Double-component epoxy resin embedding adhesive and its preparation method and can sealing technique

A technology of epoxy resin and potting glue, applied in epoxy resin glue, chemical instruments and methods, adhesives, etc., can solve the problems of high surface tension, low surface tension, bubbles cannot be eliminated, etc. Gel time, weaken the effect of difficult defoaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

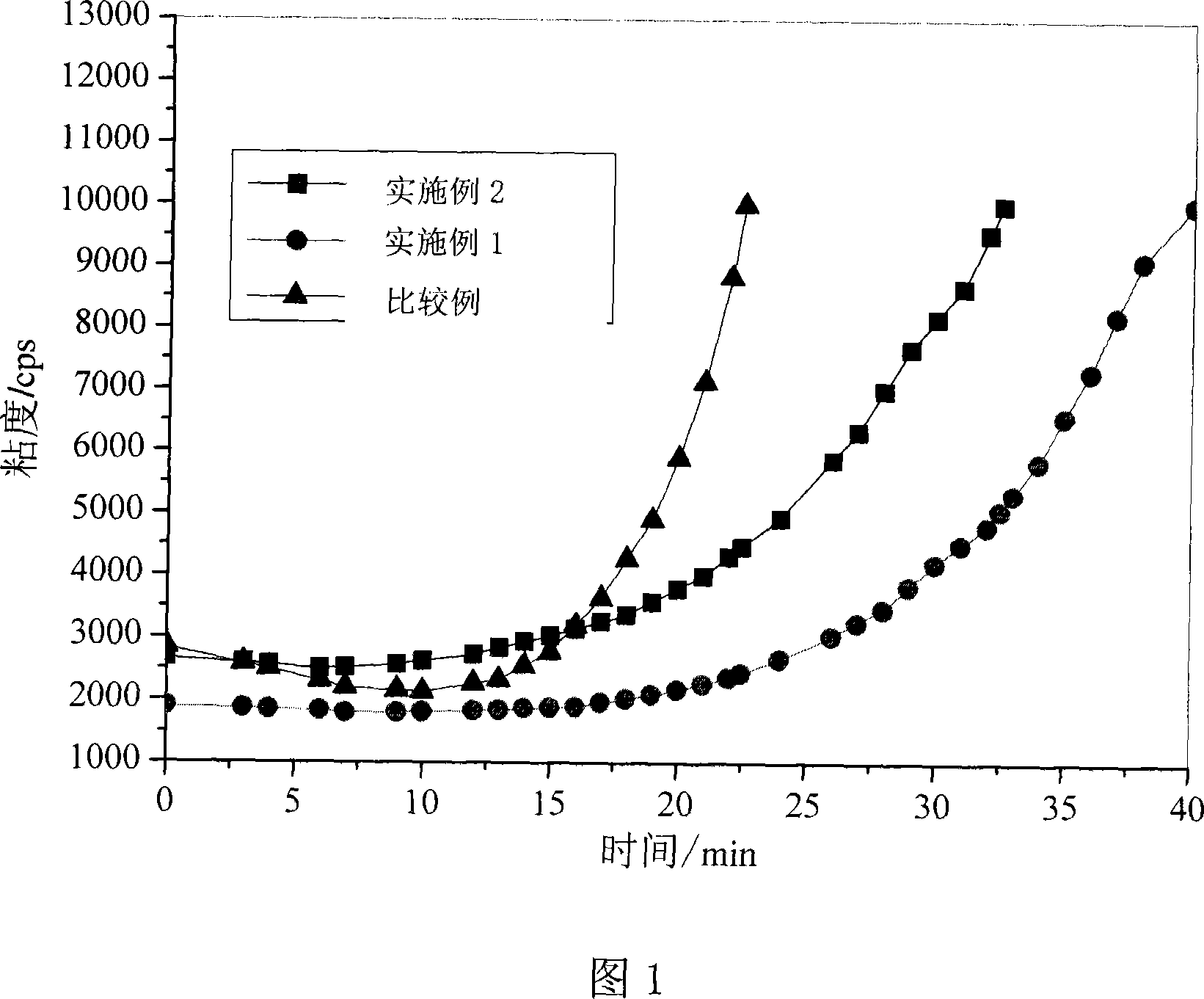

Embodiment 1

[0034] (1) Preparation of epoxy resin A component:

[0035] Add 200g bisphenol A epoxy resin in 500ml planetary mixer, add 40g reactive diluent, 1.6g defoamer and 2g black paste successively, then add 210g precipitated barium sulfate, 90g calcium carbonate, 4g fumed white carbon black, in The revolution speed is 5rpm, the rotation speed is 100rpm, without vacuuming, stir for 5 minutes, stop stirring, turn on the vacuum equipment, when the vacuum degree reaches 0.09Mpa, start stirring, the revolution speed is 30rpm, the rotation speed is 300rpm, stir for 30 Minutes, stop stirring, release the vacuum, and discharge;

[0036] (2) Preparation of curing agent B component:

[0037] Weigh 48g of fatty amine, 20g of cashew shell oil modified amine and 12g of polyetheramine into a 300ml high-speed stirring tank, and stir for 5 minutes at a rotation speed of 300rpm.

[0038] Accurately weigh 100g of the above-mentioned component A and 20g of the above-mentioned component B, and stir e...

Embodiment 2

[0041] (1) Preparation of epoxy resin A component: with embodiment 1

[0042] (2) Preparation of curing agent B component:

[0043] Weigh 48g fatty amine, 16g cashew shell oil modified amine and 16g polyether amine respectively in a 300ml high-speed stirring tank, and stir for 5 minutes at a rotating speed of 300rpm.

[0044] Accurately weigh 100g of the above-mentioned component A and 20g of the above-mentioned component B, and stir evenly to make a potting compound.

[0045] The mensuration of operation time and curing time: with embodiment 1

Embodiment 3

[0047] (1) Preparation of epoxy resin A component: with embodiment 1

[0048] (2) Preparation of curing agent B component:

[0049] Weigh 30 g of fatty amine and 30 g of cashew nut shell oil modified amine respectively in a 300 ml high-speed stirring tank, and stir for 5 minutes at a rotation speed of 300 rpm.

[0050] Accurately weigh 100g of the above-mentioned component A and 20g of the above-mentioned component B, and stir evenly to make a potting compound.

[0051] The mensuration of operation time and curing time: with embodiment 1

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com