Method for preparing modified epoxide resin embedding material

A technology of epoxy resin and potting compound, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as poor toughness and easy cracking, and achieve the effects of high filling amount, good wettability, and low linear expansion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

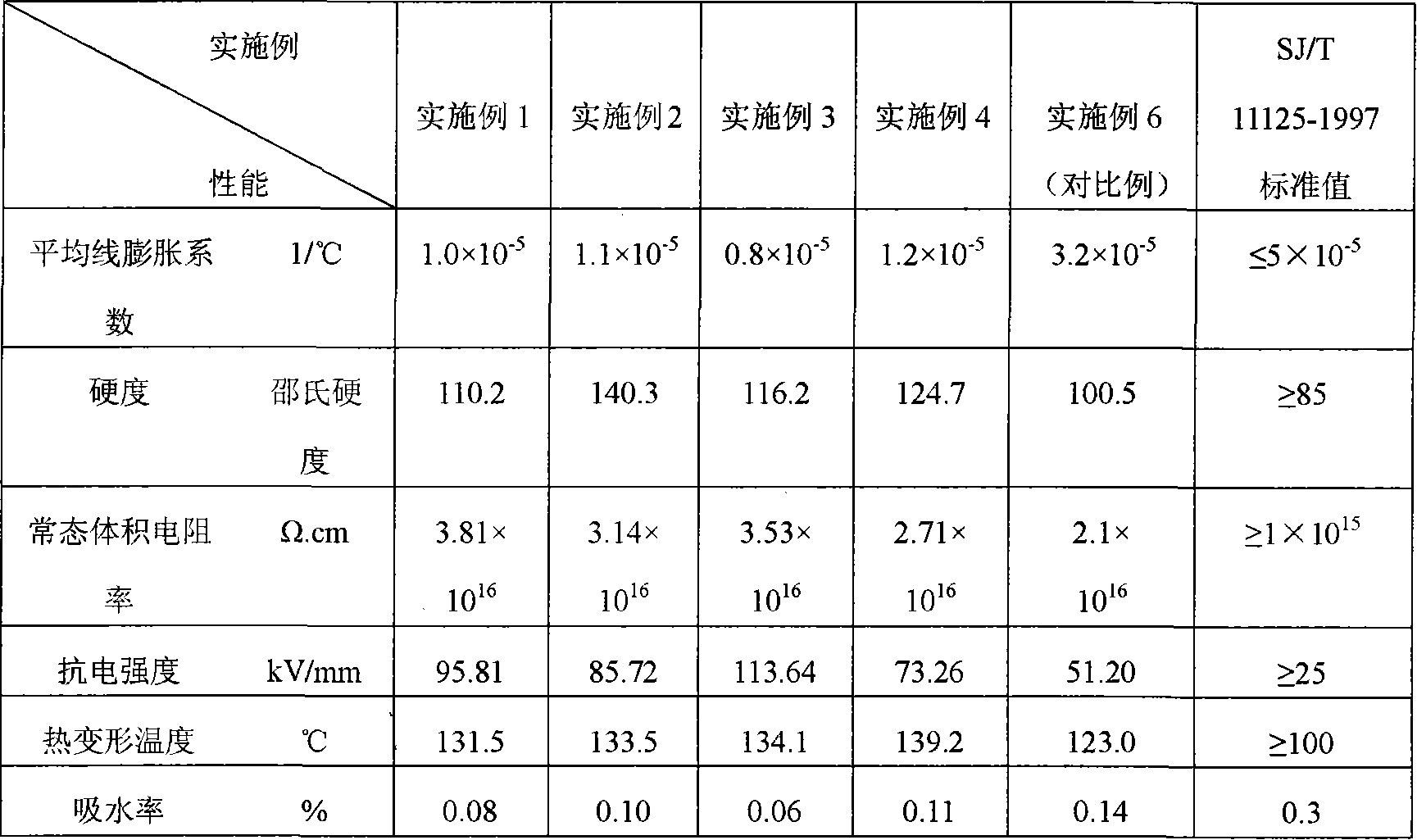

Examples

Embodiment 1

[0041] Add 3.00g of MDI into a 500mL four-necked flask equipped with a stirrer, a thermometer, and a nitrogen protection tube, raise the temperature to 85°C, pass through nitrogen protection, add 12.99g of PPG2000 dropwise under stirring, and complete the dropwise addition after 0.5h , Stir at this temperature for 2h. Then, 74.95 g of bisphenol A epoxy resin E-44 was added into the flask, and the nitrogen protection was stopped after stirring at a temperature of 85° C. for 2 h. Then the temperature was lowered to 65° C., 3.75 g of organic montmorillonite treated with octadecyltrimethylammonium chloride was added, and stirred at 65° C. for 1.5 h. Then the temperature was lowered to 40°C, 224.85g of 600-mesh active silicon micropowder, 14.99g of propylene oxide butyl ether, and 0.75g of carbon black were added, mixed evenly, and discharged to obtain liquid A. Add 63.71g of liquid methyltetrahydrophthalic anhydride and 0.64g of cyanoimidazole into a 100mL beaker, and stir evenly...

Embodiment 2

[0044]Add 4.43g of MDI into a 500mL four-neck flask equipped with a stirrer, thermometer, and nitrogen gas protection tube, raise the temperature to 120°C, pass through nitrogen gas protection, and drop 17.68g of PTMG2000 under stirring conditions, and the dropwise addition is completed after 0.5h , and stirred at a temperature of 120° C. for 1.5 h. Then add 147.37g of bisphenol A type epoxy resin E-51 into the flask, keep stirring at 120°C for 1.5h and then stop the nitrogen protection. Then the temperature was lowered to 55° C., 2.95 g of organic montmorillonite treated with dodecyl primary amine was added, and stirred at 55° C. for 2 hours. Then the temperature was lowered to 40°C, 147.37g of 400-mesh active silica powder, 14.74g of polypropylene glycol diglycidyl ether, and 0.74g of carbon black were added, mixed evenly, and discharged to obtain liquid A. Add 125.26g of liquid methyltetrahydrophthalic anhydride and 0.63g of 2-methylimidazole into a 250mL beaker and stir e...

Embodiment 3

[0046] Add 10.67g of PAPI into a 500mL four-necked flask equipped with a stirrer, a thermometer, and a nitrogen protection tube, raise the temperature to 100°C, pass nitrogen protection, add 8.01g of hydroxyl-terminated polybutadiene dropwise under stirring conditions, and pass through 0.5 After the addition of h is completed, stir at a temperature of 100° C. for 1.5 h. Then add 62.26g of bisphenol A epoxy resin E-51 into the flask, stir at 100°C for 2h, and then stop the nitrogen protection. Then the temperature was lowered to 75° C., 0.62 g of organic montmorillonite treated with cetyltrimethylammonium bromide was added, and stirred at 75° C. for 1 h. Then lower the temperature to 40°C, add 249.04g of molten silicon micropowder, 18.68g of fatty glycidyl ether, 0.75g of carbon black, and 1.25g of KH560, mix evenly, and discharge to obtain liquid A. Add 49.81g of liquid methyltetrahydrophthalic anhydride and 1.00g of 2-methyl-4-ethylimidazole into a 100mL beaker, stir well to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com