Light-weight and high-strength composite wall board and production method thereof

A high-strength composite material and wallboard technology, applied in the direction of sheets/boards, building elements, etc., can solve the problems of difficult skeleton forming, stress concentration at joints, and inappropriateness, so as to facilitate industrial production, solve stress concentration, and waterproof Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

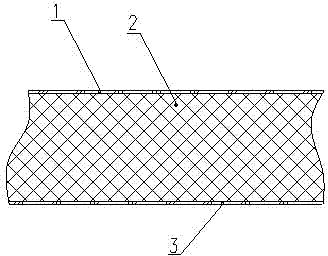

[0024] refer to figure 1 , a light-weight high-strength composite wallboard, comprising an outer skin layer 1, a sandwich layer 2, and an inner skin layer 3 from outside to inside, and the outer skin layer 1 and the inner skin layer 3 are made of high-strength glass fibers; The wall panel also includes resin embedded between the outer skin layer 1 , the sandwich layer 2 and the inner skin layer 3 by adopting a vacuum introduction method.

[0025] The sandwich layer 2 is a high-strength structural foam profiled board prepared by an ultrasonic-assisted embedding method.

[0026] The resin is unsaturated resin or epoxy resin.

[0027] The thicknesses of the outer skin layer 1, the sandwich layer 2 and the inner skin layer 3 are calculated and determined according to the required strength of the panel.

[0028] A method for producing lightweight high-strength composite wall panels, comprising the following steps:

[0029] 1) According to the calculation according to the require...

Embodiment 2

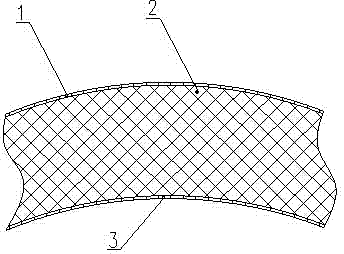

[0035] refer to figure 2 , a light-weight high-strength composite wallboard, comprising an outer skin layer 1, a sandwich layer 2, and an inner skin layer 3 from outside to inside, the outer skin layer 1 and the inner skin layer 3 are made of carbon fibers; the wall board It also includes the resin embedded between the outer skin layer 1, the sandwich layer 2 and the inner skin layer 3 by adopting a vacuum introduction method.

[0036] The sandwich layer 2 is a high-strength structural foam profiled board prepared by an ultrasonic-assisted embedding method.

[0037] The resin is unsaturated resin or epoxy resin.

[0038] The thicknesses of the outer skin layer 1, the sandwich layer 2 and the inner skin layer 3 are calculated and determined according to the required strength of the panel.

[0039] A method for producing lightweight high-strength composite wall panels, comprising the following steps:

[0040] 1) According to the calculation according to the required strength...

Embodiment 3

[0046] refer to figure 1 , a light-weight high-strength composite wallboard, comprising an outer skin layer 1, a sandwich layer 2 and an inner skin layer 3 from the outside to the inside, and the outer skin layer 1 and the inner skin layer 3 are made of high-strength glass fiber, carbon fiber and polypropylene The high-strength fiber is made of a mixture with a mass ratio of 1:2:1; the wallboard also includes resin embedded between the outer skin layer 1, the sandwich layer 2 and the inner skin layer 3 by vacuum introduction.

[0047] The sandwich layer 2 is a high-strength structural foam profiled board prepared by an ultrasonic-assisted embedding method.

[0048] The resin is unsaturated resin or epoxy resin.

[0049] The thicknesses of the outer skin layer 1, the sandwich layer 2 and the inner skin layer 3 are calculated and determined according to the required strength of the panel.

[0050] A method for producing lightweight high-strength composite wall panels, comprisi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com