Patents

Literature

119 results about "Resin embedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

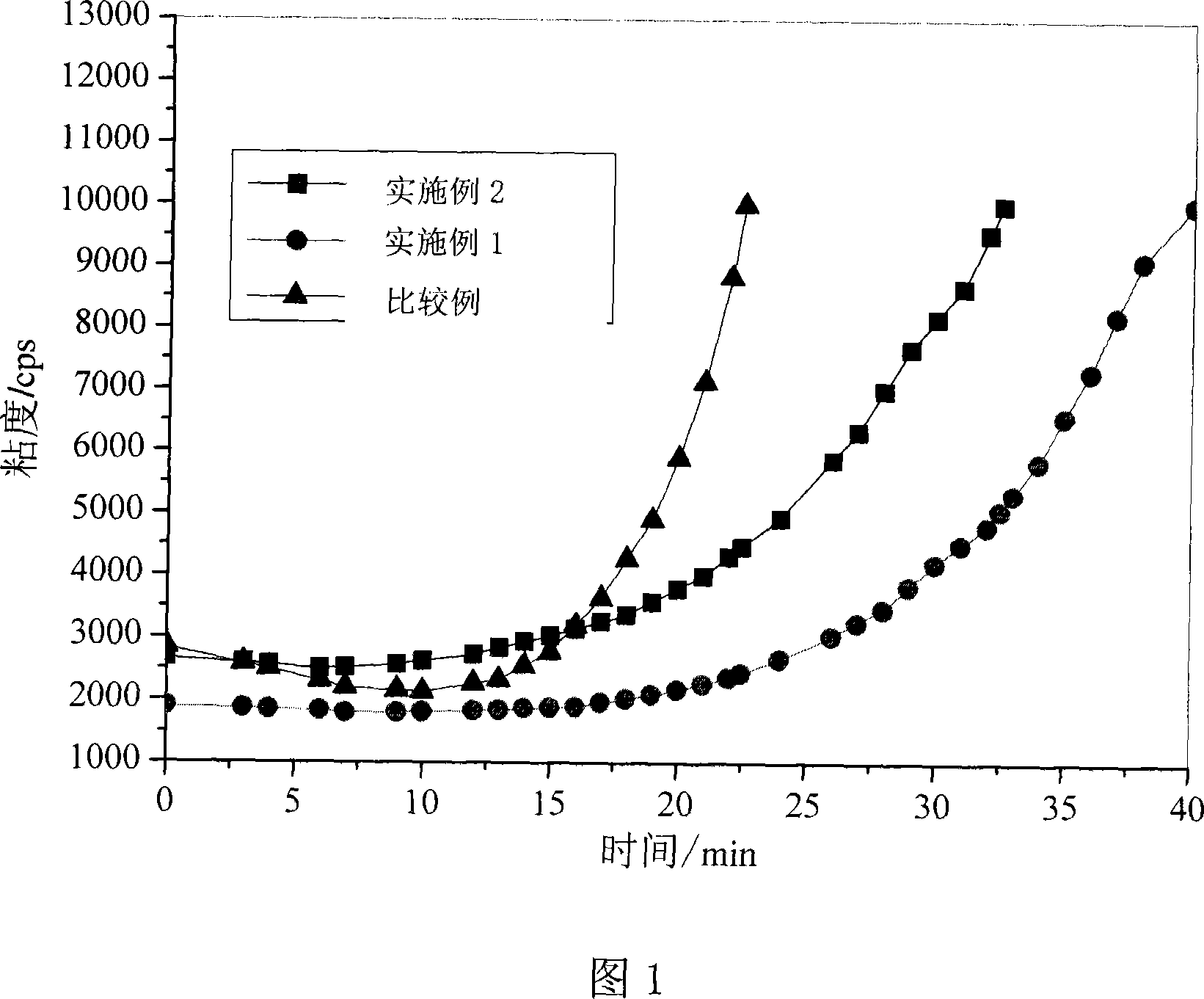

Epoxy resin embedding glue and method for producing the same

The invention relates to an epoxy resin potting adhesive which consists of component A and component B. By weight portion, the component A consists of 90-130 portions of bisphenol A type epoxy resin, 240-320 portions of filling, 15-25 portions of thinner, 10-25 portions of toughener, 1-2.5 portions of defoamer and 0.8-2 portions of black pigment, and the component B consists of 60-130 portions of estolide and 1-3 portions of imidazole accelerator. The mixing proportion of the component A and the component B is (3-5):1. The invention also provides a preparation method of the epoxy resin potting adhesive. The epoxy resin potting adhesive provided by the invention has low cost and long resting period; after being mixed, the component A and the component B have low viscidity, good wetting quality, good heat resistance, good defoaming performance, good fluidity and long operating time and are solidified between 70 DEG C and 160 DEG C; a product after solidifying has bright surface, good mechanical performance and insulating performance and high glass transition temperature; and the quality of a potting component is stable.

Owner:NICHE TECH KAISER SHANTOU

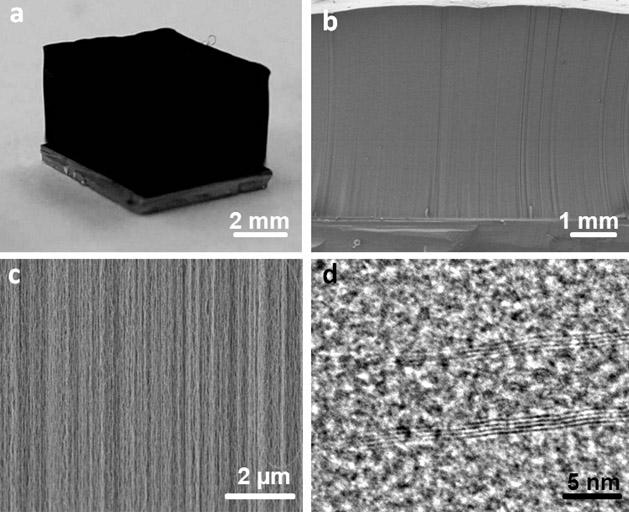

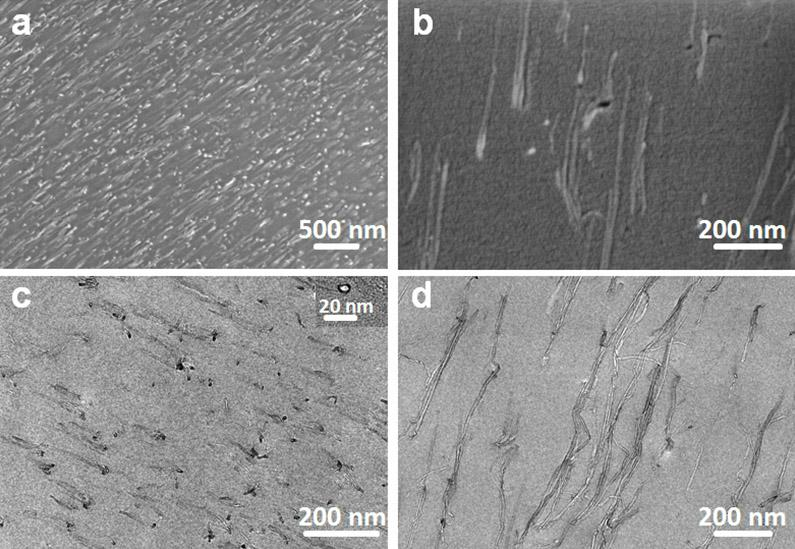

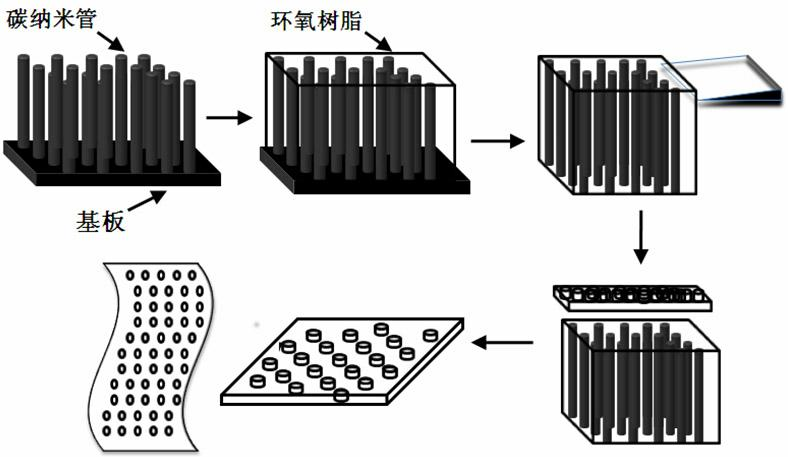

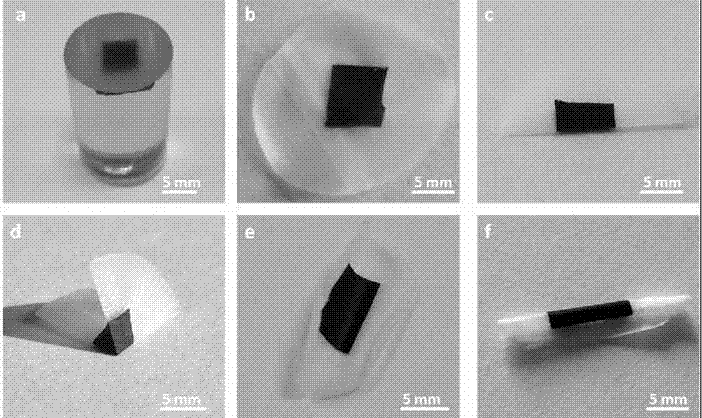

Preparation method of oriented carbon nano tube/ polymer composite membrane

The invention belongs to the technical field of carbon nano tube preparation, in particular relates to a preparation method of an oriented carbon nano tube / polymer composite membrane. Epoxy resin embedding liquid, a flexibilizer and a carbon nano tube array serve as raw materials, a resin monomer is permeated into the array with a permeating method; then, the obtained product is heated and solidified to form composite material; and finally, a sample is sliced by a slicing machine to obtain the carbon nano tube / polymer composite membrane. The carbon nano tubes in the membrane are perpendicular to the surface of the membrane and are evenly distributed; the upper surface and the lower surface of the membrane both have good electrical conductivity; in addition, the tail ends of a plurality of carbon nano tubes are opened on the surface of the membrane, which is convenient to modify or catalyze and the like; and the membrane has good flexibility and strength. Thus, the invention provides a new path for preparing the carbon nano tube membrane.

Owner:宁国市龙晟柔性储能材料科技有限公司

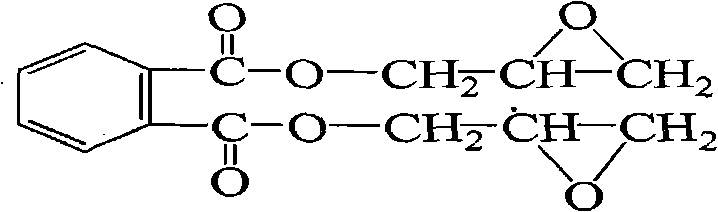

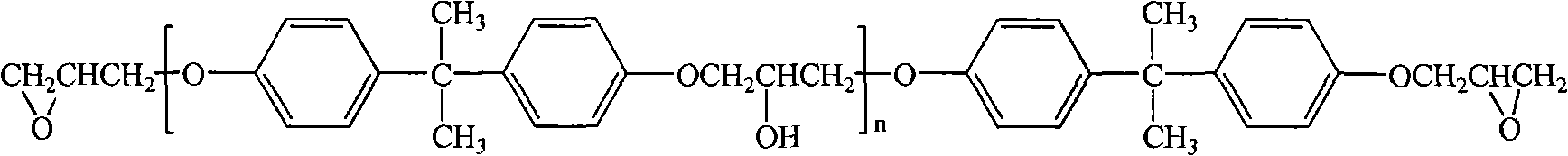

Double-component epoxy resin embedding adhesive and its preparation method and can sealing technique

ActiveCN101235269ALow viscositySave operating timeOther chemical processesEpoxy resin adhesivesEpoxyAlcohol

Bi-component epoxy resin pouring sealant and the preparation and the potting technology are disclosed, which comprises an epoxy resin A component and a cursing agent B component, wherein the curing agent B component at least comprises the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent. The potting technology comprises mixing and stirring evenly the epoxy resin A component and the curing agent B agent to conduct the potting, and spraying a layer of absolute alcohol on the surface of the pouring sealant after 10-15 minutes. The advantages are that gel time is prolonged through adopting the mixing curing agent of cashew shell oil modified amine curing agent and fatty amine curing agent, the requirement of operation time is fulfilled, and the operation time can reach 20-30 minutes, thereby being beneficial for the encapsulation of housing with large capacity, and the pouring sealant of the invention has the effect of fast curing, wherein the curing time is 1-3 hours, and defoaming is accelerated through spraying a layer of absolute alcohol on the surface of colloid after pouring, thereby making the solid gel surface bright and flat after curing.

Owner:SHANGHAI HUITIAN NEW CHEMICAL MATERIALS CO LTD

Epoxide resin curing agent, epoxide resin embedding glue and confecting method thereof

ActiveCN101225156AImprove heat resistanceImprove mechanical propertiesOther chemical processesEpoxy resin adhesivesVitrificationEpoxy

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

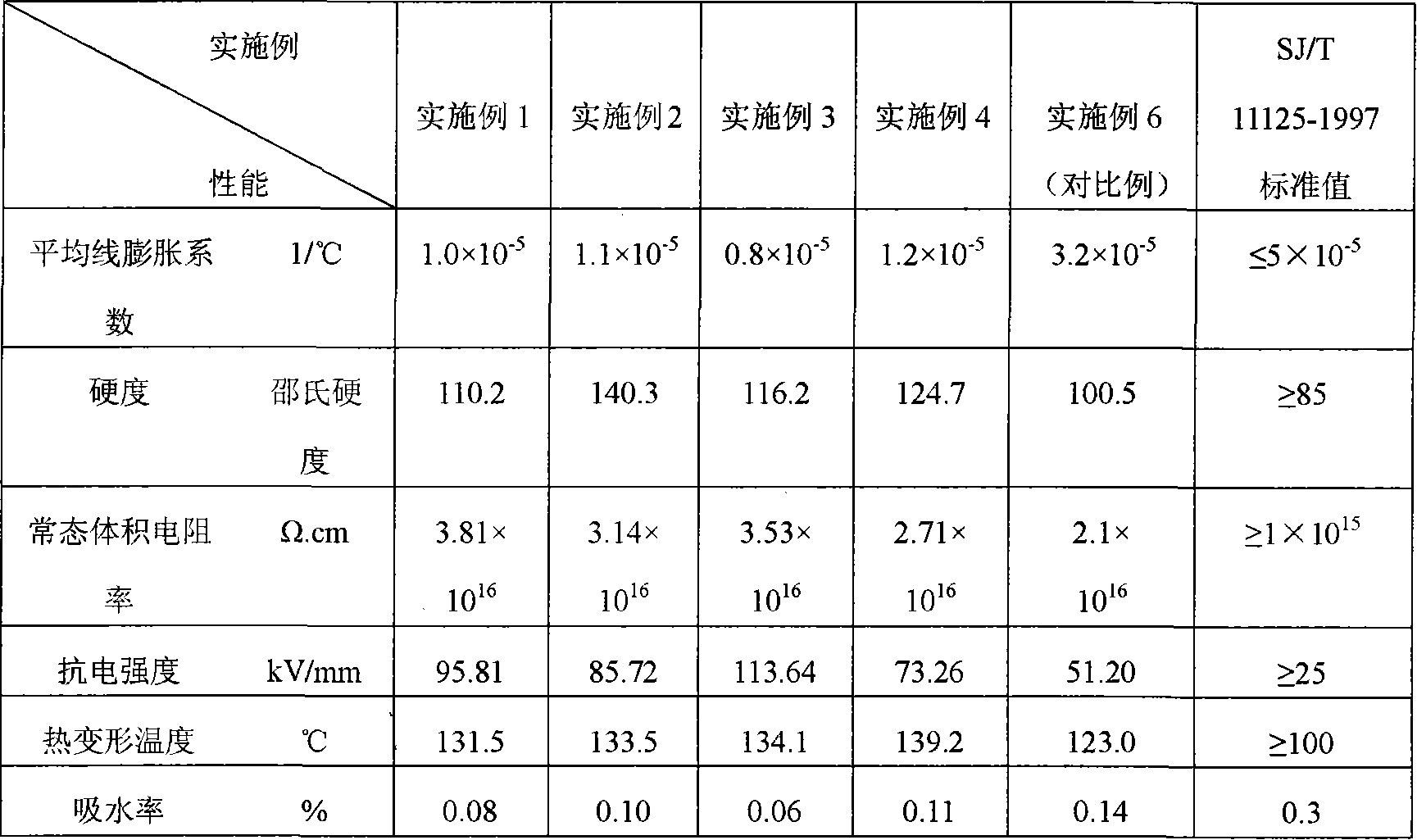

Method for preparing modified epoxide resin embedding material

InactiveCN101117560AImprove performanceLow wettabilityOther chemical processesResin embeddingFirming agent

The present invention relates to a high-powered modified epoxide resin embedding material and the preparation method. The material consists of A liquid and B liquid, wherein A liquid includes epoxide resin modified by polyurethane prepolymerization, organic montmorillonite, filling, and other addition agent, B liquid includes firming agent and accelerant. The embedding material is provided with low poison, good wetting quality and high filling quantity, the condensate is provided with low linear expansibility and good weather resisting property and tenacity; the preparation art of the embedding material is simple, the performance is excellent, and is the same with embedding an electrical apparatus element with wider working temperature range.

Owner:CHANGCHUN UNIV OF TECH

Joint construction method for preventing reflection cracks generated during spreading of asphalt on old concrete pavement

The invention relates to a joint construction method for preventing reflection cracks generated during spreading of asphalt on an old concrete pavement. The method comprises the following steps: firstly determining the inter-panel deflection difference of old concrete panels to be jointed for reinforcing; after qualification, cutting across the joints at the joints of the two old concrete panels to obtain equal-distance stripe-type grooves and then vertically drilling the end parts of the stripe-type grooves by using an impact drill; bending a reinforcing steel bar according to the hole depth, the length of the grooves and the width of the inter-panel joint and finishing forming of a horseshoe rib; after transplanting the horseshoe ribs into the stripe-type grooves and the vertical holes in the end parts, pouring epoxy resin embedded steel bar glue into the cleaned drilling holes; mixing concrete and broken stone concrete, pouring into the grooves to form an embedded steel bar protective layer; and sequentially spreading layers of protective covering surfaces on the upper layers of the two waste concrete panels from bottom to top. The method provided by the invention has the advantages that the relative vertical displacement at two sides of the old panel joint, the reflection cracks are prevented to generate and develop so as to reduce or stop reflection cracks generated during spreading of asphalt on an old concrete pavement.

Owner:SHANGHAI SHISHEN IND & TRADE CO LTD

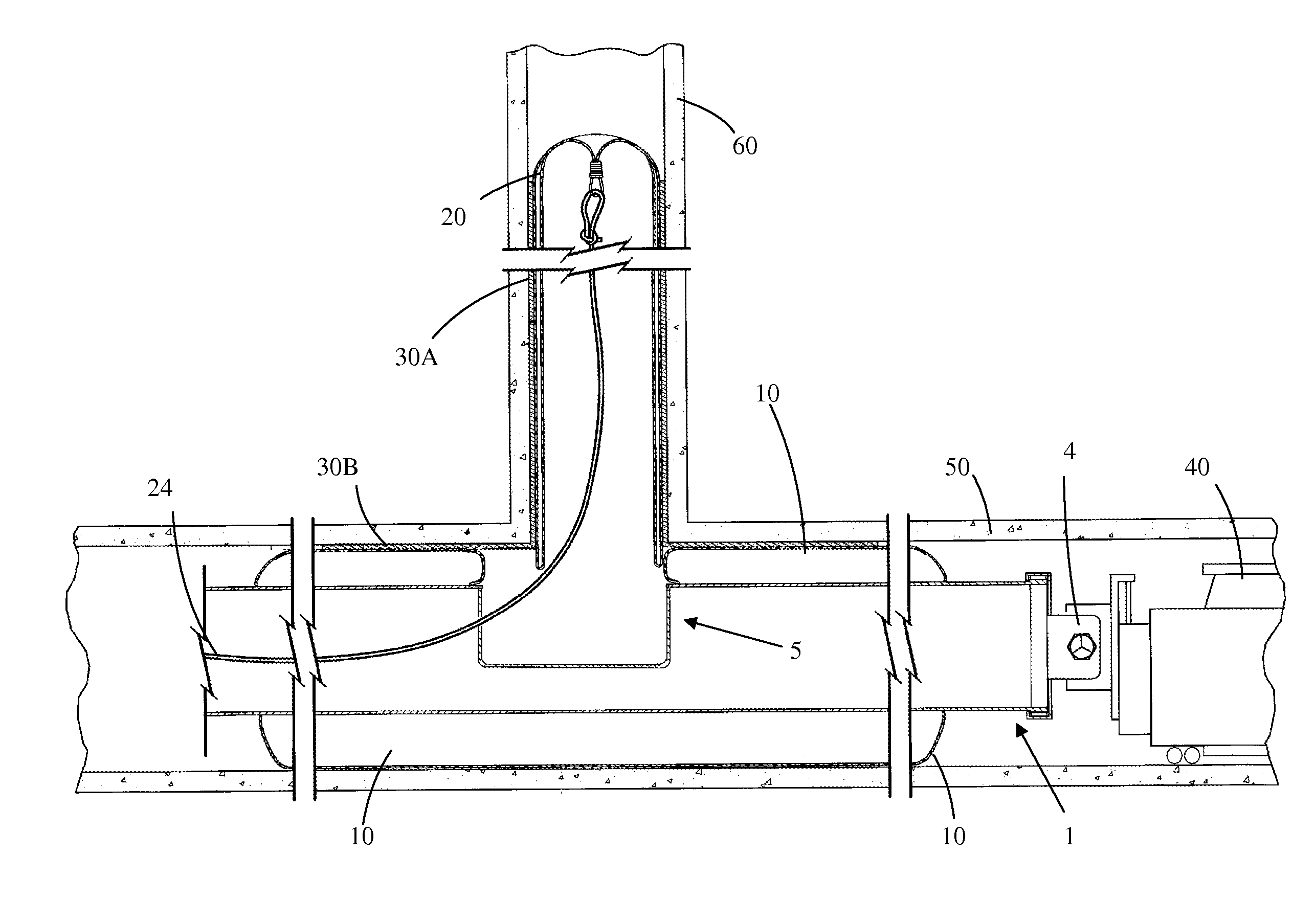

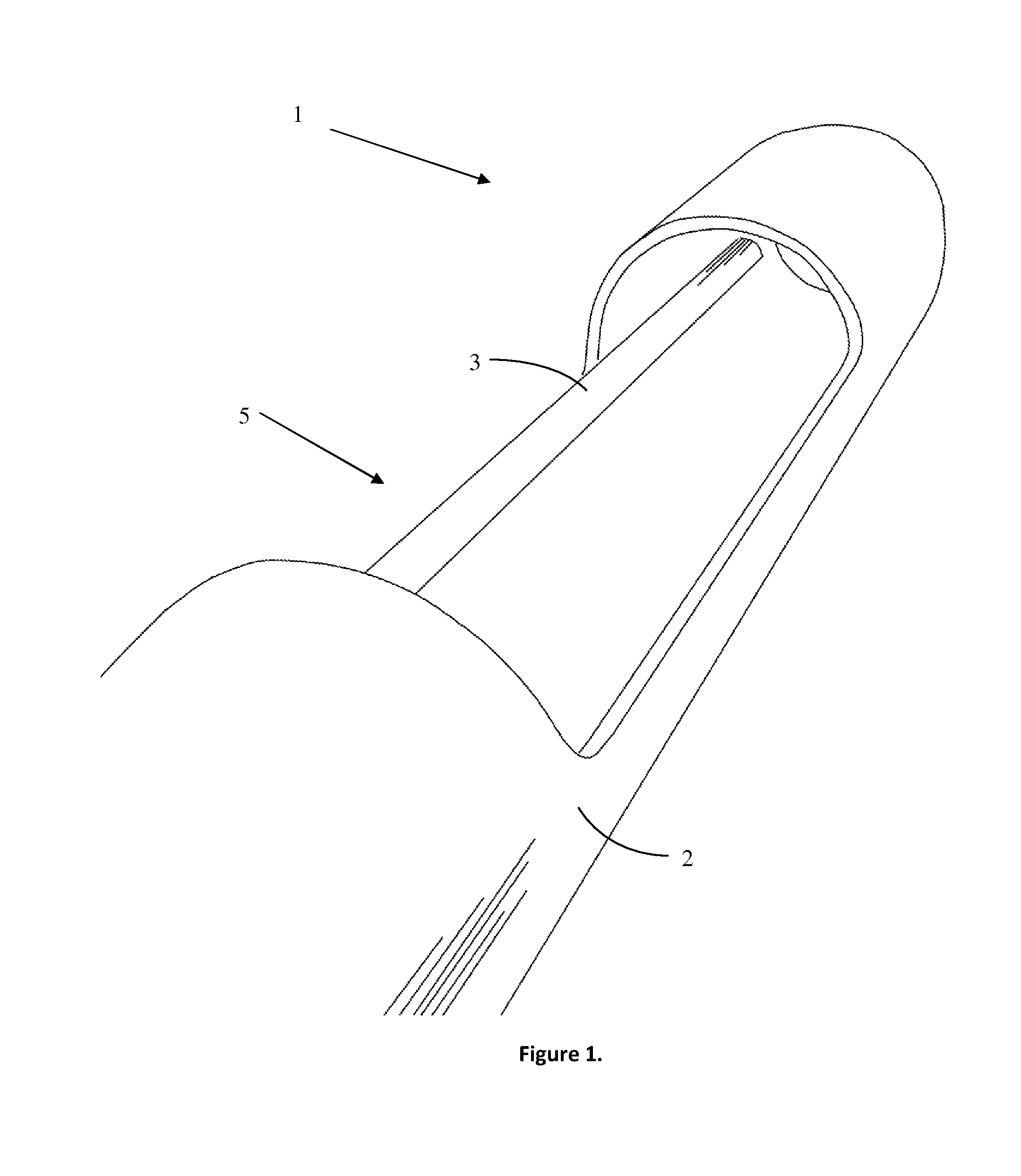

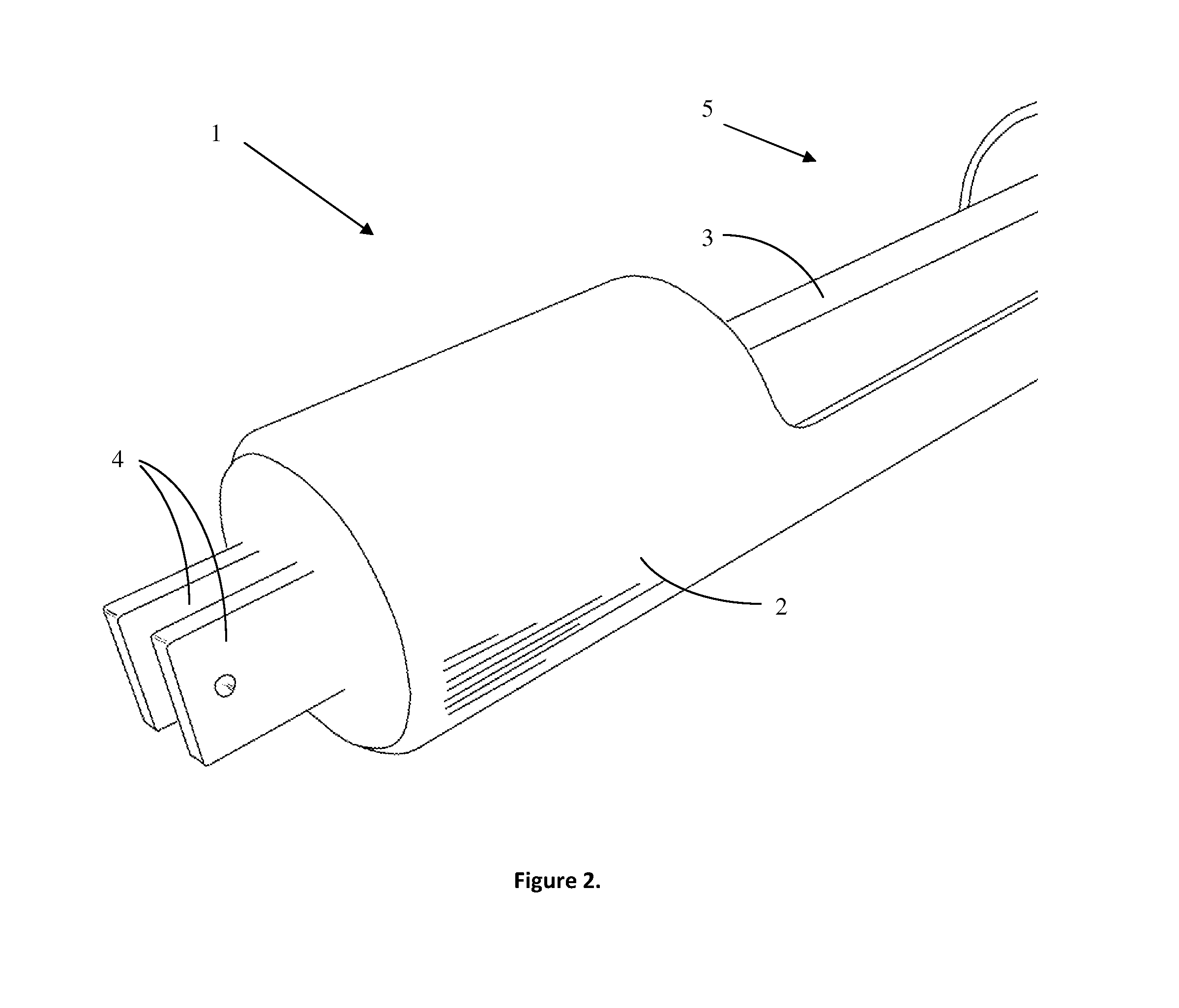

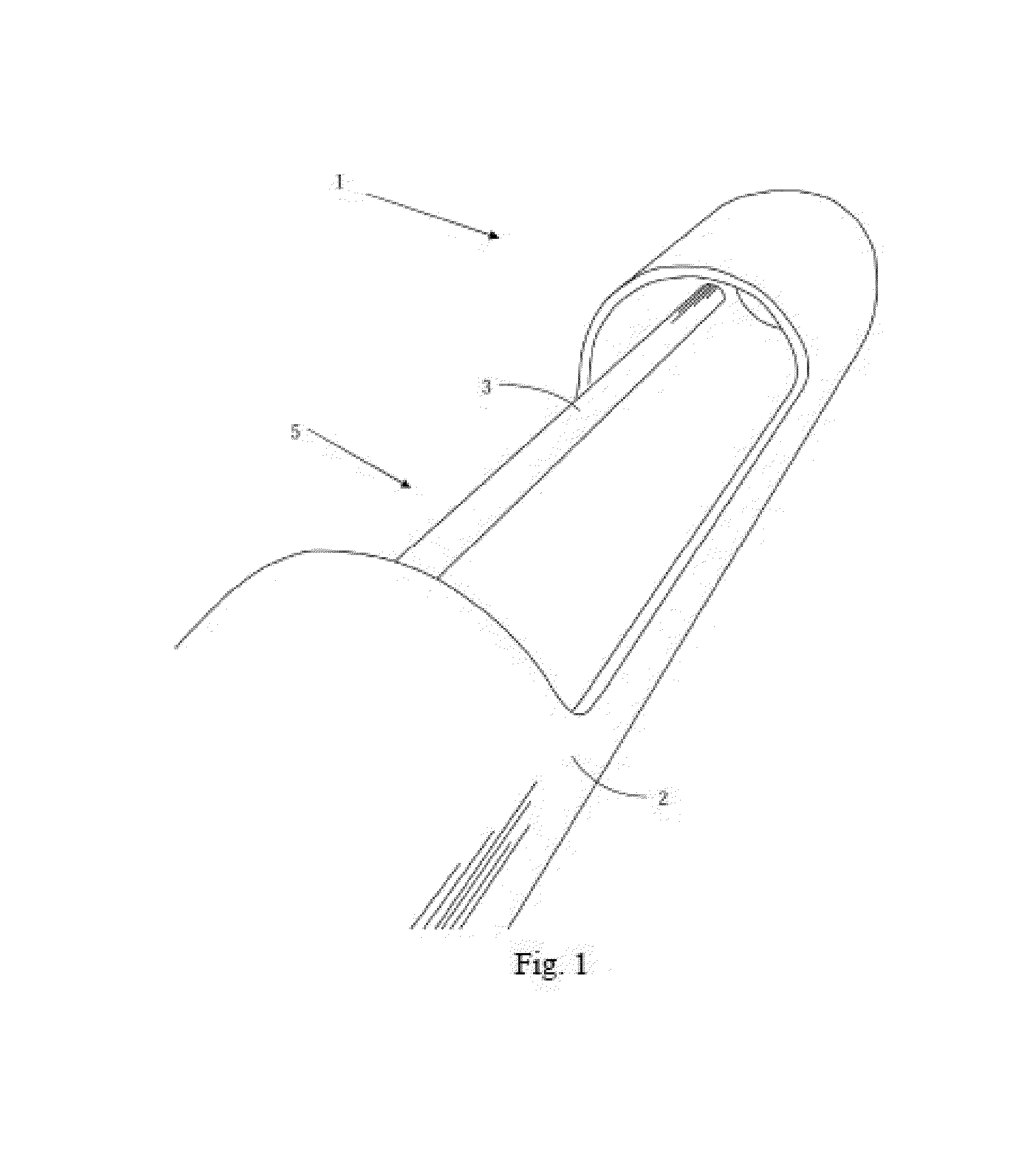

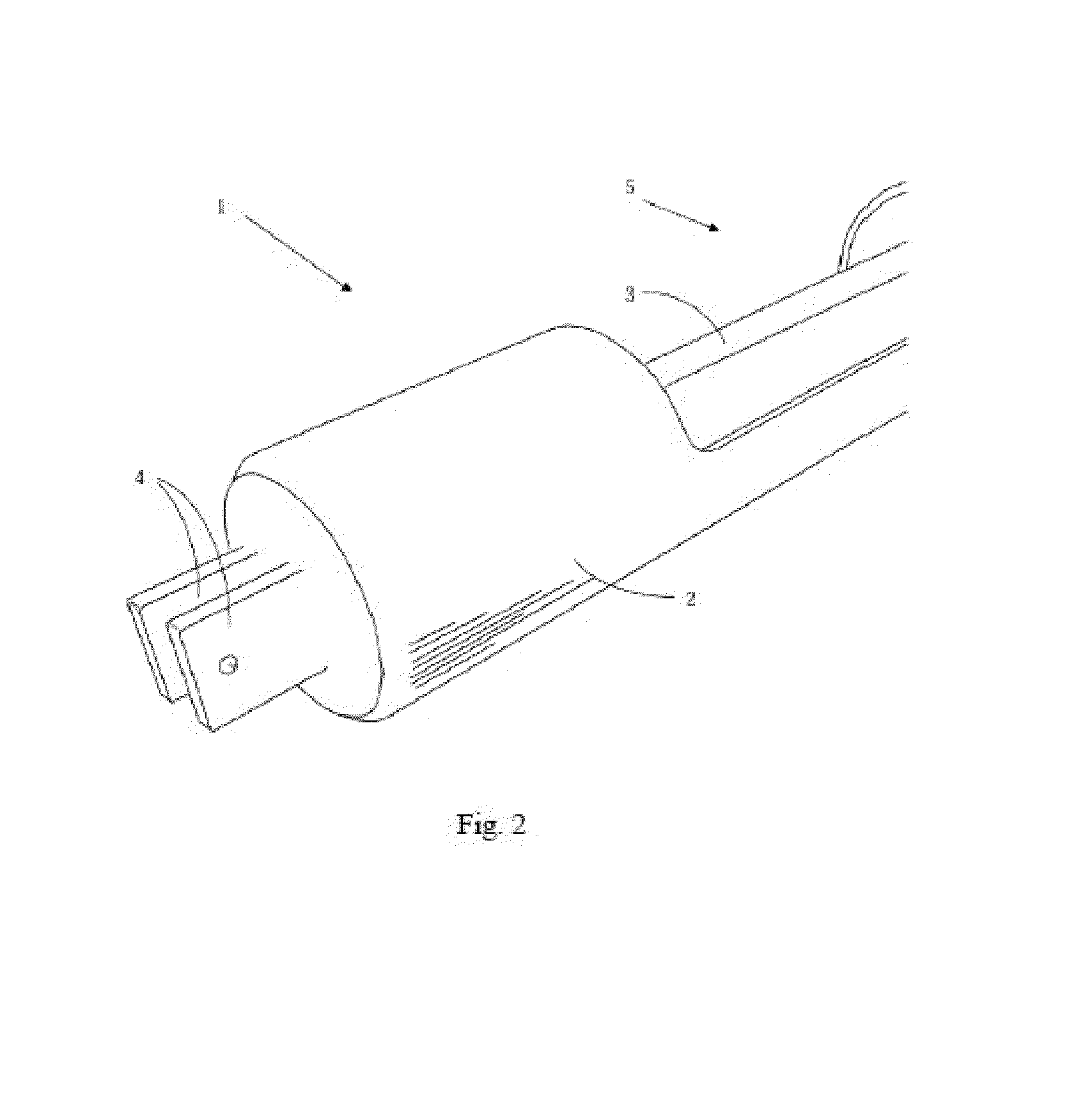

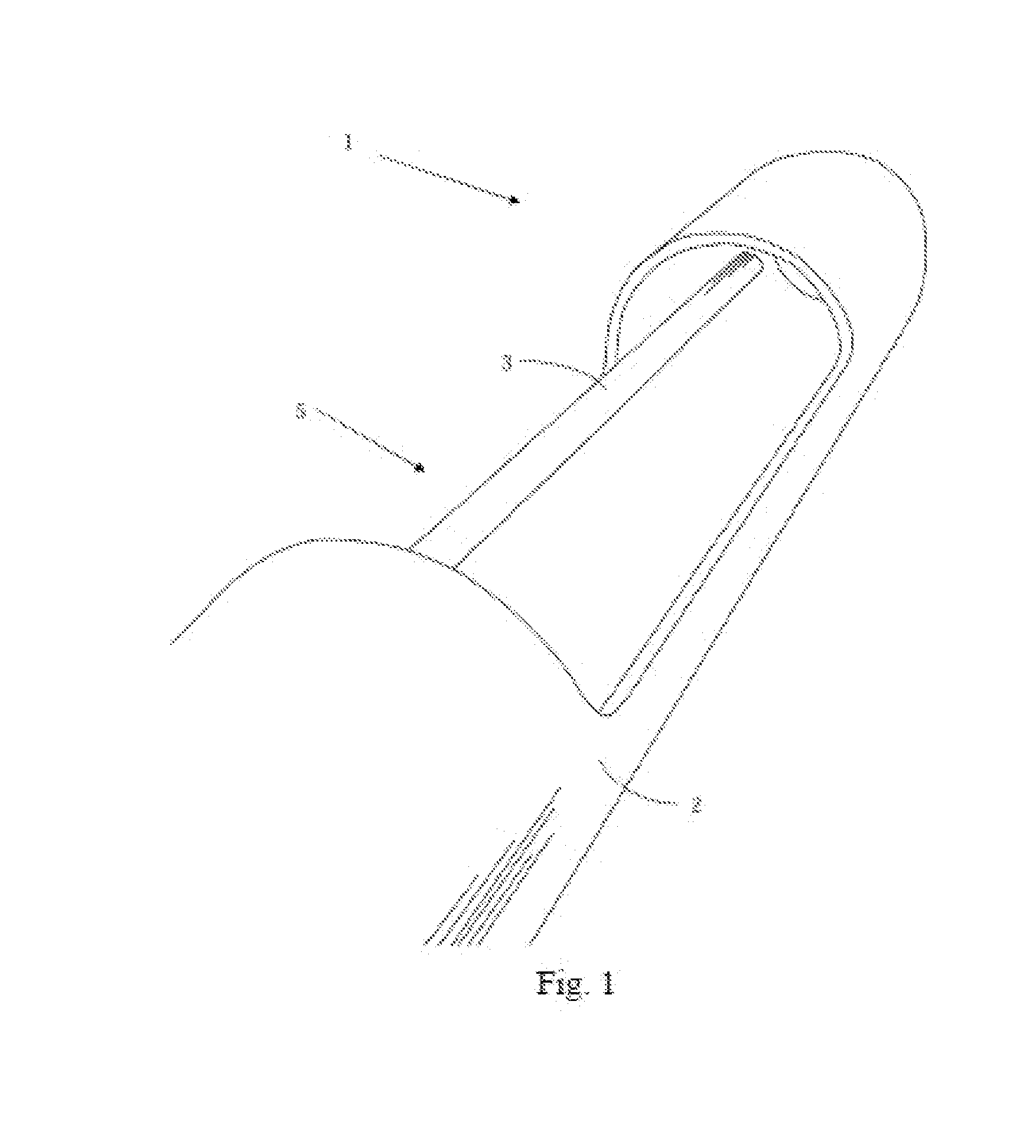

Method and device for repairing piping

ActiveUS8869839B1Avoid repairsSufficient pressureUnderground chambersPipe elementsLine tubingResin embedding

An device and method for repairing the junction of a main pipe line and a lateral pipe. The device uses a series of independently controlled bladders to adjust the timing and pressure exerted by the bladders on the pipes. The device also uses a liner assembly of resin absorbent material is formed, with a tubular lateral liner connected to a concentric circular main liner. The liner also includes an opening to facilitate loading of the liner in the device. Upon loading the bladders and resin-embedded liner into a train, the device is positioned and the bladders independently inflated, either concurrently or in sequence, installing the liner assembly onto the pipe. Once the resin is cured, the bladder assembly and launcher are removed from the sewer pipe.

Owner:PERMA LINER IND

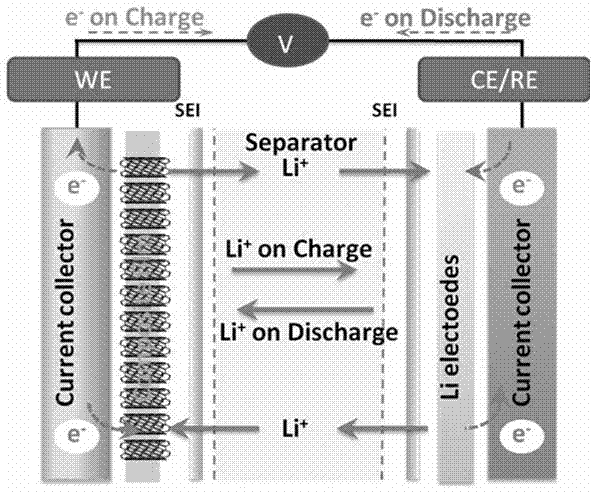

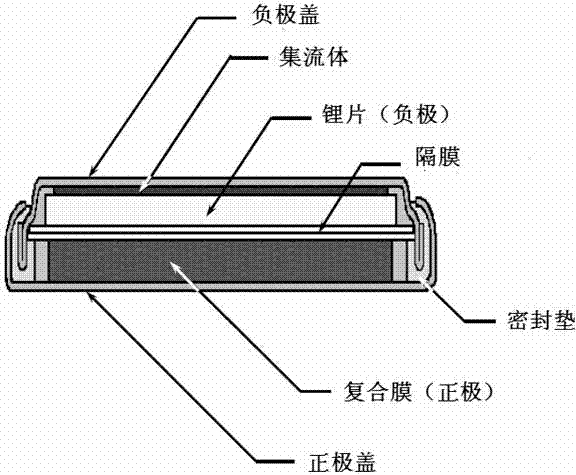

Oriented carbon nanotube/polymer composite film and its preparation method and application

ActiveCN102263221AEvenly distributedImprove conductivitySecondary cellsCell component detailsEpoxyPolymer science

The invention belongs to the technical field of lithium ion batteries and in particular relates to a CNT (carbon nano tube) / polymer composite membrane as well as a preparing method and an application thereof. The composite membrane is prepared by taking an epoxy resin embedding solution, a flexibilizer and a CNT array as raw materials and then carrying out curing, compounding and slicing on the raw materials. CNTs in the composite membrane are distributed evenly, thus the upper and lower surfaces of the composite membrane have good electrical conductivity and also have good flexibility and strength; and the surfaces of the composite membrane are provided with a large number of opened tail ends of the CNTs, and the composite membrane can be applied to lithium ion batteries widely due to the highly oriented structures of the opened tail ends. The vertically-oriented CNT / polymer composite membrane is applied to buckled lithium ion batteries and polymer lithium ion batteries and also suitable for other types of lithium ion batteries.

Owner:宁国市龙晟柔性储能材料科技有限公司

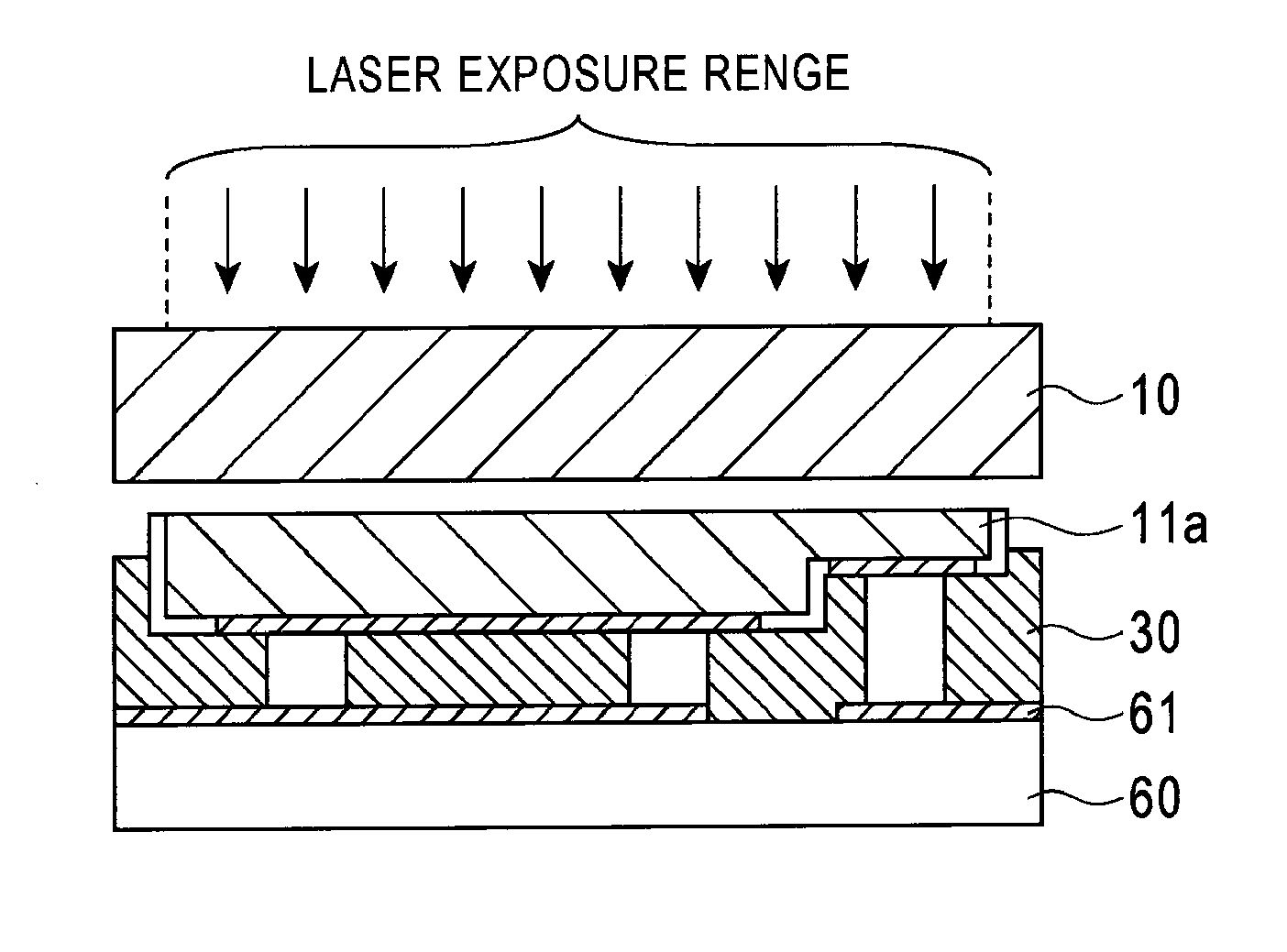

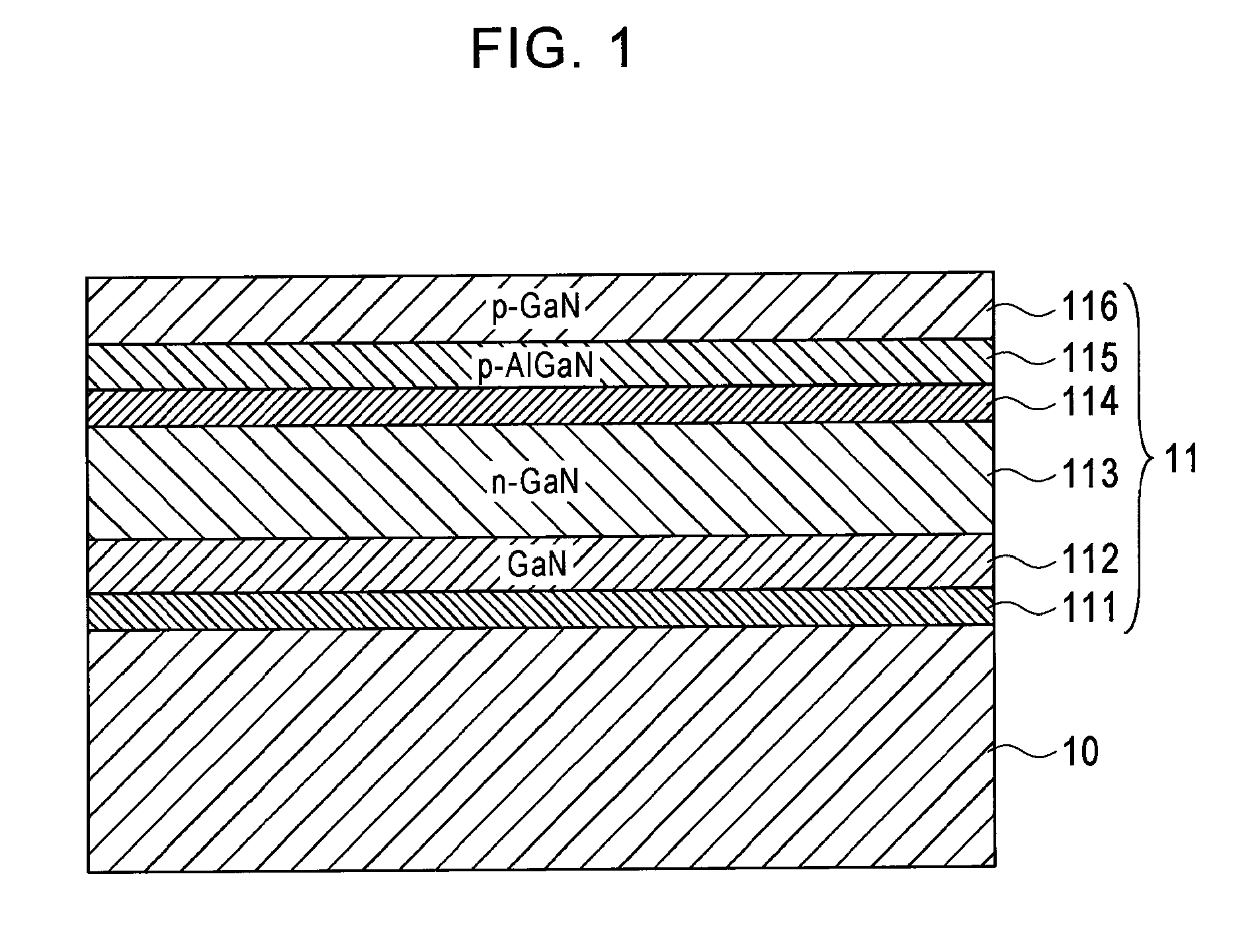

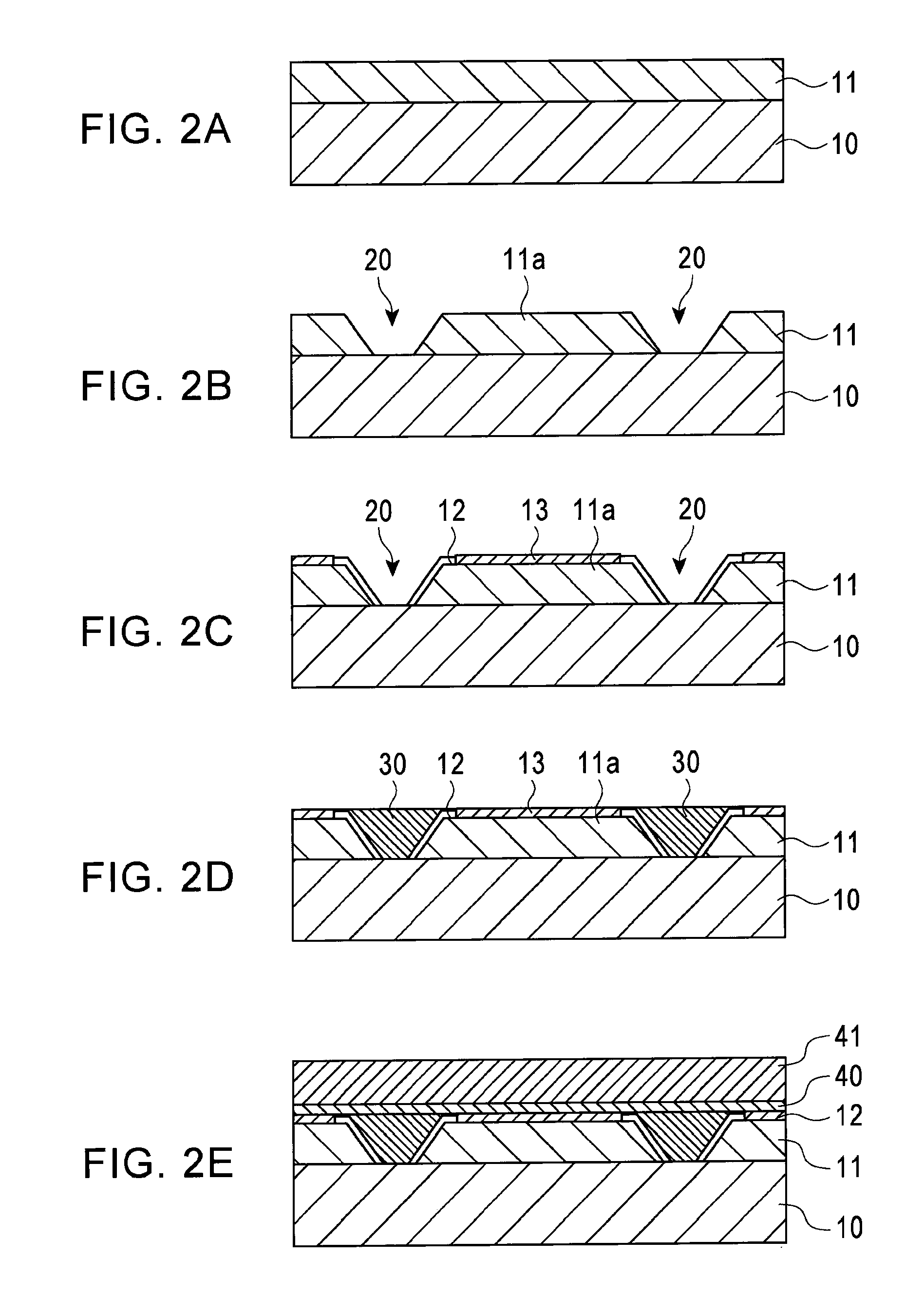

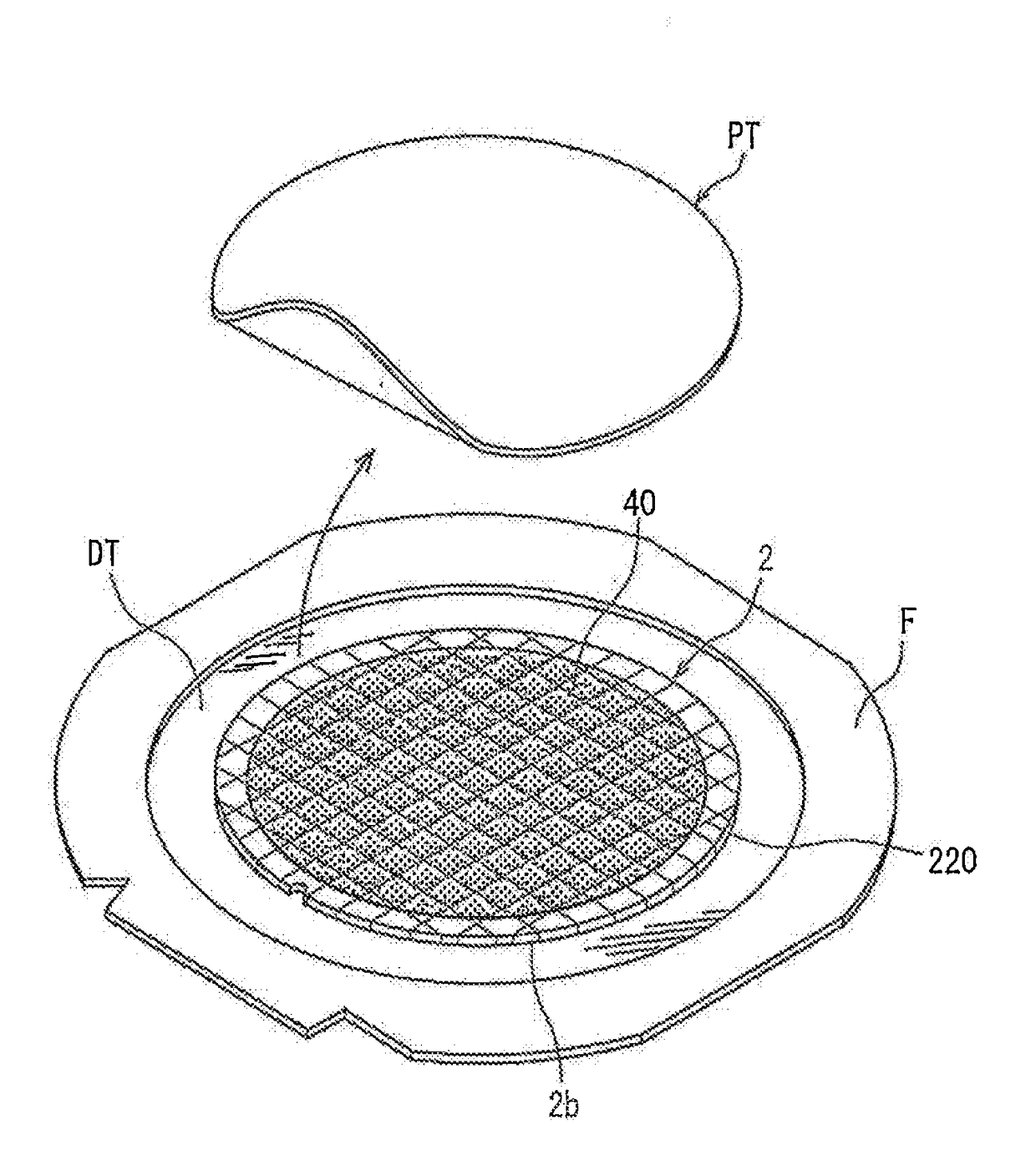

Method for manufacturing semiconductor light-emitting device

ActiveUS20110177633A1Avoid crackingReliable removalSemiconductor/solid-state device manufacturingSemiconductor devicesForeign matterResin embedding

A method for manufacturing a resin-embedded semiconductor light-emitting device that is capable of preventing a semiconductor film from being damaged when a growth substrate is delaminated using a laser lift-off method, and that is capable of preventing foreign matter from adhering to the semiconductor film when a resin material is applied. A laser exposure step to delaminate the growth substrate from the semiconductor film comprises a first laser exposure step for performing laser exposure at an energy density at which the resin is broken down but the semiconductor film is not broken down, in a range including a portion adjacent to at least one section of the semiconductor film divided by dividing grooves and at least one section of resin, and a second exposure step for performing laser exposure at an energy density at which the semiconductor film can be broken down in a range including at least one section.

Owner:STANLEY ELECTRIC CO LTD

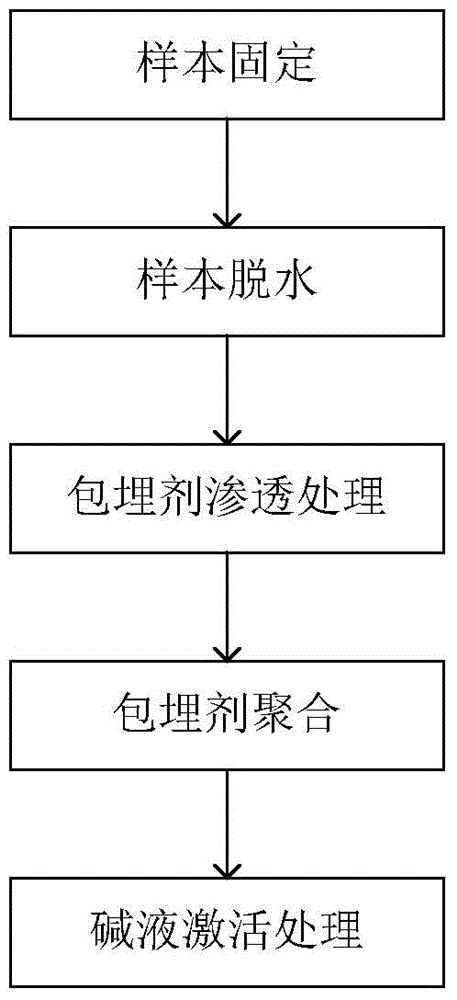

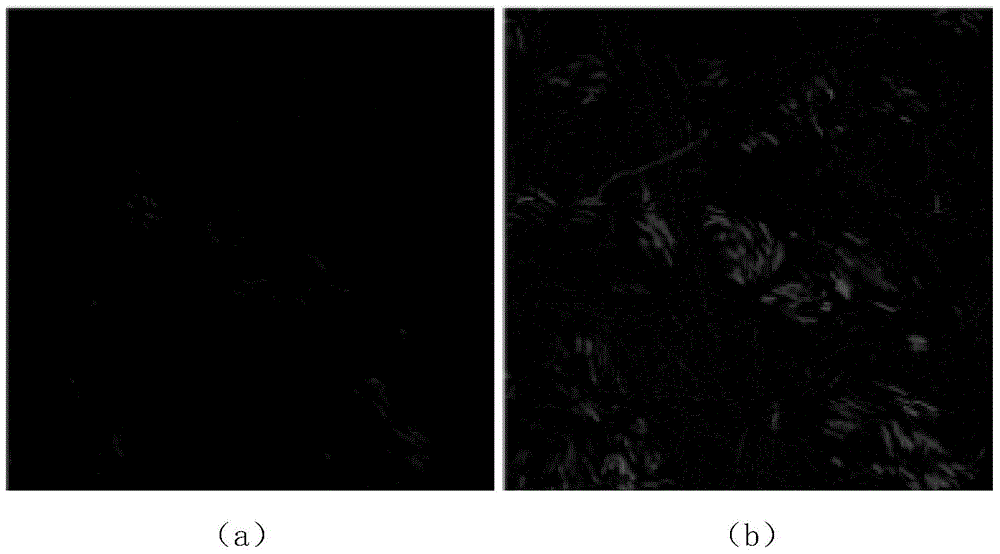

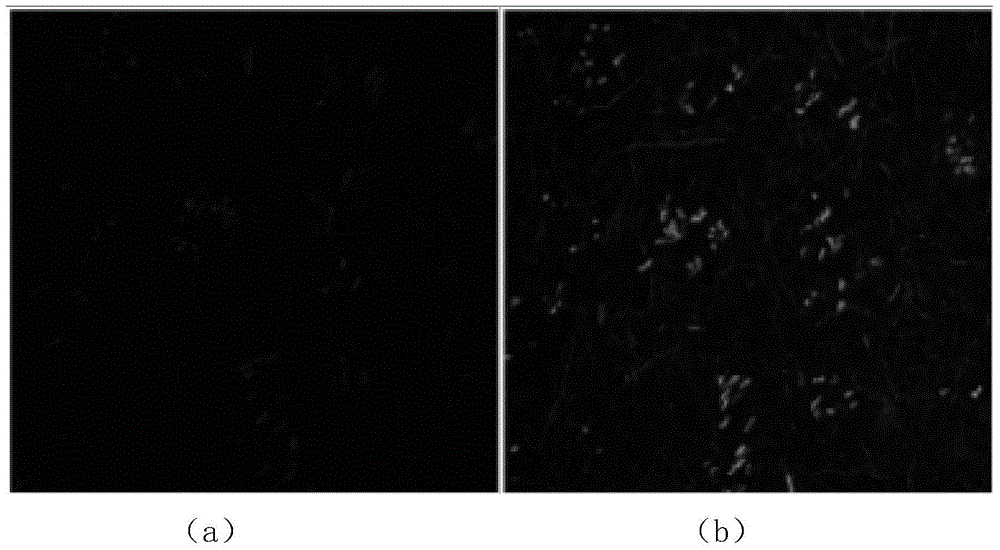

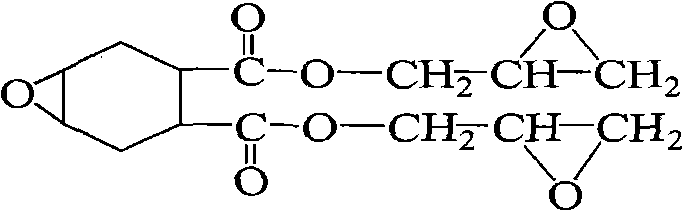

Resin embedding method for biological tissues marked by fluorescent protein and application of alkaline solution

InactiveCN105021431AHigh fluorescence intensityQuality improvementPreparing sample for investigationPermeationFluorescent protein

The invention discloses a resin embedding method for biological tissues marked by fluorescent protein. The resin embedding method comprises the following steps: (1), fixing the biological tissues marked by the fluorescent protein in a chemical fixing manner to obtain the fixed biological tissues marked by the fluorescent protein; (2), replacing the fixed biological tissues marked by the fluorescent protein with an organic solvent, so that the biologic tissues are dewatered to obtain dewatered biological tissues marked by the fluorescent protein; (3), performing embedding agent permeation treatment on the dewatered biological tissues marked by the fluorescent protein to obtain embedding-agent monomer-filled biological tissues marked by the fluorescent protein; (4), enabling the embedding agent to generate a polymerization reaction to obtain a resin-embedding sample of the biological tissues marked by the fluorescent protein; (5), soaking the resin-embedding sample in an alkaline solution, and adjusting the pH value to be 8-12. The resin embedding method for the biological tissues marked by the fluorescent protein can be suitable for biologic tissue samples of various sizes, the fluorescence intensity is high, the imaging effect is good, and the samples have excellent cutting performance.

Owner:HUAZHONG UNIV OF SCI & TECH

Immingled filling material filled polyurethane modified epoxy resin embedding material and preparation method

The invention relates to polyurethane modified epoxy resin encapsulating material filled with promiscuous padding and the preparation method, in particular to epoxy resin encapsulating material prepared by adopting the promiscuous padding mixed by glass fiber power (MG) and SiO2 or AIN and the TDE-85 epoxy resin modified by polyurethane and the preparation method thereof. By adopting the polyurethane to toughen and modify the TDE-85 epoxy resin basal body, and adopting methyl tetrahydrophthalic anhydride methpa as the curing agent, 1,4-butylene-glycol as the chain extender, trimethylol propane as the crosslinking agent, 2,4,6-tris(dimethylamino methyl) phenol as the curing accelerator, and the mixture of the MG and the SiO2 or the AlN as the padding, the epoxy resin encapsulating material is made by evenly mixing the components according to the prescriptive mass ratio, which had good technical performance, in particular to the mechanical property. The experiment indicates that the promiscuous padding can effectively make up for the performance defects of the epoxy resin encapsulating material filled with single particle padding, and has good integrated performance.

Owner:CENT SOUTH UNIV

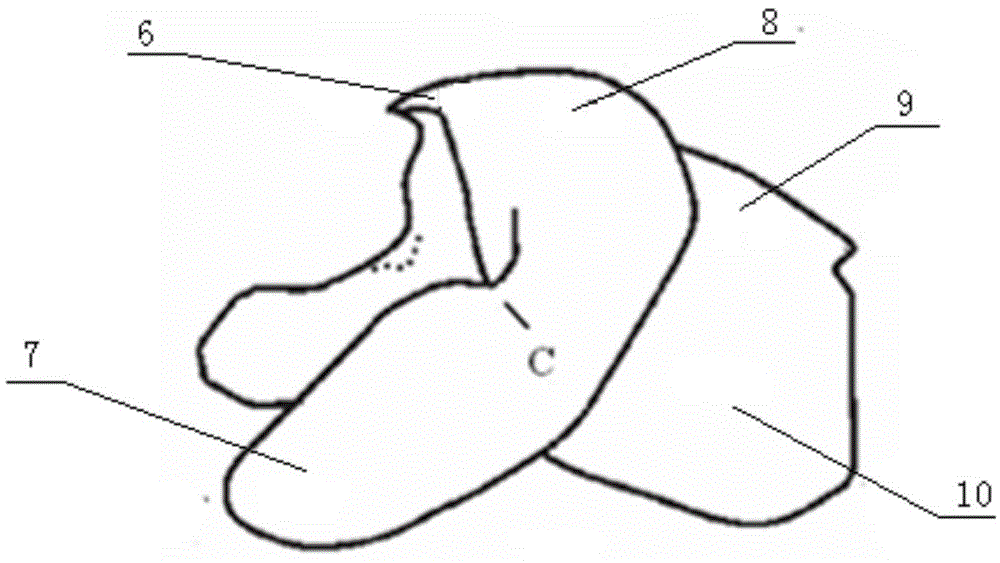

Method for grinding and preserving cephalopod otolith slices

ActiveCN102172882ANot easy to extractNot easy to grindPolishing machinesLapping machinesResin embeddingEngineering

The invention relates to a method for grinding and protecting cephalopod otolith. The method comprises the steps of extraction, soaking, placing, resin embedding, cutting, fixing on a glass slide, abrading, polishing, preservation and the like. The method can solve the problems that the cephalopod otolith is small and not easily ground, the otolith is easily broken in the grinding process and thetextures are easy to fade after polishing; and the otolith textures can be kept for long time.

Owner:SHANGHAI OCEAN UNIV

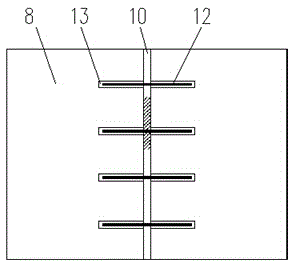

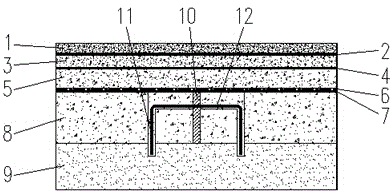

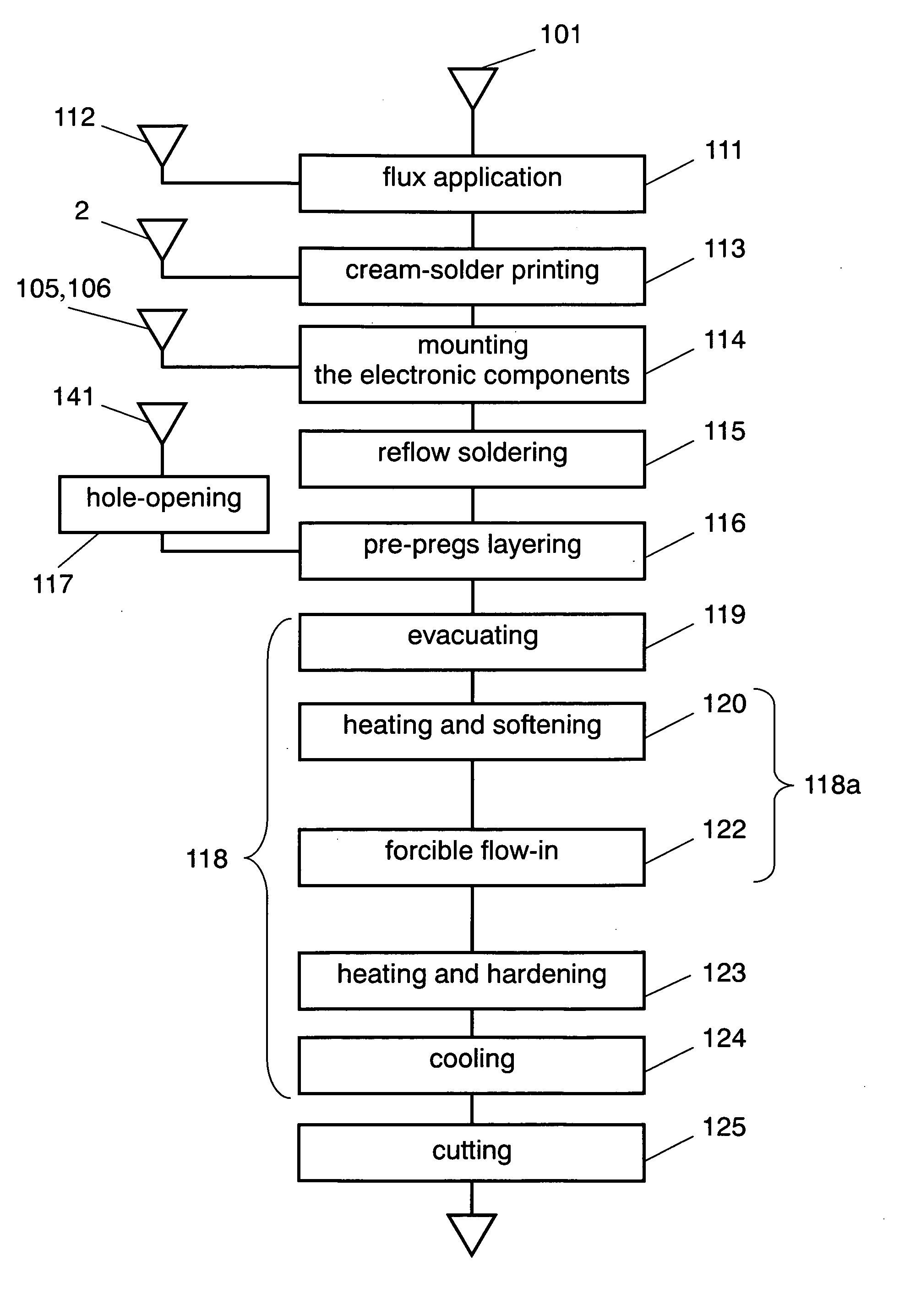

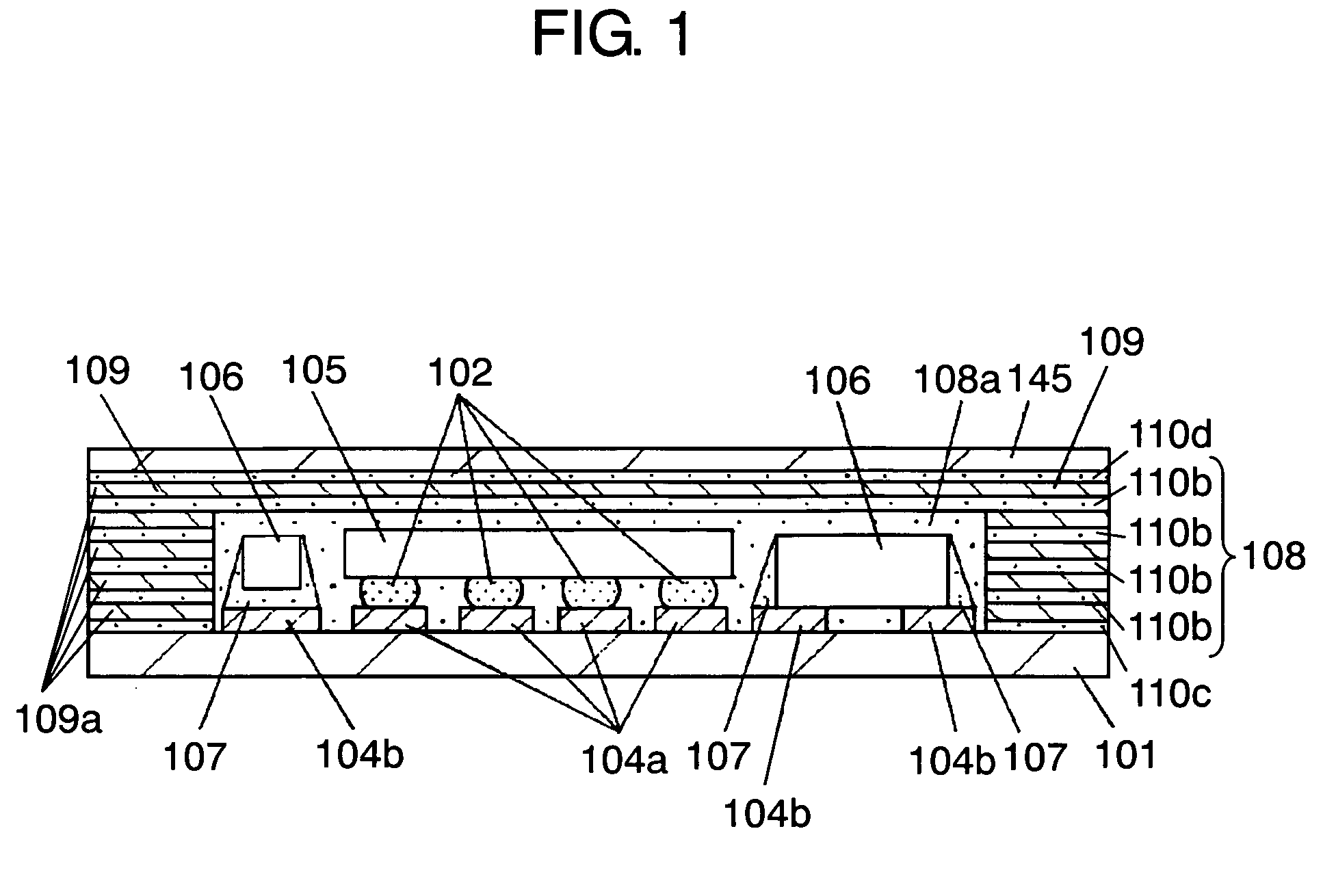

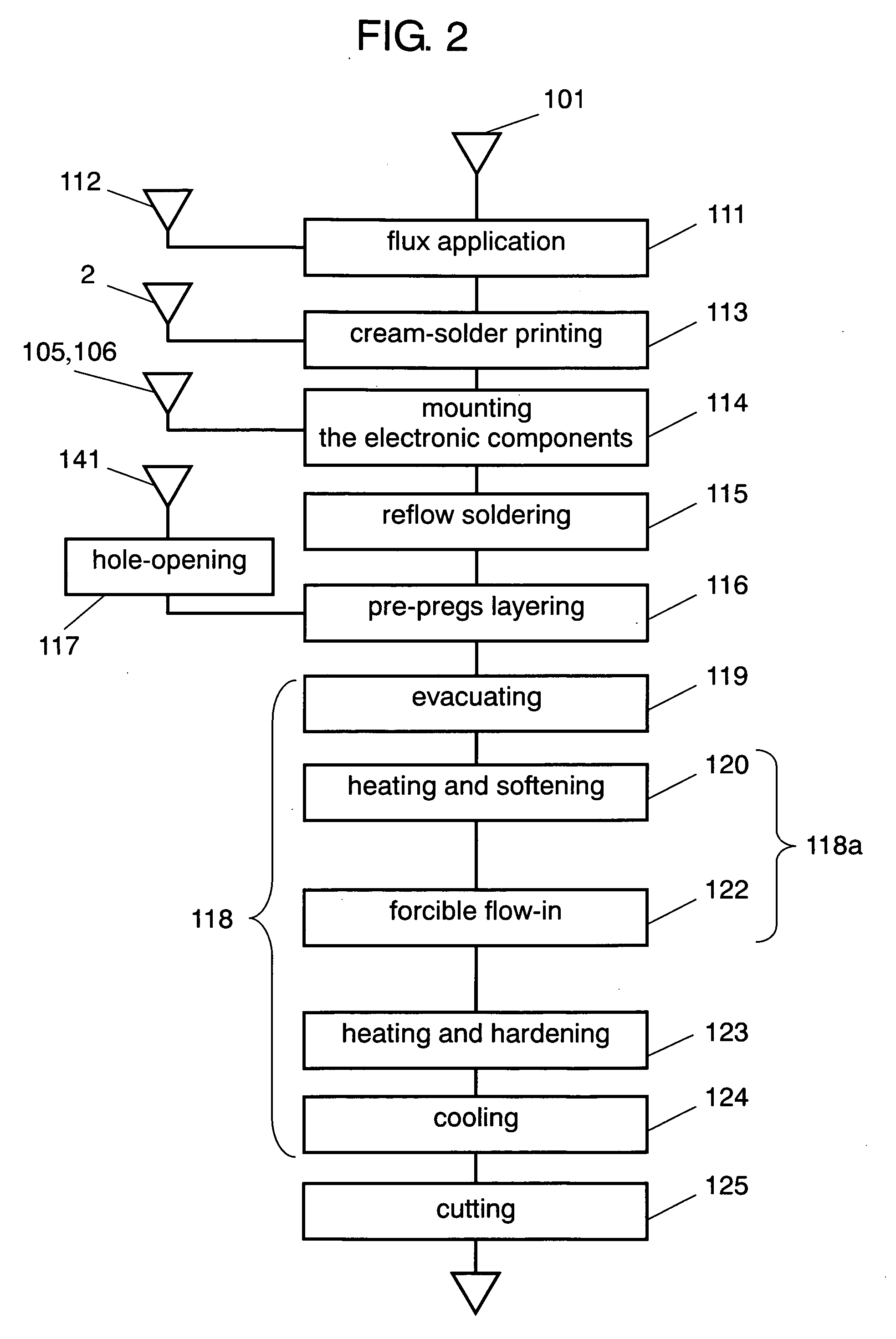

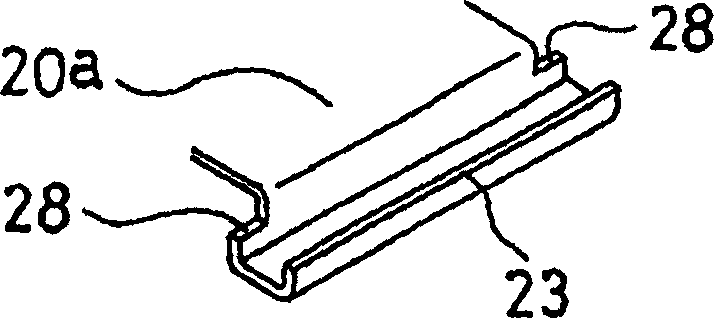

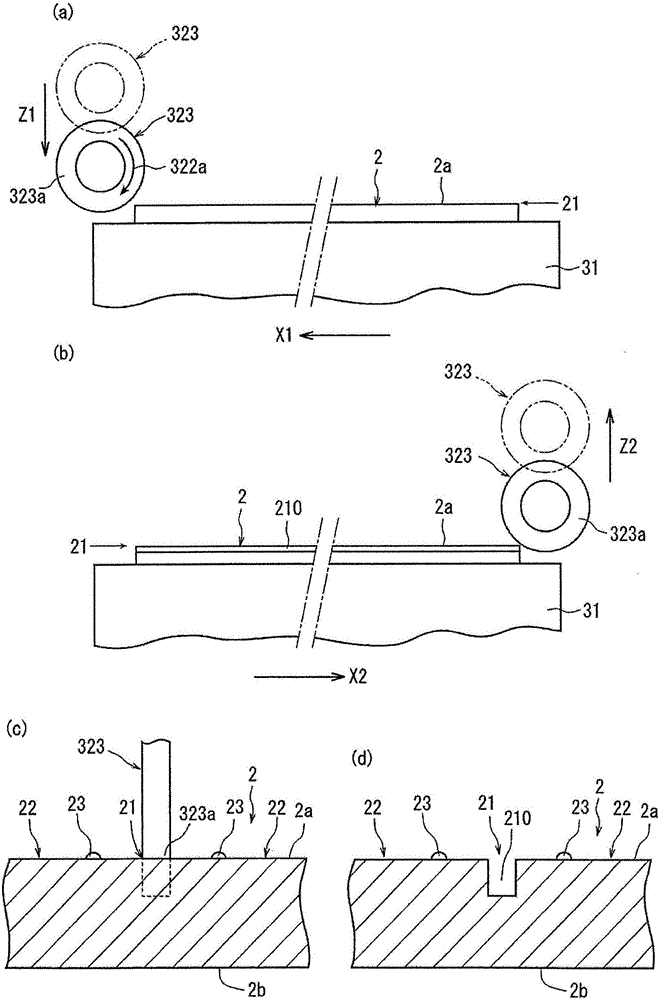

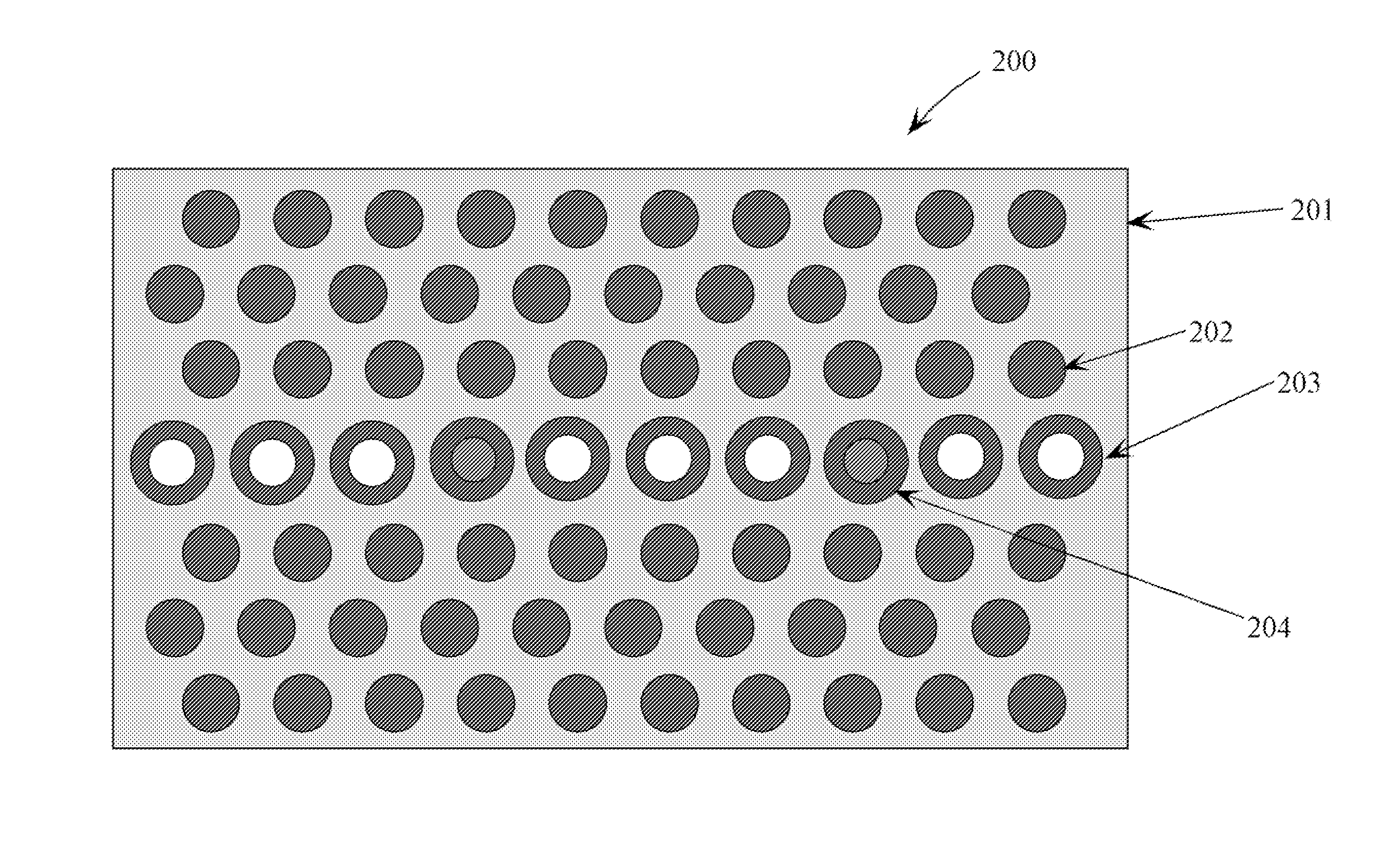

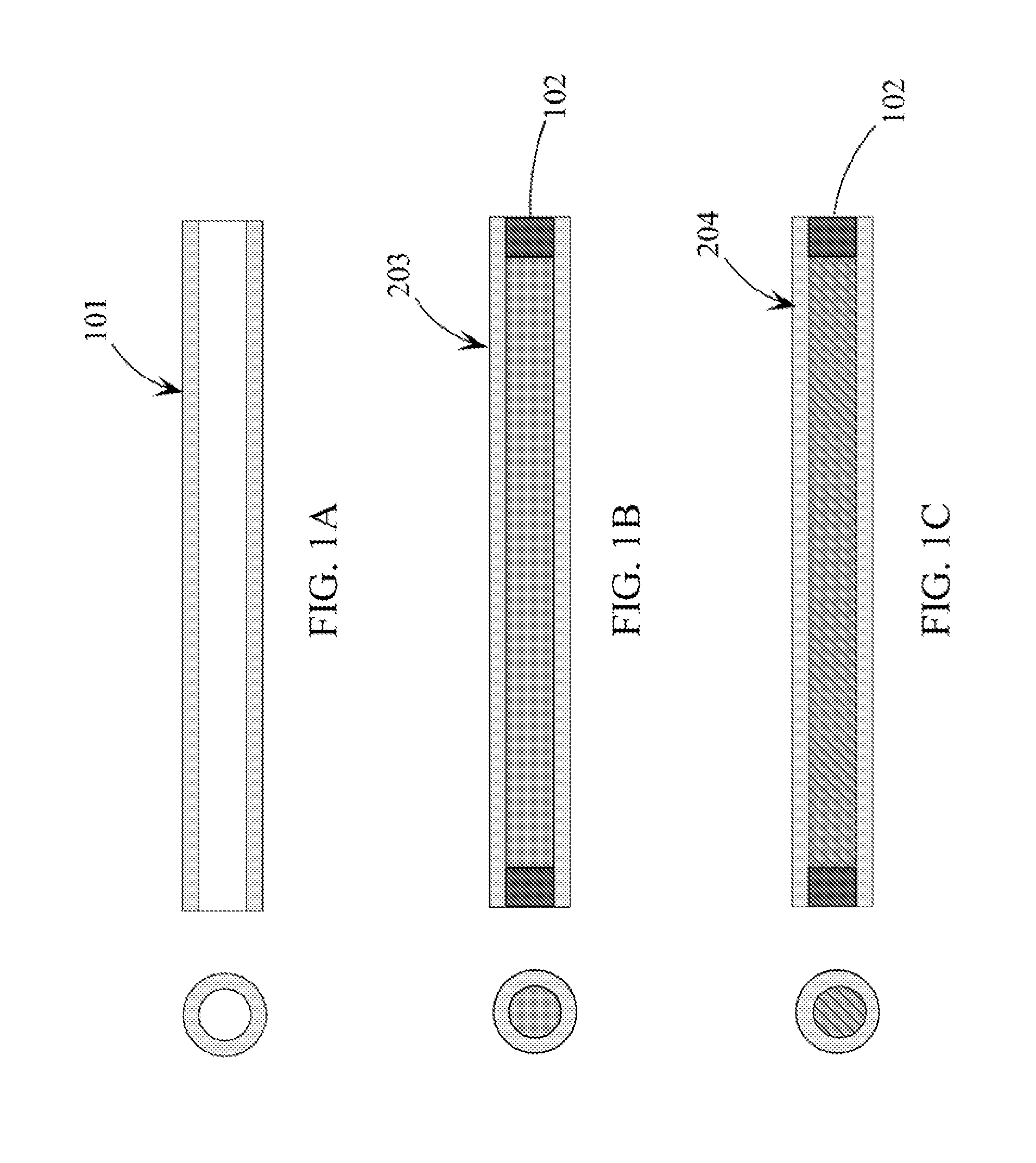

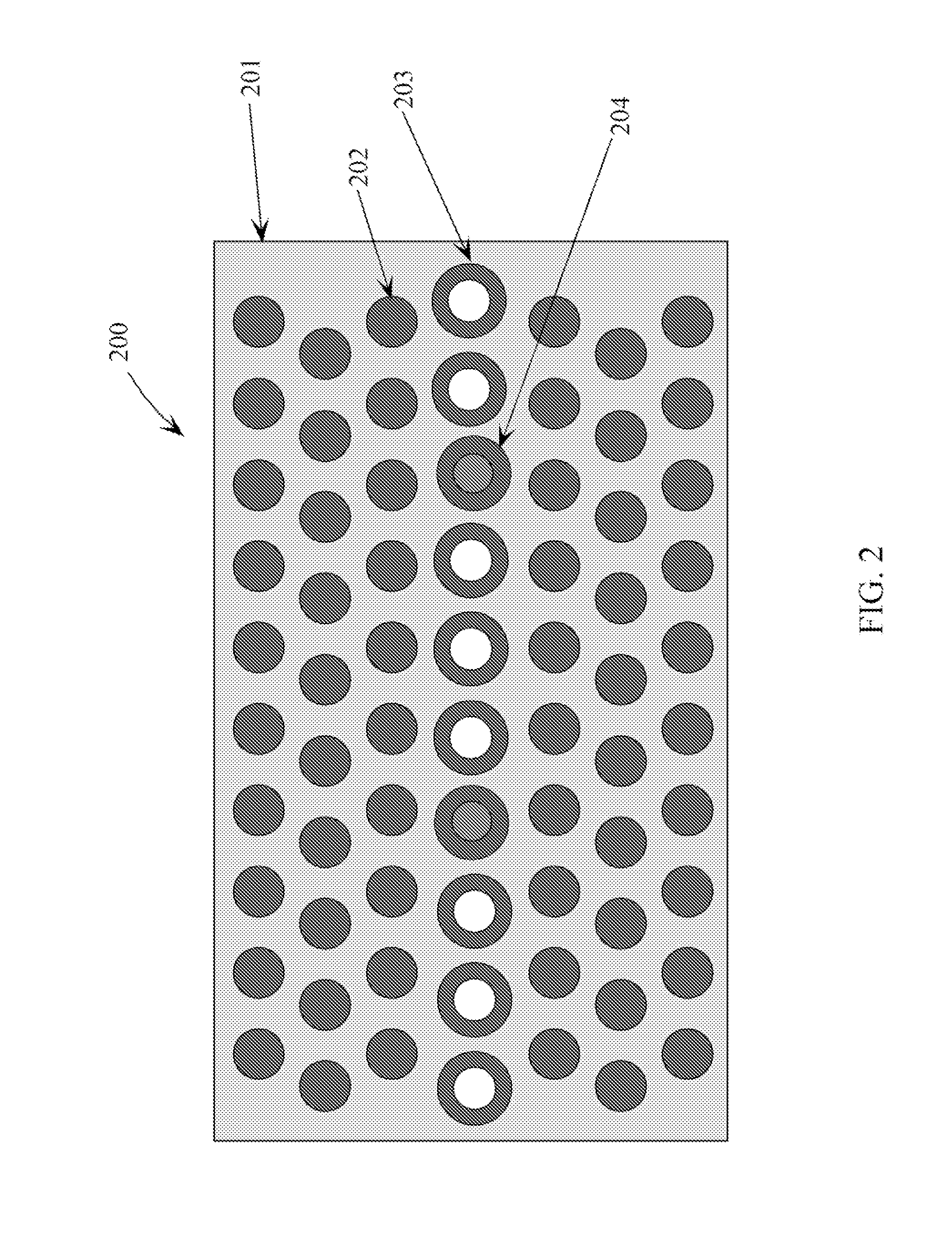

Component-embedded printed wiring board and method of manufacturing the same

InactiveUS20060260122A1Improve connection reliabilityPrinted circuit assemblingSemiconductor/solid-state device detailsResin embeddingElectronic component

A component-embedded printed wiring board (PWB) is disclosed. This PWB includes (a) a fluid-resin embedding section formed at place corresponding to electronic components such that the embedding section covers the electronic components, (b) a resin flow-speed accelerator placed in parallel with a top face of a circuit board and surrounding the embedding section, and (c) bonding resin placed at least between the accelerator and the circuit board. The fluid resin embedding section is filled up with the same resin as the bonding resin. This structure allows the accelerator to compress the resin with a pressure applied to the PWB, so that the resin tends to flow along the circuit board. As a result, the fluid-resin embedding section is thoroughly filled up with the resin without leaving any airs, and the reliable PWB is thus obtainable.

Owner:PANASONIC CORP

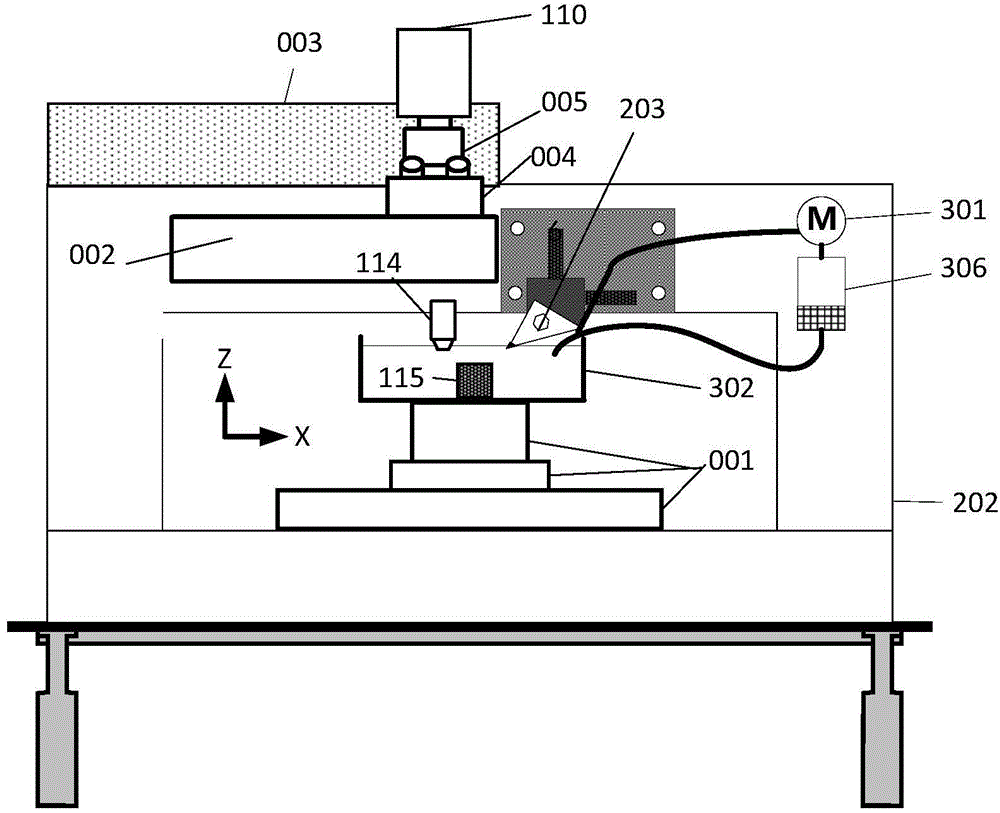

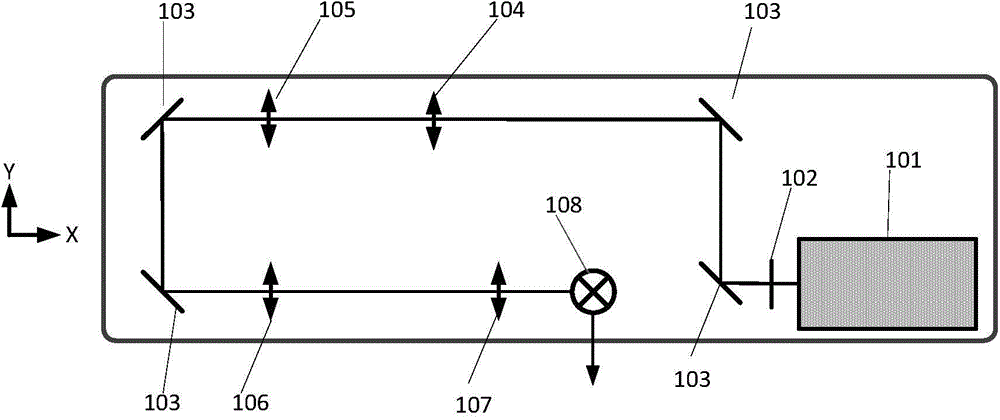

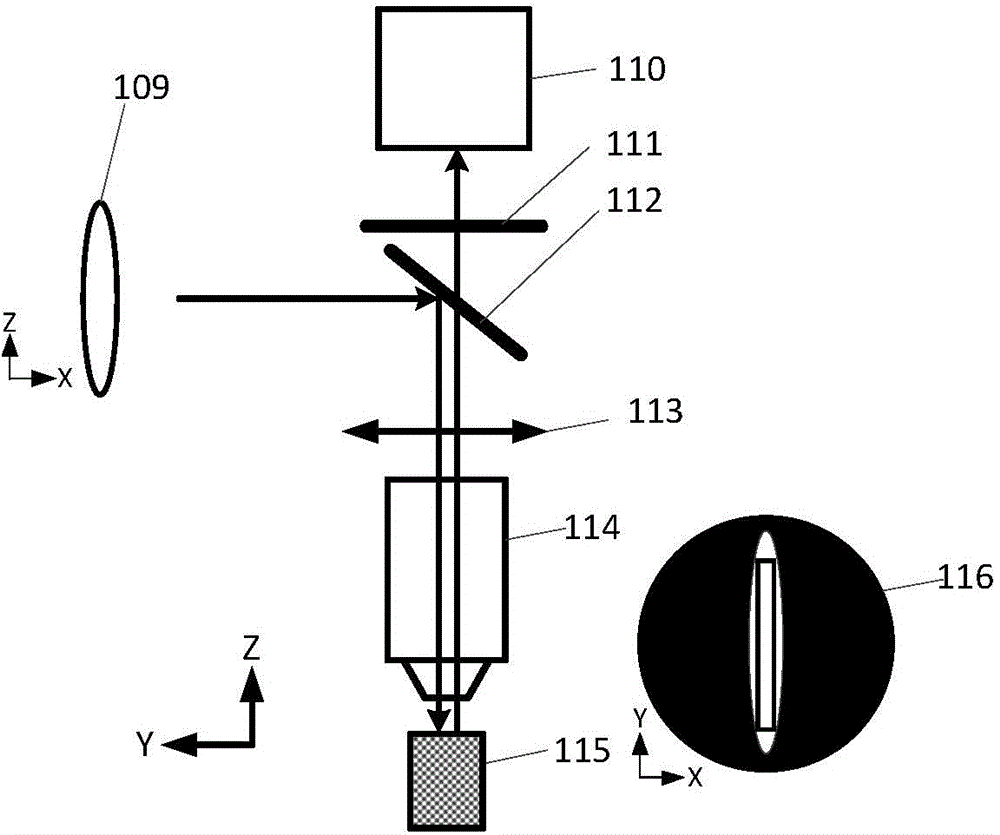

Bio-sample tomography micro-imaging system

ActiveCN104833659AFast cutting speedShorten the timeWithdrawing sample devicesAnalysis by material excitationCamera lensMicro imaging

The invention discloses a bio-sample tomography micro-imaging system which includes a low-light imaging sub system and a sample planar processing sub system. The low-light imaging sub system is used for performing integral imaging during planar processing on the sample, and the sample planar processing sub system is used for processing the surface of the sample to form a tomography for imaging by the low-light imaging sub system. The low-light imaging sub system comprises a linear scanning module and a light spot shaping module, wherein the linear scanning module comprises a linear detector and an imaging lens. The light spot shaping module, in the direction of light path, successively comprises a beam expansion unit and a beam shrinkage unit. In the invention, by means of separation of a cutting module from the imaging system, the low-light imaging sub system is designed, so that the bio-sample tomography micro-imaging system is suitable for various resin-embedded samples. By means of separation of cutting speed from imaging speed, longitudinal low-sampling quick imaging acquisition can be carried out. In addition, the bio-sample tomography micro-imaging system can perform quick 3D information acquisition on low-light objects, such as fluorescent biological organs and the like.

Owner:WUHAN OE BIO CO LTD

Method and device for repairing piping

InactiveUS8807172B2Avoid repairsSufficient pressureLayered productsLaminationLine tubingResin embedding

A device and method for repairing the junction of a main pipe line and a lateral pipe. The device uses a series of independently controlled bladders to adjust the timing and pressure exerted by the bladders on the pipes. The device also uses a liner assembly of resin absorbent material is formed, with a tubular lateral liner connected to a concentric circular main liner. The liner also includes an opening to facilitate loading of the liner in the device. Upon loading the bladders and resin-embedded liner into a train, the device is positioned and the bladders independently inflated, either concurrently or in sequence, installing the liner assembly onto the pipe. Once the resin is cured, the bladder assembly and launcher are removed from the sewer pipe.

Owner:PERMA LINER IND

Method and device for repairing piping

InactiveUS20130139922A1Avoid repairsSufficient pressureLayered productsLaminationResin embeddingAbsorbent material

A device and method for repairing the junction of a main pipe line and a lateral pipe. The device uses a series of independently controlled bladders to adjust the timing and pressure exerted by the bladders on the pipes. The device also uses a liner assembly of resin absorbent material is formed, with a tubular lateral liner connected to a concentric circular main liner. The liner also includes an opening to facilitate loading of the liner in the device. Upon loading the bladders and resin-embedded liner into a train, the device is positioned and the bladders independently inflated, either concurrently or in sequence, installing the liner assembly onto the pipe. Once the resin is cured, the bladder assembly and launcher are removed from the sewer pipe.

Owner:PERMA LINER IND

Acid-resistant epoxy resin embedding agent and preparation method thereof

InactiveCN101100594AImprove acid resistanceMeet the needs of useOther chemical processesCell sealing materialsEpoxyResin embedding

An acid-resisting epoxy-resin pouring agent and its production are disclosed. The pouring agent consists of epoxy-resin 100 proportion, anhydride 60-100 proportion, trivalent chrome complex 0.5-5.0 proportion and tertiary amine 0.3-3.0 proportion. The process is carried out by surface drying at room temperature for 4-6 hrs and curing less than 25 deg. C for 7 days or less than 80 deg. C for 2-3 hrs. The shearing strength for ABS plastic and lead is greater than or equal to 5 MPa, the acid absorptive rate is less than or equal to 0.7% at 80 deg. C in 40% sulfuric acid battery liquor. It has no acid creep and leakage. It can be used for pouring materials or acid-resisting coatings under high-temperature or high-acidity condition.

Owner:HEILONGJIANG INST OF PETROCHEM

Resin embedding fiber method for detecting fiber form

InactiveCN1884998AOmit prepolymerizationClear boundariesPreparing sample for investigationMaterial analysis by optical meansFiberPolymer science

The invention relates to a method for using resin to pack fiber, which comprises: dipping fiber into packing medium, to be polymerized at 80-120Deg. C for 2-4 hours, to obtain the fiber packing body as polymethacrylate packing system, polystyrene packing system or polyvinyl acetate packing system, wherein the invention adds polymer into monomer to adjust the viscosity of system, to avoid the pre-polymerizing reaction of monomer; in addition, it directly uses BPO to initialize monomer to process free group combined polymerization for 2-3 hours, to reach the packing demands, with simple process and high packing speed. And the invention can packing variable fibers, with clear fiber edge, better disperse degree and improved image quality.

Owner:SHANGHAI ENTRY EXIT INSPECTION & QUARANTINE BUREAU OF P R C +1

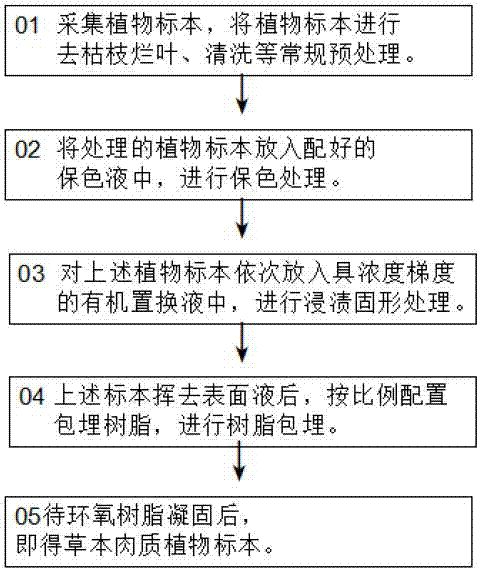

Method for preparing resin-embedded succulent herb specimen

InactiveCN107047543ALong-term color retentionHigh transparencyDead plant preservationOrganic solventResin embedding

The invention discloses a method for preparing a resin-embedded succulent herb specimen. The method comprises the following steps of (1) carrying out conventional pretreatment on succulent herbs; (2) preparing different colors of color preserving solutions, putting the succulent herbs into the color preserving solutions for immersion treatment according to the colors; (3) taking out the treated succulent herbs and rinsing by using distilled water; (4) preparing different concentration of organic solvents, putting the succulent herbs into the organic solvents for organic replacement treatment; (5) taking out the treated succulent herbs and removing the solutions on the surfaces; (6) putting the treated succulent herbs into a silica mold and embedding by using resin; and (7) condensing the resin to obtain the resin-embedded succulent herb specimen. By adopting the method, resin specimens of the succulent herbs represented by the succulent herbs can be prepared, and the specimens embedded into the resin are capable of keeping the native colors and shapes. The gap of preparation of the succulent herb specimen can be compensated, and the plant shape can be more really and intuitively displayed.

Owner:SICHUAN UNIV

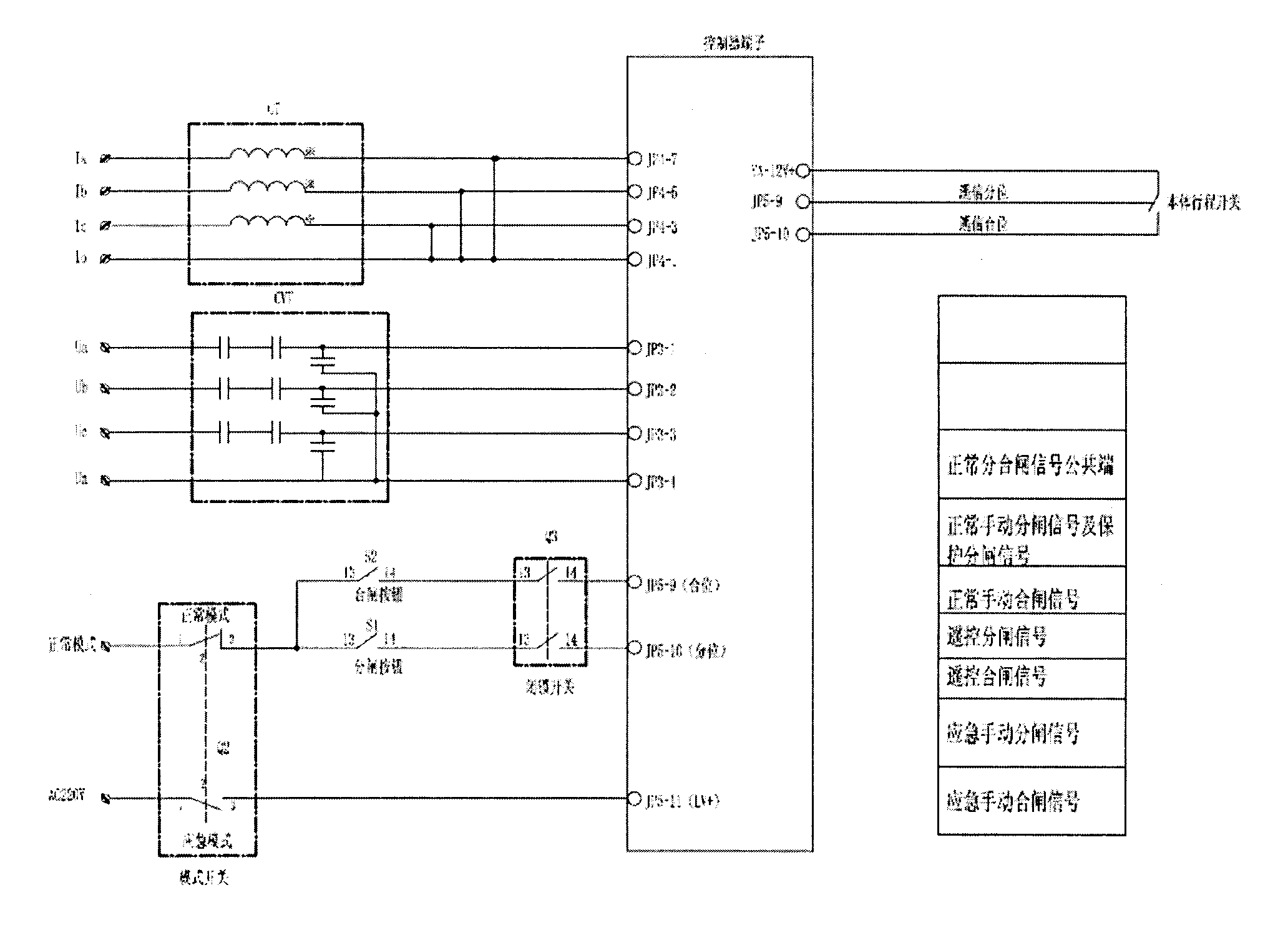

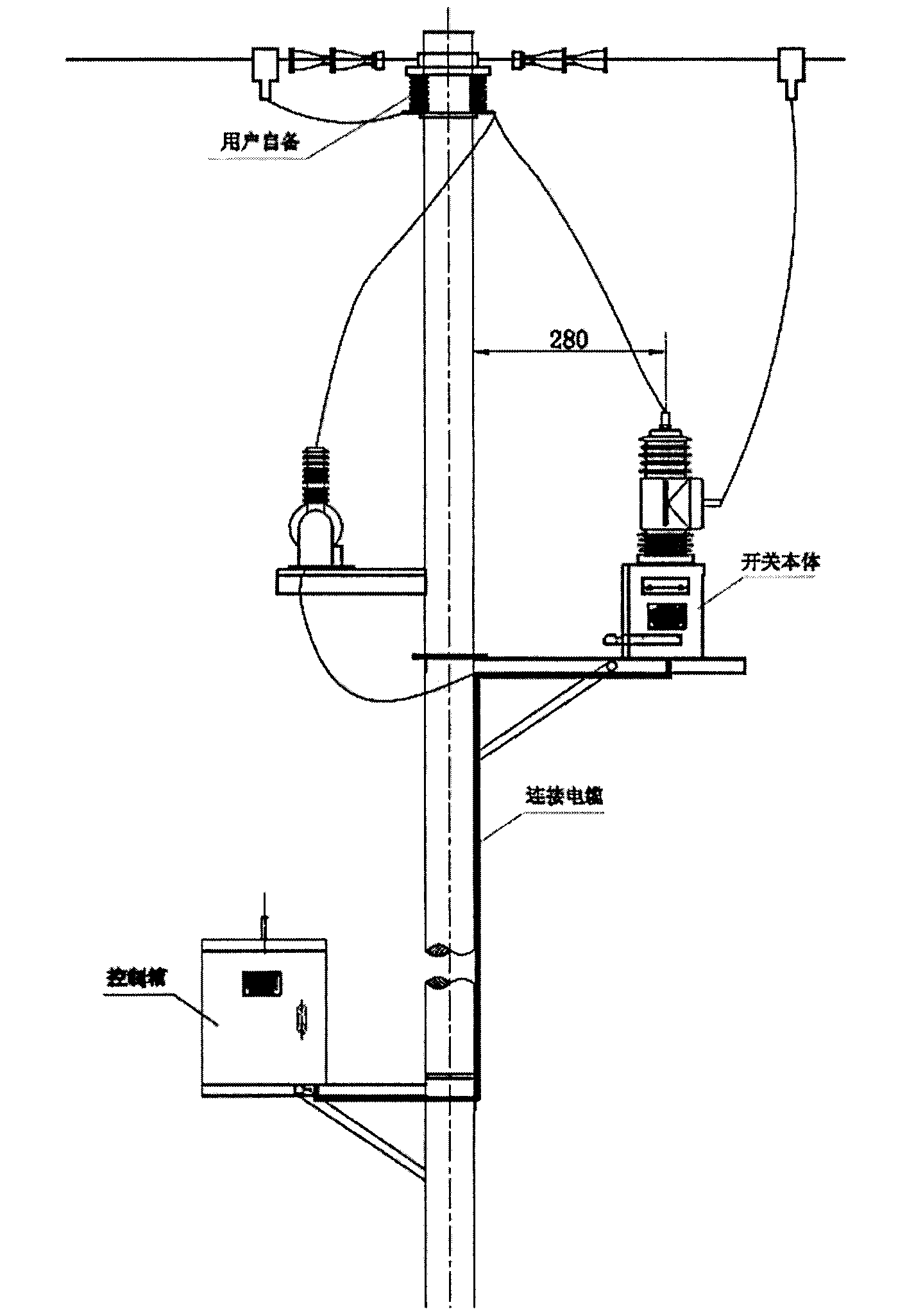

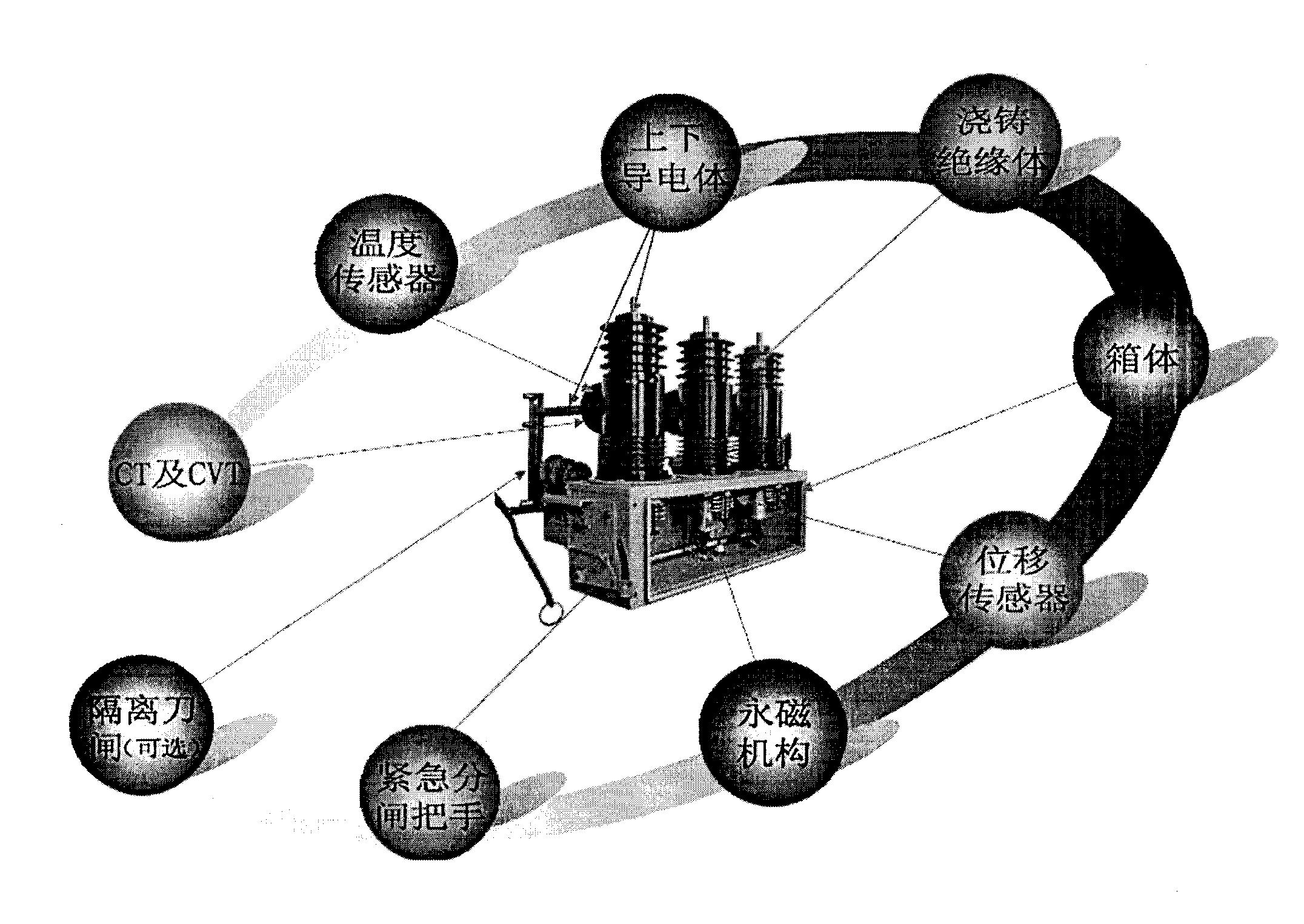

Fast and intelligent 10KV pole-mounted breaker

InactiveCN103325627AGood weather resistanceHigh strengthProtective switch detailsEmergency protective circuit arrangementsShielded cableUltraviolet lights

The invention discloses a fast and intelligent 10KV pole-mounted breaker. The fast and intelligent 10KV pole-mounted breaker is composed of a breaker body and an intelligent control box which are connected through multicore shield cables, an epoxy resin embedded pole is adopted, and the fast and intelligent 10KV pole-mounted breaker is good in weather resistance and ageing resistant, prevents ultraviolet light, and is high in strength and good in electrical insulation performance. Small-scale integrated design is adopted, a current transformer and a voltage transformer are integrated in the pole, the structure is compact, and mounting and maintenance are easy. A high-speed algorithm is adopted, exit protecting signals can be provided in 10ms, the fast mechanical property of a permanent magnetic mechanism is combined, and a line fault is removed and isolated in 25ms. A single-phase earth fault (including low current earthing) detecting function is achieved. The technology of self-diagnosis of the running state and the mechanical property of the breaker is achieved, and maintenance efficiency is improved. A low-power design technology is adopted, solar energy and CT are utilized to supply power and are mutually supplemented, an external power source is not needed, and the power-driven operation can be achieved. The fast and intelligent 10KV pole-mounted breaker is provided with an Ethernet port, and an IEC61850 specification interface is provided.

Owner:SHENZHEN JINBOLIAN ELECTRIC POWER TECH

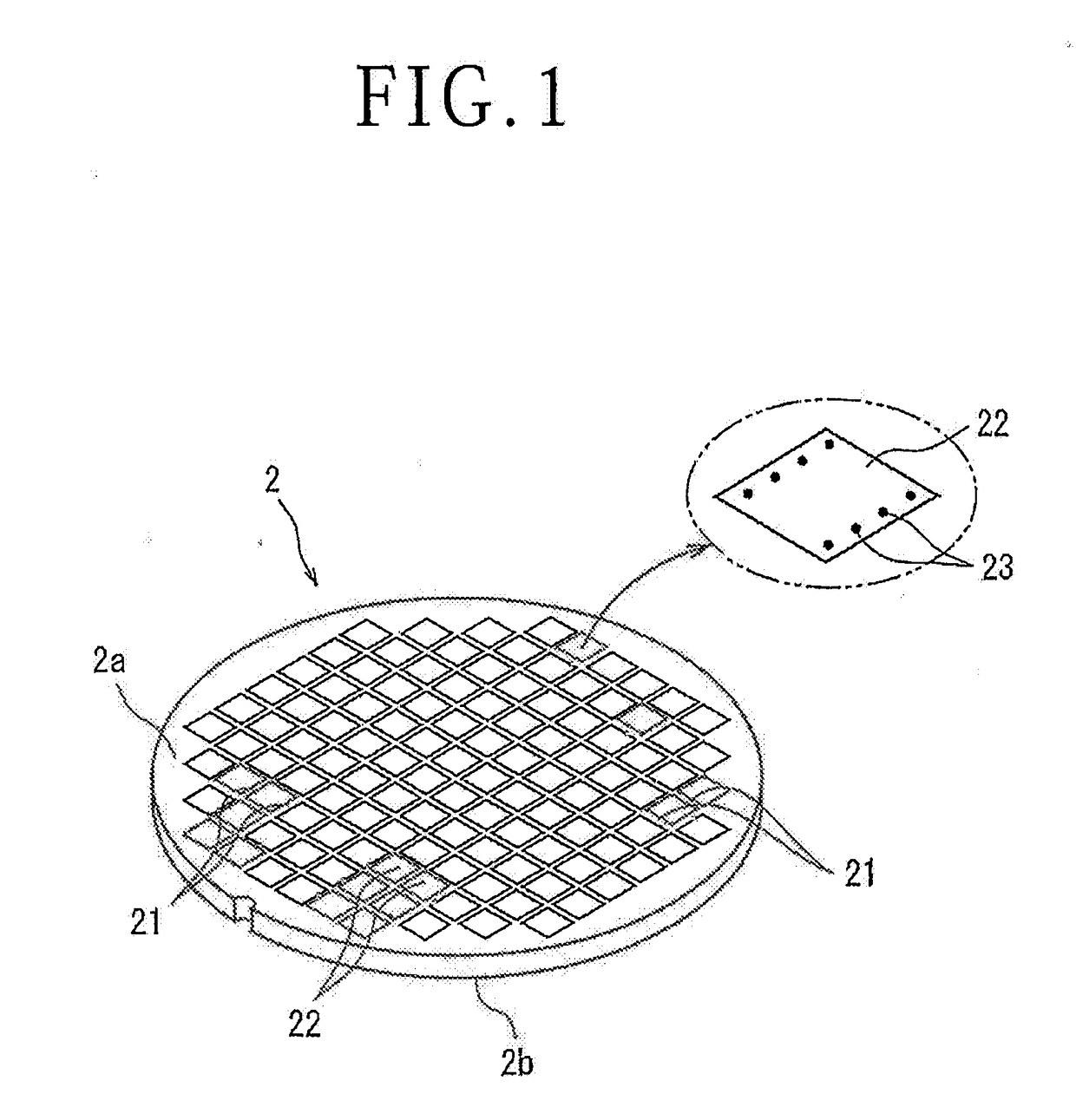

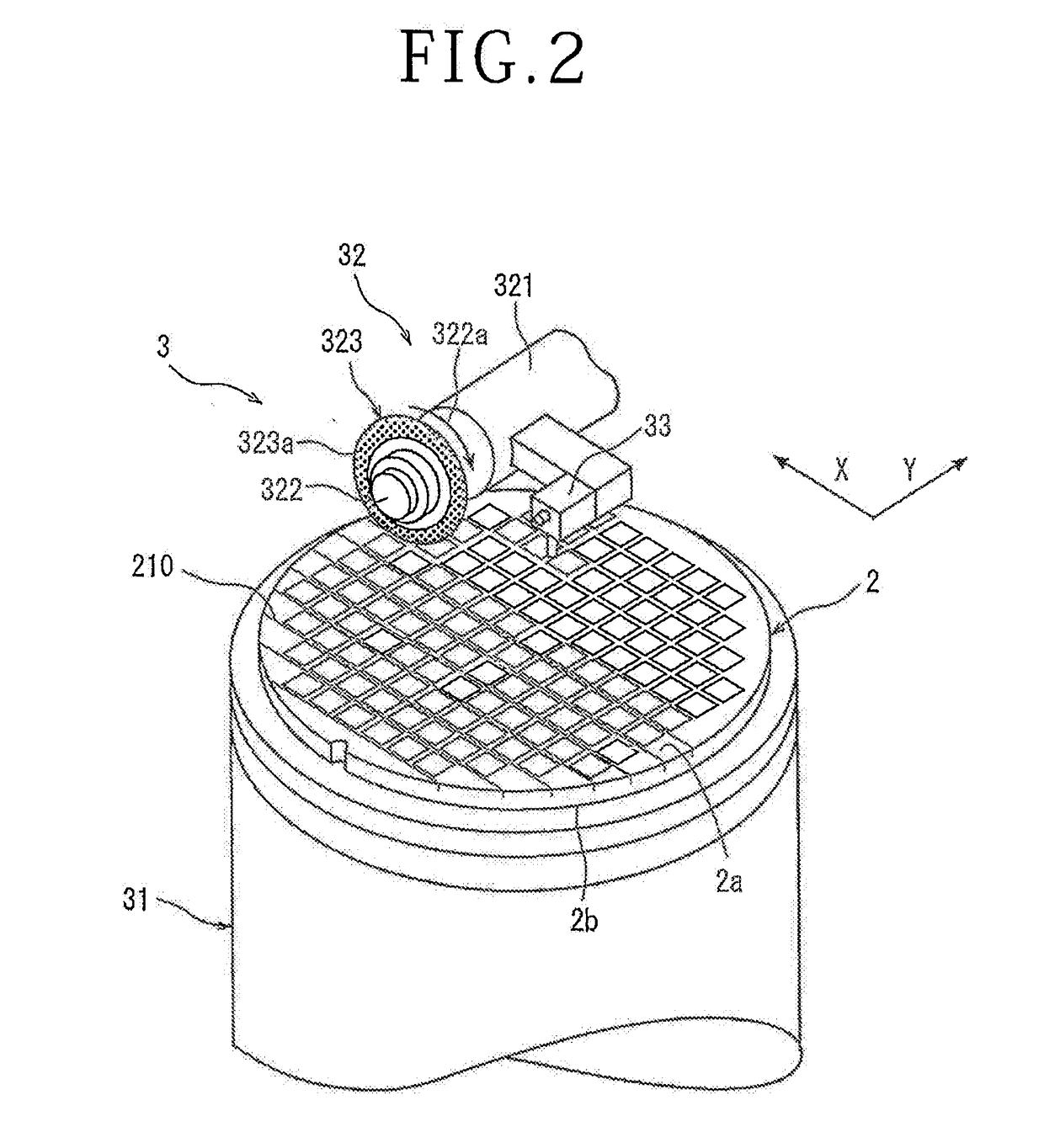

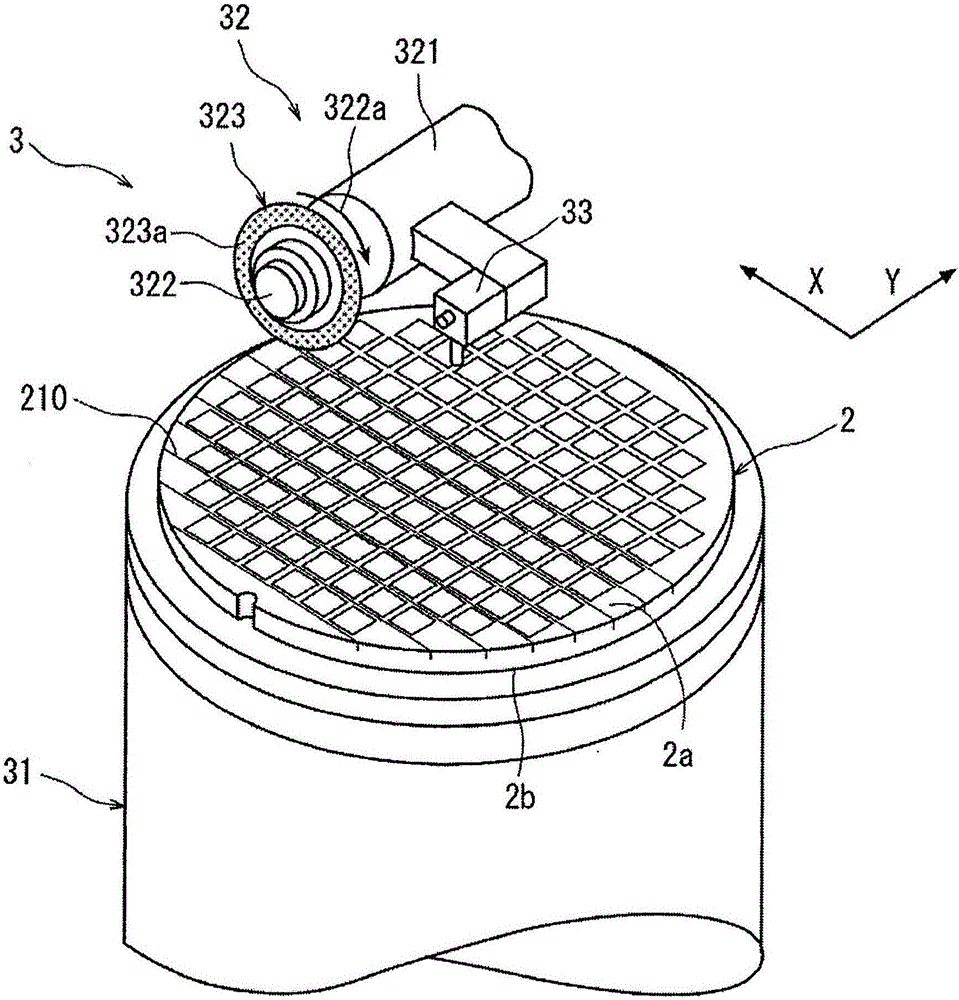

Method of processing wafer

ActiveUS20170186645A1Not to damageQuality improvementSemiconductor/solid-state device detailsSolid-state devicesResin embeddingDevice form

A wafer has a plurality of projected dicing lines on a face side thereof, a plurality of devices formed in respective areas demarcated on the face side of the wafer by the projected dicing lines, a plurality of grooves defined in the projected dicing lines, and a molding resin laid on the devices and embedded in the grooves. An outer circumferential portion of the molding resin is removed, exposing the molding resin embedded in the grooves. The molding resin embedded in the grooves exposed on an outer circumferential portion of the wafer is detected, and a laser beam is focused at a transversely central point on the molding resin embedded in the grooves. The laser beam is applied to the molding resin along the grooves, thereby forming dividing grooves in the wafer to allow the wafer to be divided into individual devices.

Owner:DISCO CORP

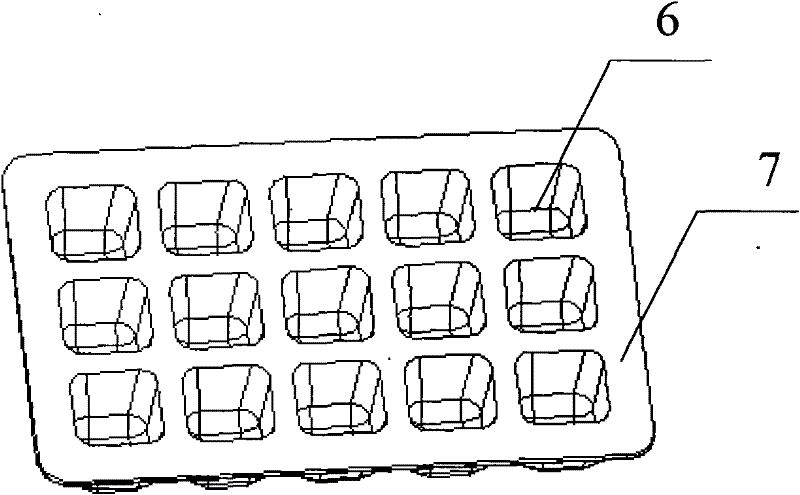

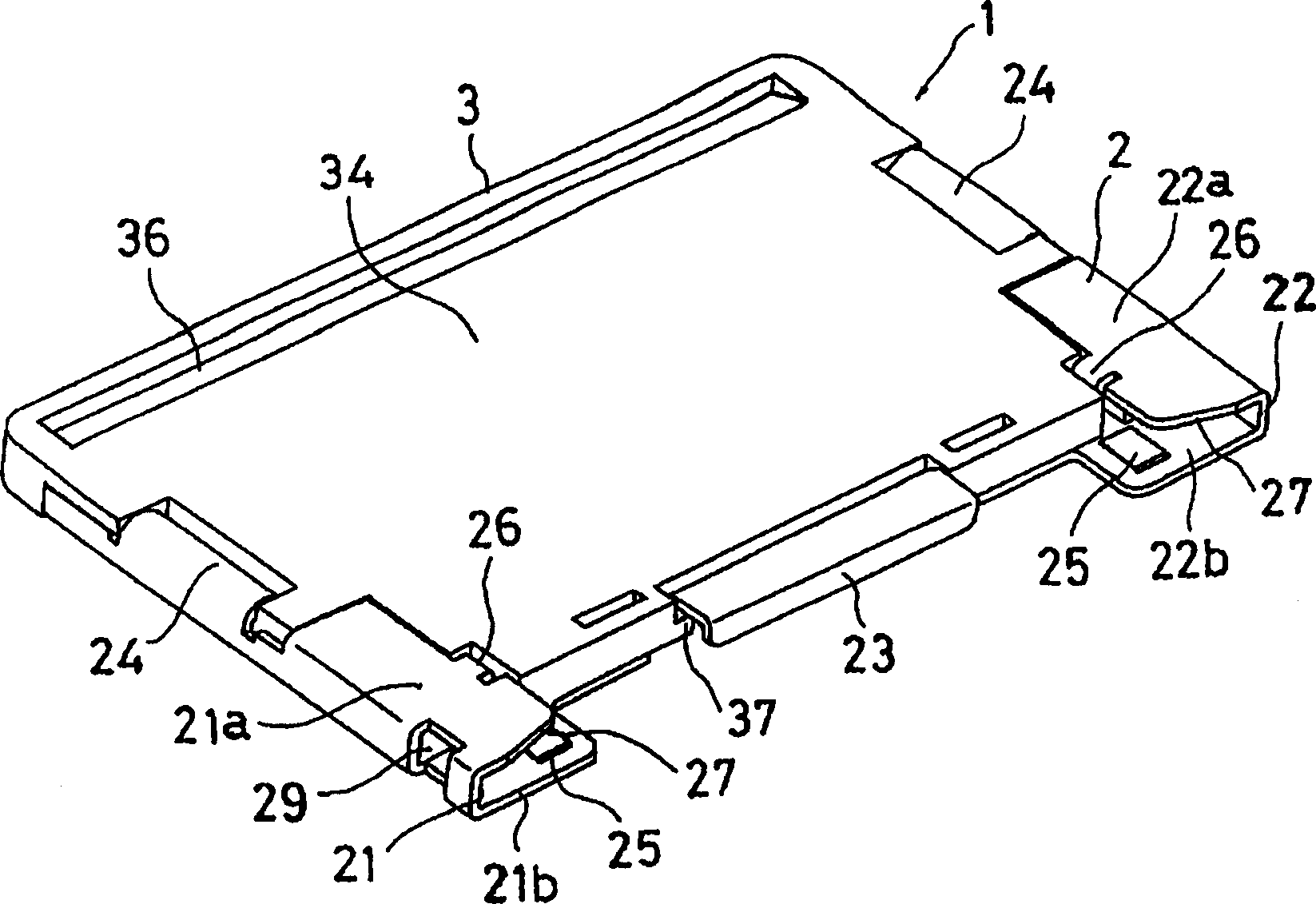

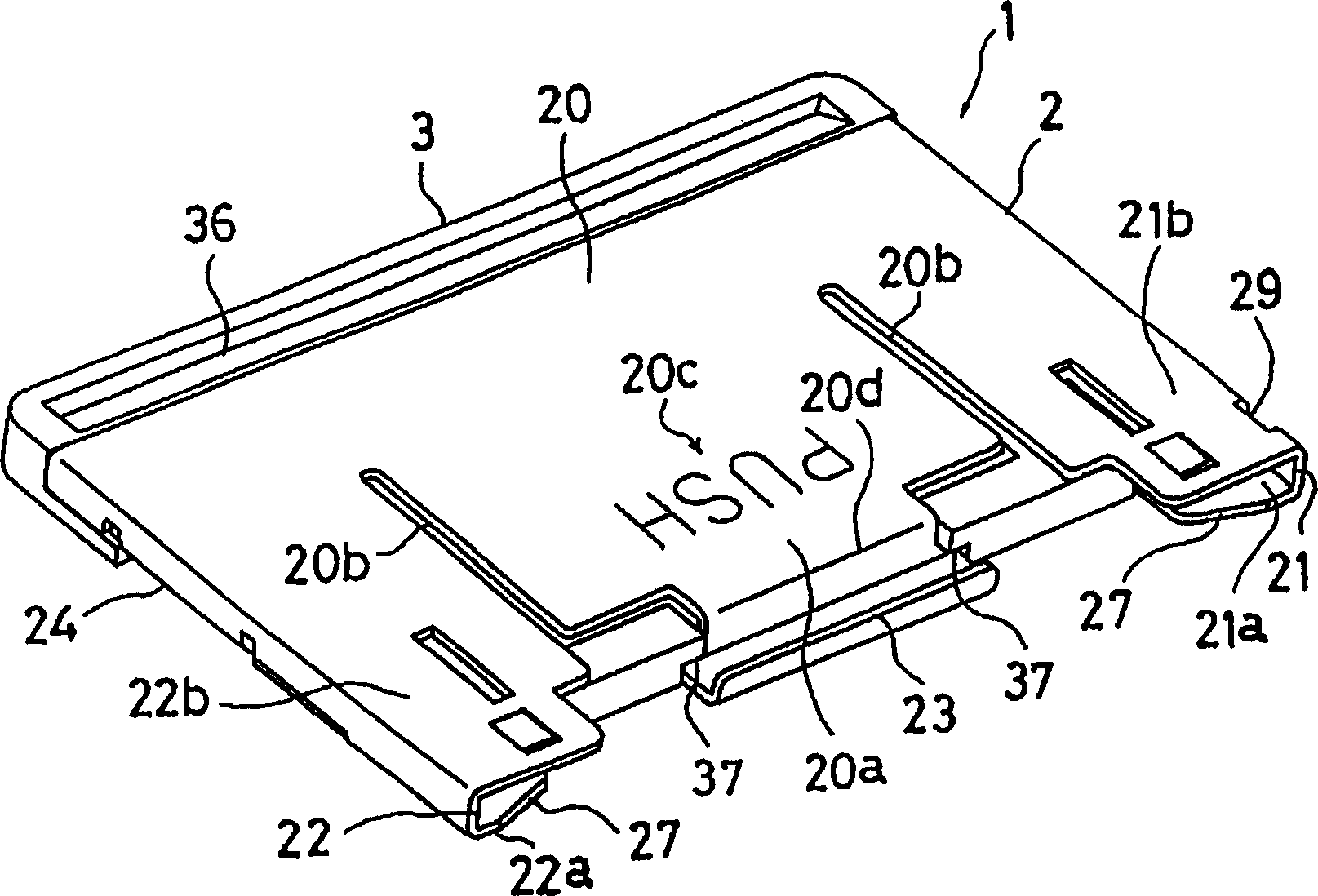

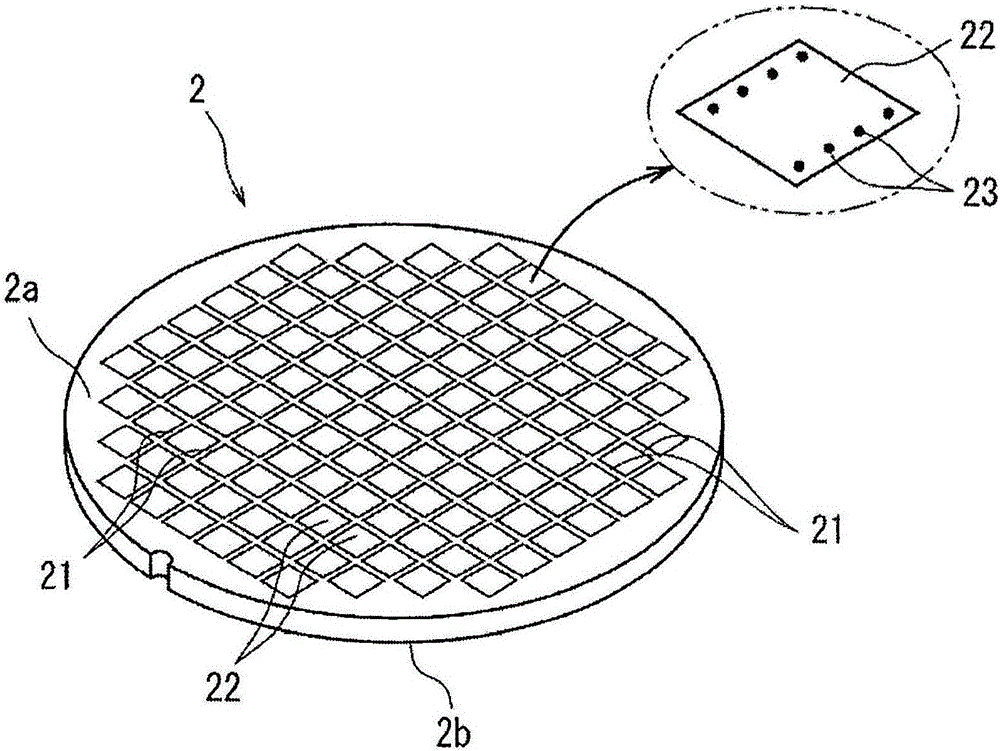

Adapter for memory card

The invention discloses adapter in use for small type memory card in general size applicable to electronic devices and mobile phones. The adapter includes parts: fitting of frame mount (2) through end part to install detachable memory card (4) freely; core part (3) composed of forming body made from resin embedded to and installed on the said fitting of frame mount (2). Thickness of the adapter is equal to thickness of memory card in the rough. The said fitting of frame mount (2) includes parts: U shaped grasp parts (21, 22) inserted to the memory card (4) in order to grip the memory card (4); shouldered sole plate part between the grasp parts (21, 22) combines with end part of the memory card (4) in order to prevent the memory card (4) from being pulled out by using blenometer; fastening nose (24) in use for fixing core part (3).

Owner:RENESAS TECH CORP

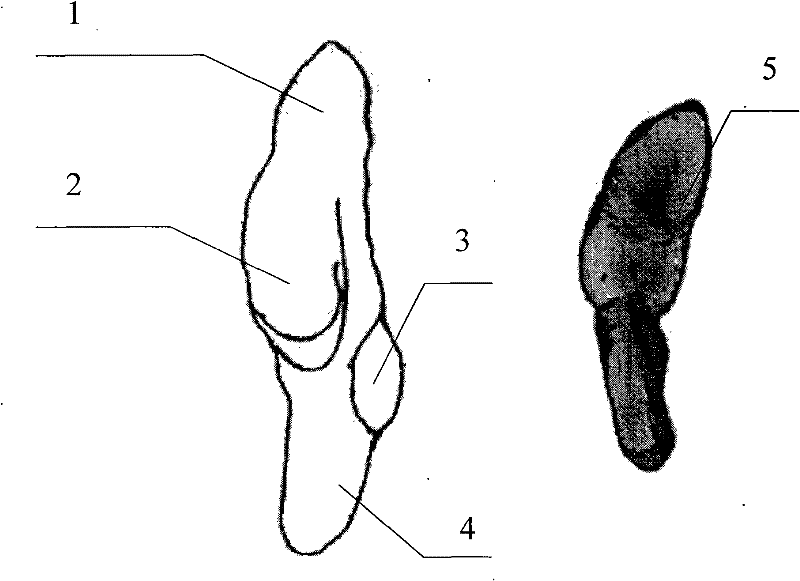

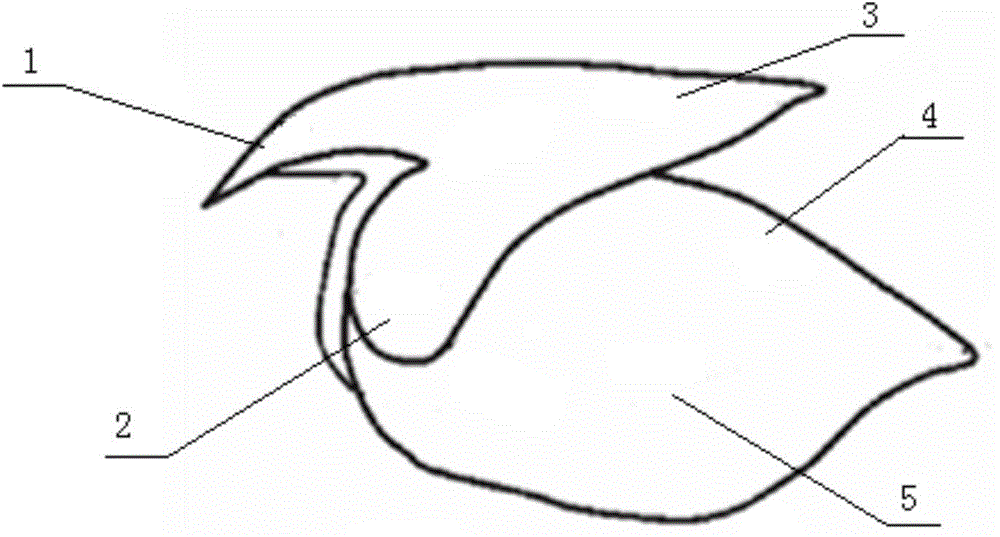

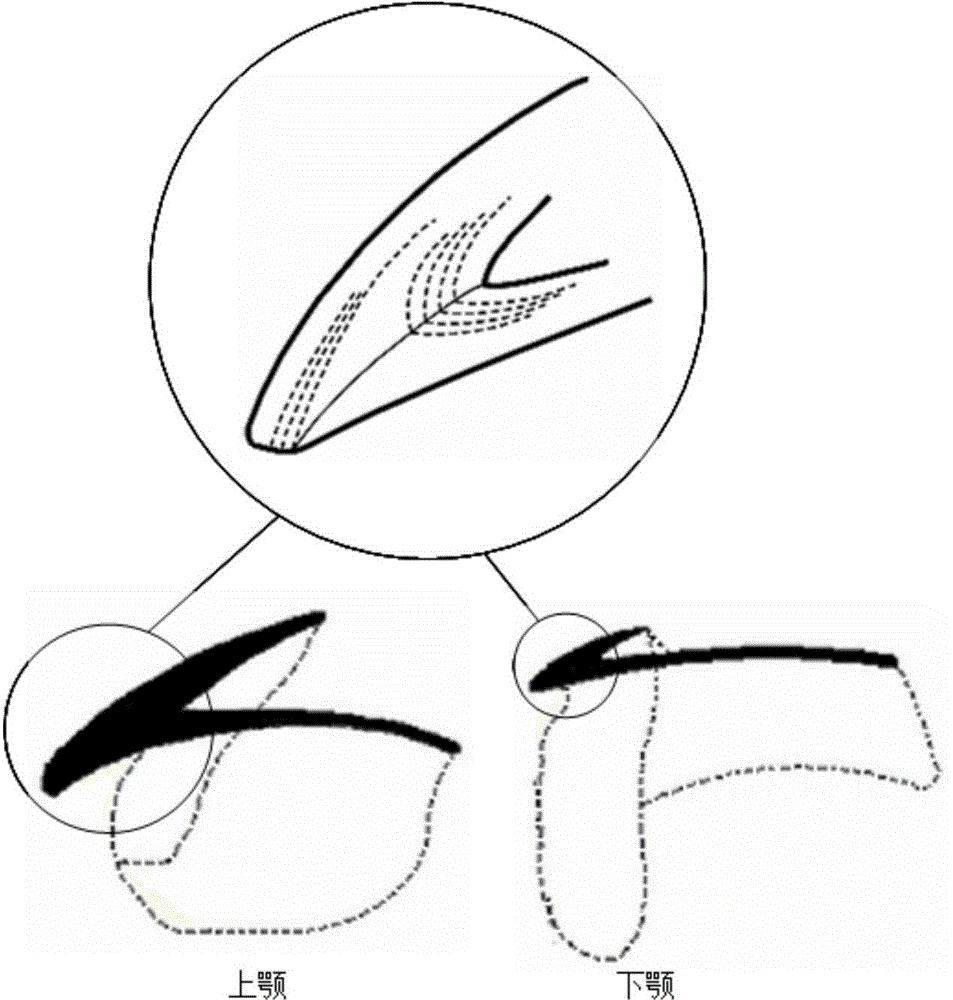

Method of identifying day age of cephalopods through beak

ActiveCN105738363AIndividual bigEasy extractionPreparing sample for investigationMaterial analysis by optical meansBeak shapeResin embedding

The invention provides a method of identifying day age of cephalopods through beaks and includes a method of grinding a beak longitudinal section and counting growth striation. The method mainly includes the steps of: extraction, cleaning, soaking, cutting, arrangement, resin embedding, cutting, immobilization on a glass slide, grinding and polishing, picture forming, and growth striation counting. In the method, the beak longitudinal section is ground respectively from the left and right sides to a core surface towards a central line. A prepared section is photographed by CCD to ensure that the growth striation can be read at any time in future. The growth striation is counted from the rear end to the front end of the beak in a direction being vertical to the growth striation all the time, thereby ensuring counting accuracy. The method solves the problems that the beak is difficult to grind and is liable to break during grinding, and the growth striation is difficult to observe and count.

Owner:SHANGHAI OCEAN UNIV

Light-weight and high-strength composite wall board and production method thereof

A light-weight and high-strength composite wall board sequentially comprises an outer covering layer, a sandwich layer and an inner covering layer from the inside to the outside, wherein the outer covering layer and the inner covering layer are made of one or a mixture of several of high-strength glass fiber, carbon fiber or polypropylene high-strength fiber; the wall board further comprises resin embedded into spaces among the outer covering layer, the sandwich layer and the inner covering layer by a vacuum introduction method. The invention further discloses a production method of the light-weight and high-strength composite wall board. The light-weight and high-strength composite wall board is simple in structure and low in production cost; mechanical properties of the wall board are above 30% better than those of a conventional square-cabin wall board; the problem of stress concentration at corners of a square cabin is solved; the production method is simple and convenient to operate and high in production efficiency, and facilitates industrial production.

Owner:衡阳泰豪通信车辆有限公司

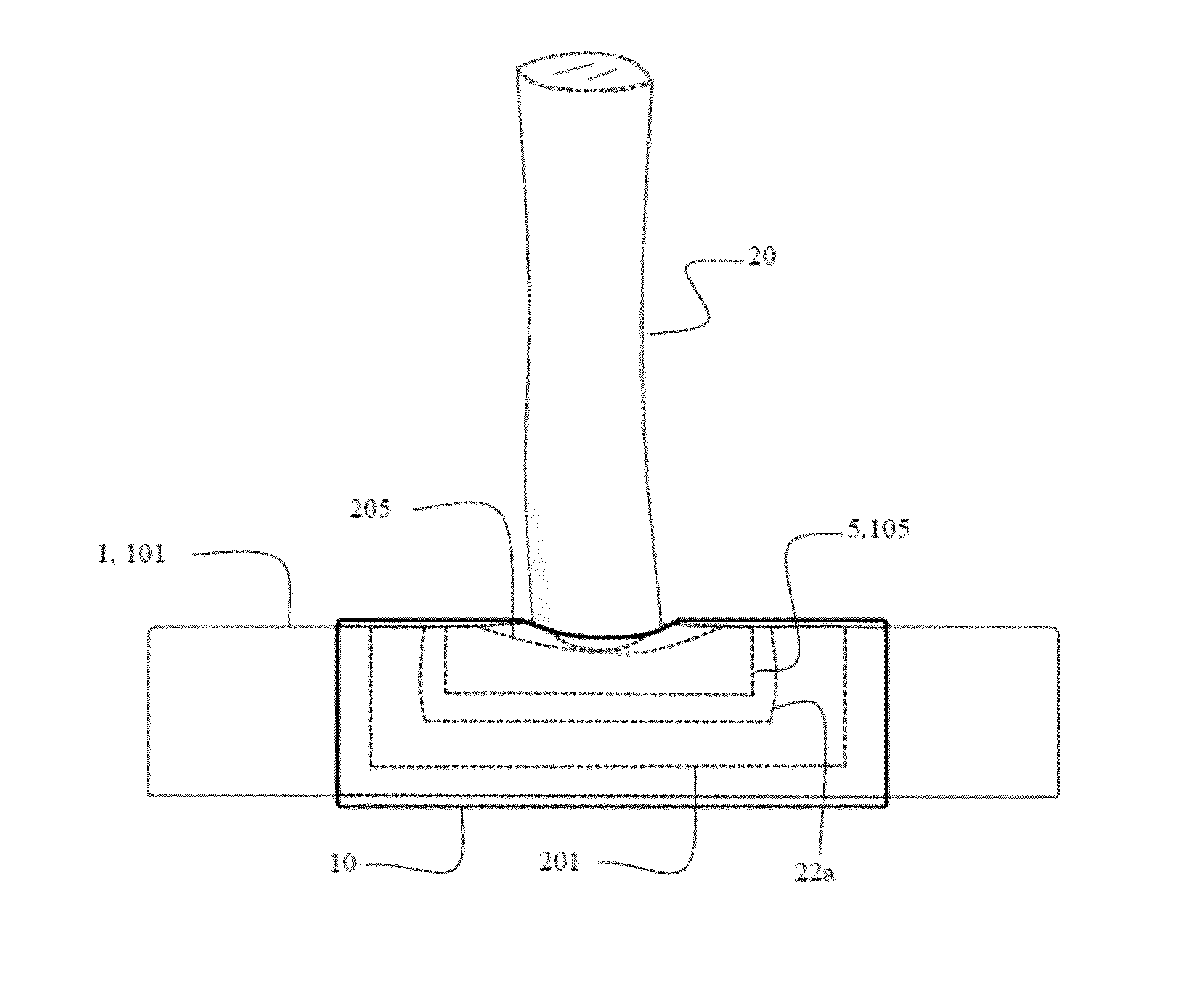

Method for machining wafer

InactiveCN106252281ASmooth rotationEliminate problems such as damageSemiconductor/solid-state device manufacturingFine working devicesResin embeddingEngineering

Provided is a method for machining a wafer to obtain wafer-scale chip scale package (WLCSP) with good quality. The method comprises: a first cutting groove forming step, including forming a first cutting groove having a depth corresponding to the finished thickness of a device along a dividing preset line from a front side of the wafer with a cutting tool having a first thickness; a molding step, including coating the front side of the wafer subjected to the cutting groove forming step with a molded resin and embedding the molded resin in the first cutting groove; a second cutting groove forming step, including forming a second cutting groove reaching the wafer and having the depth deeper than that of the molded resin coating the front side of the wafer and that of the molded resin embedded in the molded resin with a cutting tool having a second thickness thinner than a first thickness; a protective member adhering step, including applying a protective member to the surface of the molded resin deposited on the front surface of the wafer on which the second cutting groove forming step is performed; and a back surface grinding step, including grinding the back surface of the wafer on which the protective member attaching step is carried out so that the second cutting groove is exposed to divide the wafer into individual devices.

Owner:DISCO CORP

Method for making large helminth specimen

InactiveCN103814890ANon-volatileMeet application needsDead animal preservationEducational modelsEpoxyResin embedding

The invention belongs to the field of medical human parasitology and provides a method for making a large helminth specimen. The method comprises the following steps: specimen selection and collection; anesthetizing and precooling; freeze drying; epoxy resin embedding. The large helminth specimen made by using the method is capable of keeping the integrity of the appearance and shape of a helminth body for a long term, convenient to carry, diversified in appearance, free of preservative and pollutant volatilization, strong in transparency and easy to observe so as to meet the application requirement of parasitology in teaching and research processes and obtain better using effect and efficiency.

Owner:QINGDAO UNIV

Soft embedding section specimen and production method thereof

ActiveCN109523873AEasy to storeEasy to useDead animal preservationEducational modelsResin embeddingPre treatment

The invention relates to a soft embedding section specimen and a production method thereof, and belongs to the technical field of biological resin embedding section. The method comprises the steps that a biological specimen is frozen and sawed into slice section specimens, and pre-processed section specimens are obtained after dehydrating and defatting are conducted on the section specimens; the pre-processed section specimens are embedded in molds, a soft embedding agent fills the molds under a non-inducing temperature, wherein the embedding agent is an embedding agent which has flexibility after curing; curing is conducted at the inducing temperature after filling is completed, and the producing is completed. The specimen has the advantages that the flexibility after curing is better, cracking and deforming do not easily take place, and the storage and use are convenient.

Owner:河南中博科技有限公司

Self-healing material

InactiveUS20150159316A1Extended service lifeFibre typesSynthetic resin layered productsGlass fiber reinforced polymerResin embedding

A glass fiber-reinforced polymer composite includes a polymer matrix, a plurality of glass fibers embedded within the polymer matrix, a first hollow glass fiber containing a resin embedded within the polymer matrix, a second hollow glass fiber containing a catalyst suitable for curing the resin embedded within the polymer matrix. When damage occurs to such a composite, the glass fibers containing the resin and the catalyst are ruptured, resulting in their mixing together so that the resin is cured for repairing the ruptured location.

Owner:PEN

Transparent water soluble resin

The invention provides a transparent water soluble resin. The preparation method of the transparent water soluble resin comprises: mixing polyethylene glycol and polyvinylpyrrolidone according to a weight ratio of 1:0.25-0.35, keeping temperature at 25 to 30 DEG C, stirring till the polyvinylpyrrolidone dissolves completely to obtain solution, mixing the solution and transparent urea formaldehyderesin solution according to a volume ratio of 1:3-4 to obtain glue solution, adding glacial acetic acid serving as a coagulator in an amount which is 5 to 15 percent based on the volume of the glue solution, fully stirring, pumping air for 2 to 5 minutes by using a vacuum pump till a large amount of air bubbles are not generated, standing till on air bubbles are generated on surface, and obtaining the transparent water soluble resin. The molecular weight of the polyethylene glycol is 600. The polyethylene glycol has the advantages of high success rate of the coating of biological specimens, easy cracking prevention, transparency and certain hardness, and can be used for post treatment in polishing, shaping and the like and preserve the original shape of biological specimen for a longer time.

Owner:CHONGQING NORMAL UNIVERSITY

Flower ambroid accessory manufacturing method

ActiveCN105109263APrevent discolorationEasy to operateSpecial ornamental structuresFreeze-dryingUltraviolet lights

The invention provides a flower ambroid accessory manufacturing method. The flower ambroid accessory manufacturing method comprises the following steps: picking flowers and placing the flowers in a freezer for storage; placing the flowers in a pretreatment fluid to soak the flowers; performing freeze-drying treatment of the pretreated flowers to obtain freeze-dried flowers; placing the freeze-dried flowers into an aftertreatment fluid to soak the freeze-dried flowers for aftertreatment, wherein the aftertreatment fluid comprises 5-10 percent of a film-forming material, 0.1-1% of an ultraviolet light absorber and the balance of an aftertreatment solvent, the film-forming material comprises at least one of paraffin, polyethylene wax, polyethyleneglycol or silicone oil, and the aftertreatment solvent is at least one of ethanol, methyl benzene, gasoline or ethyl acetate; and performing resin embedding of the freeze-dried flowers subjected to aftertreatment. By the adoption of the technical scheme, the freeze-dried flowers can still maintain the original colors and shapes, the resin-embedded flowers still keep the original colors and shapes, and during the use of an accessory manufactured by embedding, the flowers cannot discolor or fade along with light irradiation.

Owner:NANNING MILLENNIUM ARTS & CRAFTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com