Subsection-armature motor stator and manufacturing process thereof

A motor stator and armature technology, applied in the field of segmented armature motor stator and its manufacturing process, can solve the problems of low utilization rate of magnetic conductive materials, complex manufacturing process, poor overall performance, etc. The effect of high mechanical strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

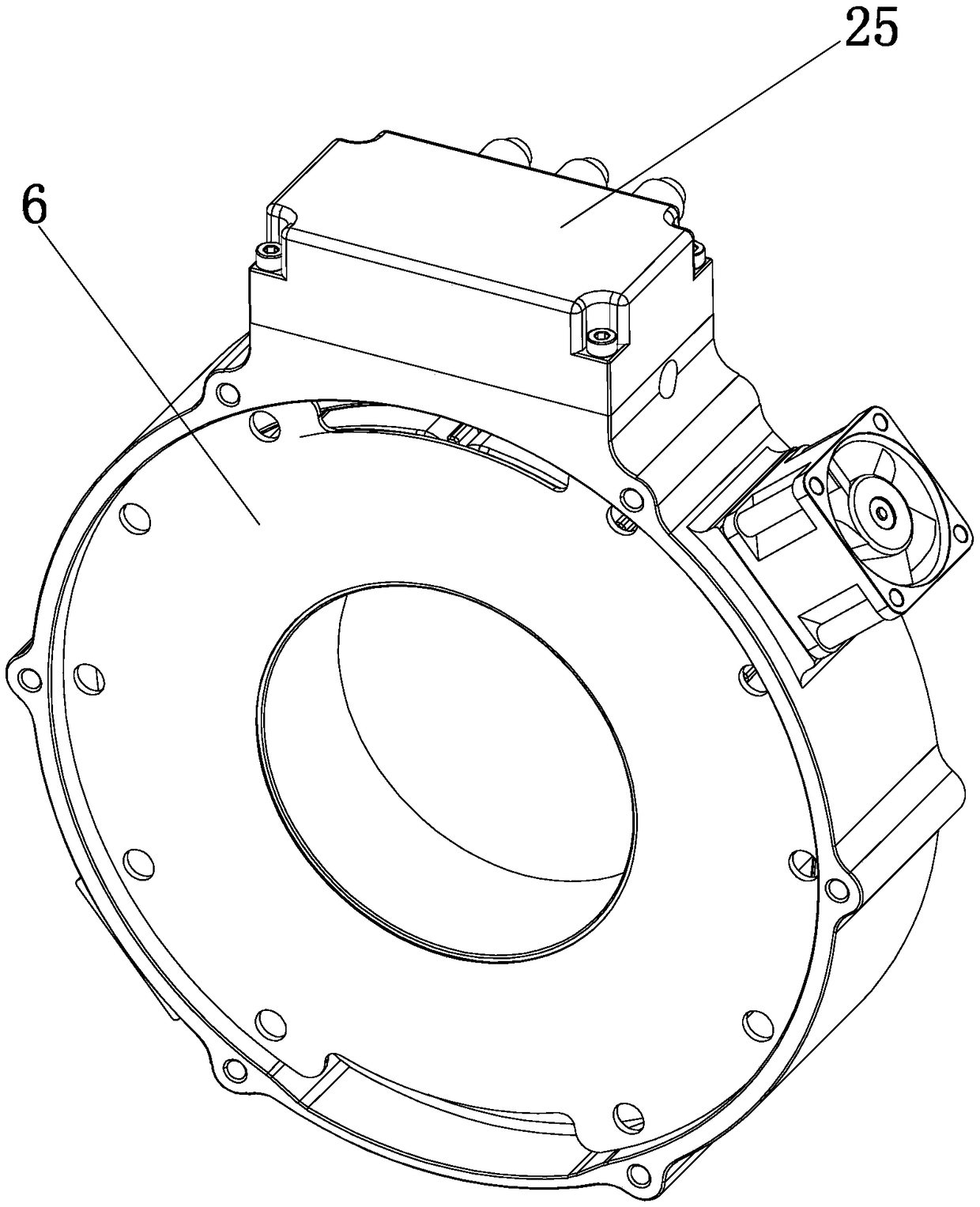

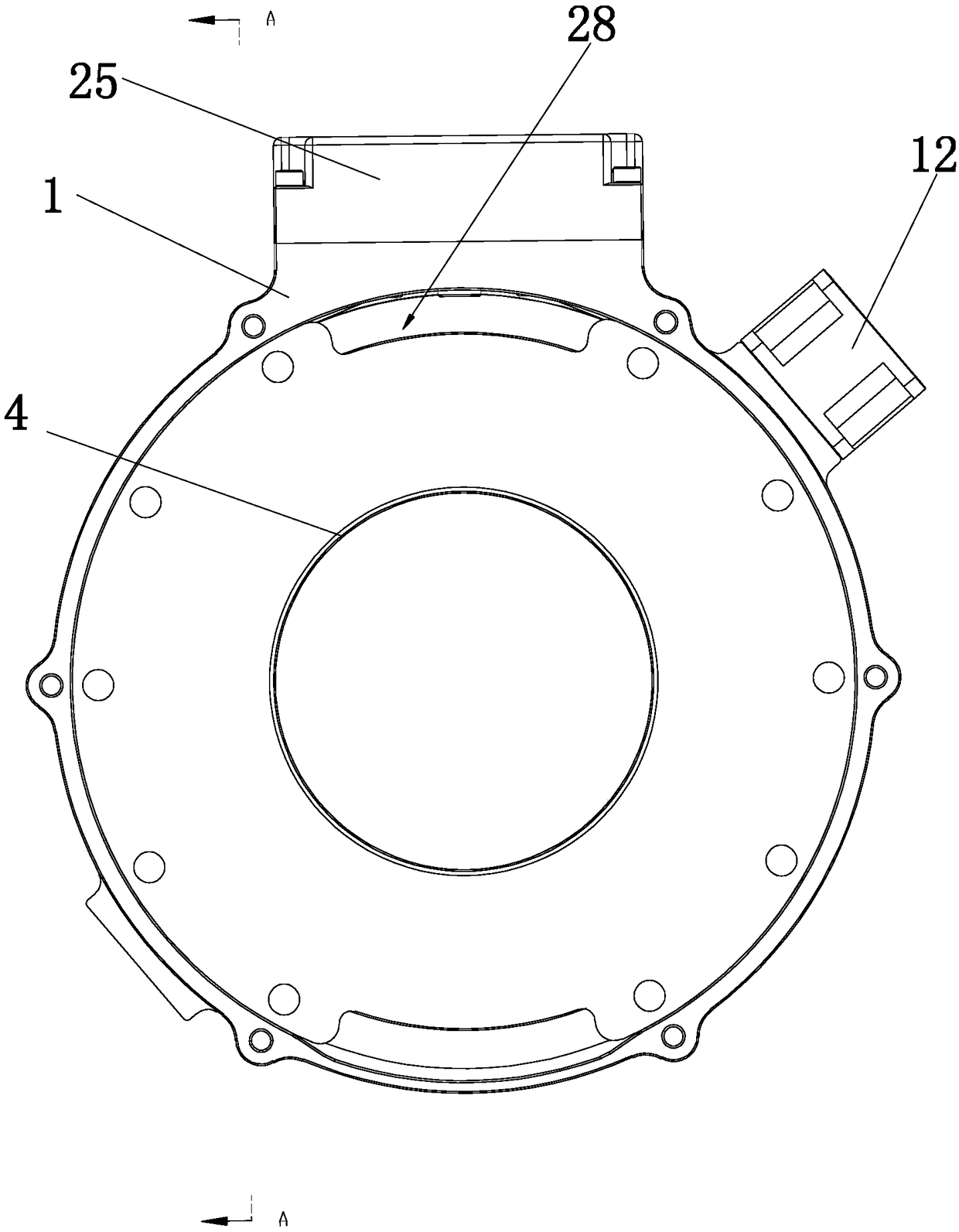

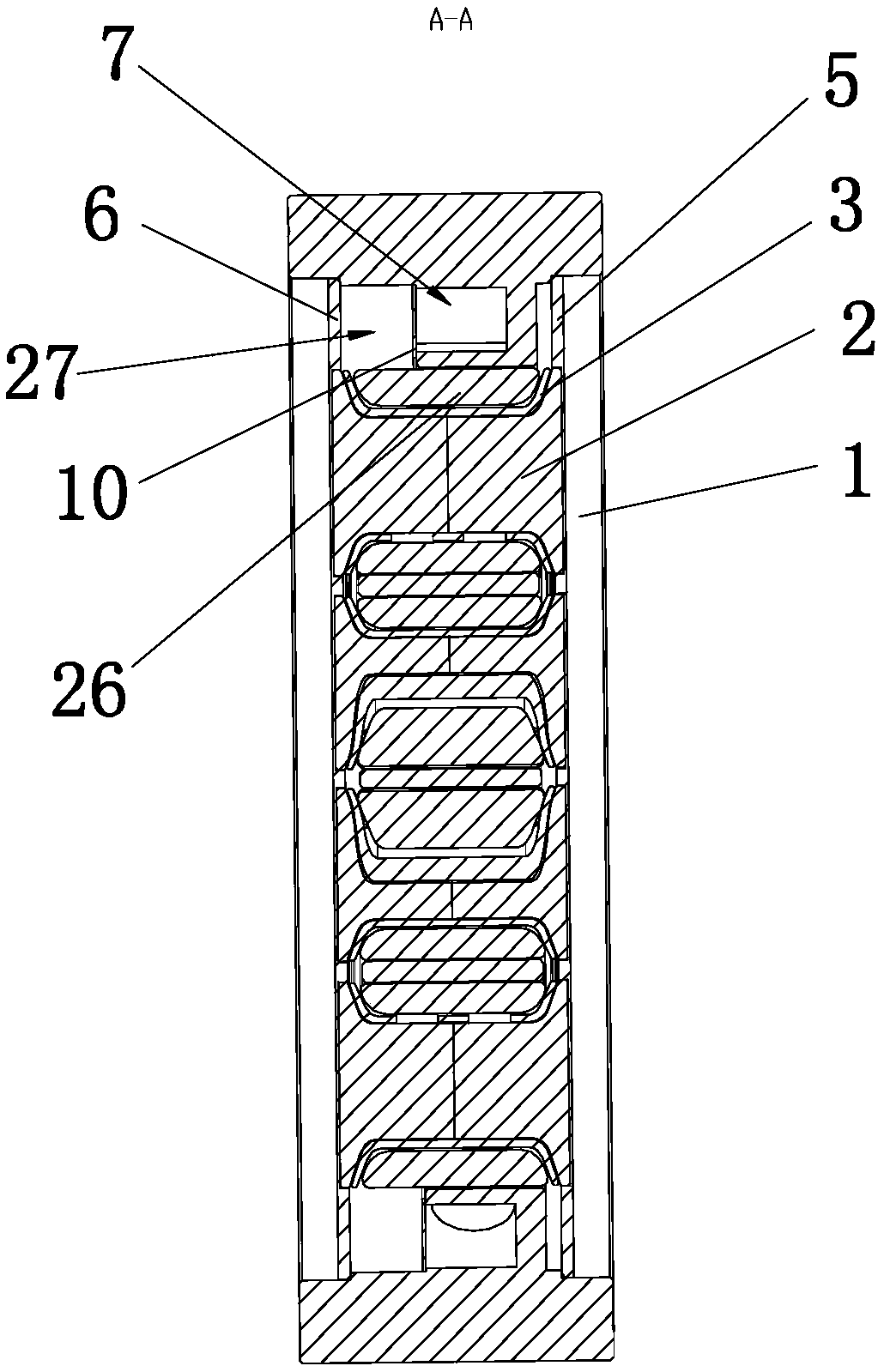

[0050] Such as Figure 1-Figure 12 As shown, the present invention provides a segmented armature motor stator, which includes a housing 1, a heat dissipation system, a terminal structure, a seal and several armature units arranged in the housing 1 and distributed in a ring shape. A placement space for the armature unit is formed between the casing 1 and the sealing member. The shell 1 is ring-shaped.

[0051] The armature unit includes an iron core 2 , a skeleton 3 and a coil 26 , the iron core 2 is inserted into the cavity of the skeleton 3 , and the coil 26 is wound on the skeleton 3 corresponding to the iron core 2 to form a winding. The iron core 2 is made of SMC material. The iron core 2 includes two identical stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com