Patents

Literature

142results about How to "Low VOC emission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Blocked mercaptosilane hydrolyzates as coupling agents for mineral-filled elastomer compositions

InactiveUS7301042B2Low VOC emissionReduce load levelSilicon organic compoundsGroup 5/15 element organic compoundsElastomerSilica particle

Rubber composition intended for the manufacture of tire casings which have improved hysteretic properties and scorch safety, based on at least one elastomer and silica by way of reinforcing filler enclosing a reinforcing additive consisting of the mixture and / or the product of in situ reaction of at least one functionalized polyorganosiloxane compound containing, per molecule, at least one functional siloxy unit capable of bonding chemically and / or physically to the surface hydroxyl sites of the silica particles and at least one functionalized organosilane compound containing, per molecule, at least one functional group capable of bonding chemically and / or physically to the polyorganosiloxane and / or the hydroxyl sites of the silica particles and at least one other functional group capable of bonding chemically and / or physically to the polymer chains.

Owner:GENERAL ELECTRIC CO

Aqueous fluoric resin and its prepn and application

InactiveCN1362422AGood chemical stabilityGood mechanical stabilityCoatingsVinyl esterPolymer chemistry

The present invention relates to a water fluororesin, its preparation and applicaltion. It is a multicomponent copolymer containing trifluorochloroethylene (A) and aliphatic carboxylic vinyl ester (B), and its composition contans (by weight portion ratio) A:B: water: emulsifying agent: initiator=15-40:10-70:90-160:0.5-8.0:0.1-1.0. Said invented product possesses good chemical stability and mechanical stability, and can be extensively used in the fields of building industry, wooden ware and paper-making industry, etc.

Owner:大连振邦氟涂料股份有限公司

Urethane acrylate composite structure

InactiveUS20050238824A1Low viscosityLow VOC emissionFilm/foil adhesivesSynthetic resin layered productsChemistryComposite structure

A composite structure includes a first layer, a support layer, and a urethane acrylate layer disposed between the first layer and the support layer. The first layer is a show surface of the composite structure. The urethane acrylate layer includes a urethane acrylate composition that includes a urethane acrylate adduct. The urethane acrylate adduct is the reaction product of an isocyanate component and a stoichiometric excess of a functionalized acrylate component. The isocyanate component has at least two isocyanate groups. The functionalized acrylate component has at least one isocyanate-reactive functional group that is reactive with at least one of the isocyanate groups for forming the urethane acrylate adduct. The resulting urethane acrylate composition is sufficiently low in viscosity for many processing applications, and the urethane acrylate layer including the urethane acrylate composition exhibits sufficient adhesion to the first layer and support layer.

Owner:BASF CORP

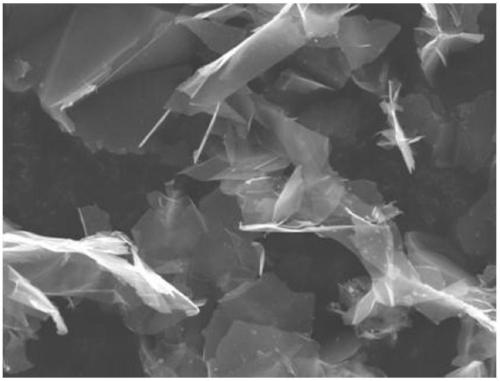

Nano-composite nylon material with spraying-free highlight performance and preparation method thereof

The invention discloses a nano-composite nylon material with a spraying-free highlight performance and a preparation method thereof. The nano-composite nylon material is prepared according to the following steps: 1) mixing caprolactam, water and organic acid; 2) increasing temperature to 180-230 DEG C and reacting for 1-5h; 3) adding modified inorganic nanometer silicate, increasing temperature to 240-280 DEG C and reacting for 1-5h, thereby acquiring a prepolymer; 4) decompressing and polymerizing the prepolymer, thereby acquiring the nano-composite nylon material. A one-step in situ polymerization method is adopted by the invention; the compatibility of modified inorganic nanometer silicate and nylon is improved; the dispersion of the modified inorganic nanometer silicate in a nylon substrate is benefited; pure nylon has excellent mechanical property, thermal performance and spraying-free highlight performance; the nano-composite nylon material is simple in preparation process; the conditions can be easily controlled; the nano-composite nylon material is suitable for industrial production and can be widely applied to the production of the plastic shell products, such as, electric tool shells, automotive upholsteries and household appliances.

Owner:南京跃贝新材料科技有限公司

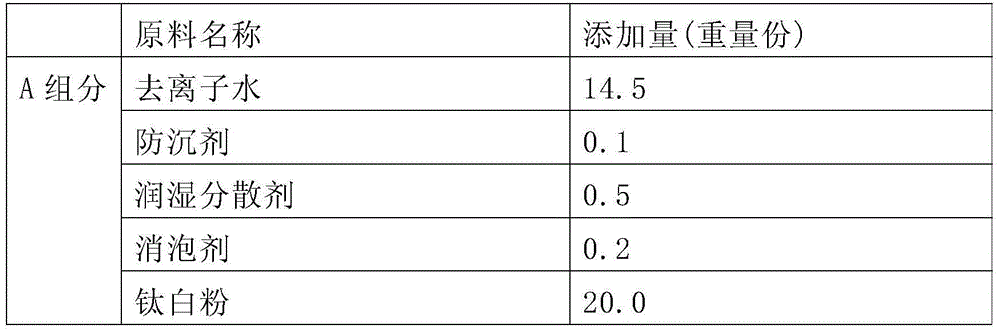

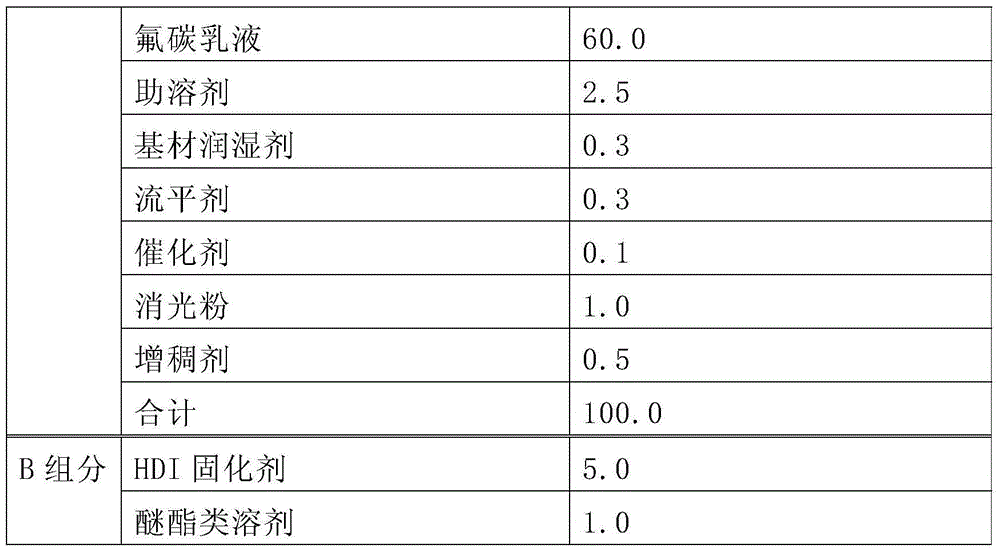

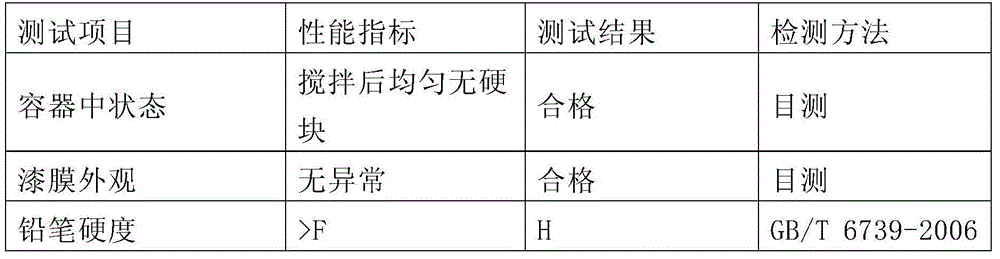

Coated water-based double-component fluorocarbon paint, and preparation and application thereof

ActiveCN104559617AIncrease the degree of cross-linkingStrong adhesionPolyurea/polyurethane coatingsPhotovoltaic energy generationWater basedPolyethylene terephthalate glycol

The invention discloses a coated water-based double-component fluorocarbon paint, and preparation and application thereof. Particularly, the paint comprises a component A and a component B in a mass ratio of (12-25):1. The component A is composed of deionized water, an anti-settling agent, a wetting and dispersing agent, a defoaming agent, a pigment, a water-based fluorocarbon resin, a substrate wetting agent, a leveling agent, a cosolvent, a catalyst, matting powder and a thickener; and the component B is composed of a polyisocyanate curing agent. The paint can be used for preparing a coated PET (polyethylene terephthalate) back panel film.

Owner:ETERNAL CHEM (CHINA) CO LTD

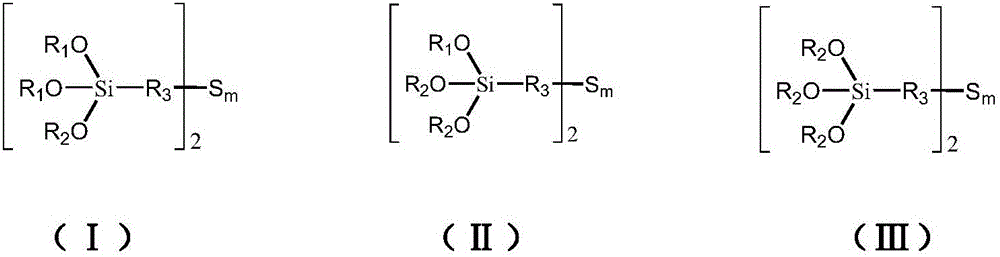

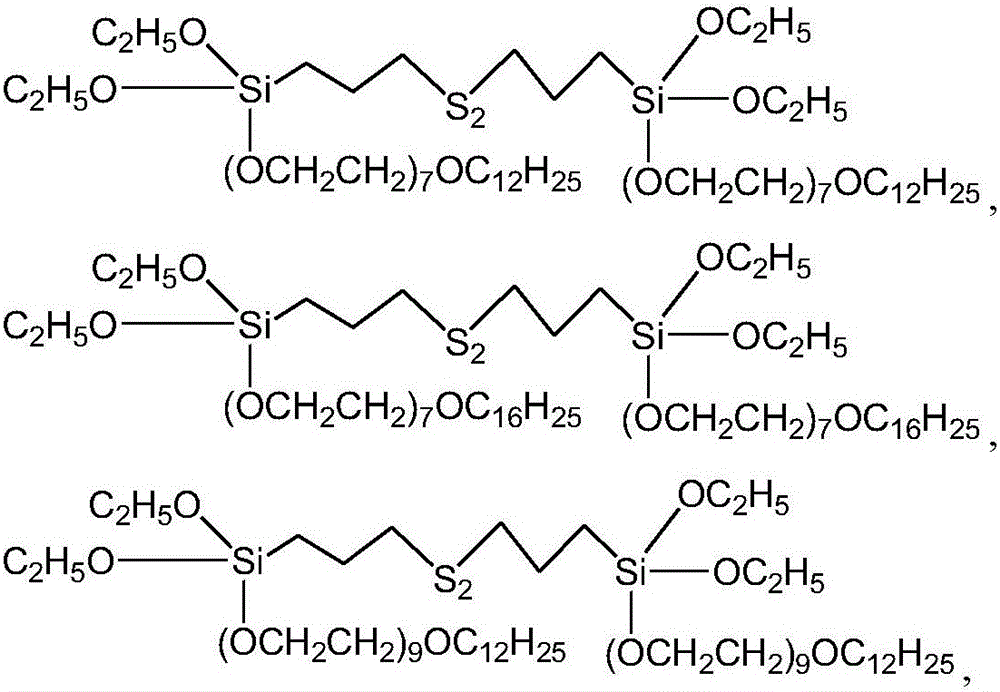

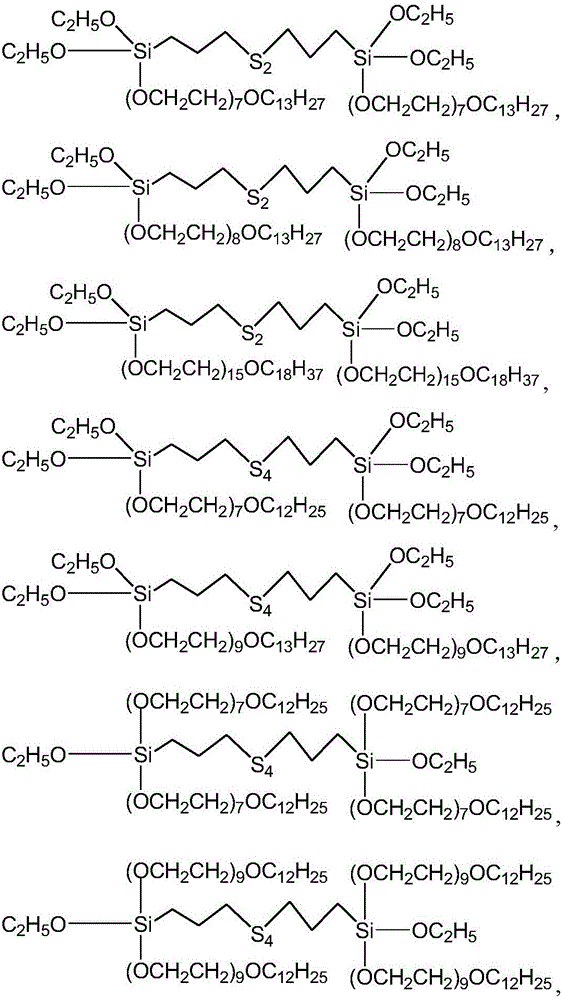

Silane coupling agent containing vinyl ether chain segment, and preparation method and application thereof

InactiveCN106674593AGood dispersionNot easy to burnPigment treatment with organosilicon compoundsVinyl etherAlcohol

The invention discloses a silane coupling agent containing a vinyl ether chain segment, and a preparation method and an application thereof. The silane coupling agent is a novel silane coupling agent. The silane coupling agent is acquired through the catalytic reaction of the traditional coupling agent with a formula (IV) structure and fatty alcohol-polyoxyethylene ether or alicyclic alcohol polyoxyethylene ether. The application of the silane coupling agent disclosed by the invention in preparing a high-performance tread rubber by in situ modifying white carbon black can effectively reduce the VOC discharge in the size mixing process and in the use process of rubber products. The silane coupling agent disclosed by the invention also can be used for modifying the liquid phase of the white carbon black; the wet-process mixing can be realized; the problems of single method for modifying the white carbon black with the traditional silane coupling agent, large energy consumption in the processing process and serious pollution can be effectively solved; and the traditional coupling agent with the formula (IV) structure and the fatty alcohol-polyoxyethylene ether in low cost are taken as the synthesis raw materials, so that the use cost of the coupling agent is lowered.

Owner:BEIJING UNIV OF CHEM TECH +1

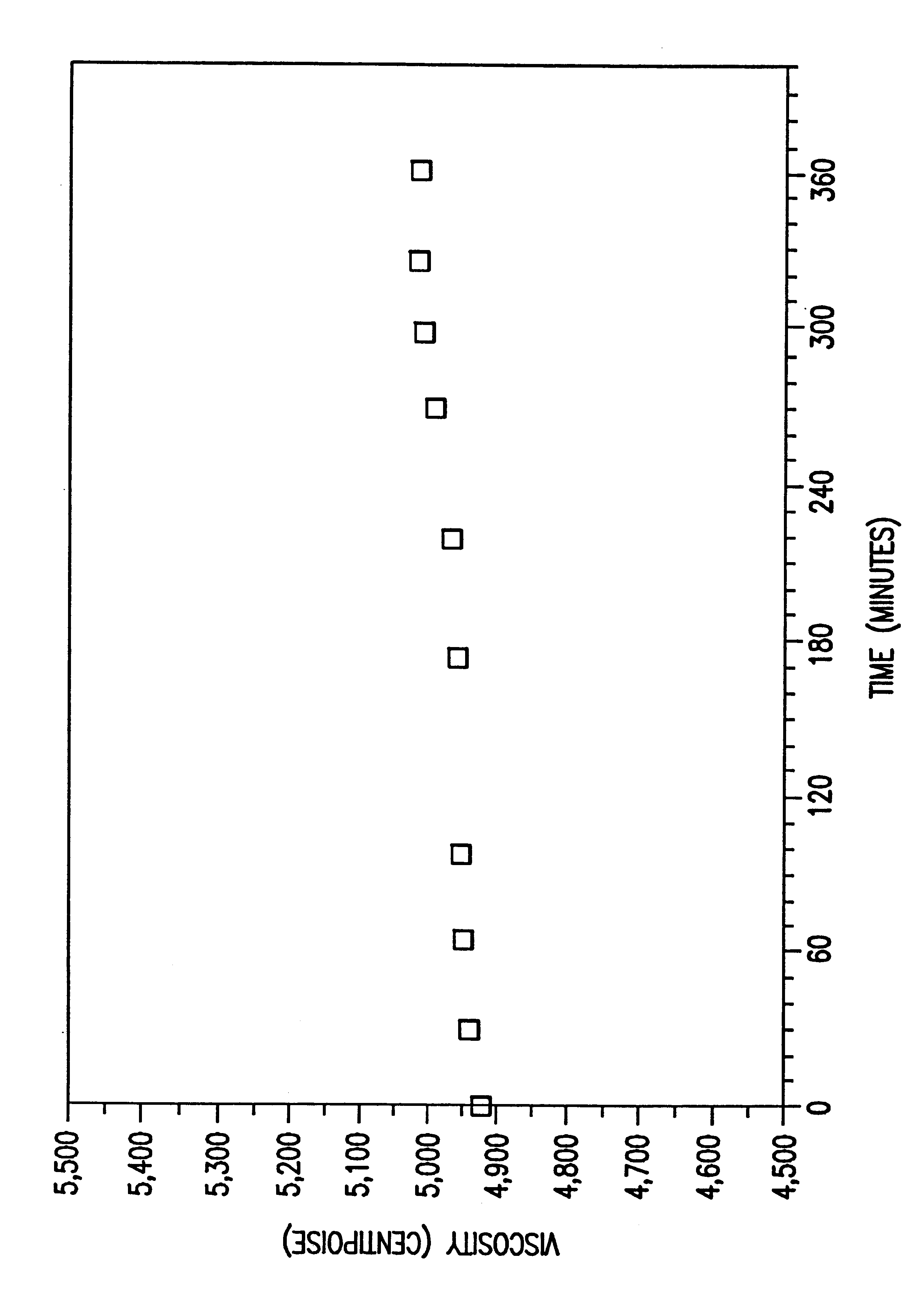

Urethane acrylate composition structure

InactiveUS20050238884A1Low viscosityBalanced reaction profilePolyureas/polyurethane adhesivesSynthetic resin layered productsUrethane acrylateAdduct

A composite structure includes a first layer and a support layer. The first layer is a show surface of the composite structure and is preformed from a polymer. The support layer includes a urethane acrylate composition that includes a urethane acrylate adduct. The urethane acrylate adduct is the reaction product of an isocyanate component and a stoichiometric excess of a functionalized acrylate component. The isocyanate component has at least two isocyanate groups. The functionalized acrylate component has at least one isocyanate-reactive functional group that is reactive with at least one of the isocyanate groups for forming the urethane acrylate adduct. The urethane acrylate composition also includes a catalyst system including a peroxide and a first metal salt. The resulting urethane acrylate composition is sufficiently low in viscosity for many processing applications, and the support layer including the urethane acrylate composition exhibits sufficient adhesion to the first layer.

Owner:BASF CORP

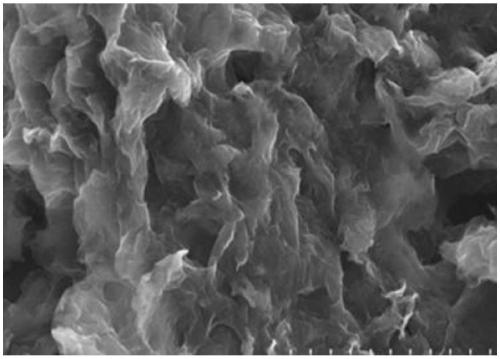

Waterborne graphene anticorrosive paint

InactiveCN109468017AGreatly reduce costsLow costAnti-corrosive paintsEpoxy resin coatingsEpoxyAdhesive

The invention discloses a waterborne graphene anticorrosive paint. A waterborne epoxy resin and a waterborne epoxy curing agent are used as adhesives, the emission of VOC (volatile organic compounds)of the paint is greatly reduced, and the waterborne graphene anticorrosive paint is environmentally friendly. An adopted waterborne graphene anticorrosive slurry has the advantages of easiness in dispersion, high stability, and even distribution of sheet diameter, meanwhile, water is used as a dispersing medium, and the process is simple and reliable, is low in cost, and is suitable for large-scale industrial production; after the graphene is added into the anticorrosive paint, an electron is rapidly transferred to a zinc powder through graphene when a corrosive medium enters a coating, the graphene and the zinc powder react to form a dense zinc oxide protection layer, and the contact between a substrate and the corrosive medium is further isolated. The graphene is of a sheet structure, particularly a quite thin sheet structure, and the anticorrosive paint doped with the graphene has a quite excellent physical isolating effect; by adding the graphene into the anticorrosive paint, the environment pollution caused by the zinc powder is reduced, and the cost of the paint is reduced while the physical mechanical property of the coating is strengthened.

Owner:HUNAN XIANGXIAN TECH

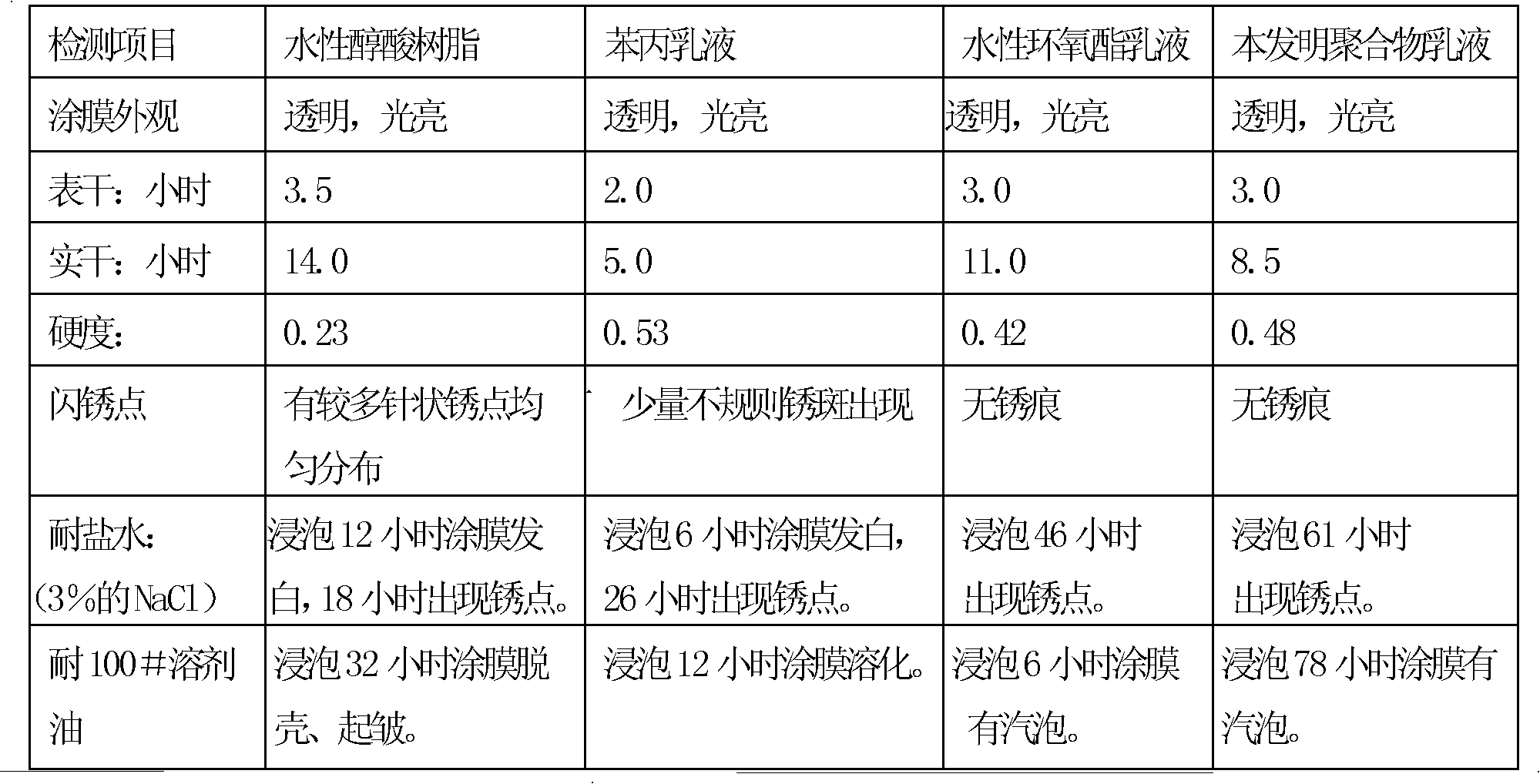

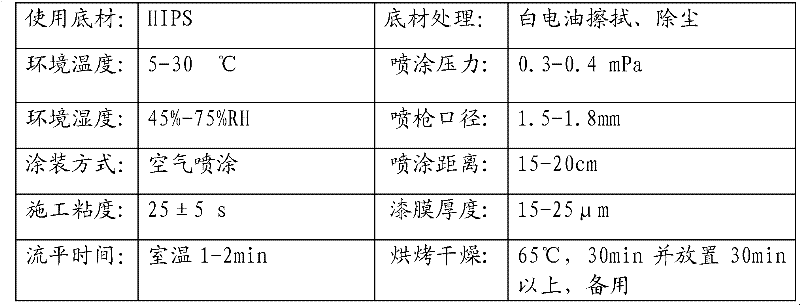

Waterborne single-component thermoplastic plastic paint and production method and construction method thereof

ActiveCN102146243AAvoid long-term contactReduce pollutionCoatingsSpecial surfacesPolymethyl methacrylatePolycarbonate

The invention provides waterborne single-component thermoplastic plastic paint and a production method and construction method thereof. The plastic paint is suitable for the coating of plastic cabinet prepared from ABS (Acrylonitrile Butadiene Styrene), PS (poly styrene), HIPS (High Impact Polystyrene), PC (polycarbonate), PMMA (polymethyl methacrylate) and the like, has good adaptability to the surface of the material and also has good adhesive force, thus the adhesive force problem of the waterborne paint on the plastic substrate can be solved. A waterborne system is adopted for the paint mainly adopts, the production and using processes are safe; and water is used as diluent, and the paint has the advantages of low toxicity, low pollution, extremely low volatile organic compound (VOC) emission and the like and meets various laws and regulations on environmental protection. Meanwhile, the paint can use different color pastes for coloring; and the paint has better decorative propertyon the substrate while the properties can not be affected. Compared with the common solvent thermoplastic acrylic paint, the paint only uses a small amount of low-toxicity alcohol ether type organic solvent, thus the influence on the plastic substrate is extremely small; and the paint film has bright colour, full appearance effect and good performances.

Owner:深圳市嘉卓成科技发展有限公司

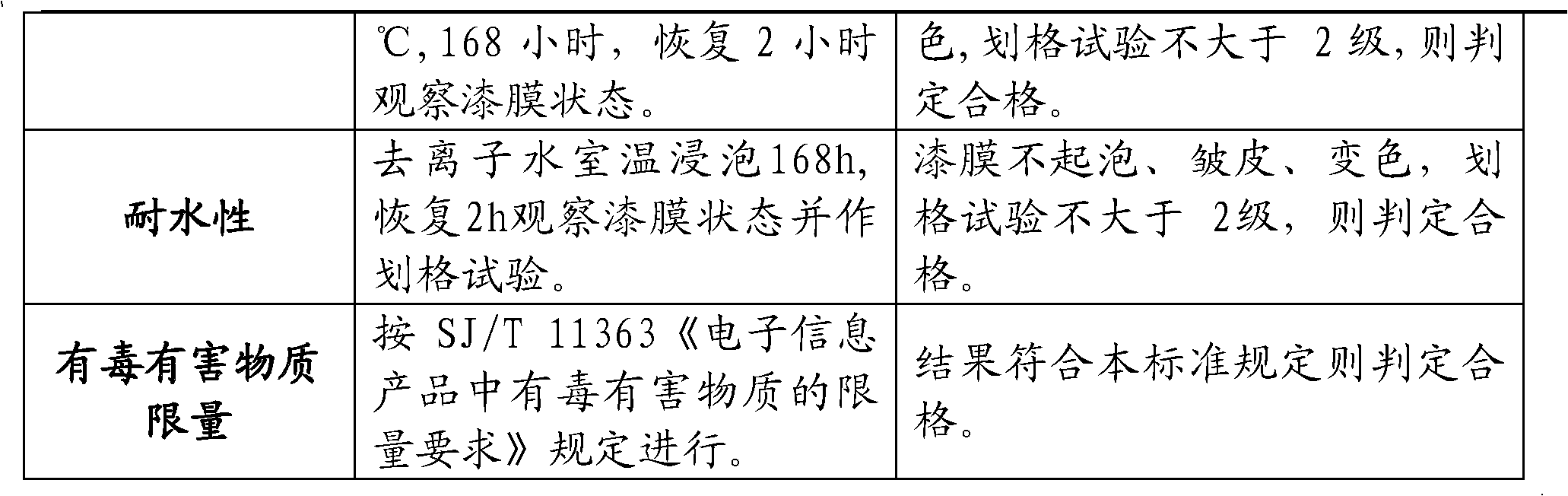

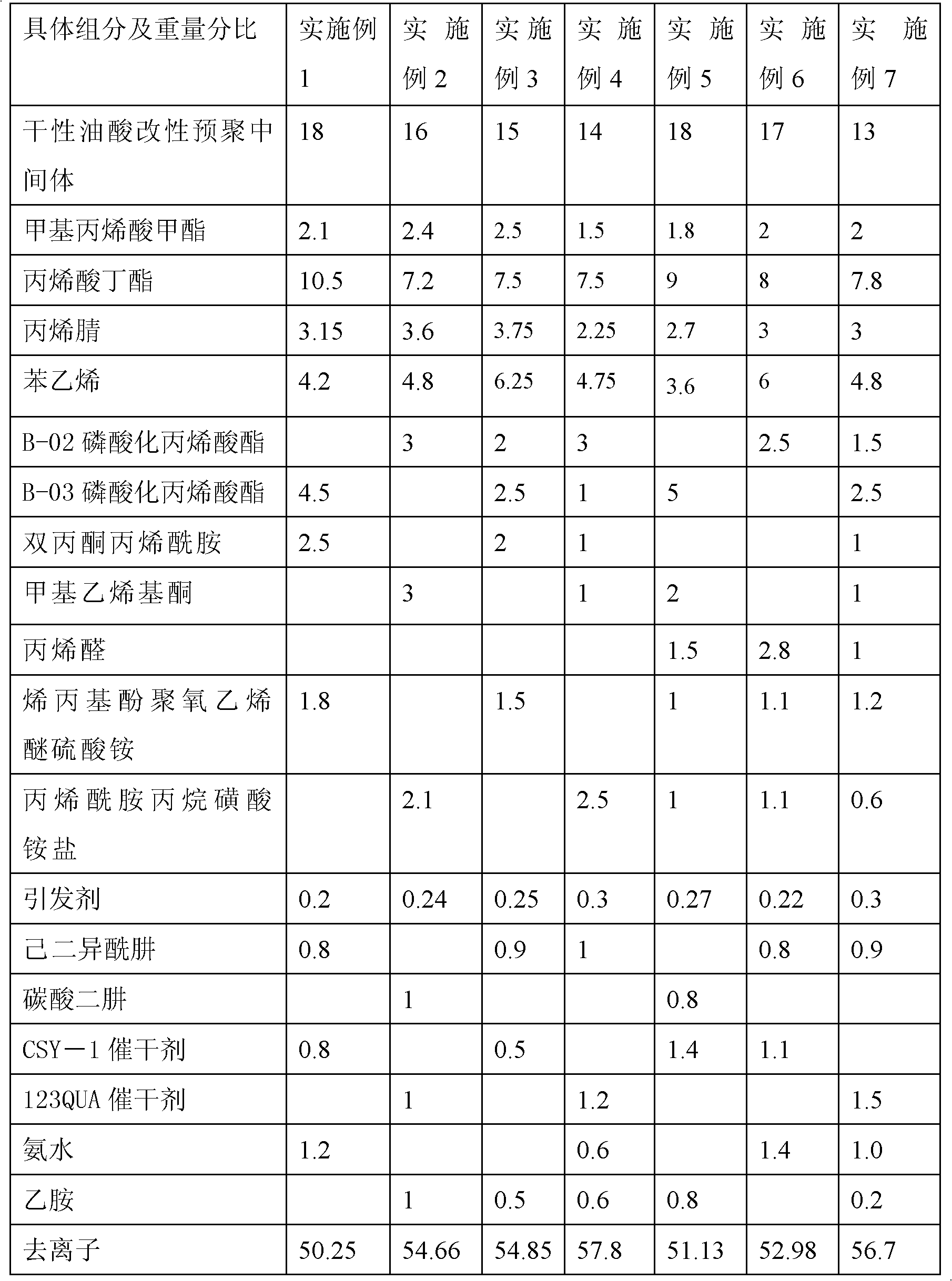

Polymer emulsion for waterborne metal anticorrosive coating and preparation method of polymer emulsion

ActiveCN102432743AHigh densityImprove salt water resistanceAnti-corrosive paintsFunctional monomerPolymer science

The invention relates to a polymer emulsion for a waterborne metal anticorrosive coating and a preparation method of the polymer emulsion. The polymer emulsion consists of the following raw materials in percentage by mass: 13.0-18.0% of drying oleic acid modified prepolymerized intermediates, 16.0-20.0% of acrylic monomers, 2.0-3.0% of functional monomers containing keto carbonyl groups, 2.5-5.0% of modified acrylic monomers, 1.5-2.5% of reactive emulsifier, 0.2-0.3% of initiator, 0.8-1.0% of compounds containing hydrazine groups, 0.5-1.5% of waterborne drier, 0.5-1.2% of volatile alkali and the balance deionized water. A soap-free emulsion polymerization process is adopted in the invention, the condensation of the keto carbonyl groups and the hydrazine groups and the oxidation polymerization, crosslinking and solidification reaction of double unsaturated bonds are generated in the filming process through introducing the keto carbonyl groups and the double unsaturated bonds on a molecular chain of waterborne polymer emulsion, so that a coating has the functions such as favorable saline water resistance, solvent resistance, rust prevention and the like.

Owner:CHANGZHOU GUANGHUI CHEM

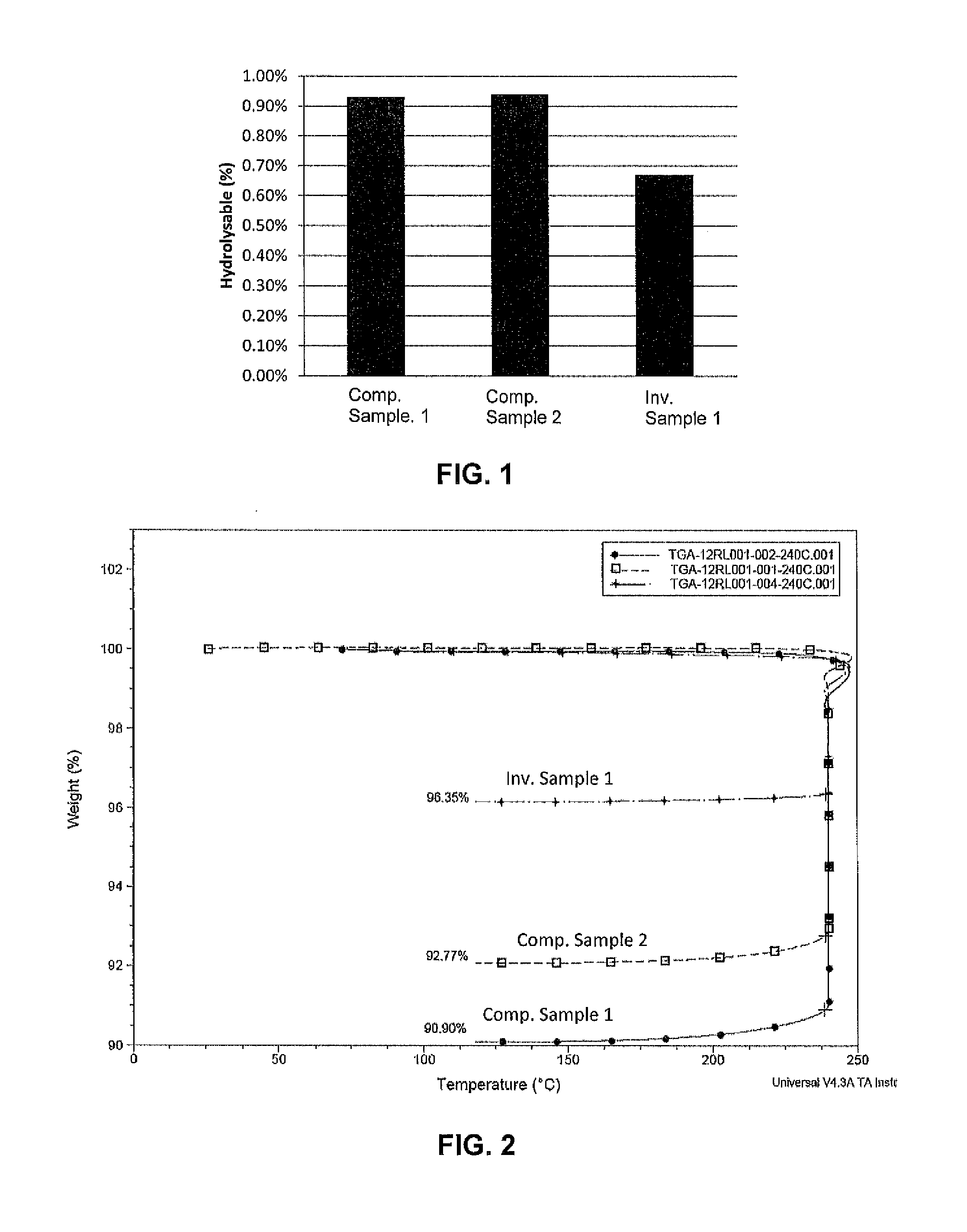

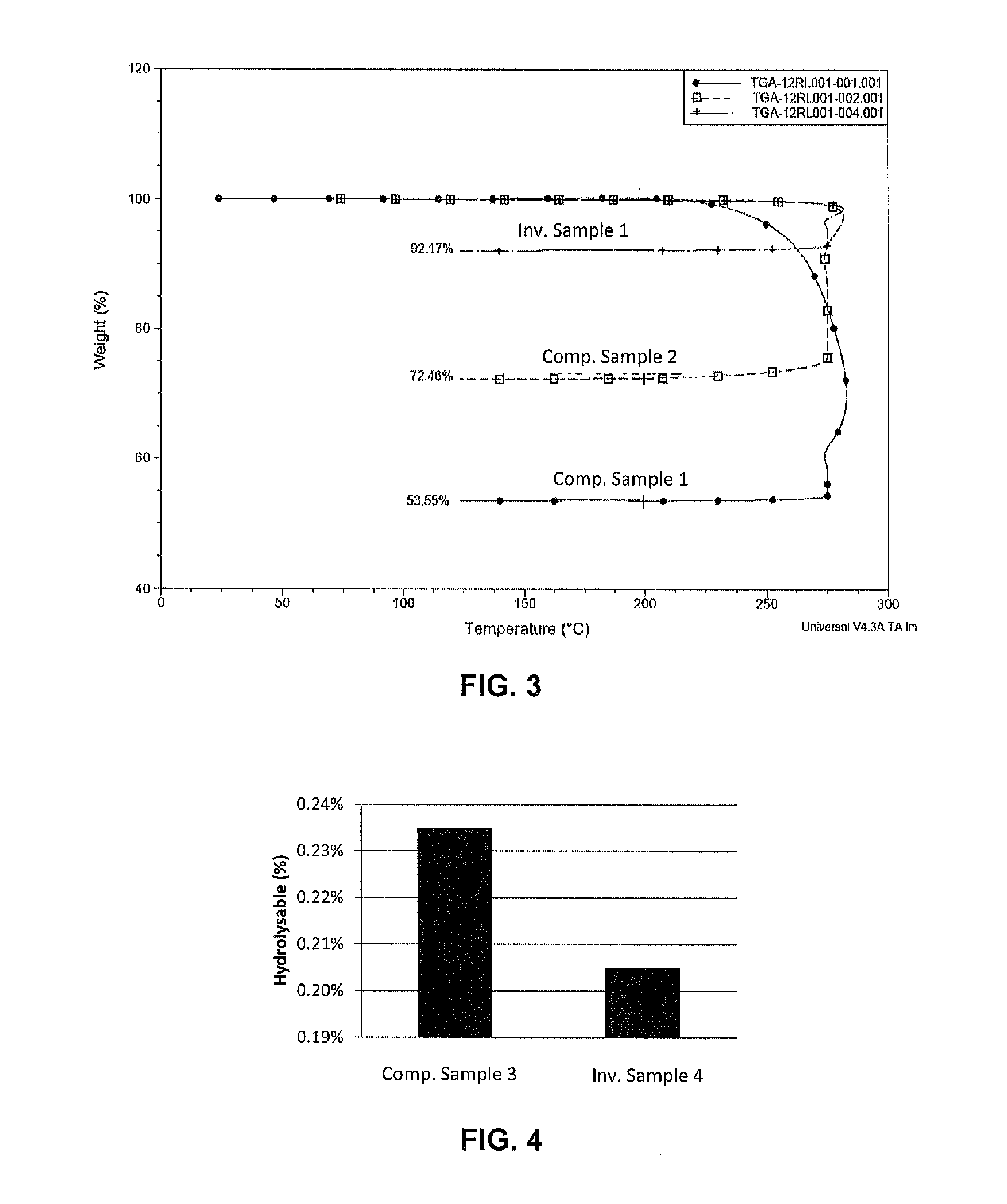

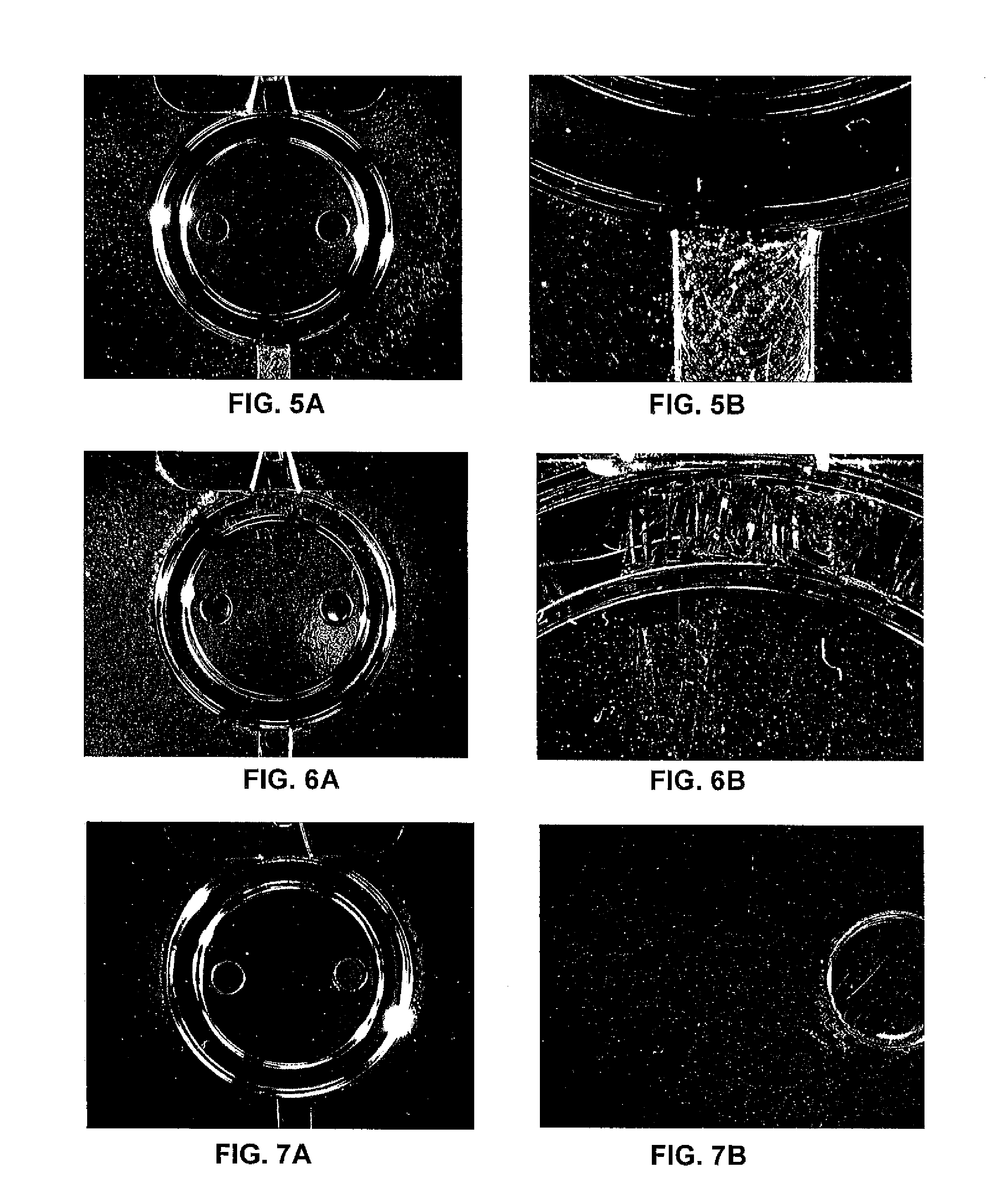

Low Emission Polyoxymethylene

Low VOC emission polyoxymethylene and compositions and products that incorporate the polyoxymethylene are described. The polyoxymethylene is end capped with compound that can prevent degradation of the polymer and subsequent emission of VOC degradation products such as formaldehyde. The end-capped polyoxymethylene can include an inorganic linkage within the polymer backbone that is the reaction product of a terminal hydroxyl group of the polyoxymethylene and a hydrolyzable group of the compound. Also disclosed are products as may be formed from the low VOC emission polyoxymethylene.

Owner:TICONA LLC

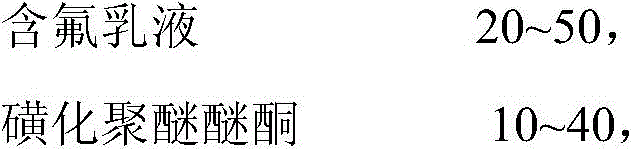

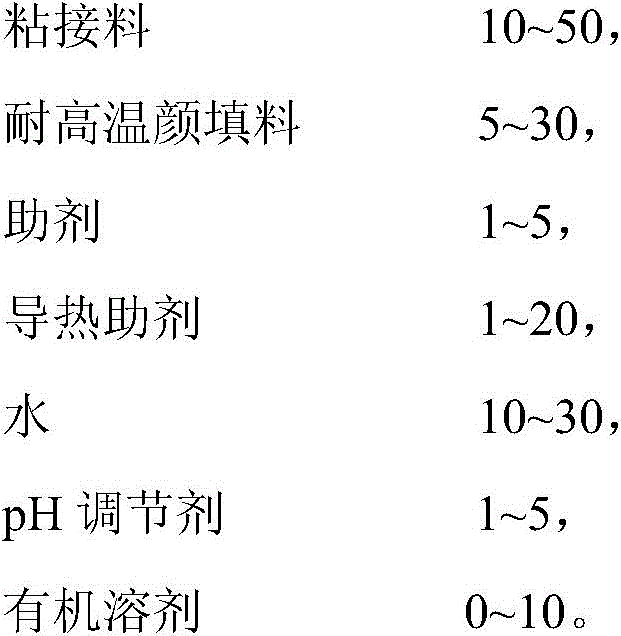

Nonstick coating with high heat conductivity and high wear resistance

ActiveCN105585911AHigh mechanical strengthHigh thermal conductivityCoatingsEnvironmental resistanceHigh resistance

The invention relates to the technical field of nonstick coatings, aims to solve the problems that a film breaks, food is scorched and the service life of the coating is greatly shortened due to heat gathering points easily caused by poorer heat distribution of non-stick pans taking a stainless steel pot and an iron pot as substrates and provides a nonstick coating with high heat conductivity and high wear resistance. The film formed by the coating has excellent mechanical strength, higher heat conductivity and also has the characteristics of low VOC emission, environmental protection and absence of toxicity.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

High build polyurethane coating

InactiveUS6274639B1Reliable and goodLow VOC emissionPolyurea/polyurethane coatingsPolyolSpray nozzle

Owner:LOCKHEED MARTIN CORP

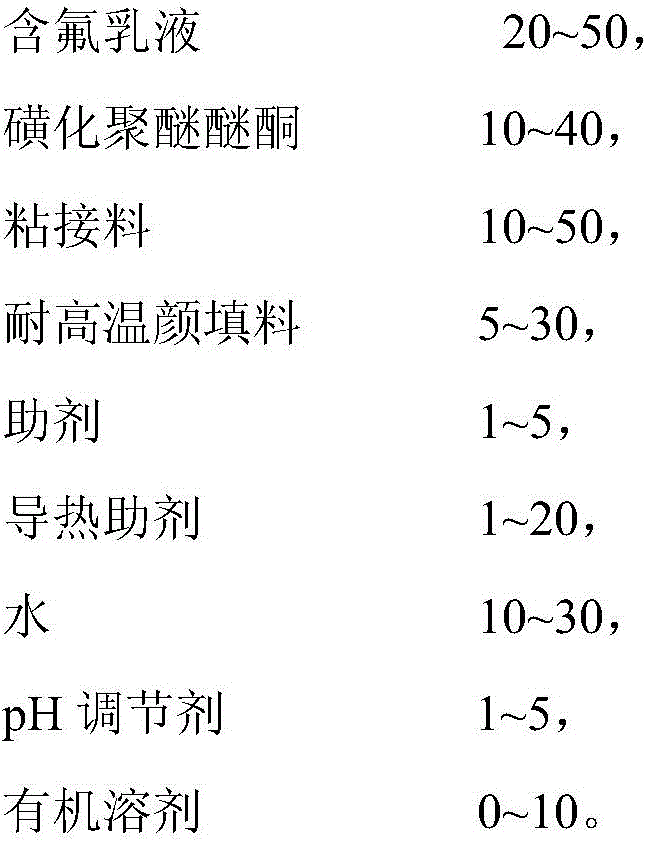

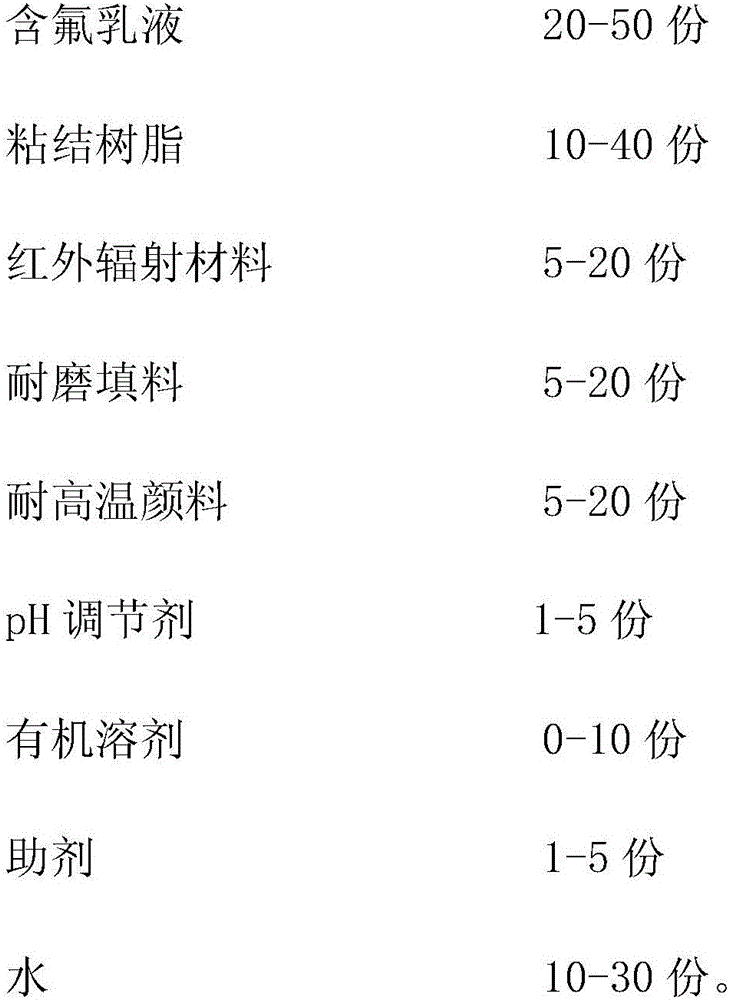

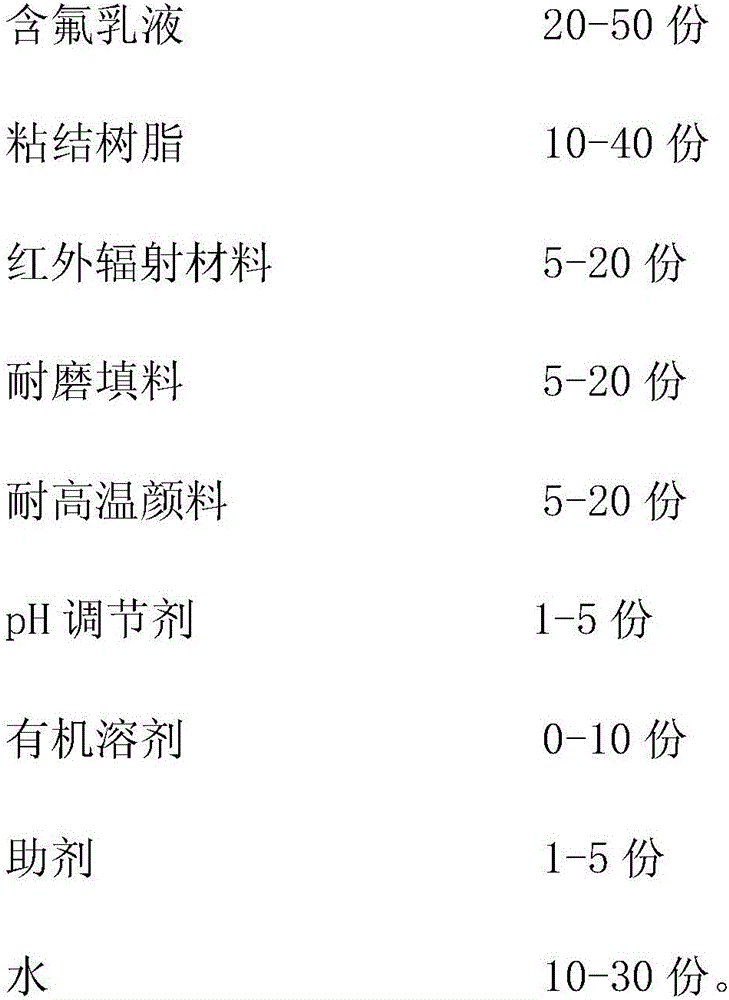

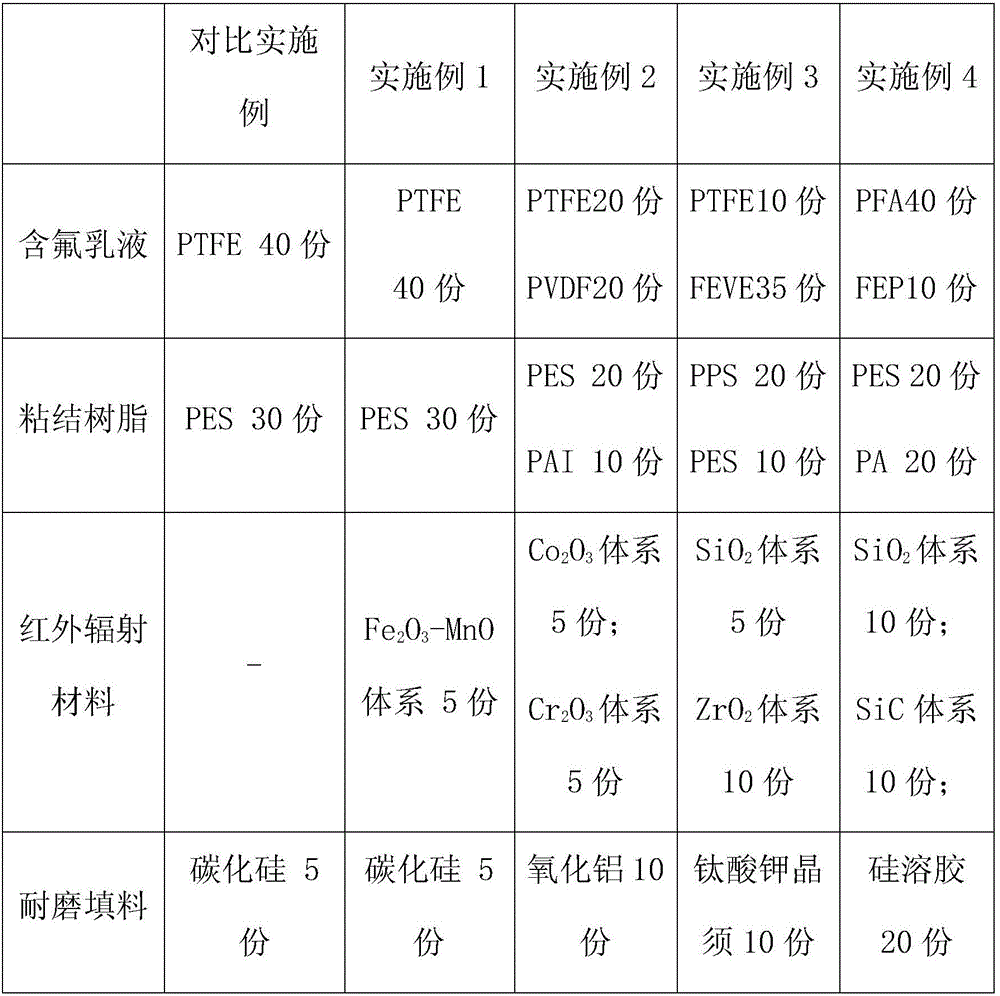

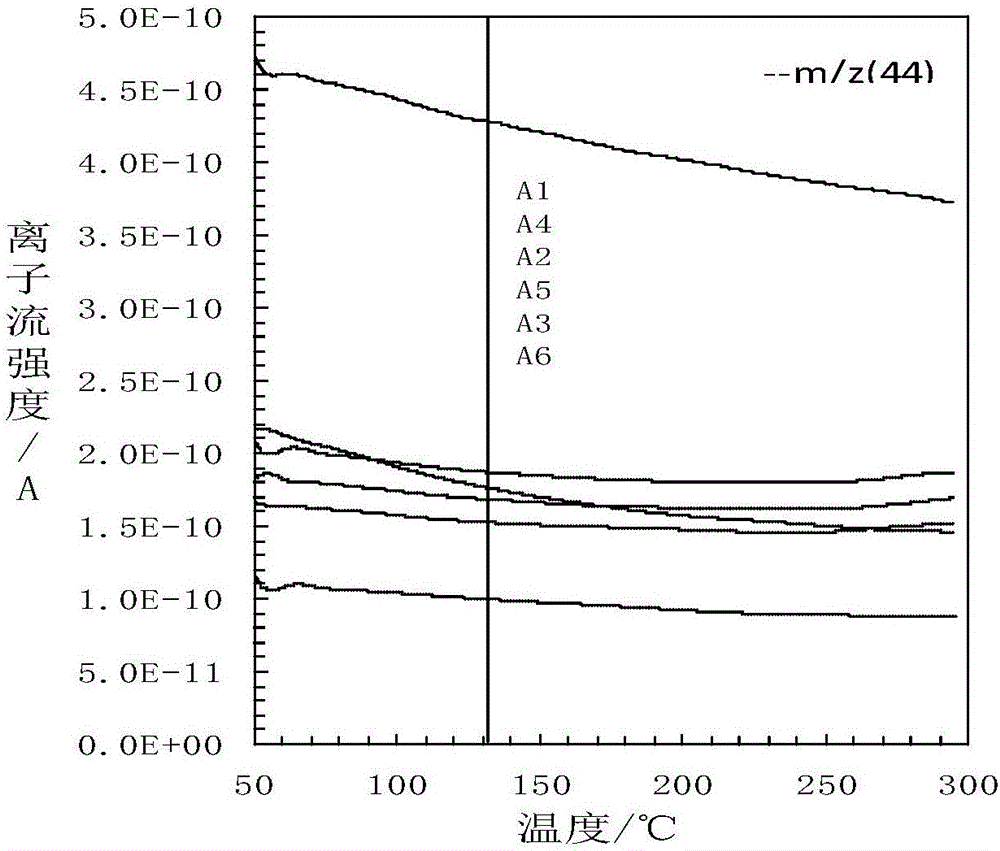

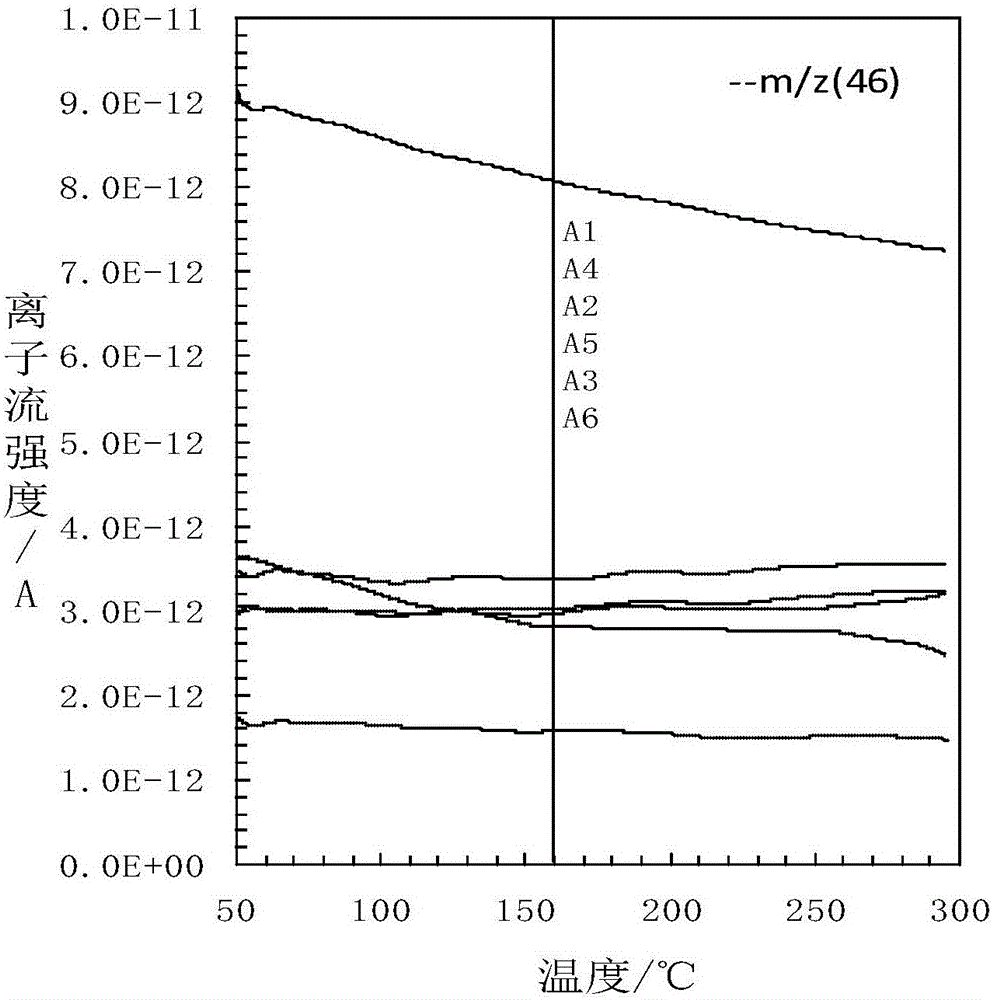

Infrared-radiation heat-dissipation water-based wear-resistant non-stick paint and preparation method thereof

ActiveCN106189562AHigh mechanical strengthImprove infrared radiation ratePolyamide coatingsMulticolor effect coatingsWater basedOrganic solvent

The invention discloses infrared-radiation heat-dissipation water-based wear-resistant non-stick paint and a preparation method thereof. The non-stick paint comprises the following components in parts by weight: 20-50 parts of fluorine-containing emulsion, 10-40 parts of bonding resin, 5-20 parts of an infrared radiation material, 5-20 parts of a wear-resistant filler, 5-20 parts of high-temperature-resistant pigment, 1-5 parts of a pH regulator, 0-10 parts of an organic solvent, 1-5 parts of an auxiliary agent and 10-30 parts of water. The non-stick paint provided by the invention is increased greatly in the heat-radiation efficiency of the non-stick paint by adding the heat-dissipation filler with high infrared radiation rate, so that; the heat generated at the bottom is effectively dissipated in the form of infrared radiation, the heat-dissipation performance of the paint is improved and heat is rapidly transferred out.

Owner:HANGZHOU JIHUA POLYMER MATERIAL CO LTD

Asphalt volatile organic compound composite inhibitor, smoke-restraining asphalt, manufacturing method of asphalt volatile organic compound composite inhibitor and manufacturing method of smoke-restraining asphalt

InactiveCN105778531AReduce releasePrevent volatilizationBuilding insulationsActivated carbonGas release

The invention relates to the technical field of restraining of an asphalt volatile organic compound, in particular to an asphalt volatile organic compound composite inhibitor, smoke-restraining asphalt, a manufacturing method of the asphalt volatile organic compound composite inhibitor and a manufacturing method of the smoke-restraining asphalt. The composite inhibitor is prepared from the following components in parts by weight: 3-7 parts of an SBS modifying agent, 1.5-5 parts of activated carbon, and 1.5-6 parts of magnalium-based layered double-hydroxyl composite metal hydroxide. The smoke-restraining asphalt is prepared from the following components in parts by weight: 87-90 parts of substrate asphalt, 4-5 parts of an SBS modifying agent, 2-4 parts of activated carbon, and 2-4 parts of magnalium-based layered double-hydroxyl composite metal hydroxide. The manufacturing method of the smoke-restraining asphalt comprises the following steps: heating the substrate asphalt to 150-170 DEG C and performing stirring in a heat insulating manner; in the stirring process, sequentially adding the SBS modifying agent, the activated carbon and the magnalium-based layered double-hydroxyl composite metal hydroxide to the substrate asphalt; after performing stirring, performing cutting. The asphalt in which the composite inhibitor is added is better in gas released effect than the smoke-retraining asphalt modified by other inhibitors, so that VOC release amount of the asphalt is greatly reduced.

Owner:CHINA GEZHOUBA GROUP CO LTD

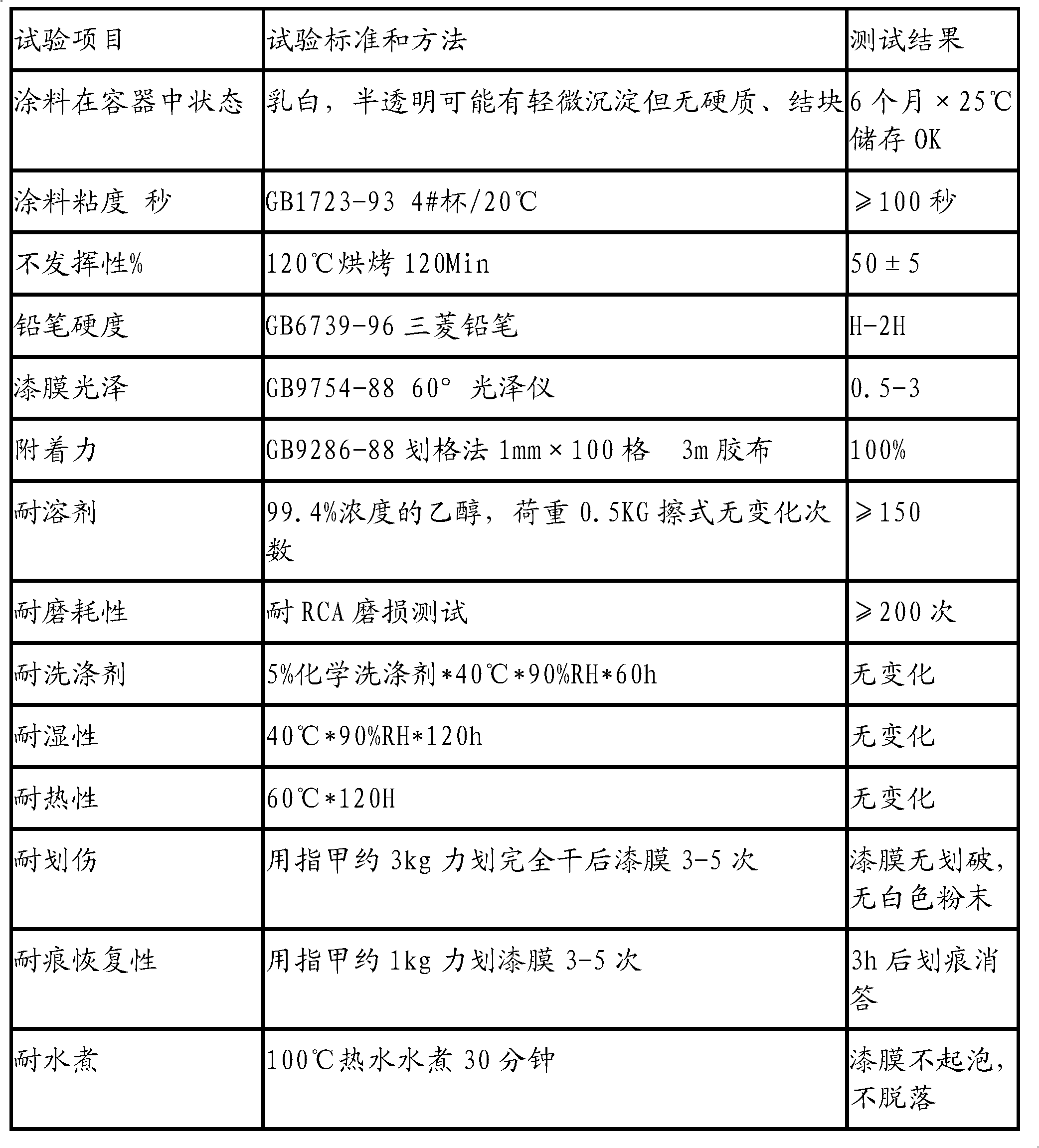

High-wear-resistance self-recovery rubber-feel plastic paint, and production and construction methods thereof

InactiveCN102146258ABeautiful appearanceIncrease elasticityPolyurea/polyurethane coatingsSpecial surfacesEpoxySelf recovery

The invention provides a high-wear-resistance self-recovery rubber-feel plastic paint which comprises a main agent, a diluter and a curing agent, wherein the main agent comprises the following components in parts by weight: 15-17.5 parts of double-component polyurethane resin A, 15-17.5 parts of double-component polyurethane resin B, 5-10 parts of 10% drying agent solution, 6-7.5 parts of matting powder, 0.5-1 part of leveling agent, 0-2 parts of epoxy modified polysiloxane, 15-20 parts of ethyl acetate, 15-20 parts of butyl acetate and 10-15 parts of phenylmethane. The invention also provides a preparation method and construction method of the paint. The paint is applicable to coating cabinets made from plastics, such as ABS (acrylonitrile-butadiene-styrene), ABS+PC (polycarbonate), HIPS (high impact polystyrene) and the like. The paint has a favorable rubber feel, and also has high RCA resistance in common rubber paint. The paint can be widely used for coating interior decorative plastic parts of 3C (Computers / Communications / Consumer electronics) products and automobiles, has favorable appearance effect and touch effect, has the characteristics of low toxicity, low pollution and lower VOC (volatile organic compound) emission, and conforms to the international environmental-protection requirements.

Owner:深圳市嘉卓成科技发展有限公司

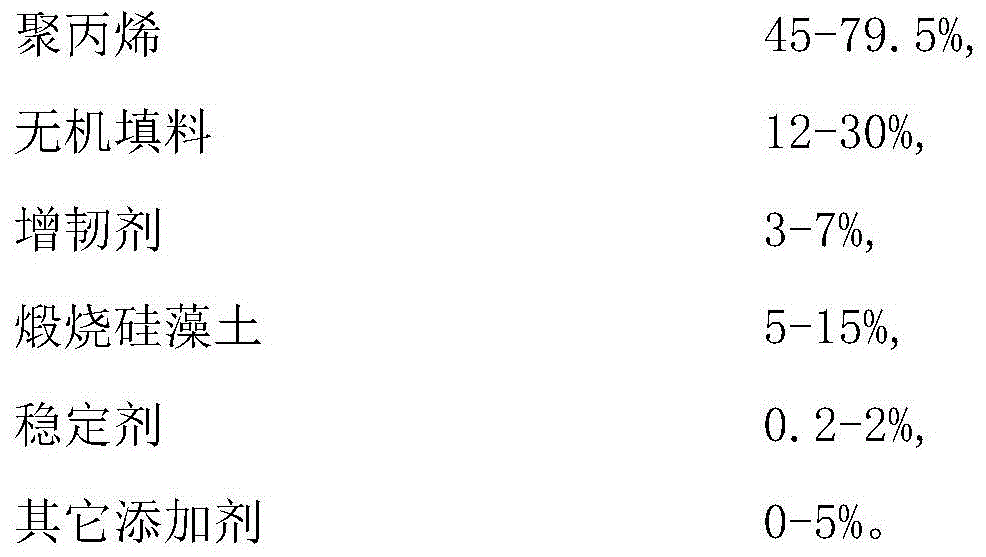

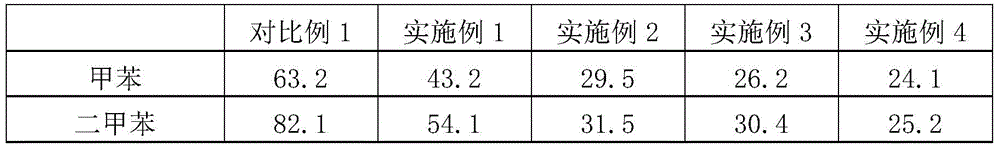

Low-VOC polypropylene composite material and preparation method thereof

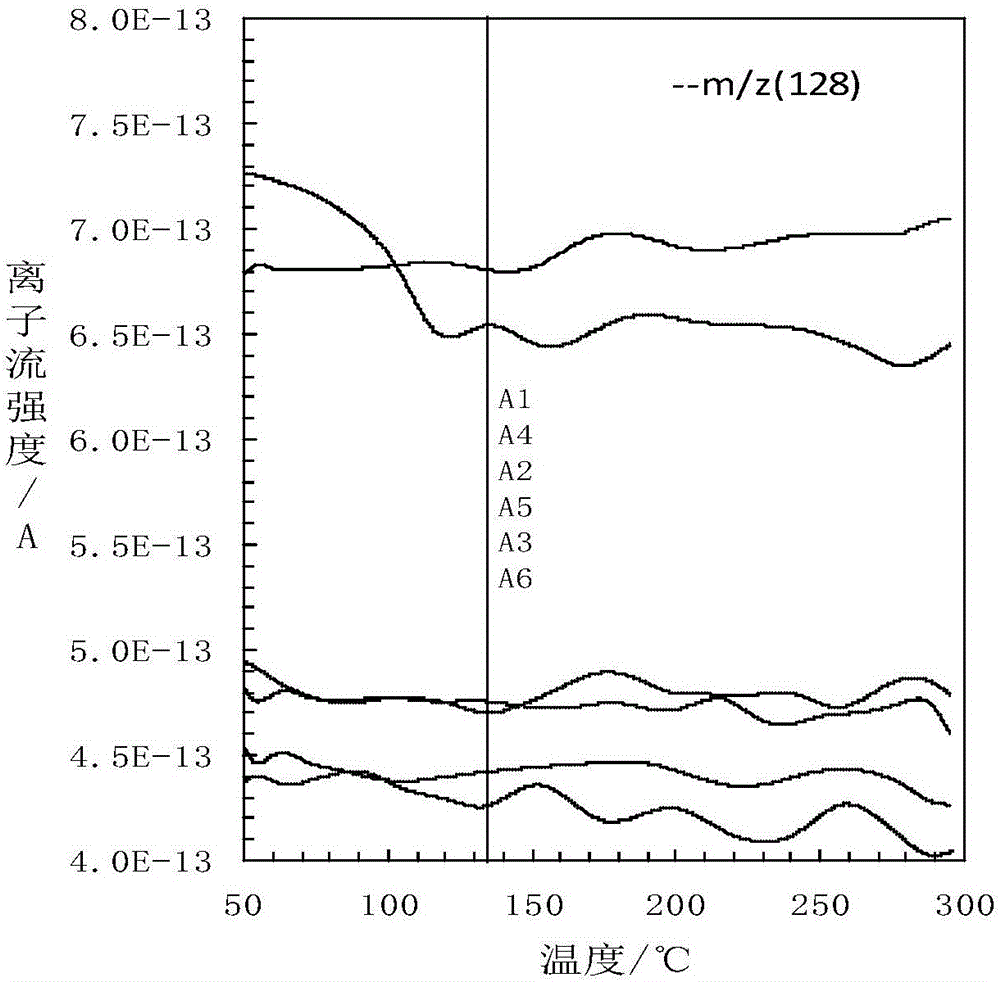

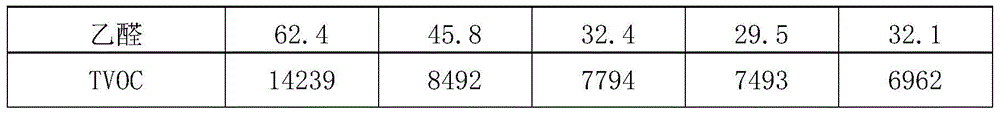

The invention discloses a low-VOC polypropylene composite material and a preparation method thereof. The low-VOC polypropylene composite material comprises the following raw materials by weight: 45 to 79.5% of polypropylene, 12 to 30% of an inorganic filling material, 3 to 7% of a flexibilizer, 5 to 15% of calcined diatomite, 0.2 to 2% of a stabilizing agent and 0 to 5% of other additives. The invention has the advantages that 1, since the calcined diatomite is used as a VOC adsorbent of the polypropylene composite material, emission of VOCs can be greatly reduced, and the preparation method is simple and can easily realize batch production; and 2, compared with other molecular-sieve synthetic adsorbents, the calcined diatomite is greatly reduced in cost and good in adsorption effect.

Owner:SHANGHAI PRET COMPOSITES

Organic silicone modified acrylate emulsion and preparation method thereof

InactiveCN105199040AImproved water resistance and stabilityLow VOC emissionDyeing processIonEmulsion

The invention relates to organic silicone modified acrylate emulsion and a preparation method thereof. The organic silicone modified acrylate emulsion is synthesized through a hard monomer, a soft monomer, a cross-linking monomer, an organic silicone monomer and a reactive emulsification monomer under the action of an initiator at one time; the preparation method comprises the following steps: dissolving the initiator into deionized water; uniformly mixing the hard monomer, the soft monomer, the cross-linking monomer and the organic silicone monomer in a premixing tank; adding an emulsifier and deionized water into a four-mouth flask to be heated to 70-90 DEG C, slowly dropwise adding the uniformly-mixed monomer mixed phase and 90% of an initiator solution for 1-3 h at the temperature of 70-90 DEG C and the rotating speed of 200-400 r / min, carrying out heat preservation for 1-3 h at the temperature of 70-90 DEG C after dropping, meanwhile, dropwise adding 10% of the residual initiator solution, and adding ammonia water for adjusting the PH to 6-8 after cooling to 50 DEG C or below. The migration of the emulsifier in a latex film is avoided through application of the reactive emulsifier and the defects of hot sticking and cold shortness of the pure acrylic resin are overcome through organic silicone modification.

Owner:WUYI UNIV

Formulations and method for raising the flash points of volatile organic solvents

ActiveUS8092715B2Not volatileLow virgin flash pointOther chemical processesOrganic compound preparationOrganic solventAlcohol

A terpene alcohol premix formulation raises the flash point of a volatile organic solvent to a level that results in a solvent solution that is less volatile. The catalytic formulation consists of a blend of two or more terpene alcohols and acetone. The blended terpene alcohols are present in the catalytic formulation in an amount of from about 5% to about 40%, by weight, based on the total weight of the terpene alcohol premix formulation. The remainder of the terpene alcohol premix formulation consists of from about 60% to about 95% acetone, by weight, based on the total weight of the terpene alcohol premix formulation.

Owner:GREENSOLVE

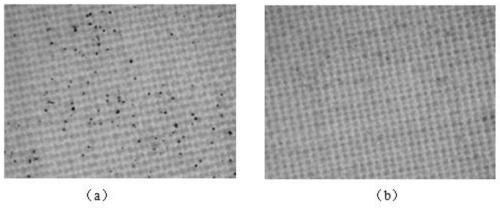

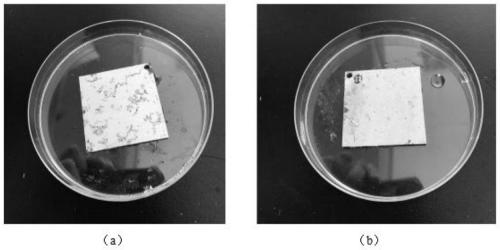

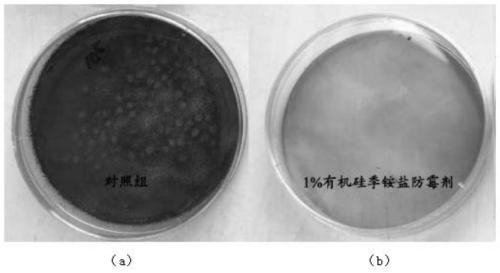

Long-acting antibacterial mildew inhibitor, preparation method thereof, and application of long-acting antibacterial mildew inhibitor in space station environment

ActiveCN111109283AImprove securityLess prone to drug resistanceBiocideFungicidesPropylene glycolAnti bacterial

The invention relates to the technical field of antibacterial mildew inhibitors, and provides a long-acting antibacterial mildew inhibitor, a preparation method thereof, and an application of the long-acting antibacterial mildew inhibitor in a space station environment. The long-acting antibacterial mildew inhibitor takes an organosilicon quaternary ammonium salt as a main sterilization component,can inhibit bacteria, saccharomycetes and fungi for a long time, is high in safety, and has no acute toxicity or accumulated toxicity hidden danger; the antibacterial mildew inhibitor has long-actingantibacterial and mildew-proof performance, and bacteria and mildew do not easily generate drug resistance; no color change hidden danger or toxic component exists, and long-term storage can be achieved; and furthermore, propylene glycol and the like are used as stabilizers, so the VOC release amount can be reduced, and the situation that toxic gas such as methyl alcohol volatilizes in the special environment of the space station and affects the health of astronauts is avoided. The long-acting antibacterial mildew inhibitor can meet the long-acting antibacterial and mildew-proof requirementsof aluminum alloy and textiles in a space station cabin, the VOC release amount of the product is low, and the air quality requirement of the space station is met.

Owner:SHENZHOUSPACEBIOTECHGRP

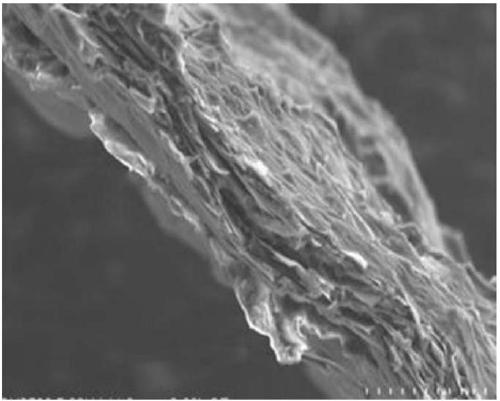

Graphene anticorrosive paint with ultrastrong anticorrosive capability

InactiveCN107603419AReduce supporting coatingLow VOC emissionAnti-corrosive paintsEpoxy resin coatingsSolventCvd graphene

The invention discloses a graphene anticorrosive paint with ultrastrong anticorrosive capability. The graphene anticorrosive paint is formed by mixing a paint A and a paint B; the paint A comprises the following main ingredients in percentage by weight: 10-50% of epoxy resin, 0.5-3% of graphene, 10-20% of fluorophosphate, 30-60% of pigments and fillers, 0.1-3% of auxiliaries, and 8-20% of solvent,and the paint B comprises the following main ingredients in percentage by weight:10-100% of amine curing agent, and 0-90% of solvent; the paint A and the paint B are respectively packaged, and the mixing ratio is prepared according to the construction demand. The graphene anticorrosive paint has ultrastrong anti-neutral salt spray performance, and single paint film can resist neutral salt spray for more than 1500h; the ultrastrong anticorrosive performance can be achieved after being matched with two layers of finish paint for coating, the anticorrosive effect achieved by coating three layersof the traditional anticorrosive paint can be achieved only by coating two layers of paint films; the paint reduces the mating coatings, and the emission of VOC can be decreased; and after being coated on a base material with the steel structure surface treatment grade being Sa2.5, the adhesion force of the paint film is up to 10MPa or above, thus meeting the coating construction requirements ofvarious steel structures.

Owner:CHONGQING SANXIA PAINTS CO LTD

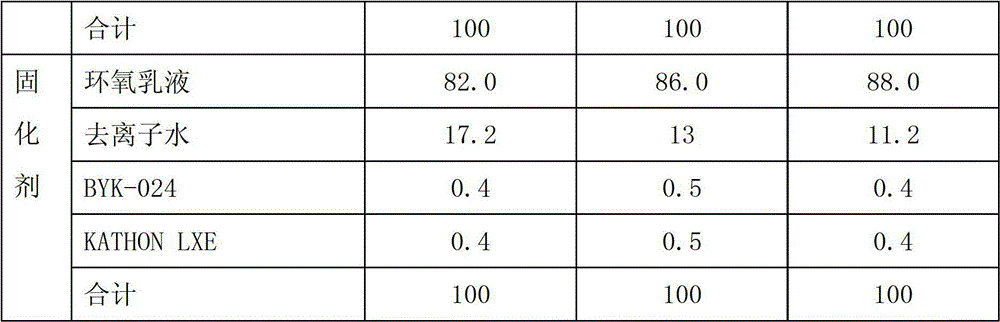

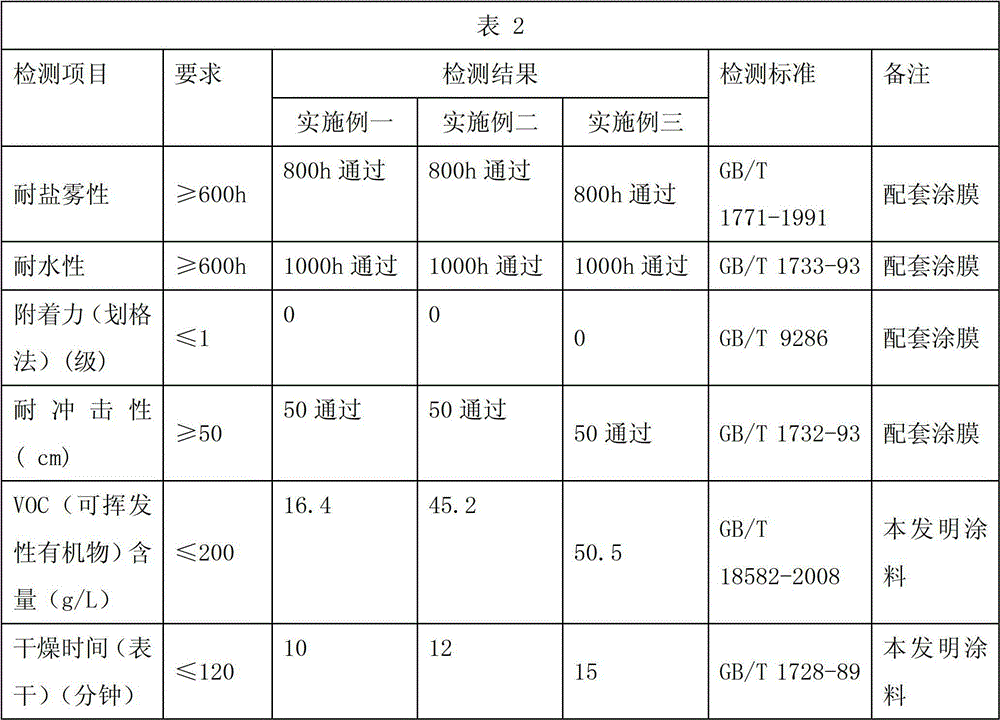

Waterborne epoxy coating for containers and preparation method of waterborne epoxy coating

ActiveCN102876194AImprove the protective effectLow VOC emissionsAnti-corrosive paintsEpoxy resin coatingsEpoxyLacquer

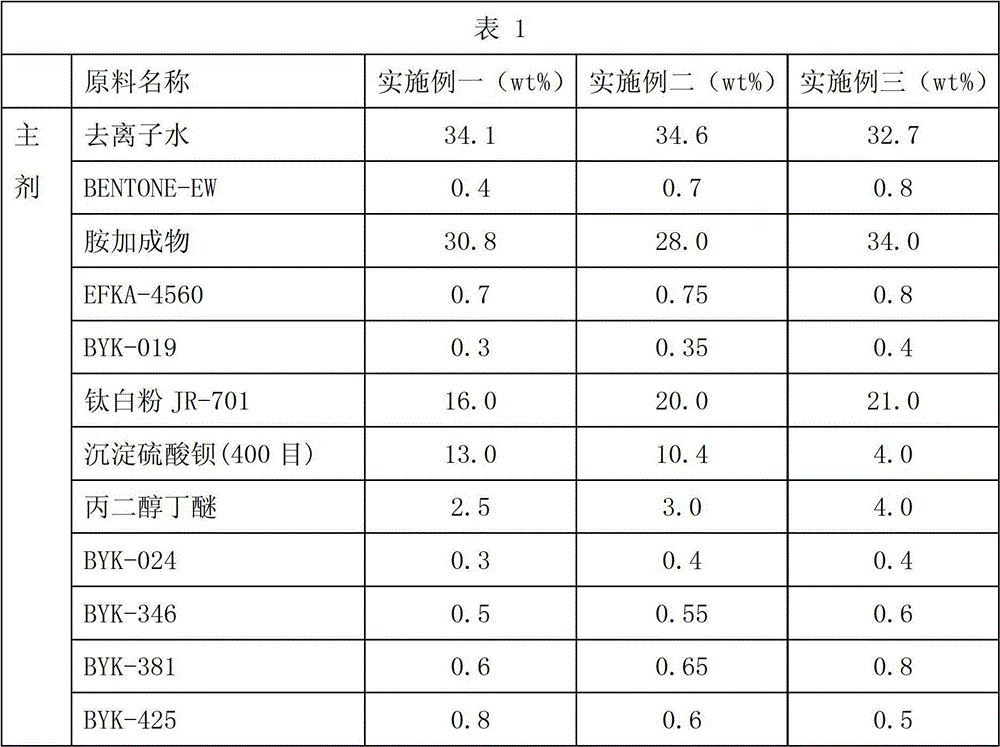

The invention discloses a waterborne epoxy coating for containers and a preparation method of the waterborne epoxy coating. The waterborne epoxy coating comprises a host and a curing agent according to a mass ratio of 2.3:1. The host comprises deionized water, anti-settling agents, amine adduct, wetting dispersants, first defoamers, pigment, packing, coalescing agents, second defoamers, base wetting agents, flatting agents and thickeners. The curing agent comprises epoxy emulsion, deionized water, second defoamers and in-can preservatives. The preparation method of the waterborne epoxy coating for containers includes steps of (1), preparation of the host; (2), preparation of the curing agent; and (3), blending the host with the curing agent according to the mass ratio of 2.3:1. The coating has low volatile organic content (smaller than 60g / L) and high environment-friendly property, the coating can be dried at a high speed (namely the surface drying time is lower than 20 minutes at the room temperature), and requirements of high production efficiency of a container production line can be met completely.

Owner:COSCO KANSAI PAINT & CHEM TIANJIN +2

Water-based acrylic sealant for automobiles and preparation method thereof

InactiveCN104327768AGood infillGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater basedWeather resistance

The invention discloses a water-based acrylic sealant for automobiles and a preparation method thereof. The sealant comprises a water-based acrylic acid emulsion, a filler, a dispersing agent, a thickener, a high-efficiency thixotropic agent, a bactericide and a defoamer. The method comprises the following steps: dispersing the water-based acrylic acid emulsion, filler and dispersing agent in a high-speed dispersion machine at the rate of 1200 rpm for 20-30 minutes; adding the thickener, and dispersing at the rate of 1000 rpm for 1-1.5 hours; and finally, adding the high-efficiency thixotropic agent, bactericide and defoamer, and dispersing at the rate of 1000 rpm for 20 minutes to obtain the uniformly dispersed water-based acrylic sealant for automobiles. The sealant has the advantages of favorable stopping property, favorable squeezing constructability, favorable weather resistance, favorable wear resistance, favorable storage stability and the like, has excellent sealability after being cured, can keep permanent sealing of the automobile body, has ultralow VOC (volatile organic compound) discharge amount especially in the coating curing process, and thus, is green and environment-friendly.

Owner:三友(天津)高分子技术有限公司

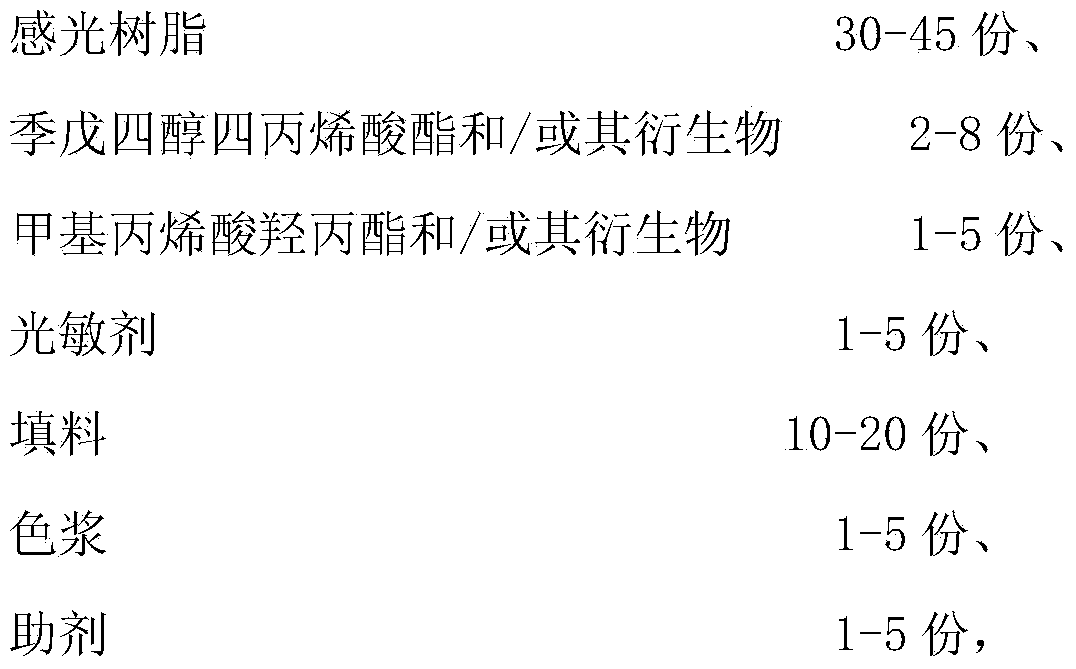

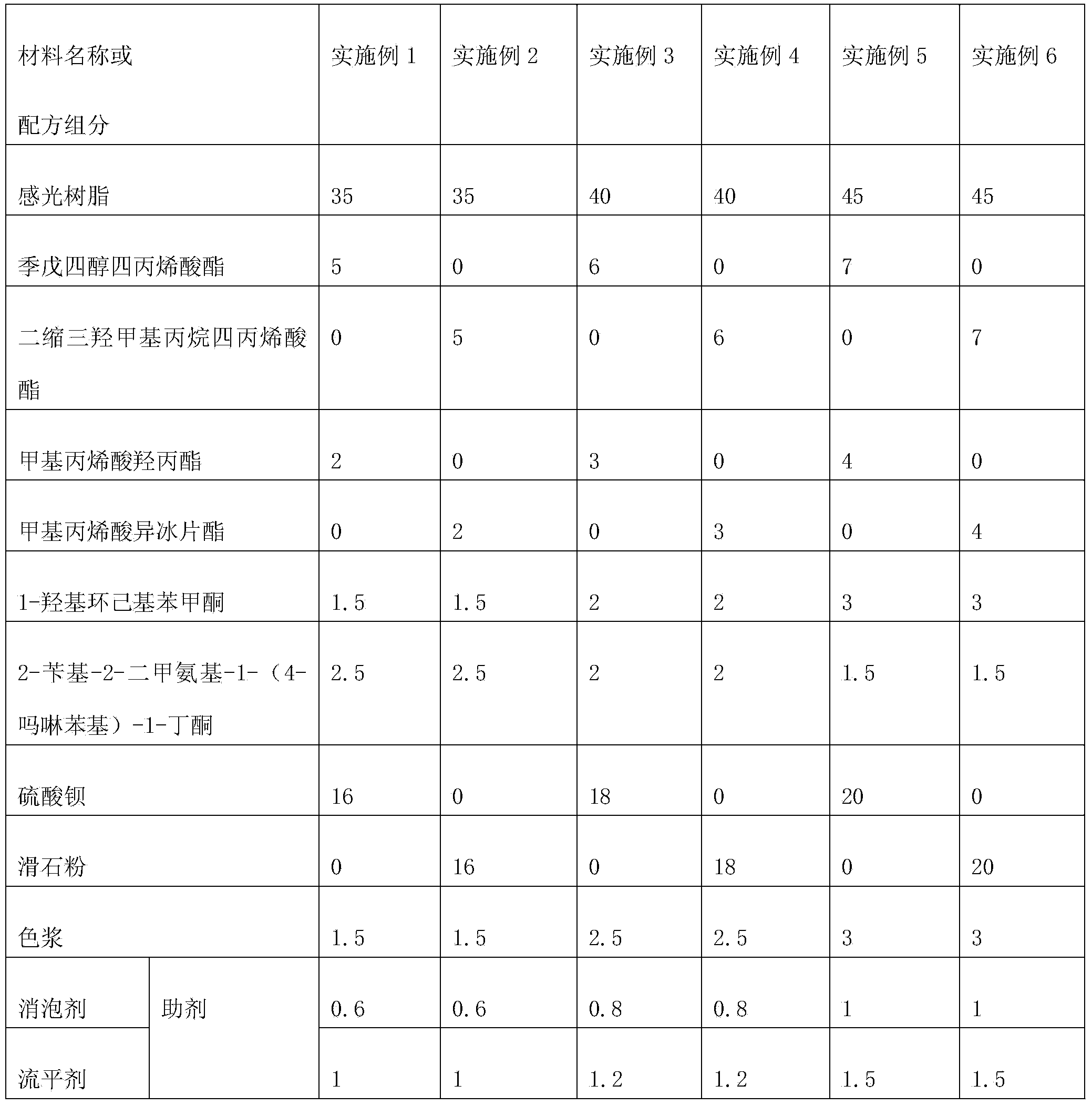

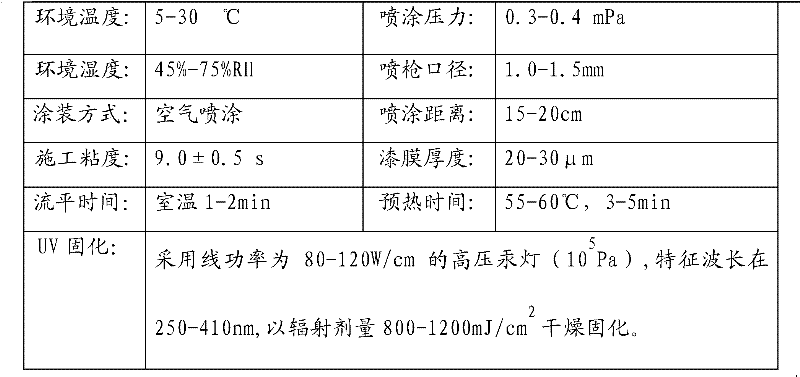

Ultraviolet-curing solder resist ink and preparation method thereof

The invention discloses a preparation method of ultraviolet-curing solder resist ink. The ultraviolet-curing solder resist ink is composed of 30-45 parts of photosensitive resin, 2-8 parts of pentaerythritol acrylate and / or derivative thereof, 1-5 parts of hydroxypropyl methacrylate and / or derivative thereof, 1-5 parts of photosensitizer, 10-20 parts of filler, 1-5 parts of colour paste and 1-5 parts of auxiliaries. After grinding, viscosity of the ink is low, the ultraviolet-curing solder resist ink is applicable to being printed on a single sided board of a printed circuit board plant, and the effects of beautifying appearance and protecting circuits are realized; meanwhile, the ultraviolet-curing solder resist ink has excellent smoothness property, insulativity and high heat resisting property after ultraviolet-curing is carried out.

Owner:江门市阪桥电子材料有限公司

Emulsion Composition and Vehicle and Ink Compositions and Printing Process and Method Thereof

InactiveUS20080241389A1Low VOC emissionReduce the temperatureOther chemical processesFilm/foil adhesivesBoiling pointPrinting ink

An emulsion composition comprises water, a hydrocarbon distillate having a boiling point of 215 to 325° C., and a surfactant having a hydrophilic lipophilic balance number of 10 or less. A vehicle composition, an ink composition, a lithographic printing process and a method to improve a lithographic printing process comprise the emulsion composition which when used in a lithographic printing ink can reduce emission of volatile organic compounds and reduce the time at start-up to establish print quality.

Owner:LUBRIZOL ADVANCED MATERIALS INC

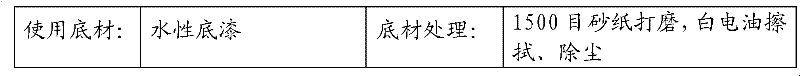

One-component waterborne thermoplastic coating matched with UV-radiation curing coating as well as production method and construction method thereof

InactiveCN102181211AReduce pollutionAvoid long-term contactPretreated surfacesCoatingsThermoplasticDiluent

The invention provides a one-component waterborne thermoplastic coating. The coating is applicable to coating ABS (acrylonitrile-butadiene-styrene), PS (polystyrene), HIPS (high impact polystyrene), PC (polycarbonate), PMMA (polymethyl methacrylate) and other types of plastic enclosures; and the coating has the advantages of good adaptability to material surfaces, good substrate adhesive force and good interlayer adhesive force, and solves difficulties such as adhesive force of the waterborne coating on the plastic substrate and a plurality of shrink holes on a UV-radiation curing finish paint matched with the waterborne coating. The coating mainly adopts a waterborne system and is safe for production and application; the coating takes water as a diluent, thus having the advantages of low toxicity, low pollution, extremely low emission of VOCs (volatile organic compounds) and the like and complying with various environmental protection laws and regulations; and meanwhile the coating can be colored with different color paste, thus providing better decorative property for the substrate without affecting the original performance. The invention further provides a production method and a construction method of the product; and the production method and the construction method are simple and convenient, and the adopted production and construction equipment is convenient to wash.

Owner:深圳市嘉卓成科技发展有限公司

High build polyurethane coating

An improved durable, low density, high build polyurethane coating is disclosed, as well as its method of manufacture. A slow reacting polyisocyanate is combined with a polyol so as to form a uniform mixture with an extremely long pot life. The low viscosity uniform mixture can then be sprayed onto a substrate using a conventional spray gun. A polyurethane catalyst is introduced after formation of the uniform mixture, preferably via a second spray nozzle so that catalyst is externally mixed into the polyisocyanate / polyol spray stream. This is a 100%, or near 100%, solids system so that there is very low volatile organic compound emissions.

Owner:LOCKHEED MARTIN CORP

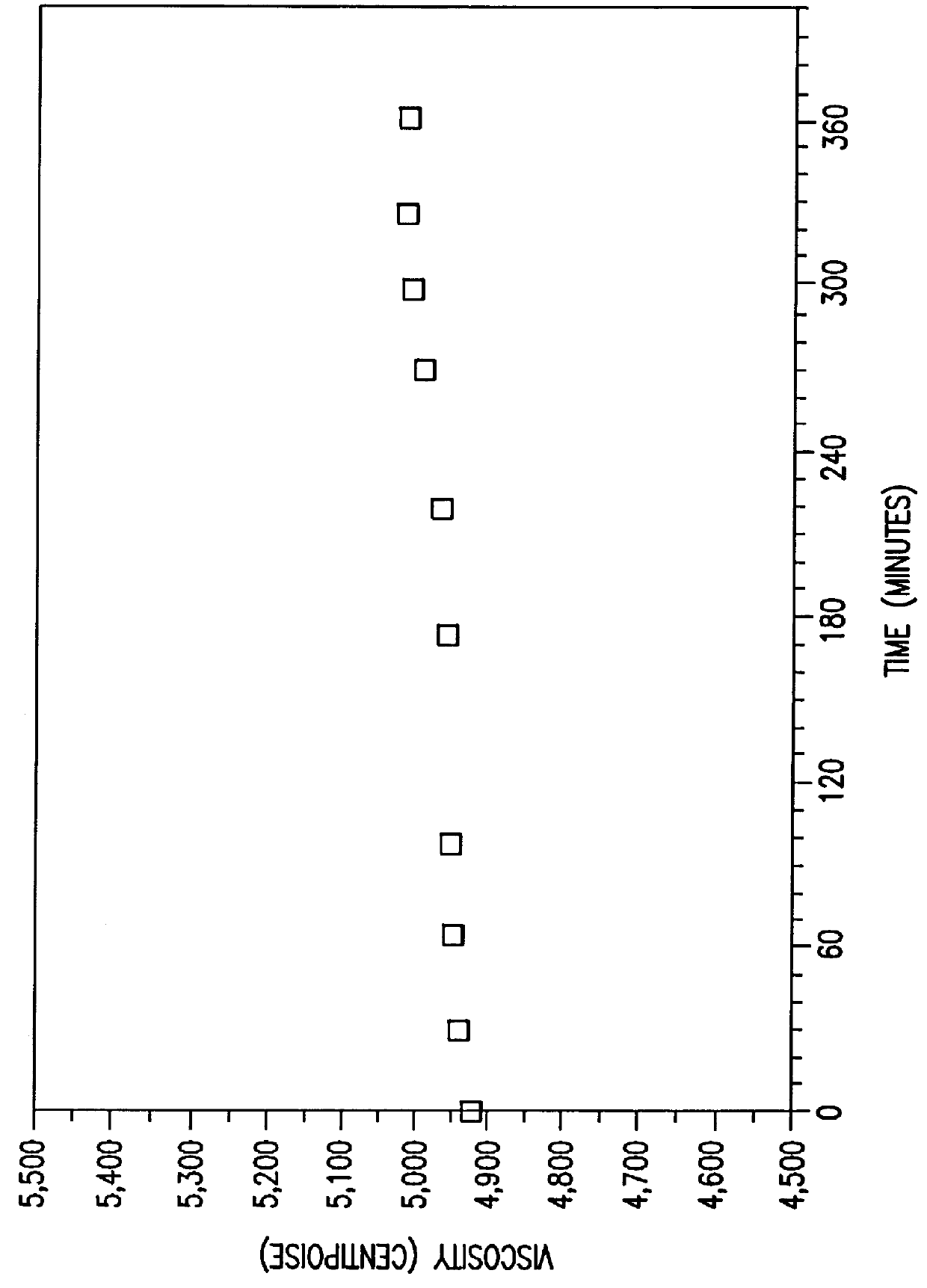

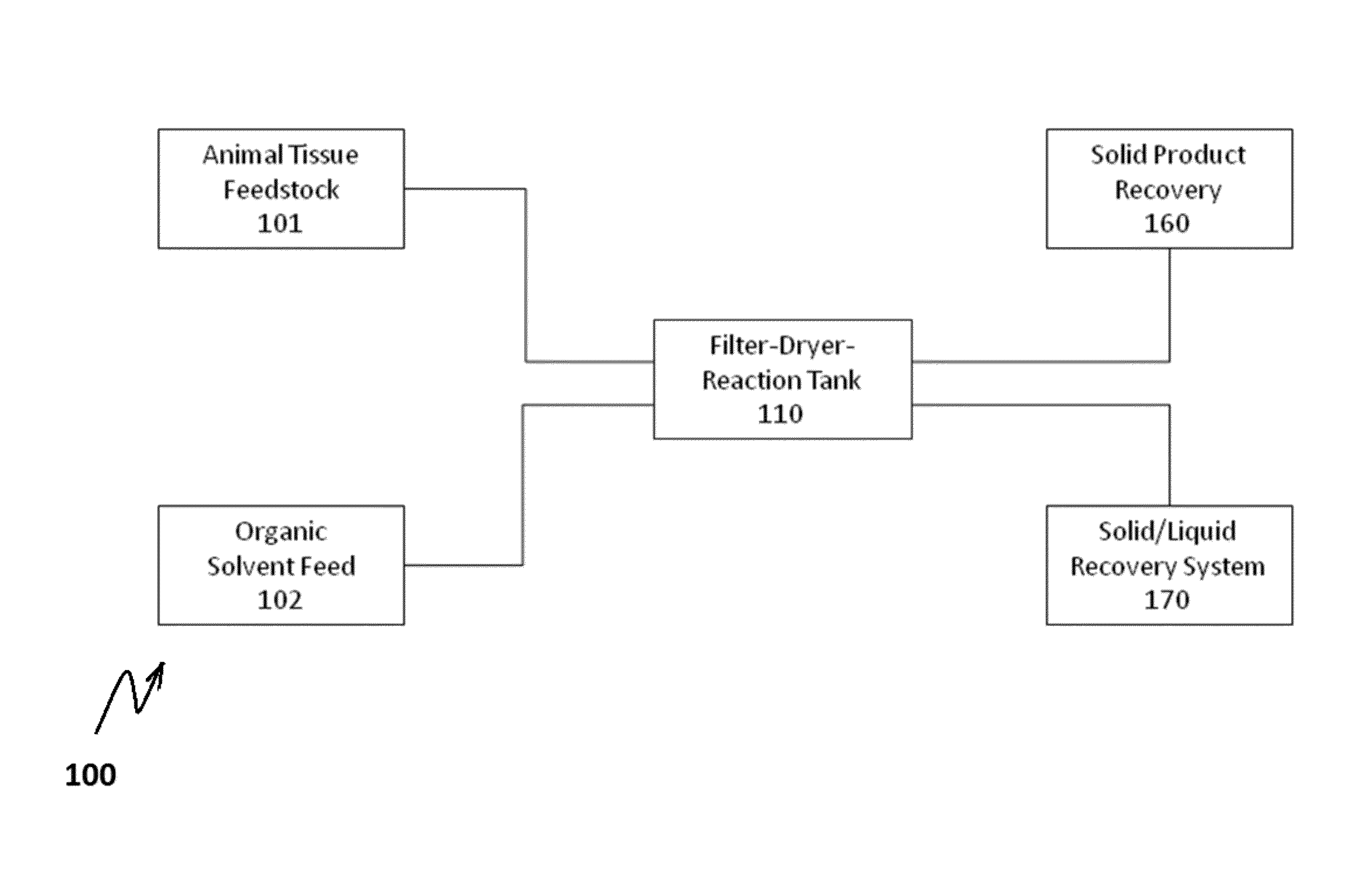

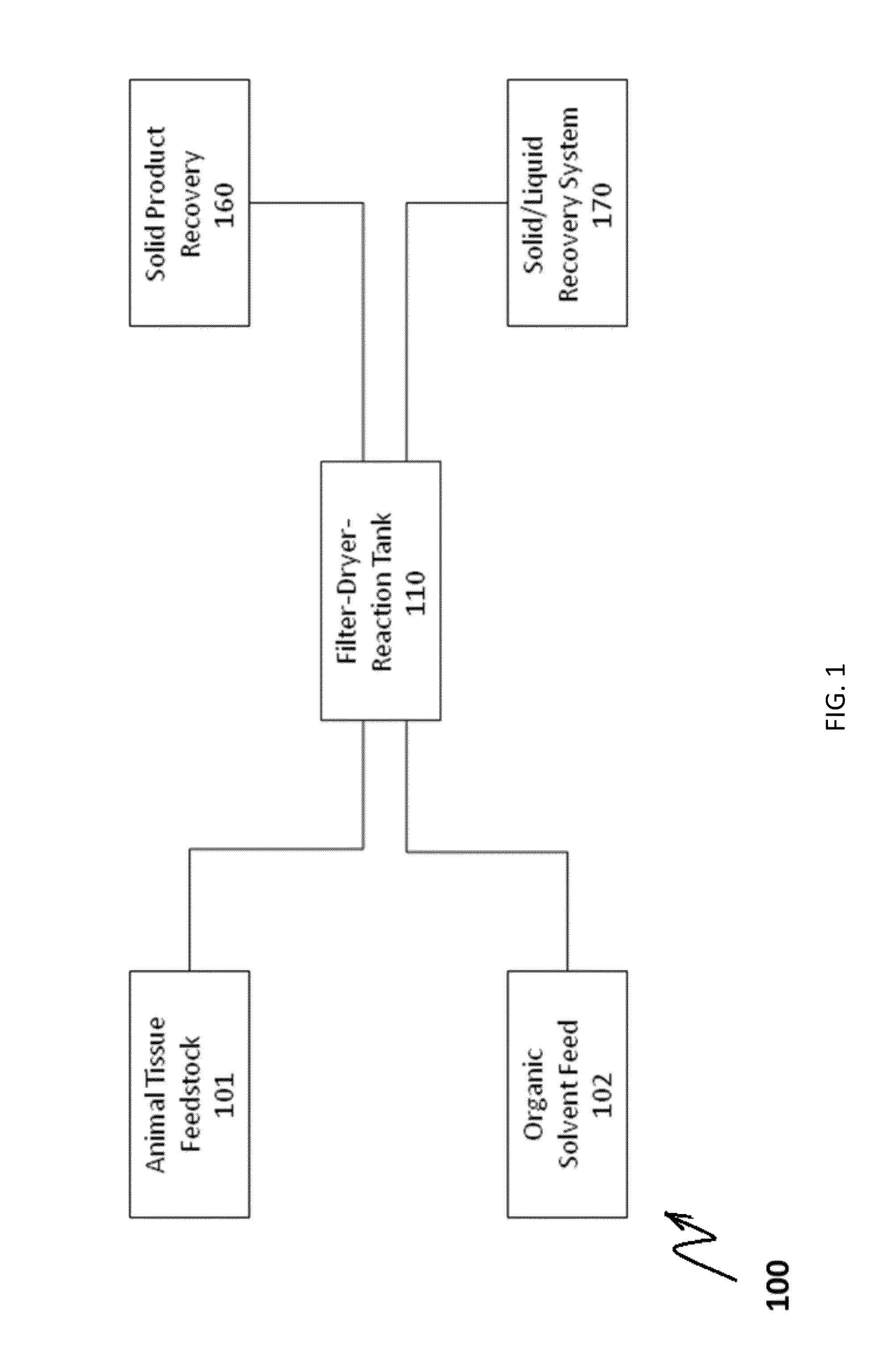

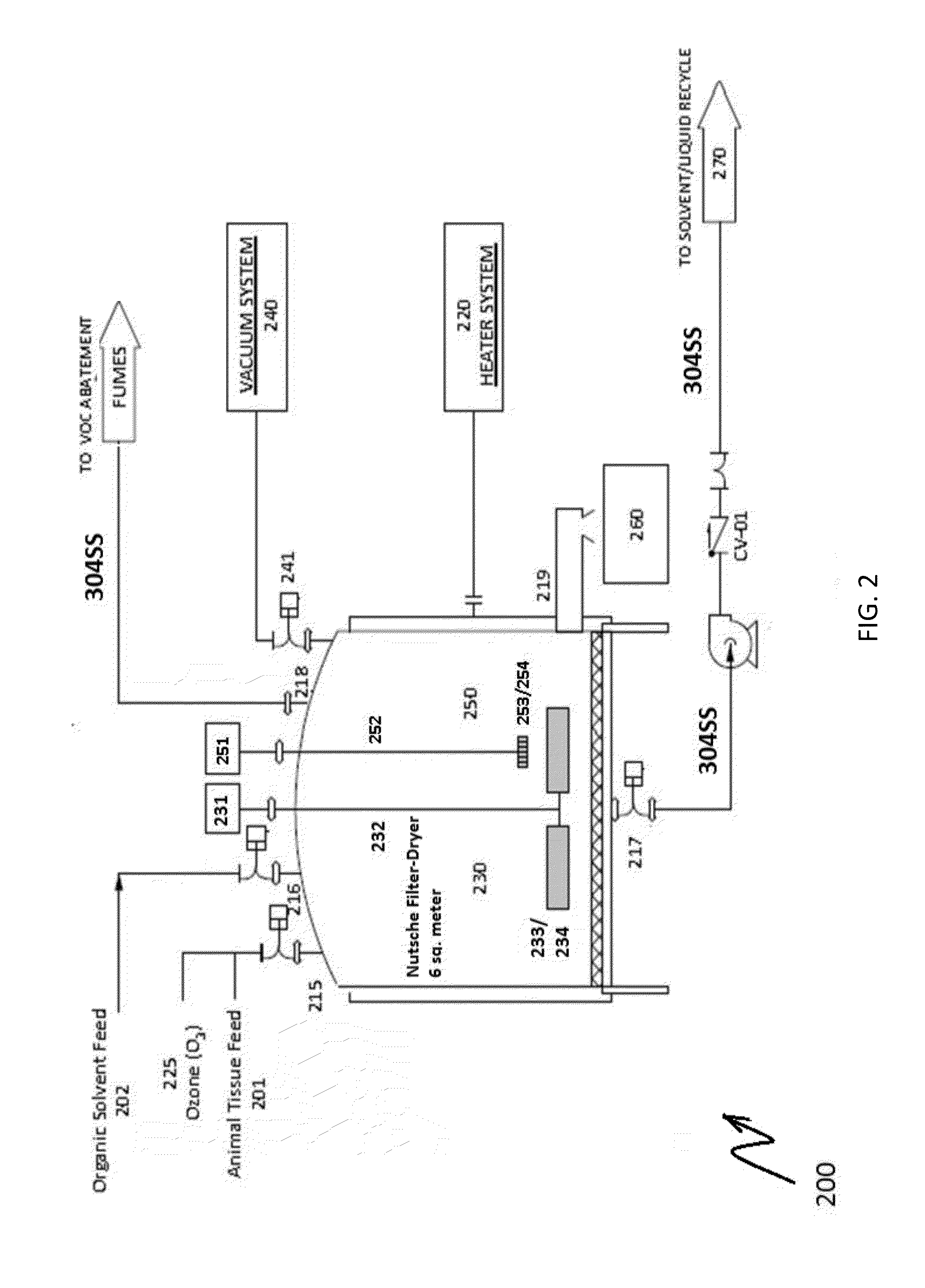

Automated method and system for recovering protein powder meal, pure omega 3 oil and purified distilled water from animal tissue

ActiveUS20140272045A1Increase productionExtended shelf lifeProtein composition from fishSolvent extractionOrganic solventDistillation

The present invention describes a method and an automatic system for recovering protein powder meal, crude and pure omega-3 oil and purified distilled water from a mixture of animal tissue processed in a filter-drier-reaction tank. Animal tissue, for example fish, and organic solvent are directly or indirectly fed into the filter-drier-reaction tank. The filter-drier-reaction tank mixes, heats, and separates solid and heavy liquid portions of the mixture, the organic solvents are automatically recycled back in to the system after distillation. The solid portion is retained in the filter-drier-reaction tank and baked. Solid protein powder product (the protein powder meal) is thus recovered.

Owner:ADVANCE INT INC

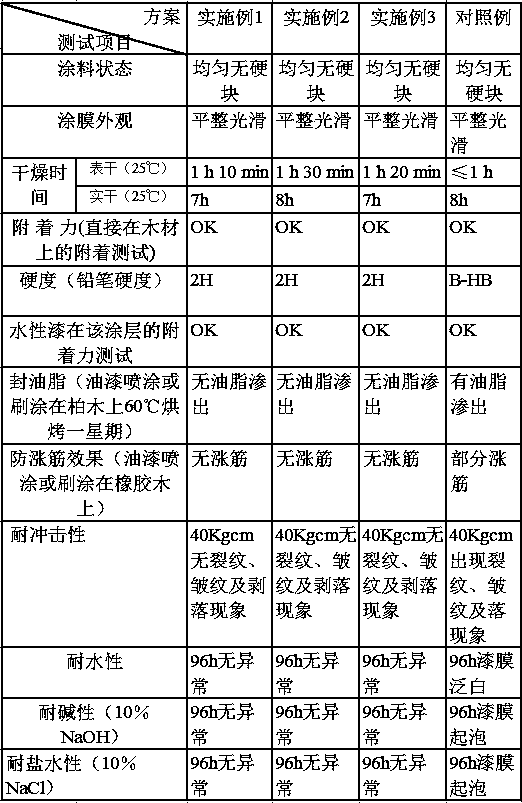

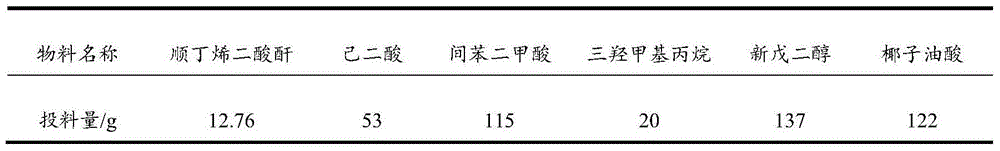

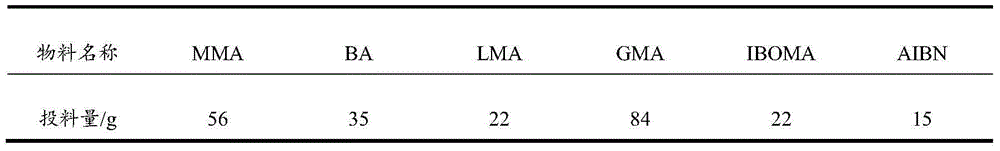

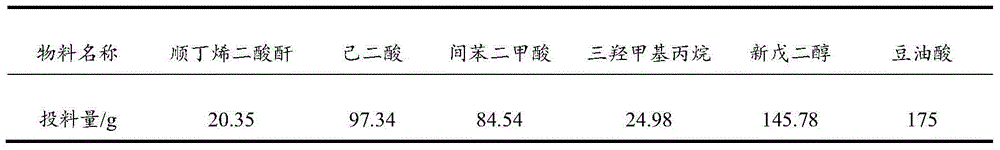

Epoxy sealing agent for timber product and preparation method and application thereof

The invention relates to the field of high polymer materials, in particular to an epoxy sealing agent for a timber product. The epoxy sealing agent for the timber product comprises a first component and a second component; the first component comprises, by mass percentage, 49-56% of non-ionic water-borne epoxy emulsion, 16-19% of epoxy-acrylic emulsion, 3.2-8.7% of first auxiliary and 16.3-31.8% of water, wherein the mass ratio of the non-ionic water-borne epoxy emulsion to the epoxy-acrylic emulsion is 3:0.8-1.2, and the sum of the mass percentages of the compositions of the first component is 100%; the second component comprises, by mass percentage, 14.8-24.6% of water, 75-85% of water-borne epoxy hardener and 0.2-0.4 % of second auxiliary, wherein the sum of the mass percentages of thecompositions of the second component is 100%. The sealing agent not only has a good sealing effect, but also has a better rib swelling resistance effect; meanwhile, compact paint film is formed, so that the hardness of timber is enhanced in disguised form, and construction attachment of subsequent water paint is not affected; no organic solvent exists, and VOC emission is low, so that the sealingagent is more environmentally friendly. The invention further discloses a preparation method and application of the sealing agent.

Owner:深圳澳达新材料有限公司

Novel method for preparing crylic acid modified resin for two-component waterborne polyurethane adhesive

ActiveCN104672399ALow costSolve prone to substrate peelingPolyureas/polyurethane adhesivesMaterial defectPolyurethane adhesive

The invention belongs to the field of adhesives, and discloses a novel method for preparing crylic acid modified resin for a two-component waterborne polyurethane adhesive. The novel method comprises the following steps: directly selecting polymer resin or synthesizing polymer resin from raw materials, adding a solvent into the polymer resin or synthesizing polymer resin from raw material, thereby modifying by using vinyl or crylic acid and an ester monomer at certain temperature or in the presence of an initiator, and further implementing a reaction on organic amino and acid substances, thereby obtaining the crylic acid modified resin for the two-component waterborne polyurethane adhesive. By adopting the method, crylic acid modified resin can be prepared, and can be directly used or is combined with a component containing isocyanate to obtain a polyurethane adhesive after chain expansion, the isocyanate group in the adhesive can be preferably reacted with active groups of resin in a waterborne environment, and can stably exist in the waterborne environment; in addition, compared with a solvent type polyurethane adhesive, the adhesive is relatively low in VOC content, the defects that an ordinary waterborne polyurethane adhesive can be stripped from a substrate, has bubbles in an adhesive film, is poor in adhesion and has material defects after being used can be avoided, and the cost of the polyurethane adhesive can be lowered.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com