Waterborne graphene anticorrosive paint

A water-based graphene and anti-corrosion coating technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as manpower loss, and achieve the effects of reducing VOC emissions, easy dispersion, and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

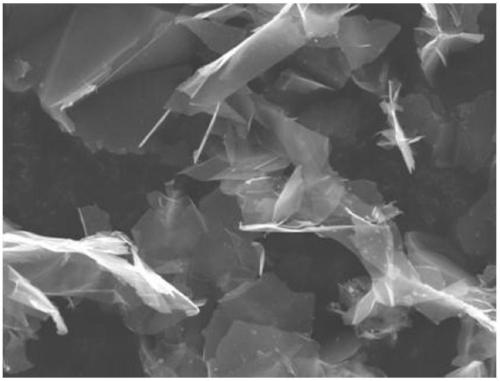

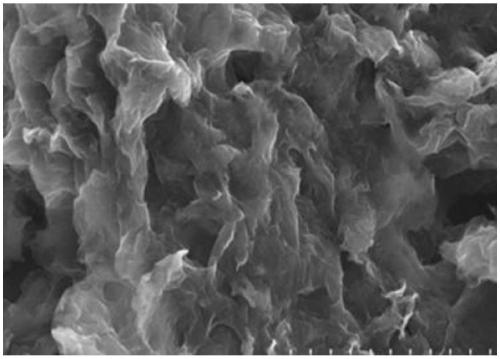

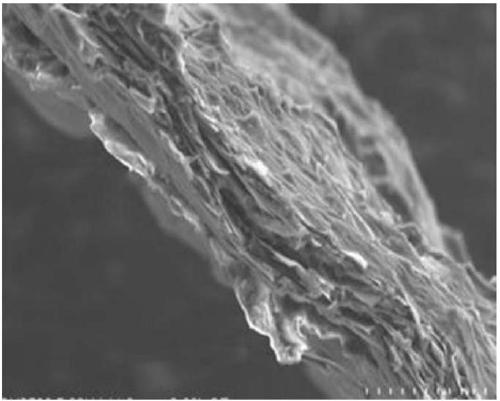

Image

Examples

Embodiment 1

[0035] The invention provides a kind of water-based graphene anticorrosion paint comprising following raw materials in parts by weight:

[0036] Table 1: Reference and preferred formula of graphene anticorrosion slurry;

[0037] material code

Example 1-1

Example 1-2

Example 1-3

1

Intercalated expanded graphite

1.0-15.0

6

1.0

15.0

2

SN5040

0.1-2.0

1.2

2.0

0.1

3

BYK181

0.1-2.0

0.4

0.1

2.0

4

AMP-95

0.1-2.0

0.5

2.0

0.1

5

0.1-5.0

2.0

0.1

5.0

6

Deionized water

80.0-98.0

85.9

98.0

80.0

7

Absolute ethanol

1.0-10.0

4.0

1.0

10.0

[0038] Preparation process of water-based graphene anti-corrosion slurry:

[0039] According to the preferred formula in Table 1, mix the material dispersing cylinders with material numbers 1, 2, 3, 6, and 7 slowly and ev...

Embodiment 2-1

[0041] A kind of waterborne graphene anticorrosion coating, used raw material formula is as follows table 2.

[0042] Table 2

[0043]

[0044]

[0045] Water-based graphene anti-corrosion coating preparation process A component:

[0046] S1. Add the materials numbered 1, 2, 3, 5, and 6 in the A component in Table 2 to the dispersion tank respectively, and disperse at high speed for 60 minutes;

[0047] S2. Add the materials numbered 4 and 7 of the A component materials in Table 2 to the dispersion tank respectively, and disperse at a medium speed for 30 minutes;

[0048] S3. Detect, filter and package to obtain component A of the water-based graphene anti-corrosion coating.

[0049] Water-based graphene anti-corrosion coating preparation process B component

[0050] S1. Add the materials of component B in Table 2, numbered 1, 2, 7, and 8, into the dispersion tank respectively, and stir at a low speed for 30 minutes;

[0051] S2. Slowly add materials numbered 4, 5, a...

Embodiment 2-2

[0057] A kind of water-based graphene anticorrosion coating, used raw material formula such as table 3.

[0058] table 3

[0059]

[0060] The coating preparation process is the same as that in Example 1. According to the ratio of component A: component B = 3: 1, component A and component B are mixed and dispersed evenly, and then the coating is made into panels for testing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com