Waterborne epoxy coating for containers and preparation method of waterborne epoxy coating

A water-based epoxy coating and epoxy coating technology, applied in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve problems such as hidden safety hazards and environmental problems of solvent-based container coatings, and achieve low human harm and excellent protective performance. , The effect of low VOC emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

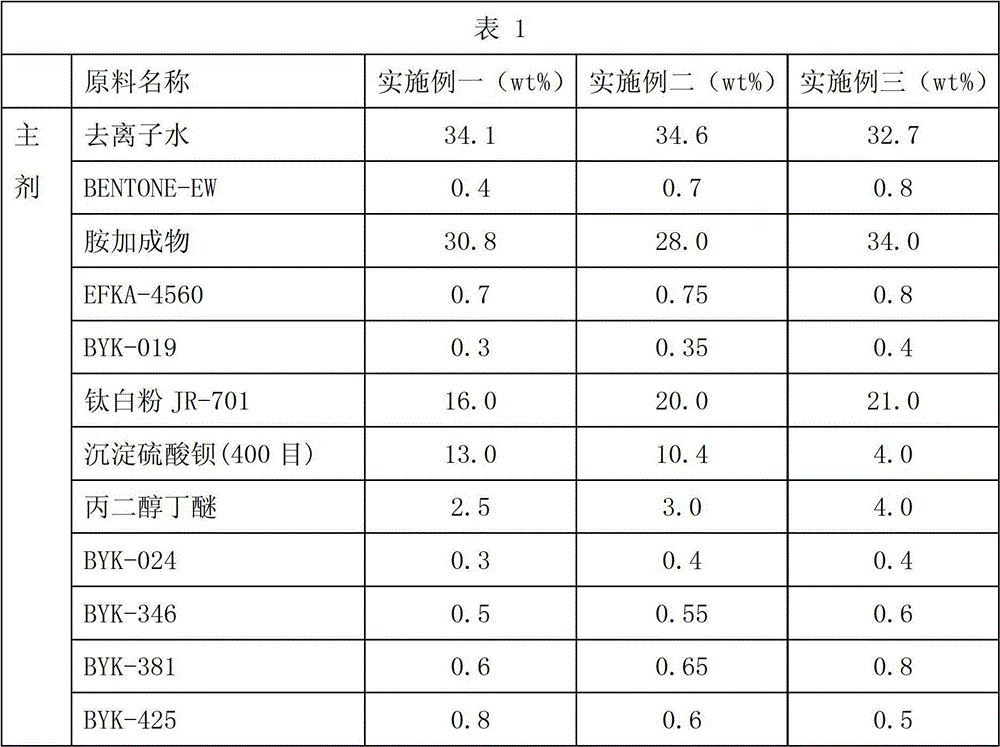

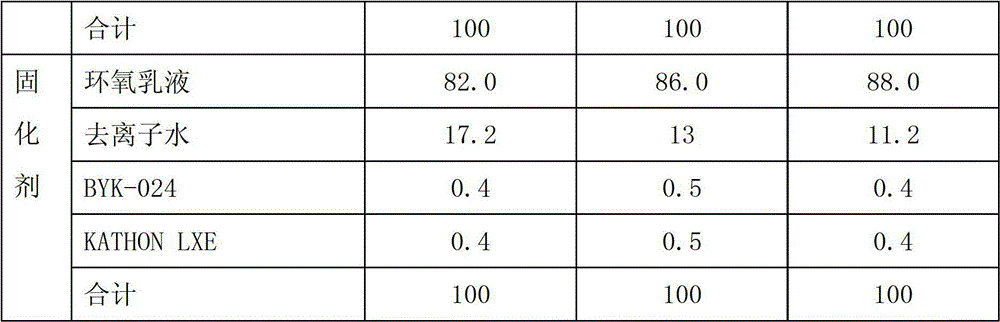

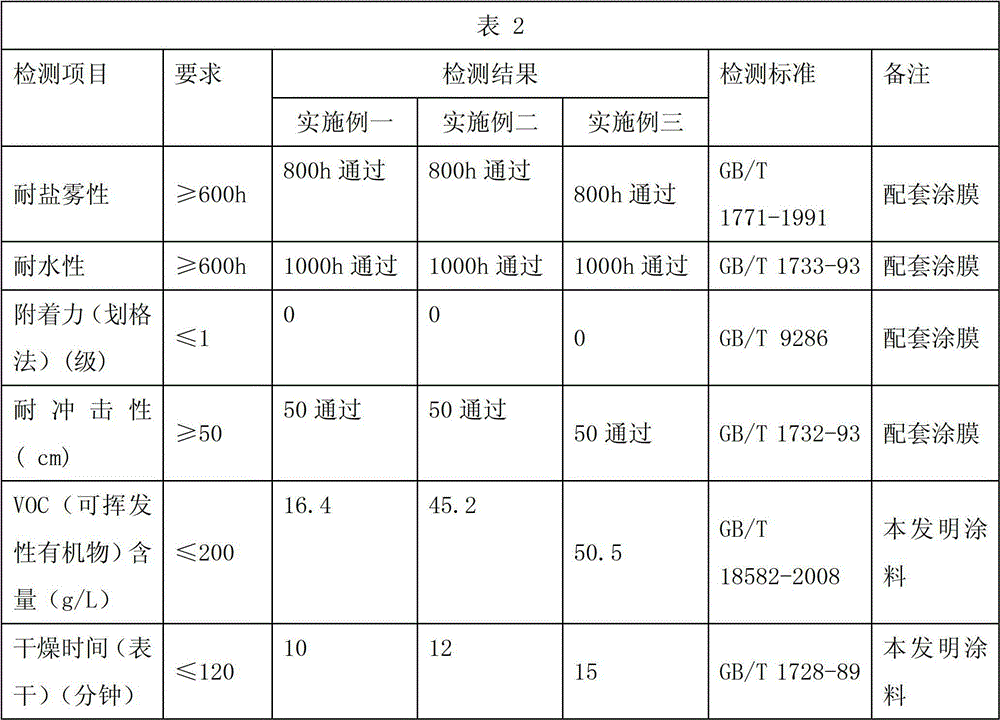

[0034] The main agent and curing agent formula of container water-based epoxy paint in embodiment one to embodiment three are as shown in table 1:

[0035]

[0036]

[0037] Epoxy emulsion is the epoxy emulsion Waterpoxy1455 of German BASF company. The amine adduct is Waterpoxy751, an amine adduct of BASF, Germany. Propylene glycol butyl ether is a film-forming aid. Rutile type titanium dioxide JR-701 is used as pigment; 400 mesh precipitated barium sulfate is used as filler. EFKA 4560 is a wetting and dispersing agent, BYK-346 is a substrate wetting agent, and BYK-381 is a leveling agent. BYK-019 is defoamer 1, BYK-024 is defoamer 2. The anti-settling agent is BENTONE-EW; BYK-425 is the thickener; KATHON LXE is the preservative in the tank.

[0038] The preparation method of container water-based epoxy paint in embodiment one to embodiment three is as follows:

[0039] (1) Preparation of main ingredient: first add deionized water according to the formula amount, sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com