Joint construction method for preventing reflection cracks generated during spreading of asphalt on old concrete pavement

A technology of reflective cracks and construction methods, which is applied in the direction of roads, roads, pavement details, etc., can solve uneconomical problems, achieve the effect of preventing reflective cracks, preventing the occurrence and development of reflective cracks, and reducing relative vertical displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, first, the deflection pretreatment of the old concrete panels is carried out, and the deflection difference between the two old concrete panels that need joint reinforcement is measured, and the old concrete with a deflection difference exceeding 0.04-0.06mm is selected. panel.

[0031] For old concrete panels with a deflection difference between 0.04-0.06mm, the joint construction method of paving asphalt reflective cracks on the surface is realized through the following steps:

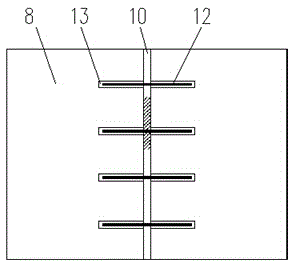

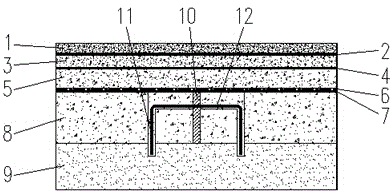

[0032] The first step, the pretreatment of planting reinforcement: in the joint of the two old concrete panels 8, the additional stress concentration area of the vehicle load acts on the joint and cuts out strip grooves 13 at equal intervals across the joint, and the strip grooves 13 are the planting Rib position, use impact drill to carry out vertical drilling to the end of strip groove 13 again, and this hole extends to be positioned at the inside of base 9 at the lower...

Embodiment 2

[0045] In this embodiment, the deflection difference between the two old concrete panels requiring joint reinforcement is measured, and the old concrete panels whose measured value of the deflection difference exceeds 0.06 mm are selected.

[0046] For the old concrete panels whose deflection difference exceeds 0.06mm, when performing joint treatment of overlaying asphalt reflective cracks, it is necessary to pre-treat the old concrete panels before planting bars on the basis of Example 1. The slab grouting treatment is carried out on the concrete slab, so that the deflection difference between the slabs is less than the allowable value of the deflection difference, which is convenient to meet the requirements of the design standard and ensure the effectiveness and success rate of the subsequent reinforcement. The grouting material is cement mortar with compressive strength ≥ 15Mpa. The gradation composition of cement mortar is: cement: water = 1.0:5, and based on the total mas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com