Condenser

A condenser and subcooling technology, which is applied in the direction of evaporator/condenser, refrigerator, refrigeration components, etc., can solve the problems of poor heat transfer surface area efficiency of heat dissipation pipes, increase condenser volume, sacrifice condenser performance, etc., and achieve improved Effects of heat dissipation, quantity reduction, and requirement reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

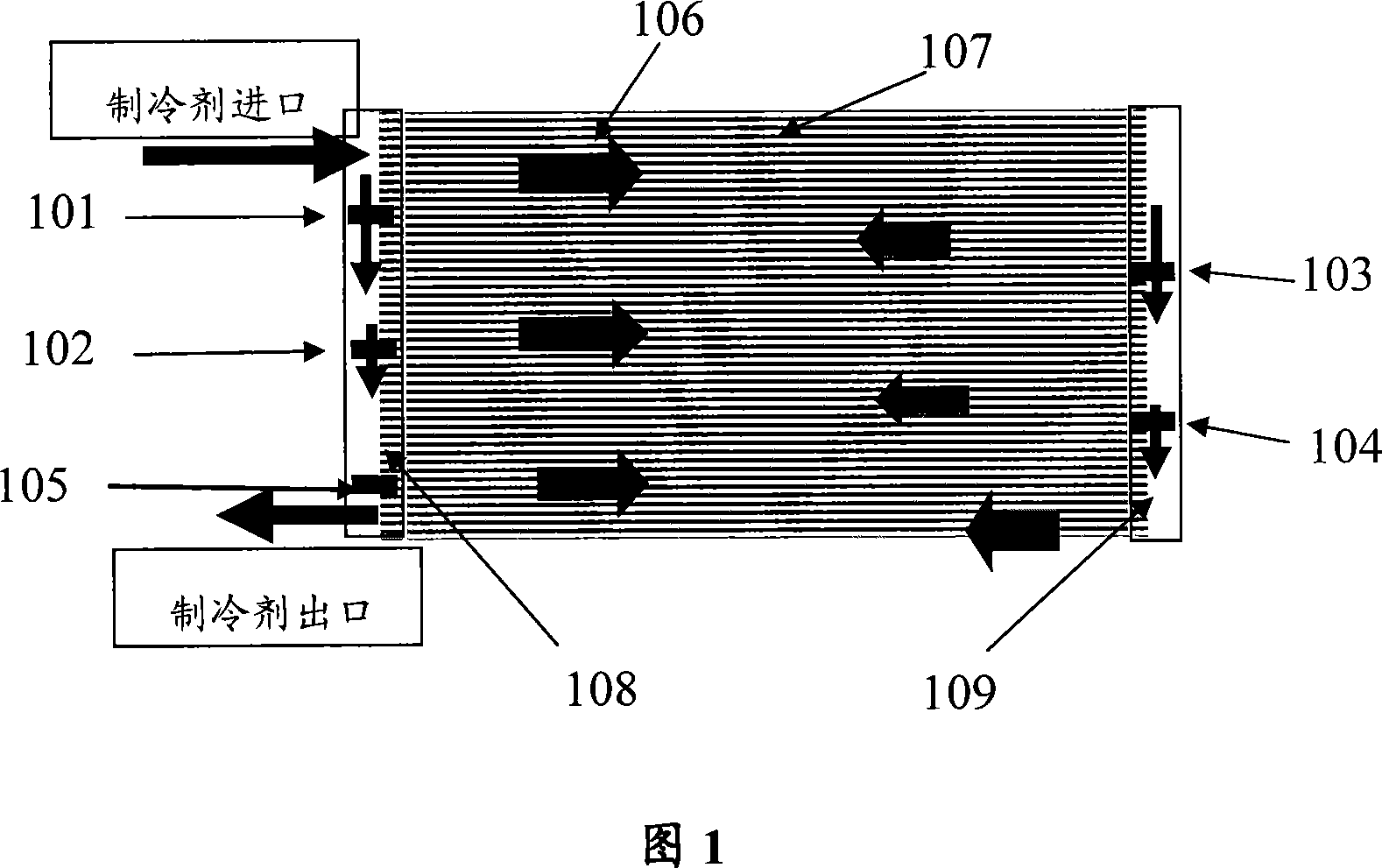

[0037] Please refer to FIG. 1 , which is a schematic structural diagram of the first embodiment of the present invention.

[0038] As shown in Figure 1, it is a non-supercooled condenser, including a number of regularly arranged radiating tubes 107, a first header 108 and a second header connected to the two ends of the radiating tubes and communicated therewith. 109. A refrigerant inlet and a refrigerant outlet are respectively arranged on the first header 108, and several baffles are arranged alternately in the two headers so that the refrigerant flows back from the inlet to the outlet in the condenser, and the baffles Among them, the partition 101, the partition 102, the partition 103 and the partition 104 are provided with through holes.

[0039] When the superheated steam of the refrigerant enters the first header 108 of the condenser, most of the superheated steam enters the heat dissipation pipe 107, that is, enters the desuperheating area, while a part of the superheat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com