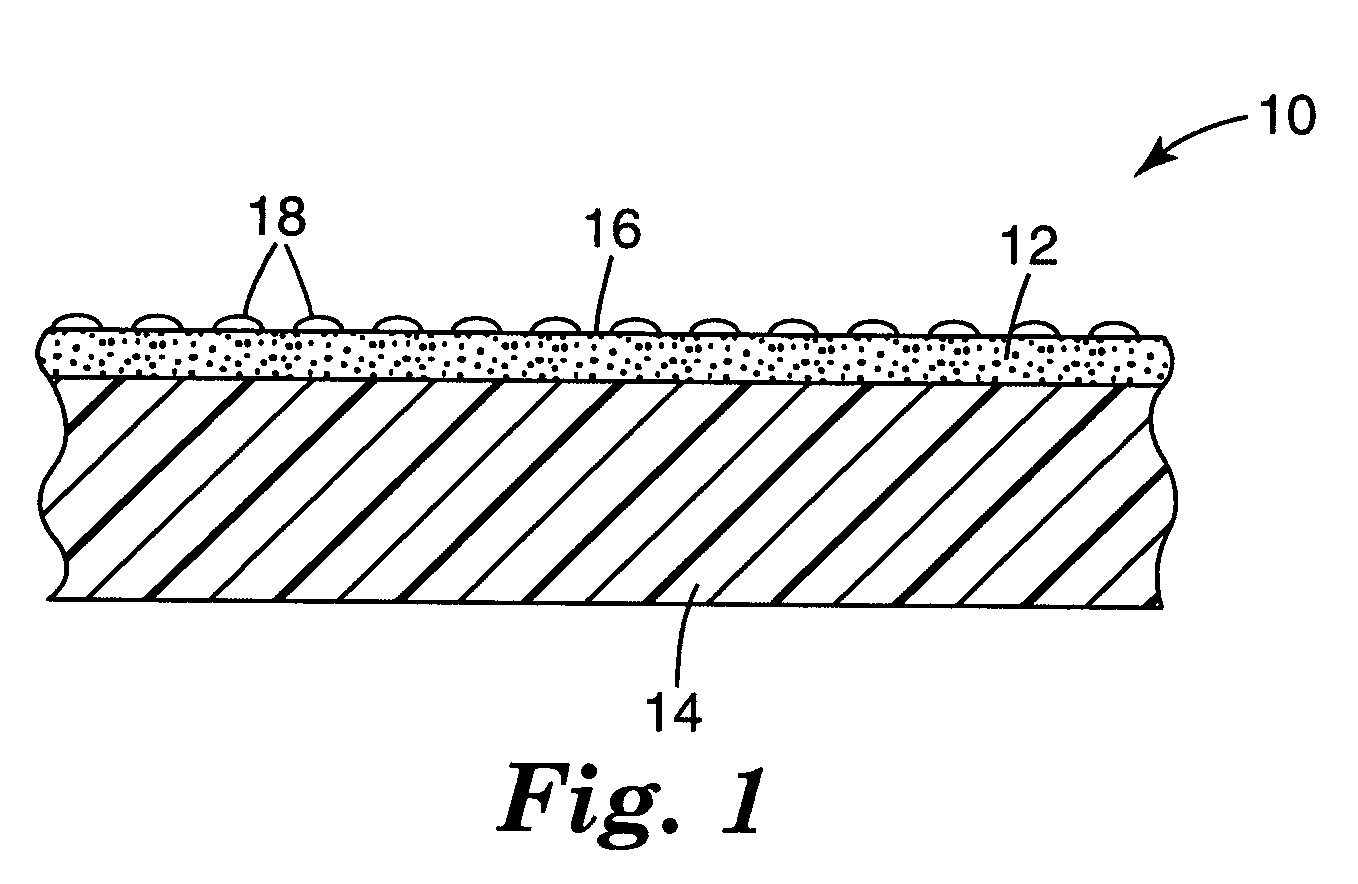

Biologically-active adhesive articles and methods of manufacture

The present invention is a method of coating an adhesive layer. The method includes non-contact depositing a fluid solution onto the adhesive layer and allowing the fluid solution to substantially dry, where the fluid solution comprising a biological active. The fluid solution exhibits a Hildebrand solubility parameter of at least about 3.7 MegaPascals<1 / 2> greater than a Hildebrand solubility parameter of the adhesive layer.

Owner:3M INNOVATIVE PROPERTIES CO

Denitrification method for heavy oil

ActiveCN104212478AHigh selective removal capacityReduce lossesRefining with acid-containing liquidsReaction temperatureFuel oil

The invention relates to a denitrification method for heavy oil. The method includes: reacting a composite denitrification agent with heavy oil, and at the end of the reaction, separating the denitrification agent and denitrified oil. The reaction temperature is 20DEG C-150DEG C, the dosage of the denitrification agent accounts for 5-150% of the heavy oil volume. The denitrogenation agent is composed of component A, component B and component C. A is one or more of the complexing agent TiCl4, TiSO4, CuCl2, and FeCl3, B is one or more of oxalic acid, citric acid, and phthalic acid, and C is a solvent with a Hildebrand solubility parameter ranging from 4.7 to 6 and is one or more of cyclopentane, cyclohexane, methylcyclohexane, ethylcyclohexane, decahydronaphthalene, and tetrahydronaphthalene. In terms of mass ratio, A accounts for 10-30%, B accounts for 10-30%, and C accounts for 40-80%. At the end of the reaction, the denitrified oil and the denitrification agent can be separated by settlement separation. The method can reach a denitrogenation rate up to over 70% and a yield up to 65%.

Owner:PETROCHINA CO LTD

Low residue antiperspirant gel-solid stick compositions containing select gellants

Anhydrous antiperspirant gel-solid stick compositions are disclosed comprising a particulate antiperspirant active, a solid non-polymeric gelling agent selected from the group consisting of 12-hydroxystearic acid, 12-hydroxystearic acid, esters, amides of 12-hydroxystearic acid, and combinations thereof; and an anhydrous liquid carrier, the average solubility parameter ((cal / cm 3 ) 0.5 ) is about 3-13; wherein the visible residue index of the composition is about 11-30 L-value, the product hardness is about 500-5000 g·force, elastic modulus (G′) and viscous modulus (G″) The ratio is about 0.1-100.The refractive indices of the particulate antiperspirant active, the solid non-polymeric gelling agent and the anhydrous liquid carrier need not be matched. The solid non-polymeric gelling agent preferably has an average particle size of less than about 1 micron and / or crystalline particles in the form of elongated particles having an aspect ratio greater than about 2. These antiperspirant gel-solid stick compositions provide improved low residue performance, efficacy and aesthetics.

Owner:THE PROCTER & GAMBLE COMPANY

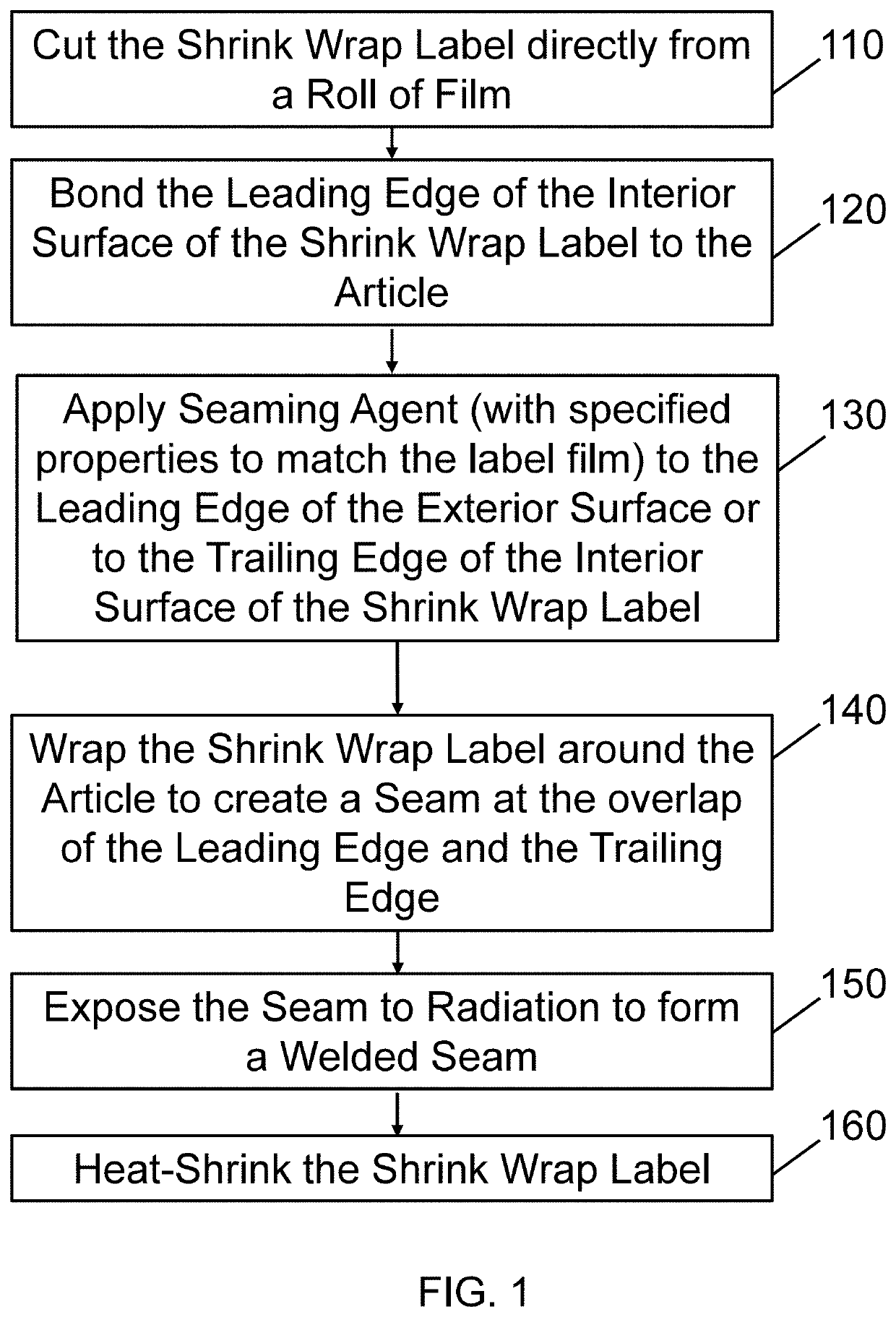

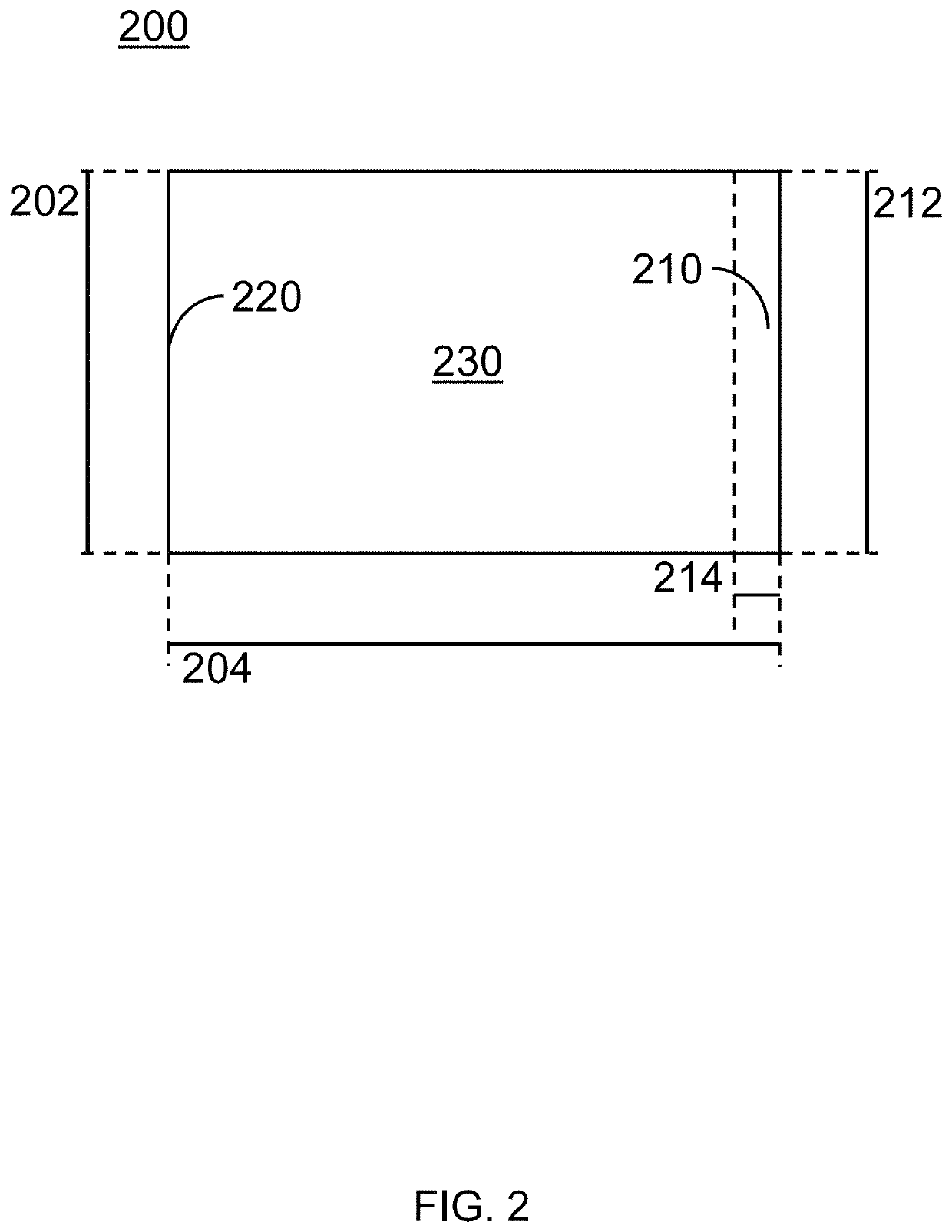

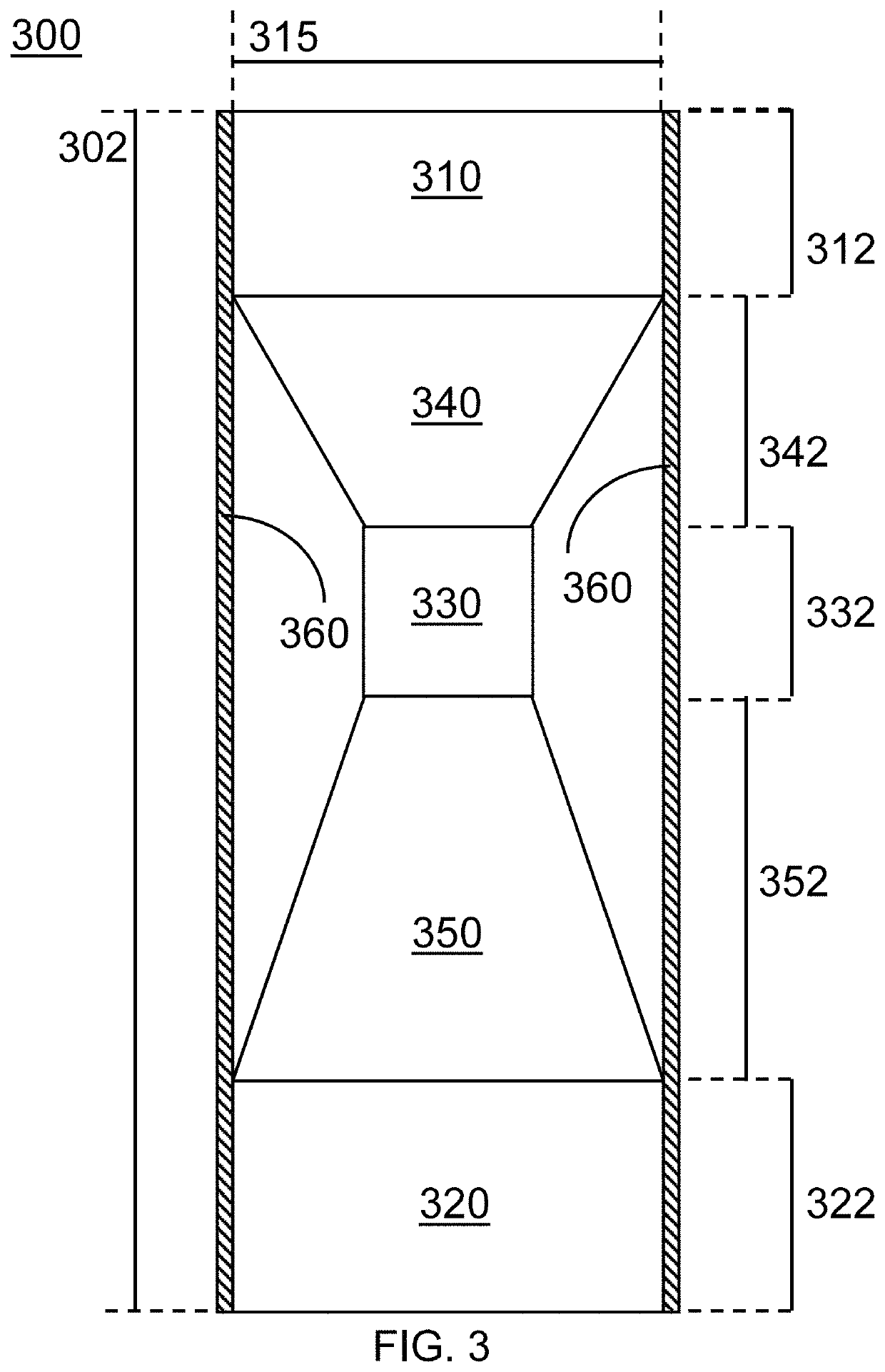

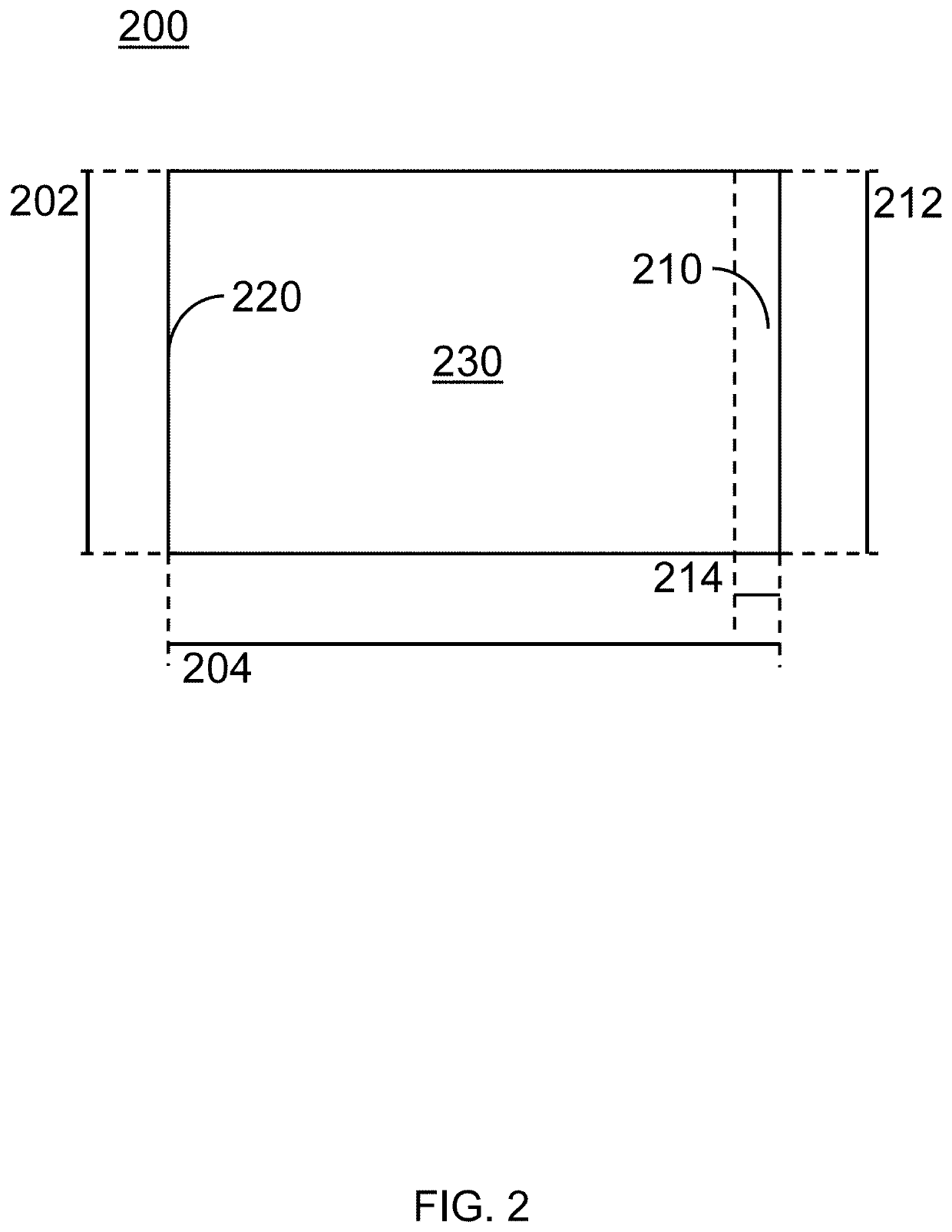

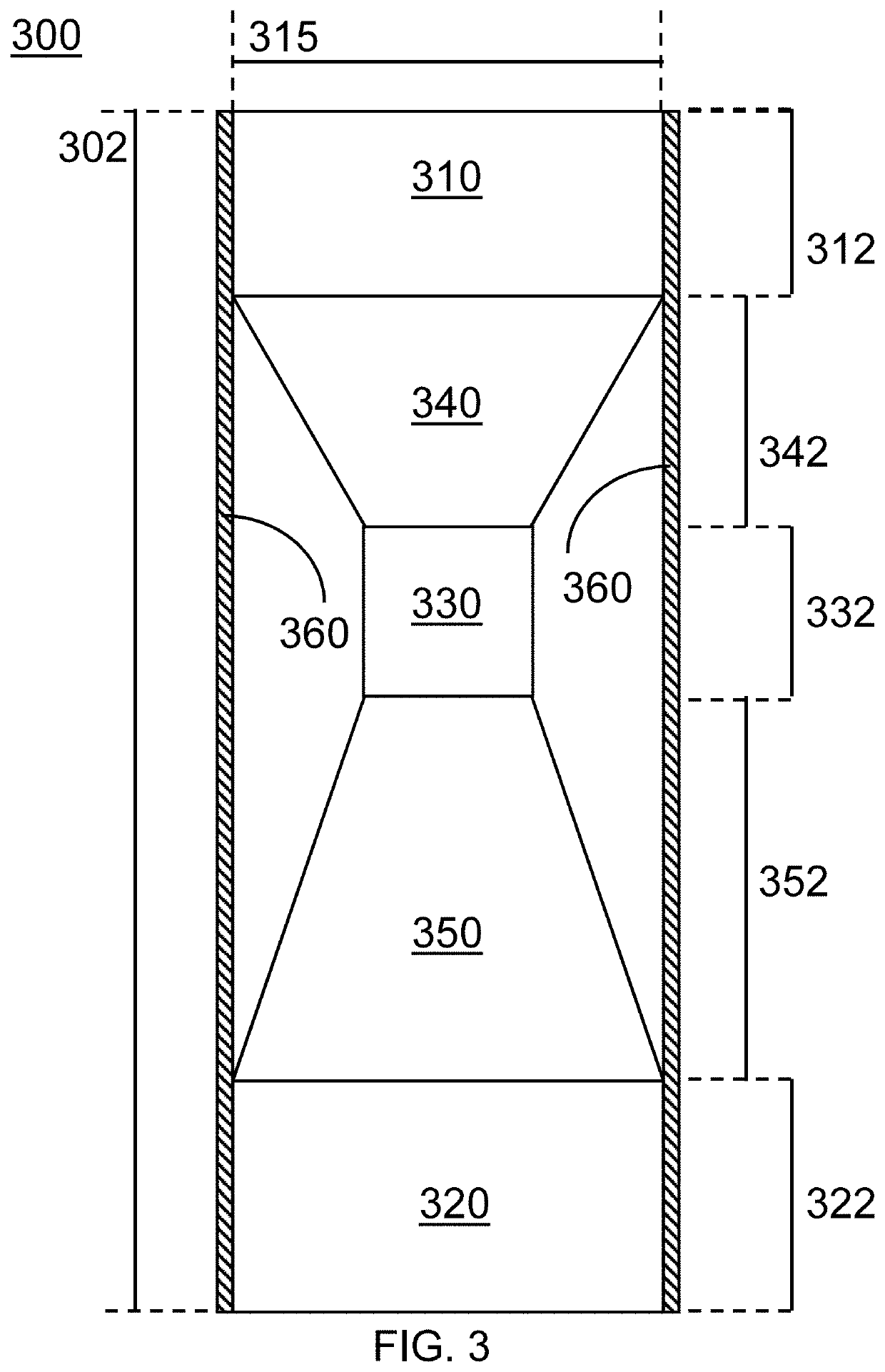

Shrink wrap labels for shaped articles

ActiveUS10858545B2Increase speedLower cost of capitalFilm/foil adhesivesAdhesive processes with adhesive heatingThin membraneEngineering

Methods for applying high shrink wrap labels to a shaped article are disclosed. The leading edge of the label is bonded to the article. A seaming agent is applied, and the label is wrapped around the article. The seaming agent is then exposed to radiation to cure the seaming agent, and the label is then exposed to heat to cause heat-shrinking. The label is made of a film with at least one external layer that has a Hildebrand solubility parameter. The seaming agent includes a component having a Hildebrand solubility parameter that is within 2.2 MPa1 / 2 or within 4.4 calories1 / 2·cm−3 / 2 of the Hildebrand solubility parameter of the external layer of the film. The seaming agent also has a viscosity of at least 1 centipoise and less than 1000 centipoise when measured at any temperature between ambient temperature and 60° C. Articles including such affixed high shrink wrap labels are also disclosed.

Owner:POLYSACK FLEXIBLE PACKAGING LTD

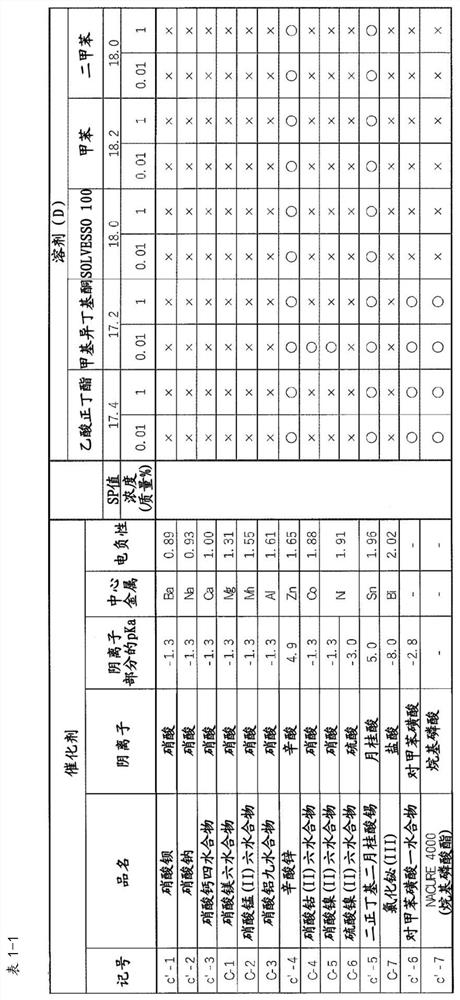

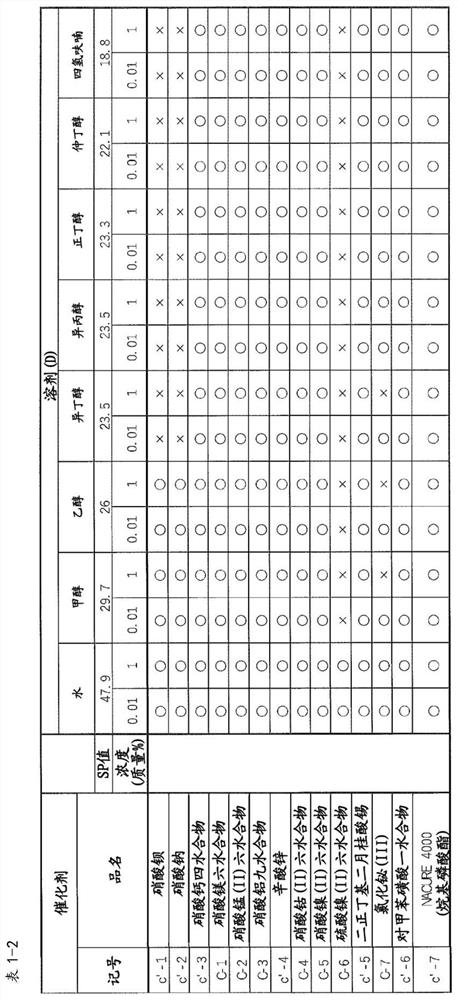

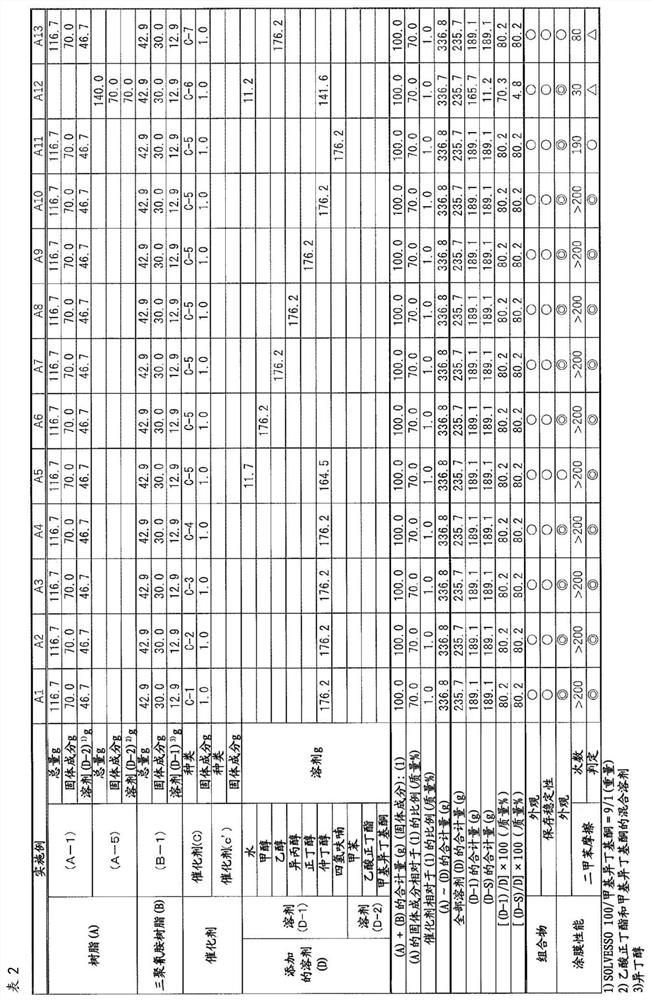

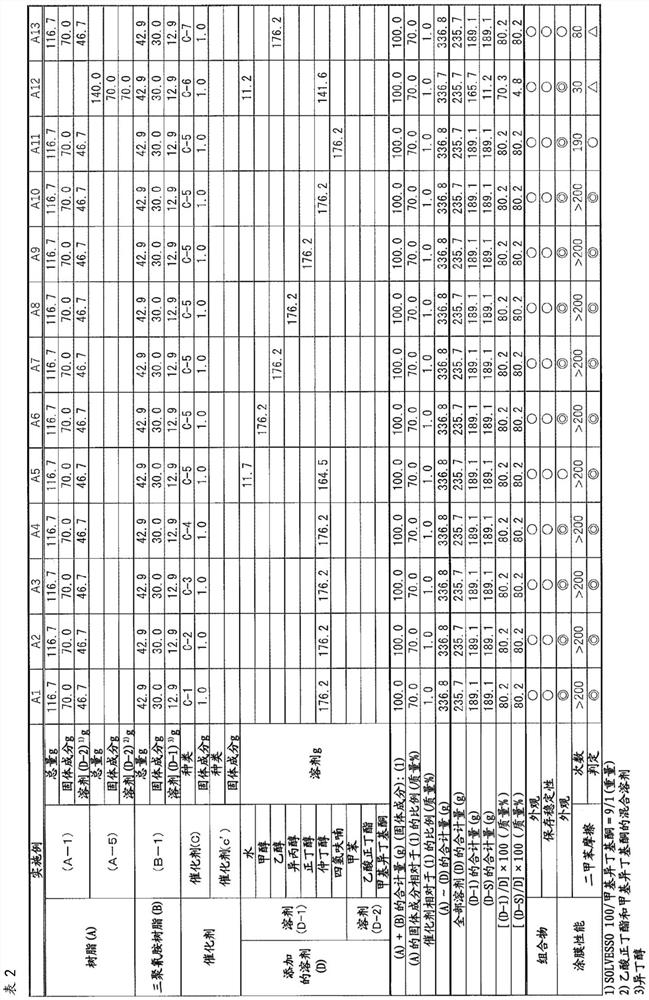

Thermosetting resin composition, coating material for pre-coated metal, cured product, and laminate

ActiveCN112004890ALow storage stabilityIncreased durabilityLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePtru catalyst

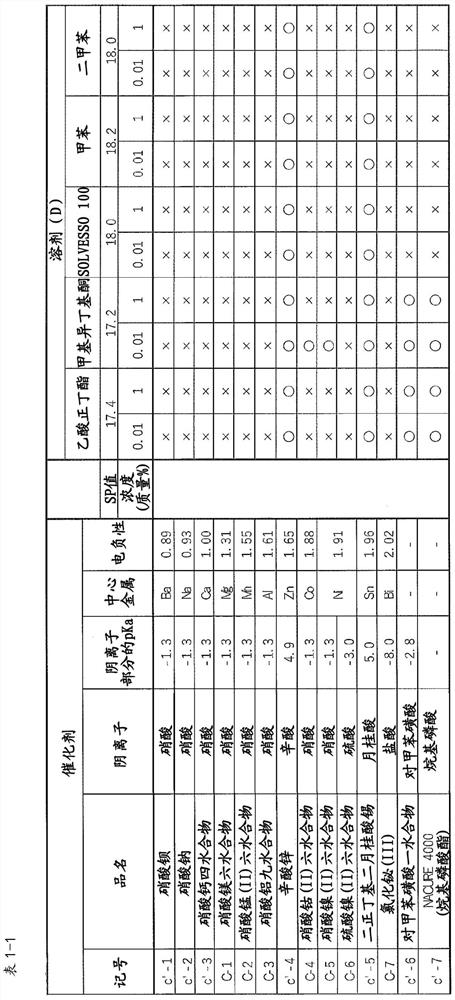

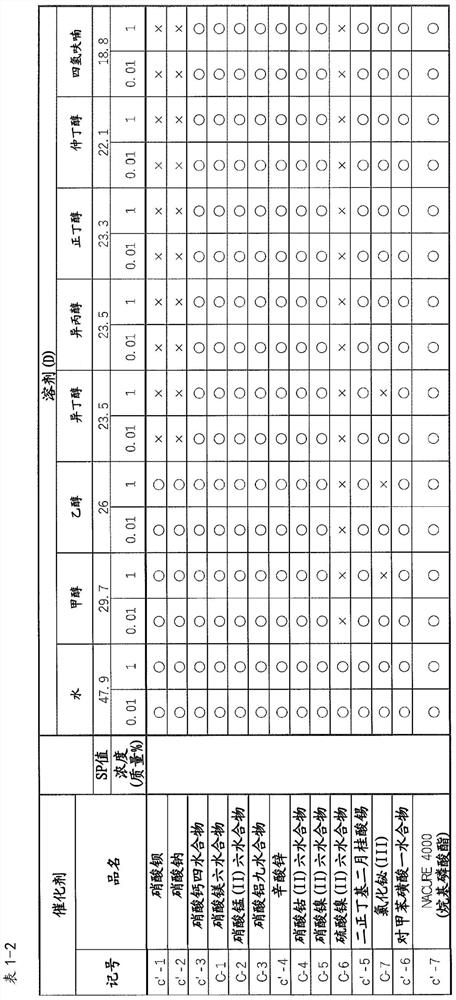

The purpose of the present invention is to provide a thermosetting resin composition that has excellent storage stability and is able to obtain, at a low temperature, a cured film having excellent durability and appearance. The thermosetting resin composition according to the present invention contains: a resin that has a specific hydroxyl group; (B) an alkyl etherified melamine resin; (C) a Lewisacid catalyst that comprises a cation comprising a metal having a Pauling electronegativity of 1.31 to 2.02, and that comprises, as a counter anion, a deprotonated protonic acid having an acid dissociation constant pKa of no more than 1.0; and (D) a solvent, wherein the solvent (D) contains a solvent (D-1) that has a Hildebrand solubility parameter value (SP value) of 18.6 to 47.9, the content ofthe solvent (D-1) is at least 21% by mass with respect to the total amount of the solvent (D), and within the solvent (D-1), the content of a solvent (D-S) that has a solubility of the Lewis acid catalyst (C) of at least 0.01% by mass is at least 4% by mass with respect to the total amount of the solvent (D).

Owner:MITSUI CHEM INC

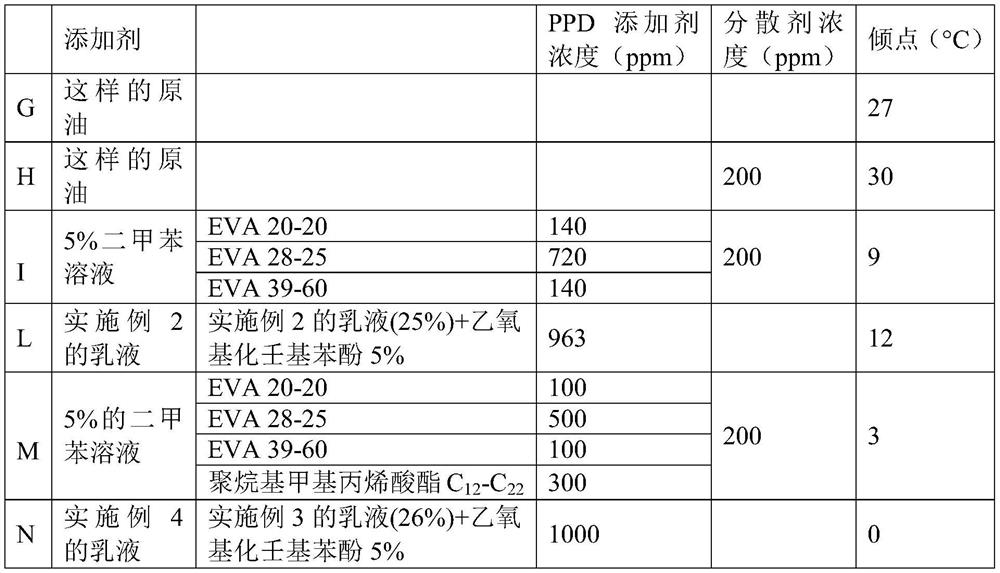

Aqueous emulsions containing ethylene-vinyl acetate copolymers, preparation process thereof and their use as Anti-gelling additives of crude oils

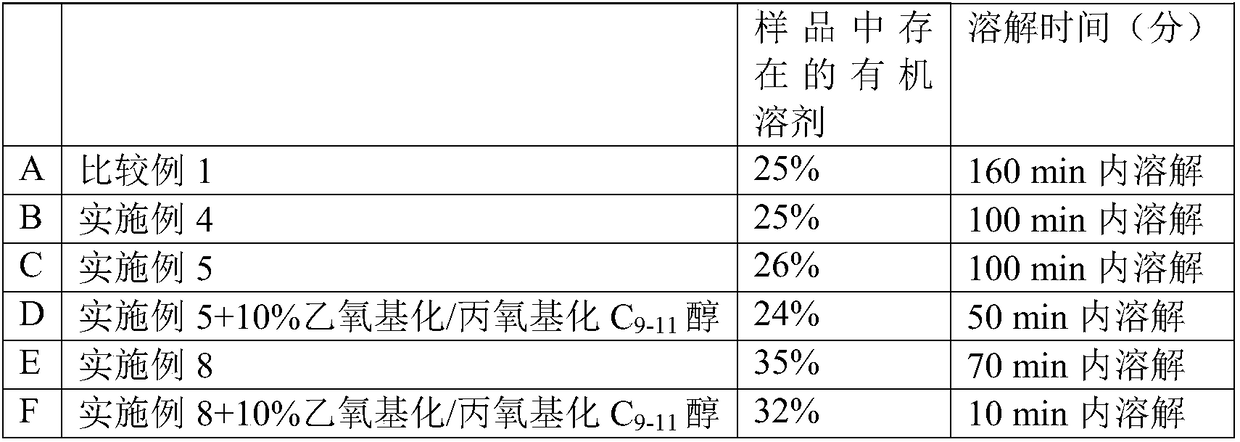

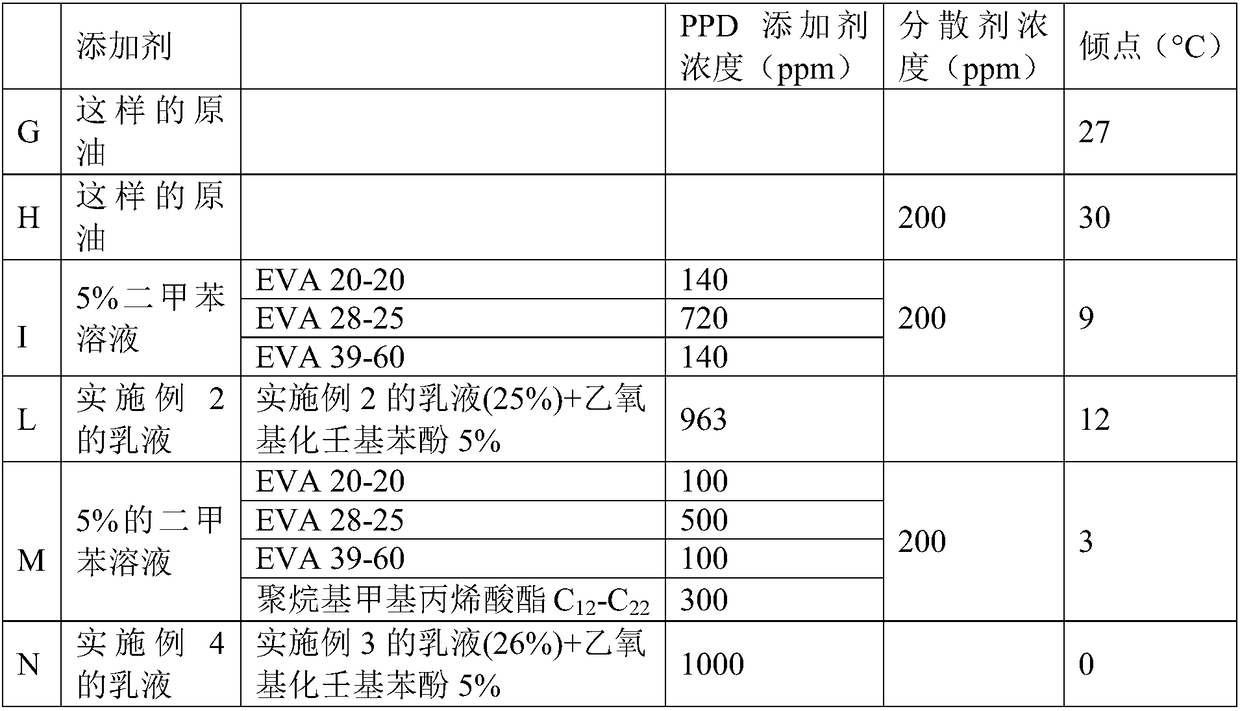

ActiveCN108368272APromote homogenizationImprove solubilityLiquid carbonaceous fuelsFuel additivesPolymer scienceMeth-

The present invention relates to an aqueous emulsion comprising: a) from 50% to 60% of an organic phase dispersed in an aqueous phase, said organic phase containing a mixture including from 24% to 30%, calculated with respect to the final emulsion, of ethylene-vinyl acetate copolymers and / or polyalkyl(meth)acrylates, indicated in the present description as polymeric component, and a high-boiling organic solvent, or a mixture of said solvents; b) a primary emulsifier at a concentration higher or equal to 0.1% and lower than or equal to 3% by weight, calculated with respect to the final emulsion; and c) from 37% to 47% of an aqueous phase, wherein the ratio between said polymer component and said organic solvent in the final aqueous emulsion is at least 1 / 1 and where the organic solvent andany polymer of the polymeric component have a Hildebrand solubility parameter [delta] such that the difference ([delta]solvent_[delta]polymer) is lower than 2 in absolute value for any polymer of thepolymeric component.

Owner:VERSALIS SPA +1

Heavy aromatic solvents for catalyst reactivation

ActiveUS11168266B2Hydrotreatment operations starting-upCatalyst regeneration/reactivationAromatic solventPtru catalyst

Owner:SAUDI ARABIAN OIL CO

Reflective material

ActiveCN103003067BGood light diffusion effectIncrease brightnessMirrorsSynthetic resin layered productsSurface roughnessReflective layer

Disclosed is a novel reflective material which exhibits excellent reflection properties and particularly excellent light diffusing properties. The disclosed reflective material is provided with a resin layer (B) that contains at least two kinds of thermoplastic resin having different solubility parameters (SP values) on at least one surface of a resin layer (A) having internal voids. The reflective material is characterised in that, due to the combination of the thermoplastic resins having different solubility parameters (SP values), the arithmetic mean roughness (Sa) of the three-dimensional surface roughness of the resin layer (B) is at least 0.5µm.

Owner:MITSUBISHI CHEM CORP

Aqueous emulsion containing ethylene-vinyl acetate copolymer, process for its preparation and use thereof as antigelling additive for crude oil

ActiveCN108368272BImprove solubilityLow viscosityLiquid carbonaceous fuelsFuel additivesPolymer scienceMeth-

The present invention relates to an aqueous emulsion comprising: a) 50% to 60% of an organic phase dispersed in an aqueous phase, said organic phase comprising 24% to 30% of the Mixtures of ethylene-vinyl acetate copolymers and / or polyalkyl(meth)acrylates, indicated in the specification as polymer components, with high-boiling organic solvents or mixtures of said solvents; b) relative to the final emulsion, the concentration Greater than or equal to 0.1% and less than or equal to 3% by weight of the primary emulsifier; c) 37% to 47% of the aqueous phase; wherein, in the final aqueous emulsion, the polymer component and the organic solvent are The ratio between the two is at least 1 / 1, and wherein the organic solvent and any polymer of the polymer component have a Hildebrand solubility parameter δ, such that for any polymer of the polymer component, the difference (δ 溶剂 _δ 聚合物 ) is less than 2 in absolute value.

Owner:VERSALIS SPA +1

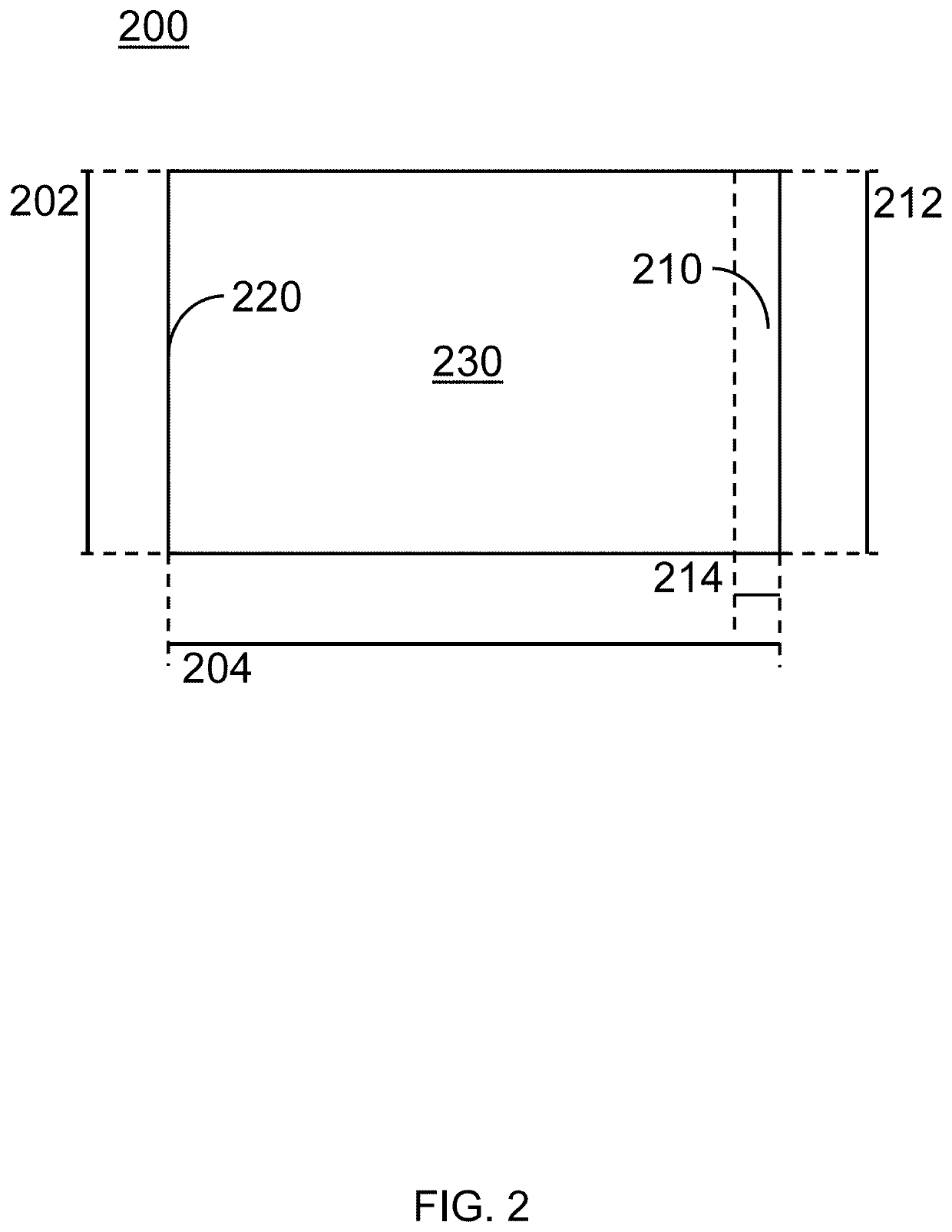

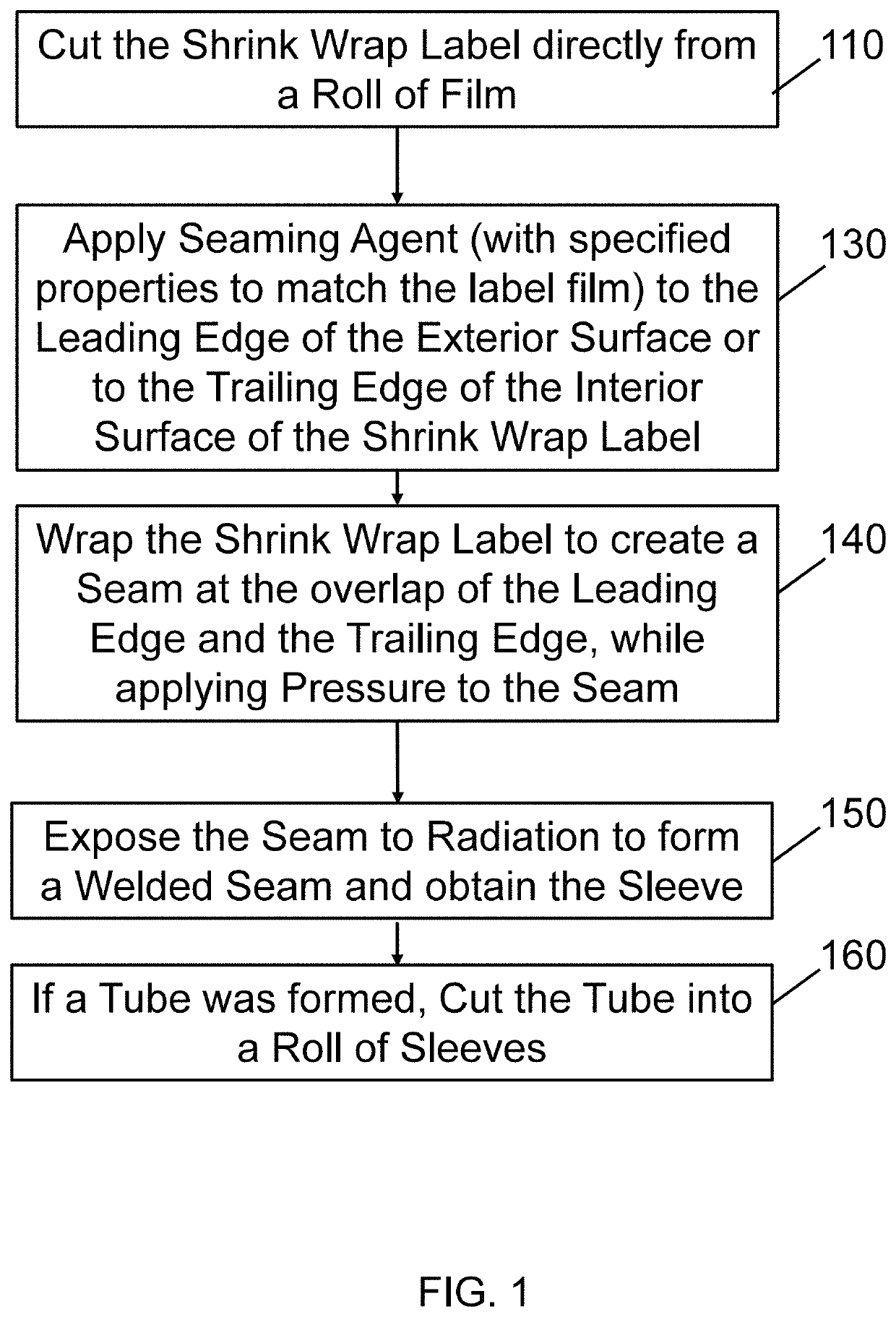

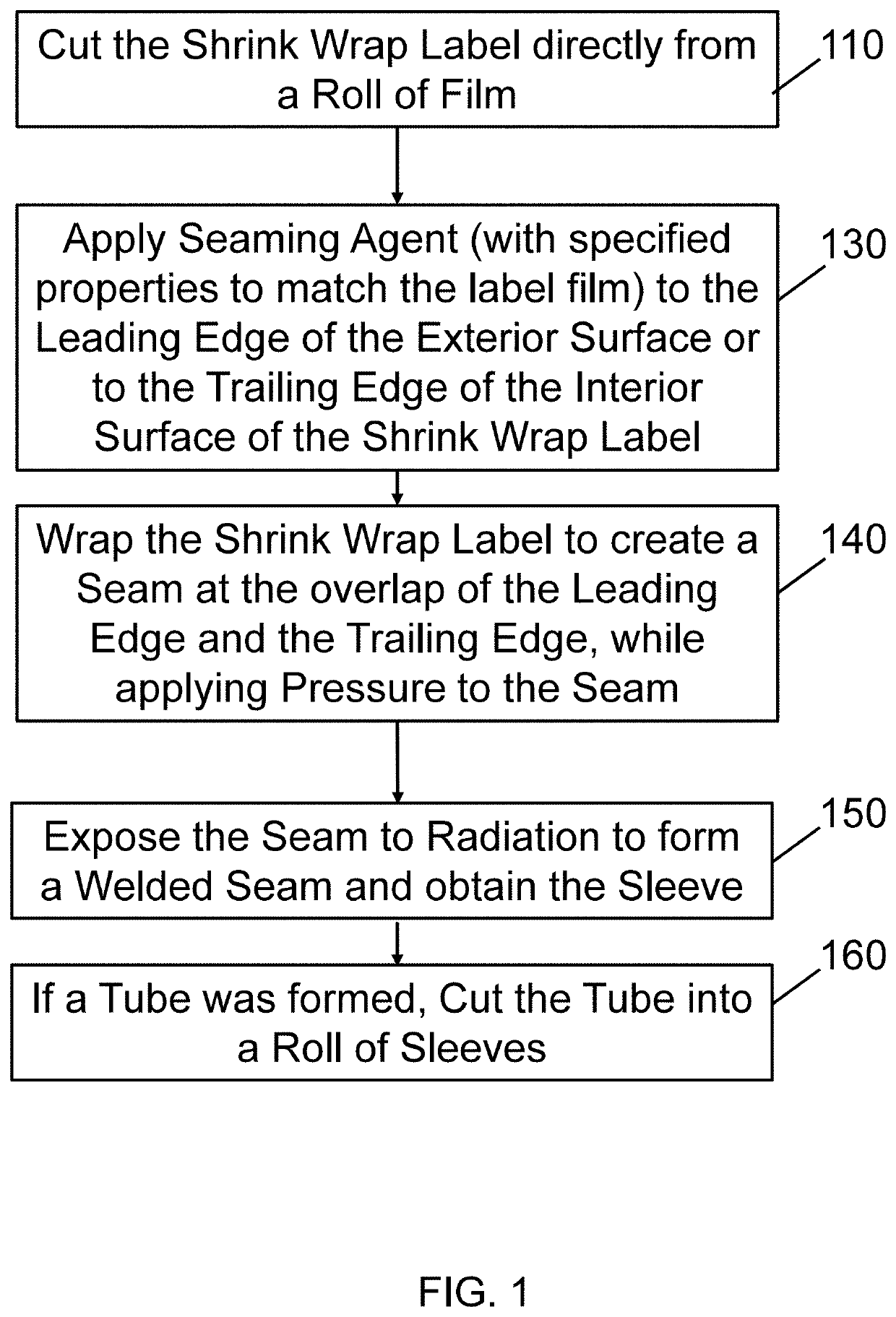

Methods for forming high shrink wrap label sleeves

ActiveUS10899920B2Improve compatibilityIncrease crosslink densityLabelling short rigid containersLabelling machinesThin membraneEngineering

Methods for forming high shrink wrap label sleeves directly from a roll are disclosed herein. A seaming agent is applied to the label, where the trailing edge will overlap the leading edge to form a seam. The seaming agent is then exposed to radiation to cure the seaming agent and form a sleeve. The label comprises a film with at least one external layer that has a Hildebrand solubility parameter, and the seaming agent includes a component having a Hildebrand solubility parameter that is within 2.2 MPa1 / 2 or within 4.4 calories1 / 2·cm−3 / 2 of the Hildebrand solubility parameter of the external layer of the film. The seaming agent also has a viscosity of at least 1 centipoise and less than 1000 centipoise when measured at any temperature between ambient temperature and 60° C.

Owner:POLYSACK FLEXIBLE PACKAGING LTD

Methods for forming high shrink wrap label sleeves

ActiveUS20200087505A1Low VOC emissionImprove compatibilityLabelling machinesLabelling short rigid containersThin membraneEngineering

Methods for forming high shrink wrap label sleeves directly from a roll are disclosed herein. A seaming agent is applied to the label, where the trailing edge will overlap the leading edge to form a seam. The seaming agent is then exposed to radiation to cure the seaming agent and form a sleeve. The label comprises a film with at least one external layer that has a Hildebrand solubility parameter, and the seaming agent includes a component having a Hildebrand solubility parameter that is within 2.2 MPa1 / 2 or within 4.4 calories1 / 2·cm−3 / 2 of the Hildebrand solubility parameter of the external layer of the film. The seaming agent also has a viscosity of at least 1 centipoise and less than 1000 centipoise when measured at any temperature between ambient temperature and 60° C.

Owner:POLYSACK FLEXIBLE PACKAGING LTD

Method for recovering carboxylic acids from dilute aqueous streams

InactiveUS8828231B2Solid sorbent liquid separationWater/sewage treatment bu osmosis/dialysisOrganic acidBoiling point

Improvement in separating lower, C2 saturated and / or C3, and / or C4, saturated and / or unsaturated mono carboxylic acids from aqueous streams via extraction by using as the extractant an organic acid or ester or mixtures thereof with a melting point below 10° C., a normal boiling point between 190 and 280° C. and a Hildebrand solubility parameter between 8 and 11 cal1 / 2 cm−3 / 2.

Owner:ARKEMA INC

Thermosetting resin composition, coating material for precoated metal, cured product, and laminated body

ActiveCN112004890BLow storage stabilityIncreased durabilityLiquid surface applicatorsSynthetic resin layered productsPolymer sciencePtru catalyst

An object of the present invention is to provide a thermosetting resin composition capable of obtaining a cured film excellent in durability and appearance at low temperature and having excellent storage stability. The thermosetting resin composition of the present invention comprises: (A) a resin having a specific hydroxyl group, (B) an alkyl etherified melamine resin, (C) a Lewis acid catalyst comprising a metal having a Pauling electronegativity of 1.31 to 2.02. A cation and a counter anion which is a deprotonated form of a protonic acid whose acid dissociation constant pKa is 1.0 or less, and (D) a solvent, the solvent (D) includes a solvent (D) having a Hildebrand solubility parameter value (SP value) of 18.6 to 47.9 -1), the content of the solvent (D-1) is 21% by mass or more relative to the total amount of the solvent (D), and the solvent (D-1) has a solubility of the Lewis acid catalyst (C) of 0.01% by mass or more The content of (D-S) is 4% by mass or more relative to the total amount of the solvent (D).

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com