Semi-trailer tractor working platform device

A working platform and tractor technology, which is applied in the directions of vehicle components, transportation and packaging, and the arrangement of pedals or ladders, can solve the problems of low rigidity and difficult assembly, and achieve the effects of easy assembly, easy operation and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

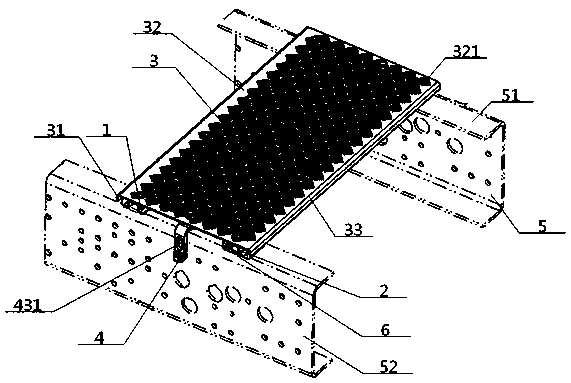

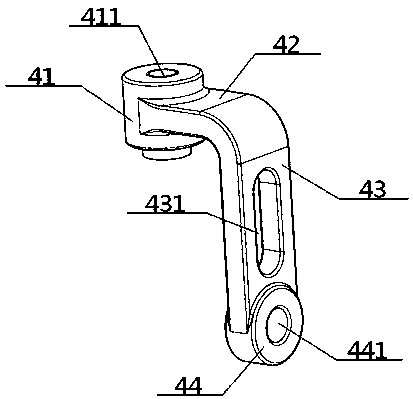

[0043] see Figure 1 to Figure 3 , a working platform device for a semi-trailer tractor, comprising a platform plate 3, a connecting bracket 4, and a left reinforcing plate 1 and a right reinforcing plate 2 parallel to each other, the top surfaces of the left reinforcing plate 1 and the right reinforcing plate 2 are all connected to each other. The bottom surface of the platform deck 3 is connected, the bottom surfaces of the left reinforcing plate 1 and the right reinforcing plate 2 are in contact with the upper wing surface 51 of the longitudinal beam 5, and the intersection of the left reinforcing plate 1 and the platform deck 3 is close to the platform deck 3 The left side of the right reinforcement board 2 and the junction of the platform deck 3 are arranged near the right side of the platform deck 3, and the connecting bracket 4 is located between the left reinforcement board 1 and the right reinforcement board 2. Preferably, the cross-sections of the left reinforcing pl...

Embodiment 2

[0045] Basic content is the same as embodiment 1, the difference is:

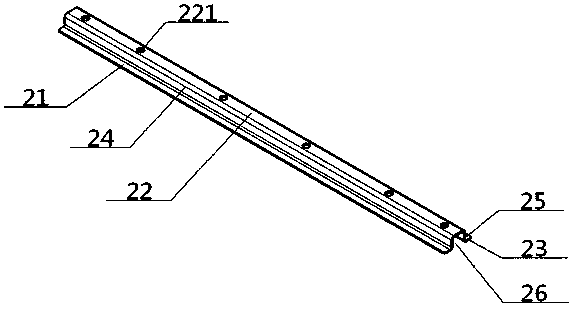

[0046] When the cross-sections of the left reinforcement board 1 and the right reinforcement board 2 are several fonts, they all include a left bottom plane 21, a mid-high plane 22 and a right bottom plane 23, and the mid-high plane 22 is higher than the left bottom plane 21 and the right bottom plane. The plane 23 is set, the inner end of the left bottom plane 21 is connected to one end of the middle height plane 22 through the left vertical board surface 24, and the other end of the middle height plane 22 is connected to the inner end of the right bottom plane 23 through the right vertical board plane 25 , and the left vertical plate surface 24, the middle high plane 22, and the right vertical plate surface 25 are clamped into a downwardly opening reinforcing cavity 26; the angle between the left bottom plane 21 and the left vertical plate surface 24, and the right The angle between the bottom plane 23 an...

Embodiment 3

[0048] Basic content is the same as embodiment 1, the difference is:

[0049] The bottom surfaces of the left reinforcing plate 1 and the right reinforcing plate 2 are bonded to the upper wing surface 51 of the longitudinal beam 5 through the shock-absorbing rubber 6 . Alternatively, shock-absorbing rubber 6 is filled in the reinforcement cavity 26 directly above the upper airfoil 51 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com