Patents

Literature

734results about How to "Not easy to burn" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

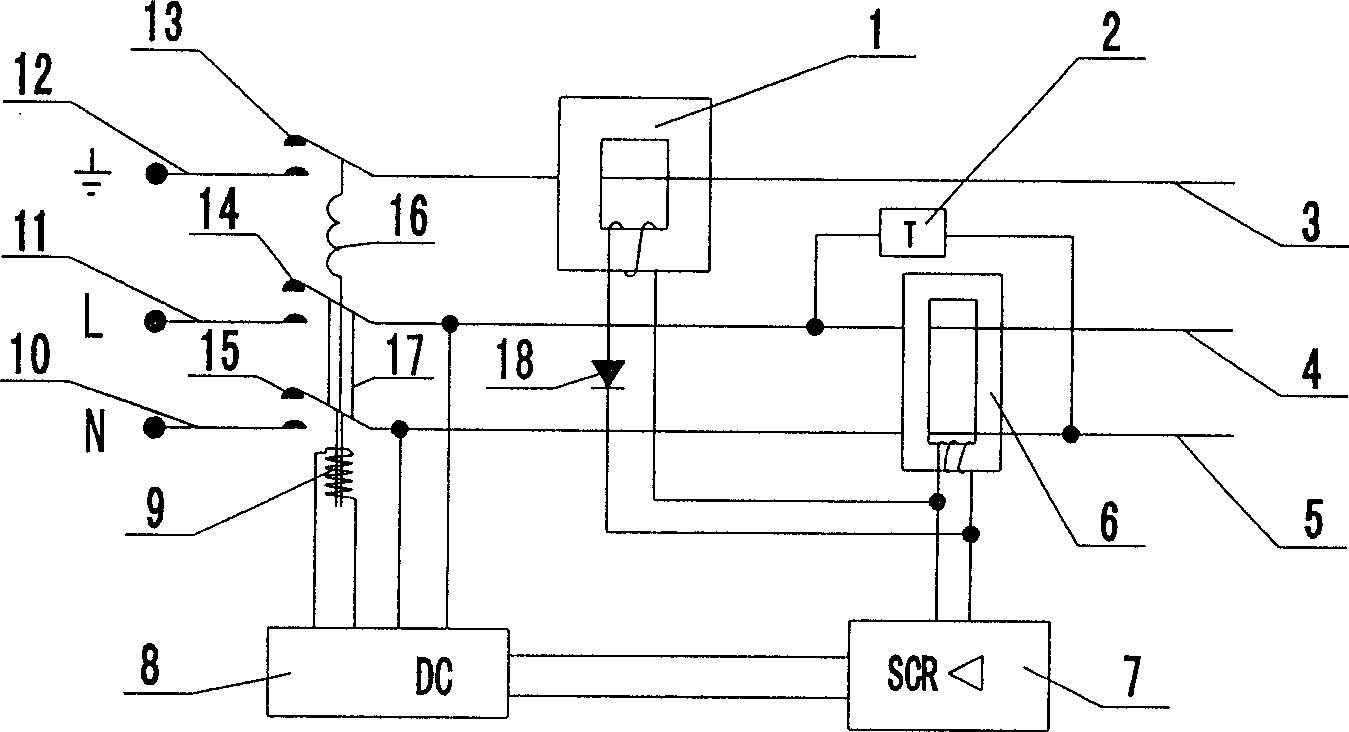

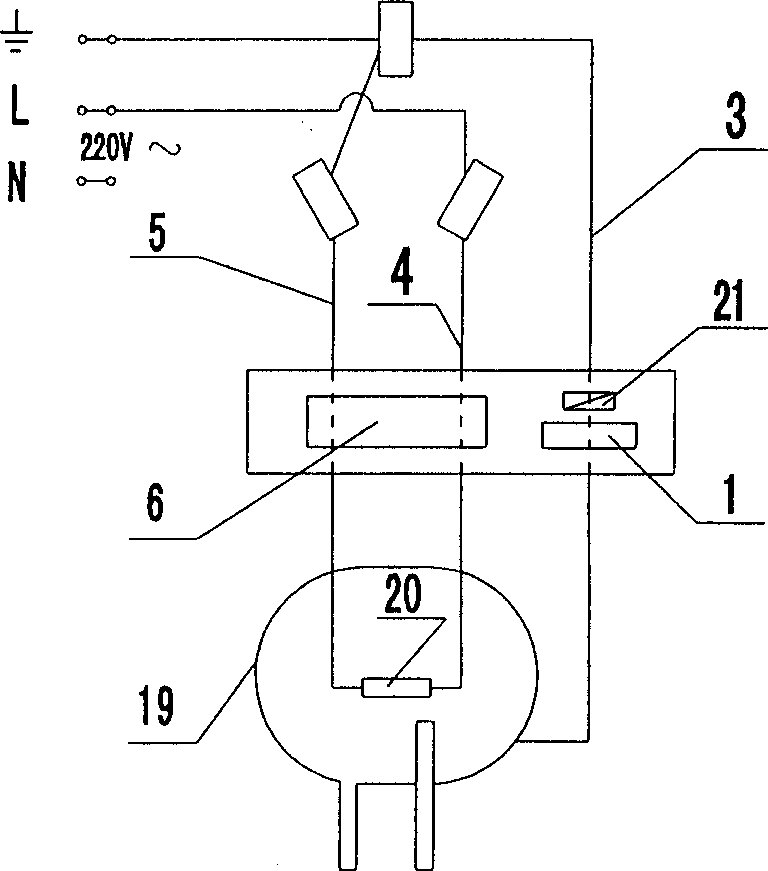

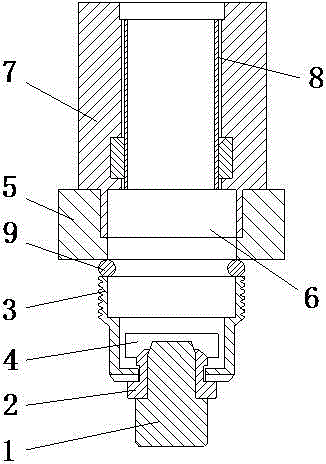

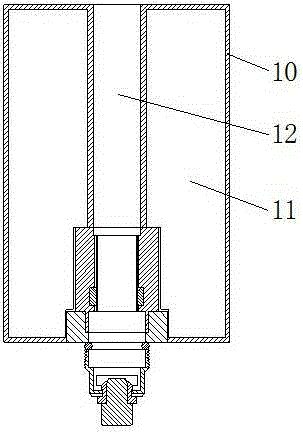

Leakage protection plug

InactiveCN1142618CGuarantee personal safetyMeet the requirements of safe electricity useCoupling device detailsEmergency protective arrangements for automatic disconnectionSpring forceEngineering

Owner:刘睿刚

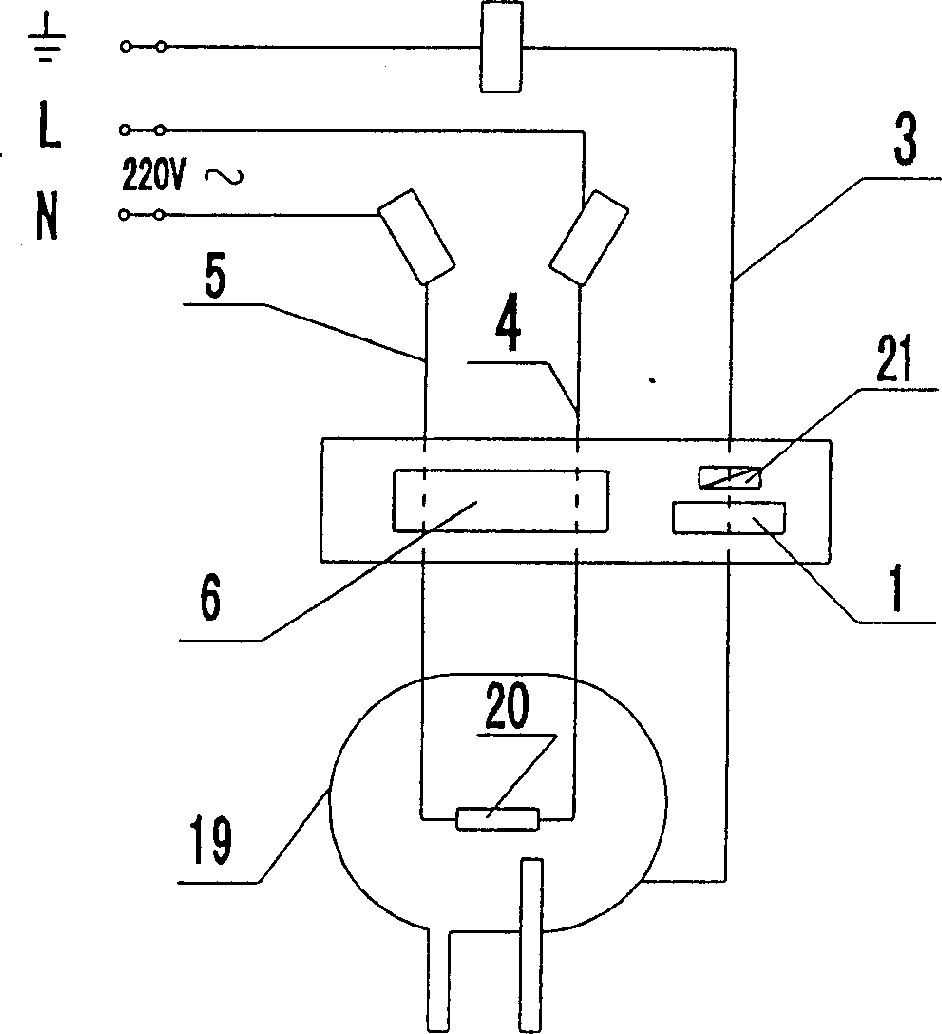

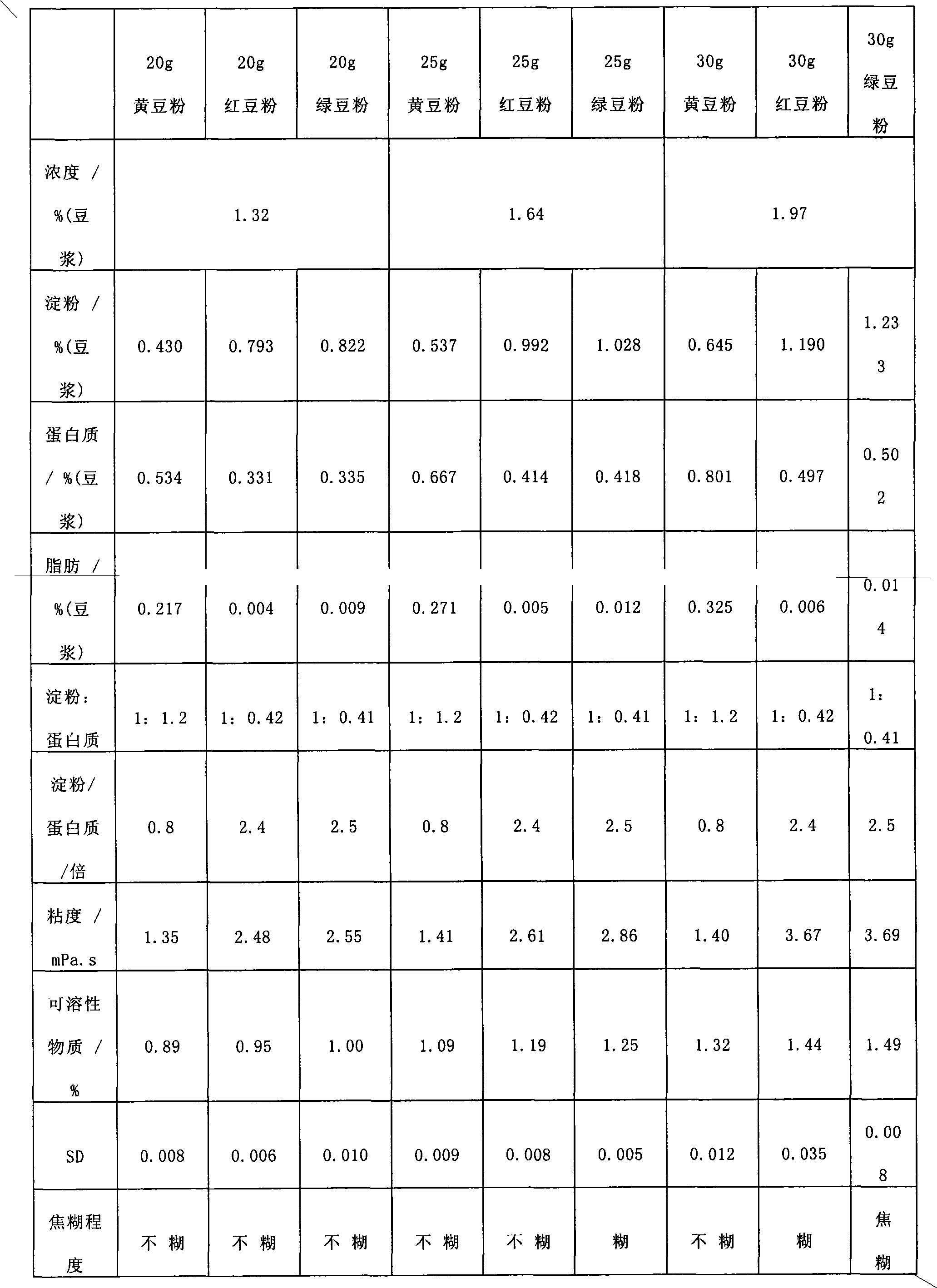

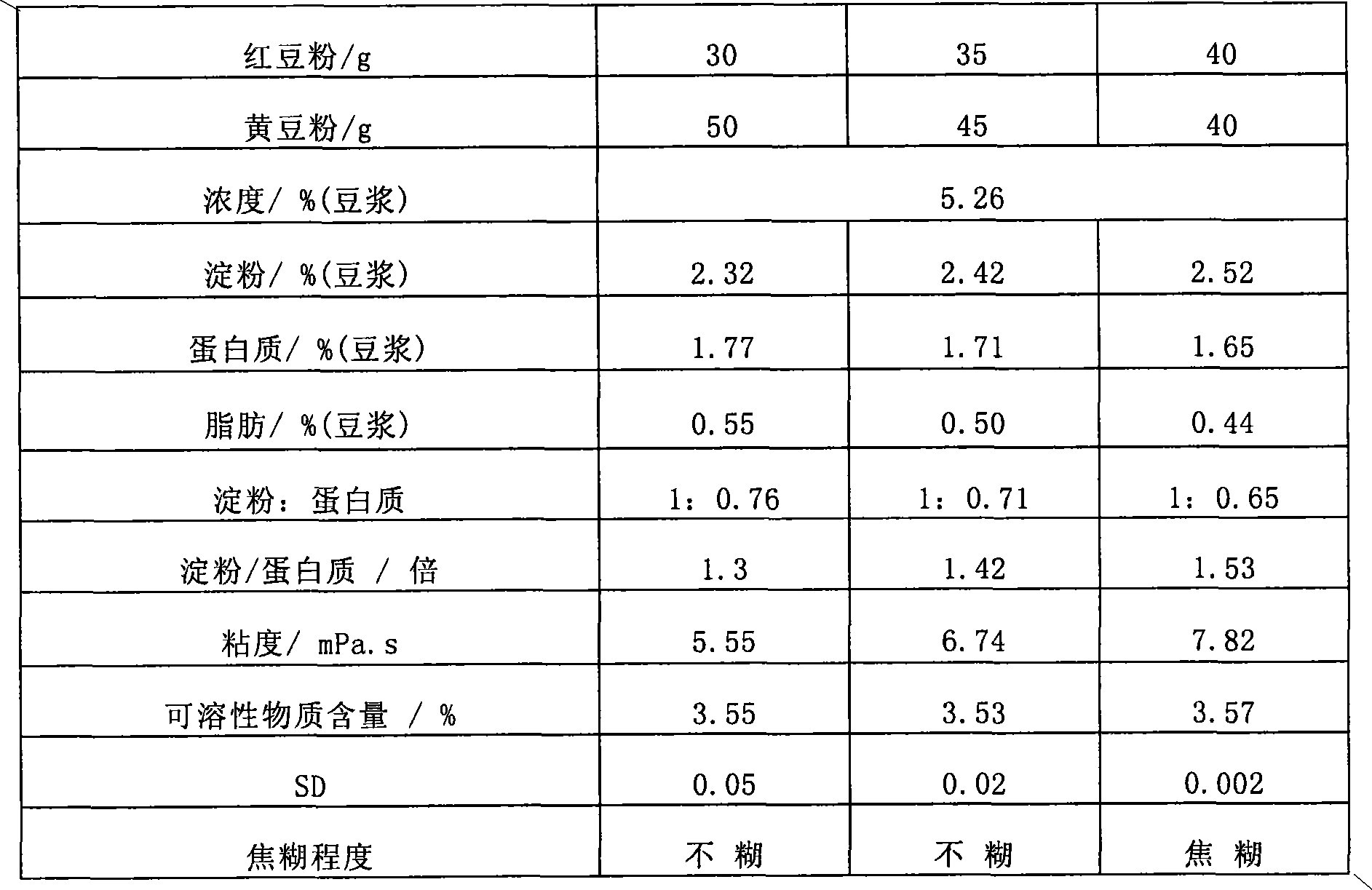

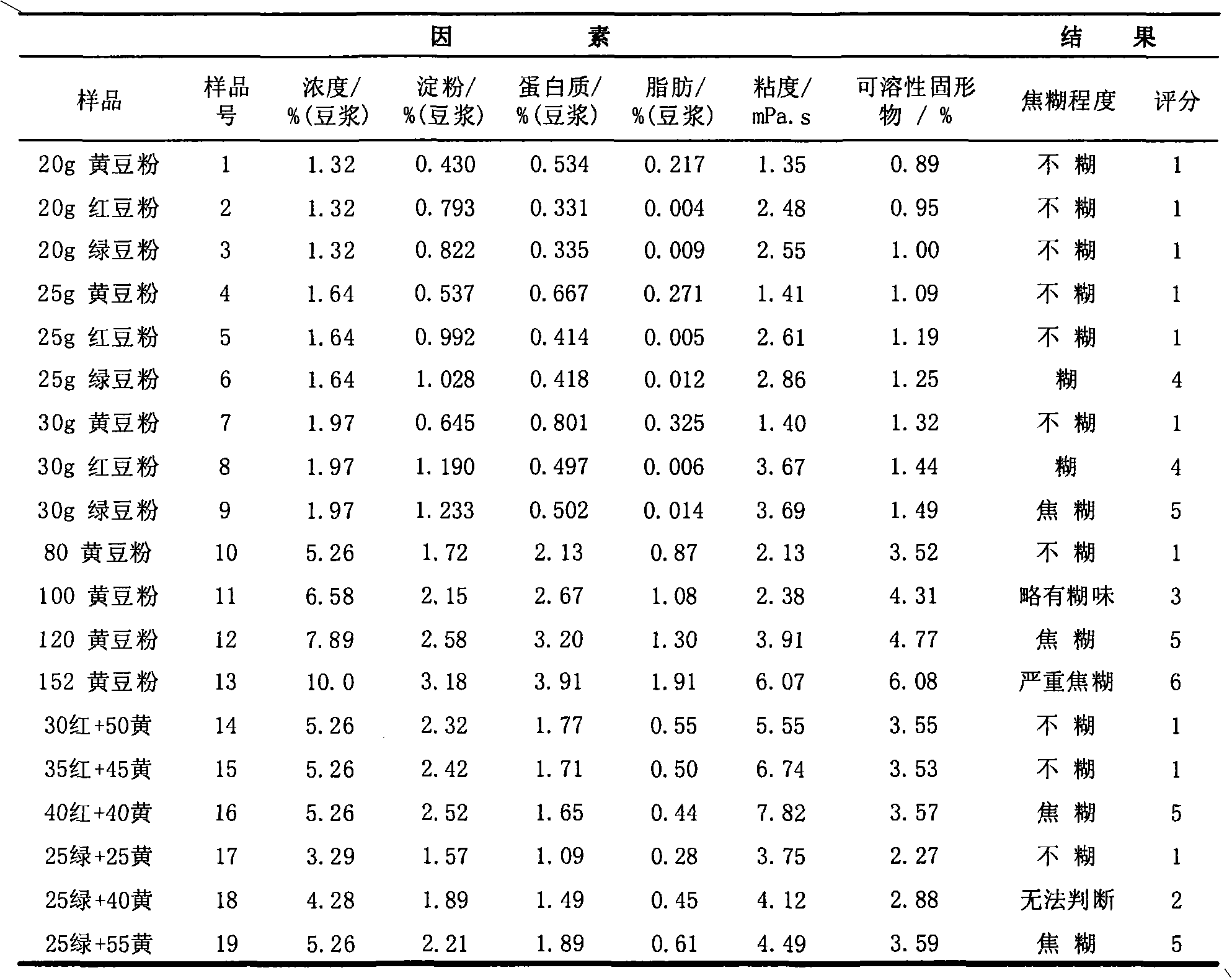

Raw material for making soybean milk and preparation method thereof

ActiveCN101884402AReasonable proportionIncrease nutritionFood preparationMilk substitutesSoybean mealSoybean oil

The invention discloses a raw material for making soybean milk and a preparation method thereof. Based on the total weight of the raw material and water, the raw material accounts for less than or equal to 6 weight part.

Owner:秦皇岛金海食品工业有限公司

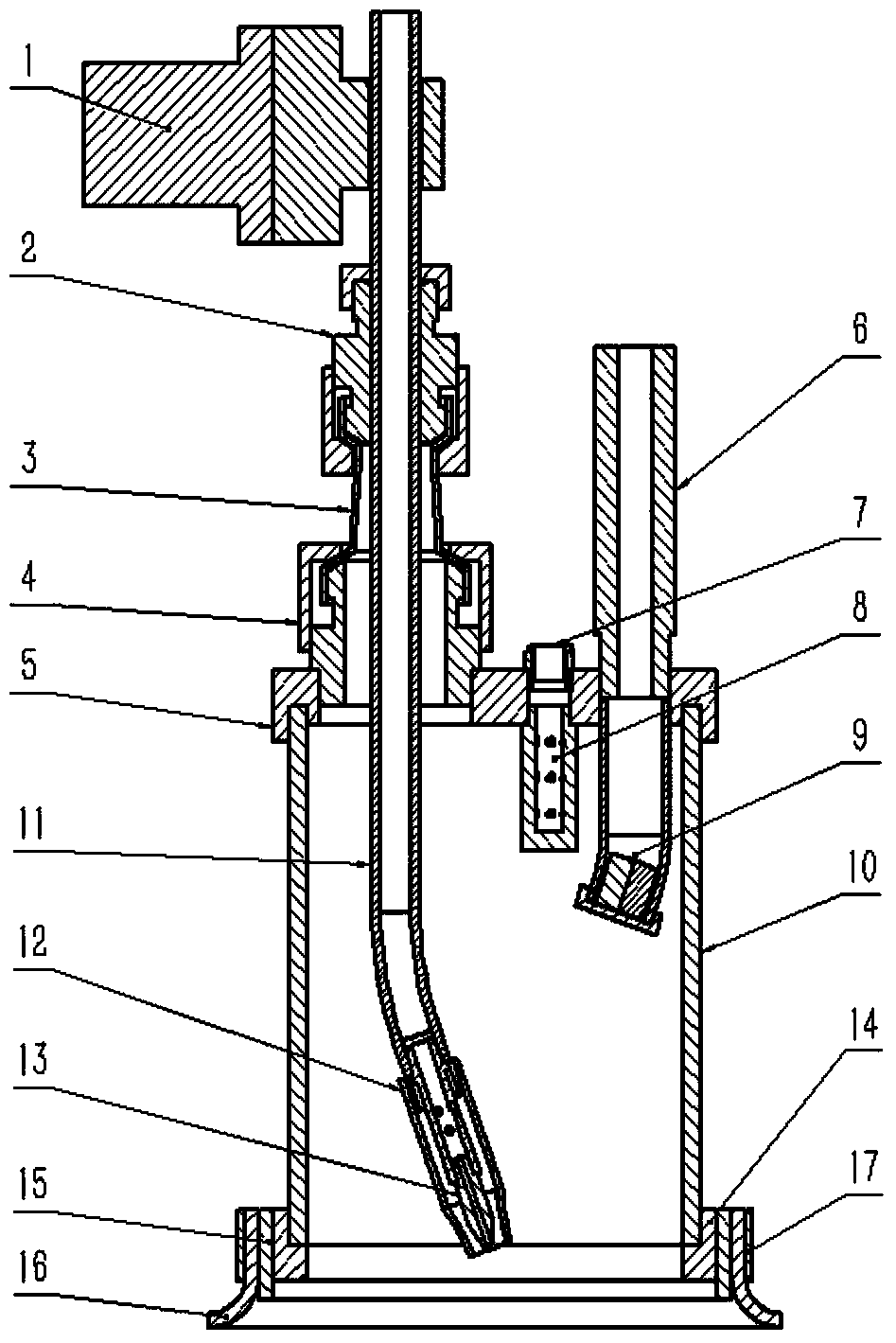

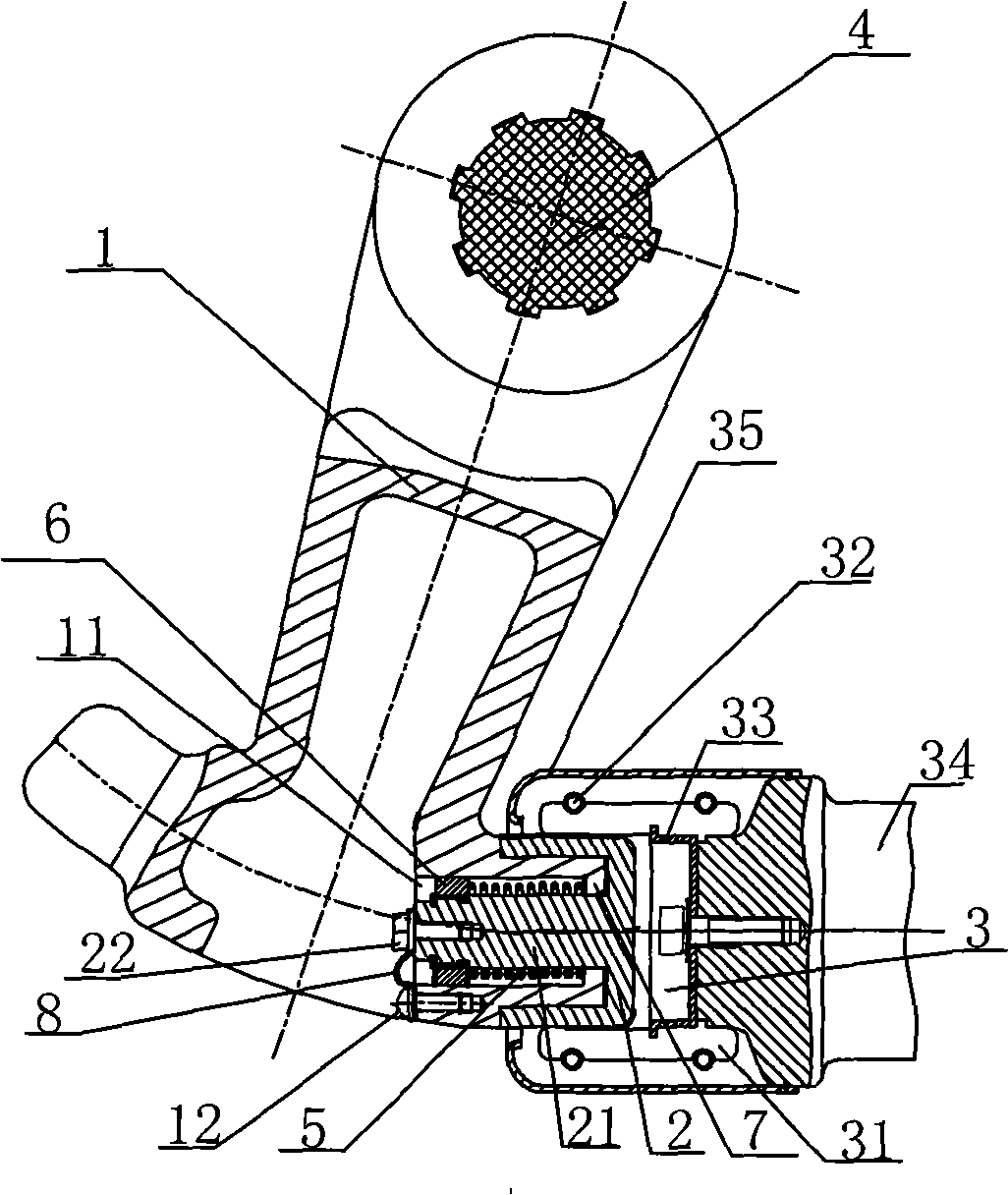

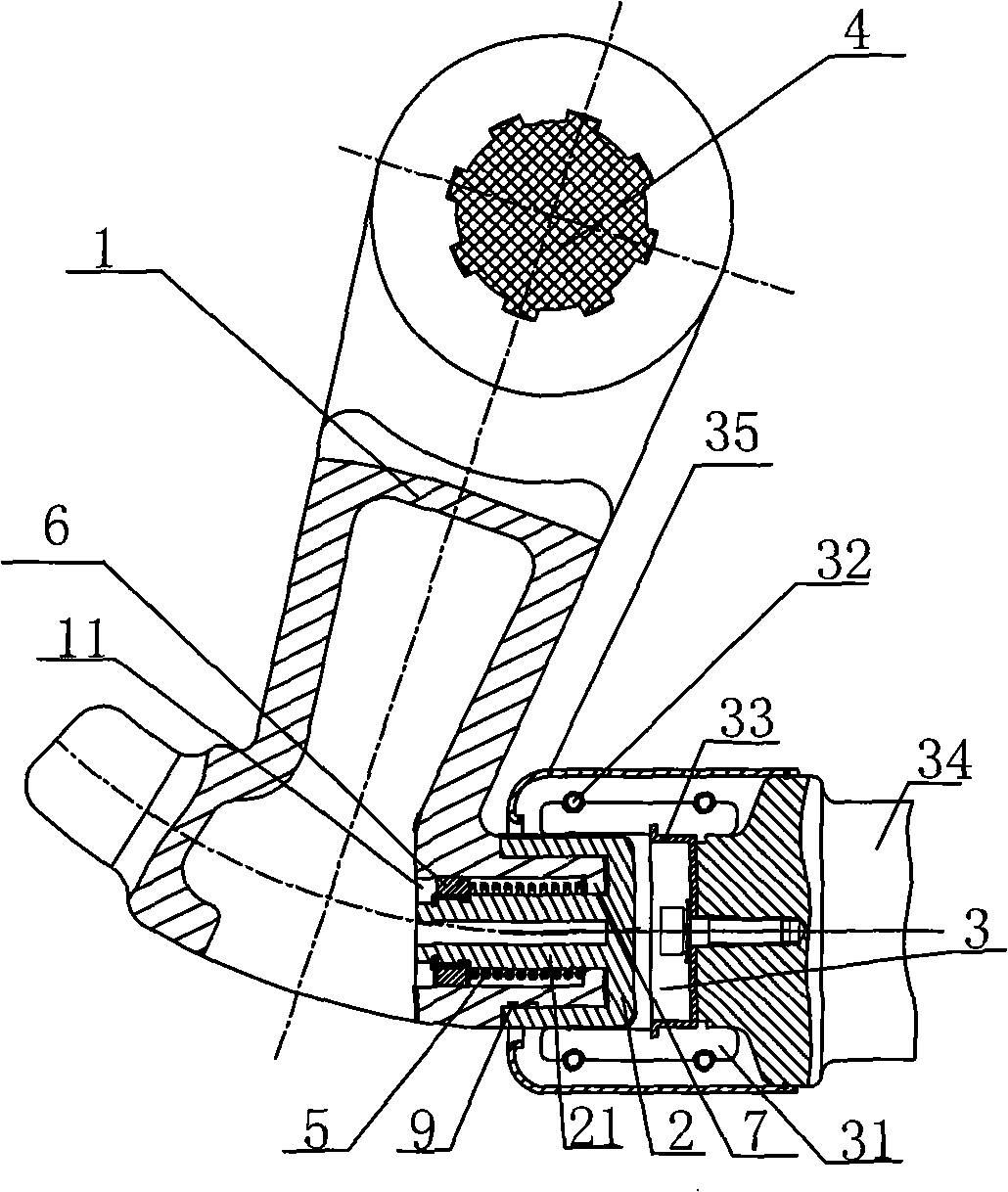

Special portable miniature drainage cover for automatic underwater local dry-method welding

InactiveCN103433606ARealize free adjustmentAvoid unfusedElectrode supporting devicesWelding accessoriesEngineeringCopper

The invention provides a special portable miniature drainage cover for automatic underwater local dry-method welding. A drainage cover body of the drainage cover comprises an upper end cover, an organic glass cover and a lower end cover. A clamping rod, an air inlet quick plug connector, a lower locking sleeve, a cooling air chamber and an underwater camera component are fixed to the upper side of the upper end cover and the lower side of the upper end cover through threaded connection respectively, and the upper end cover and lower end cover are connected with the organic glass cover through threads. A welding oscillator is clamped on the upper portion of a copper welding torch of a welding gun. According to the structure of a drainage sealing device, drainage felt and a felt skirt are arranged on the periphery of the lower end cover, and the drainage felt and the felt skirt are fastened on the lower end cover through hose clamps; the copper welding torch of the welding gun is fastened through an upper locking sleeve and the lower locking sleeve, the welding gun is inserted into the organic glass cover, and an elastic rubber leather sheath is arranged between the upper locking sleeve and the lower locking sleeve. The special portable miniature drainage cover for automatic underwater local dry-method welding has the advantages of being simple in structure, exquisite, convenient and fast to use, low in cost, obvious in drainage effect, and stable and reliable in welding process. Moreover, a connector with the quality of on-land welding is formed, the welding efficiency is improved and the special portable miniature drainage cover is easy to popularize.

Owner:TIANJIN UNIV

Modified amino resin expansion type water flame-proof paint

InactiveCN101117510AImprove flame retardant performanceIncreased resistance to ignitionFireproof paintsEmulsion paintsPliabilityMelamine

The present invention relates to amino resin intumescent aqueous flame retardant coating, in particular to an intumescent aqueous flame retardant coating. The present invention eliminates the release of harmful organic volatile compounds of the inflaming-retardant coating in use, improving poor fire resistant performance of dewatering catalyst due to a high disassembling temperature, solving the problems of long manufacturing period, low efficiency and high cost of the inflaming-retardant wood materials. The materials for the present invention comprises amino resin, polyvinyl acetal resin, dewatering catalyst, melamine, charring agents, dope assistant, antifoaming agent, palette filling and water. The present invention has storage for a long time, good cohesion, slow and low emission of heat and low emission of smoke, enjoying good flexibility and good strike-resistant performance; furthermore, the present invention can be manufactured easily and used conveniently and can be easily popularized without emission of harmful organic volatile in use. Compared with a prior wooden inflaming-retardant liquid, the present invention has the advantages of simple process, convenient operation, low cost and high efficiency.

Owner:NORTHEAST FORESTRY UNIVERSITY

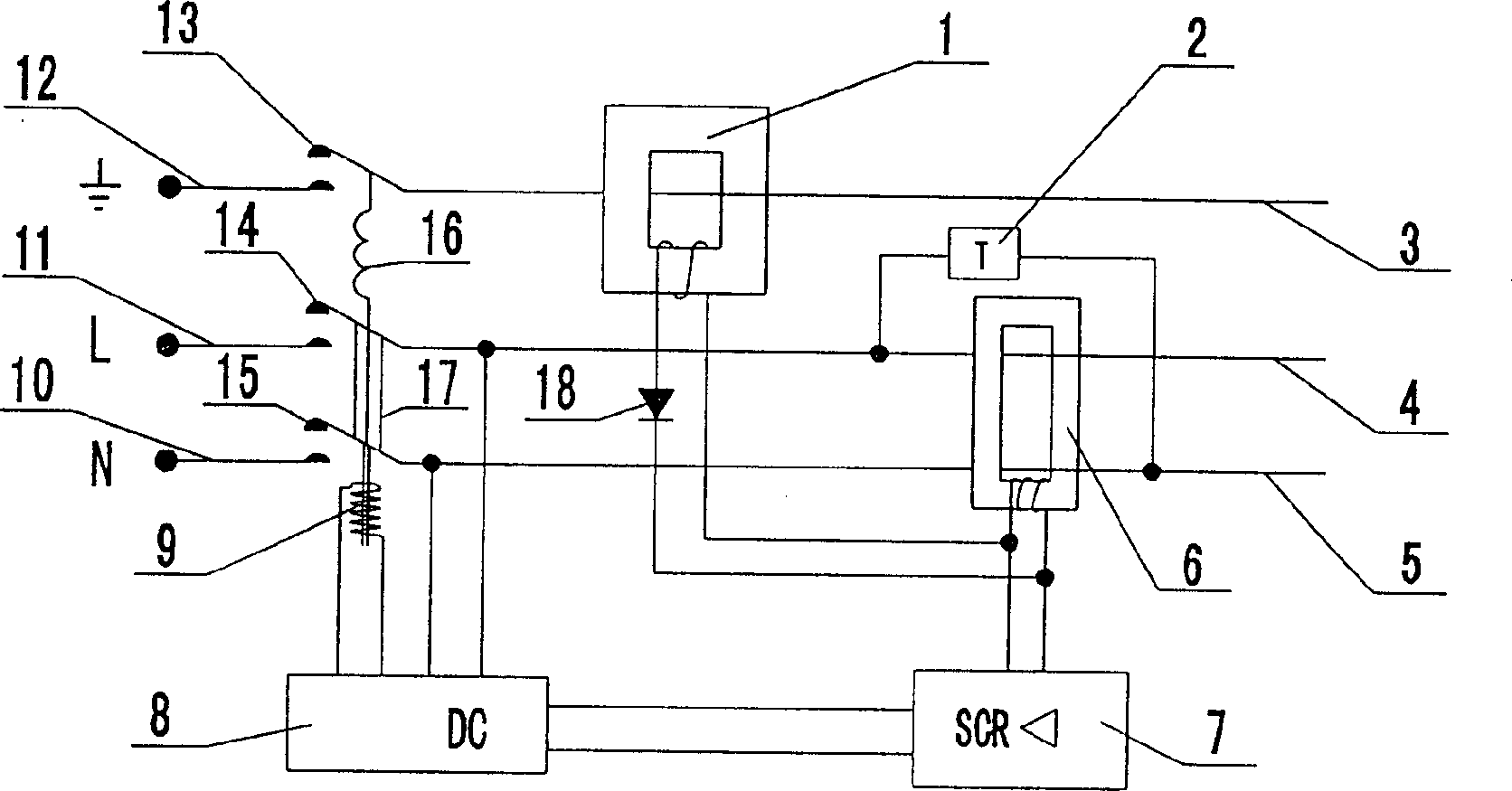

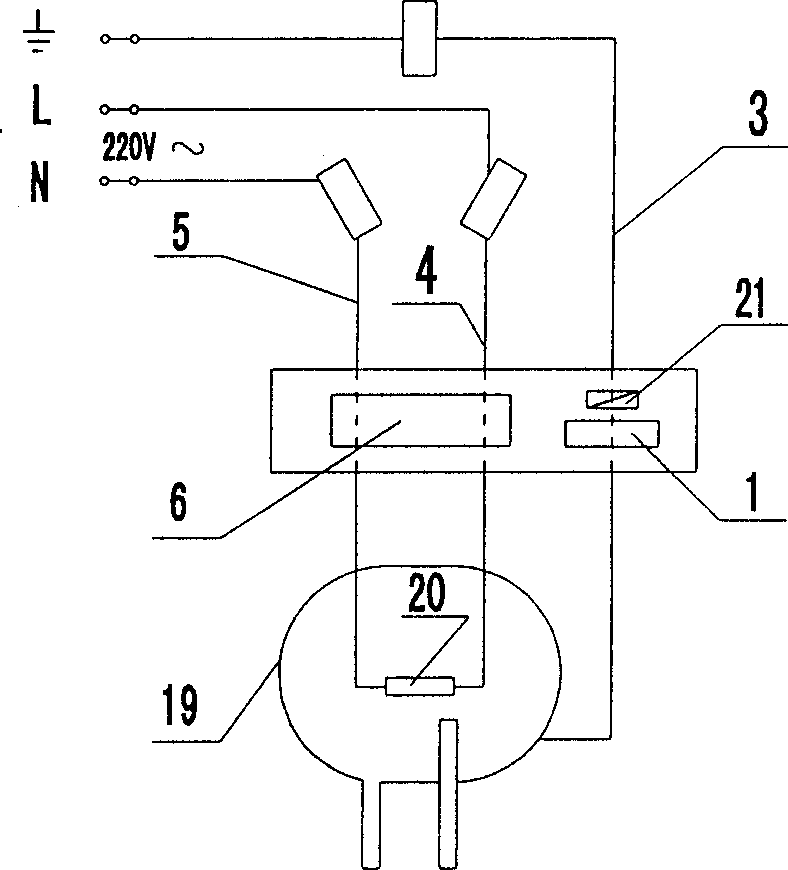

Leakage protection plug

InactiveCN1350352AGuarantee personal safetyEnsure user safetyCoupling device detailsEmergency protective arrangements for automatic disconnectionInductorEngineering

A multi-function leakge protection plug not only can prevent the electric shock accident caused by electrical appliance fault but also can prevent the electric shock accident caused by the power source fault. Therefore, it has earth line live line detecting inductor in the earth line of power source line, zero sequence current mutual inductor, a pair of contact terminal setting between the sub-breaker to each line of phase, zero and earth within the plug, a spring at between the sub-breaker upper end and the copper leaf of earth line active contact terminal to let the spring force attracting to each other always exist on the pair of earth line contact terminal. The safety requirement in electrical operation can be achieved by connecting earth line first and then phase and zero lines or cutting of phase and zero lines first and then earth line when the free releasing device is acting No matter the residual current exists between phase and zero lines or the abnormal cunent exists on theearth line three electrodes in the plug will be cut off simultaneously.

Owner:刘睿刚

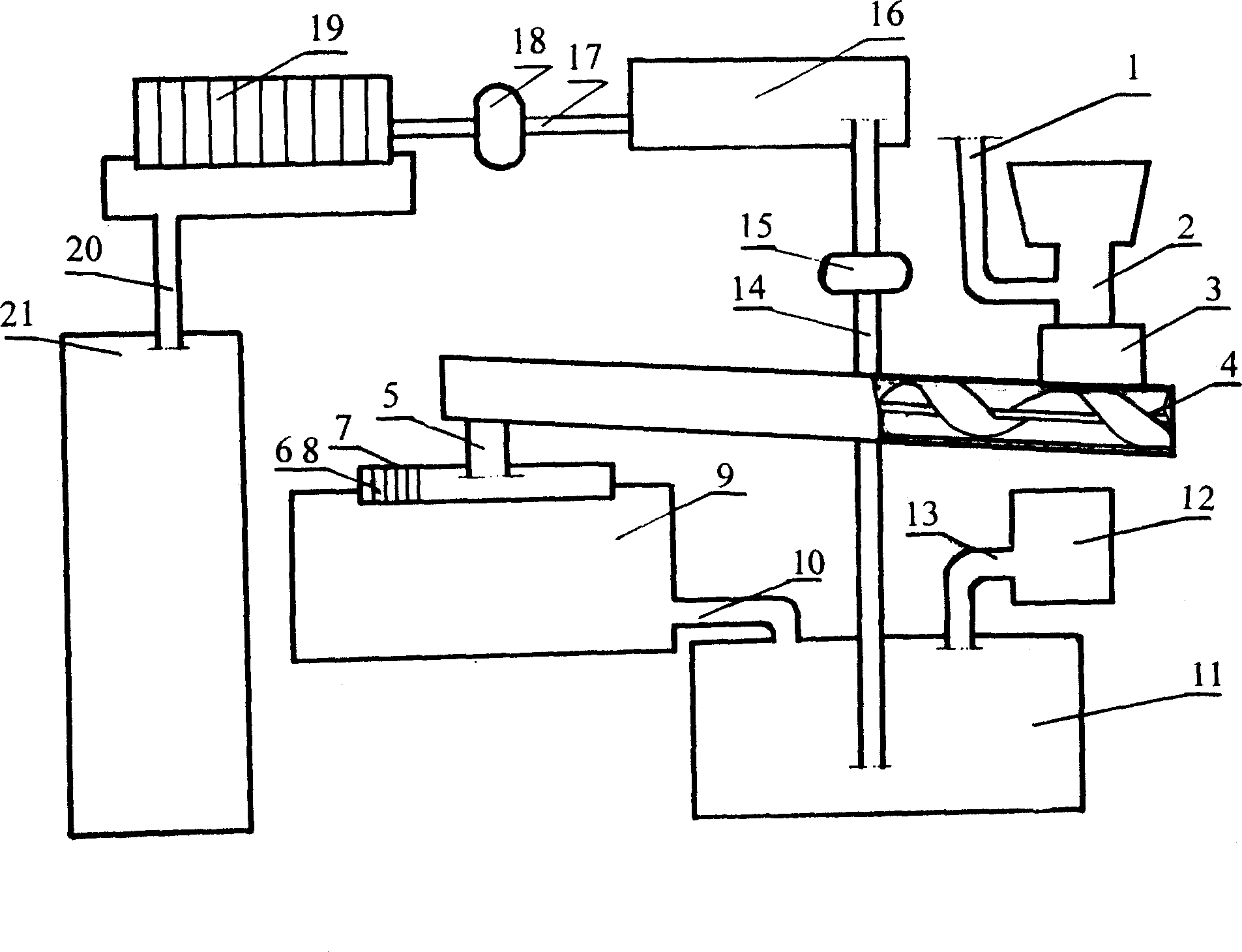

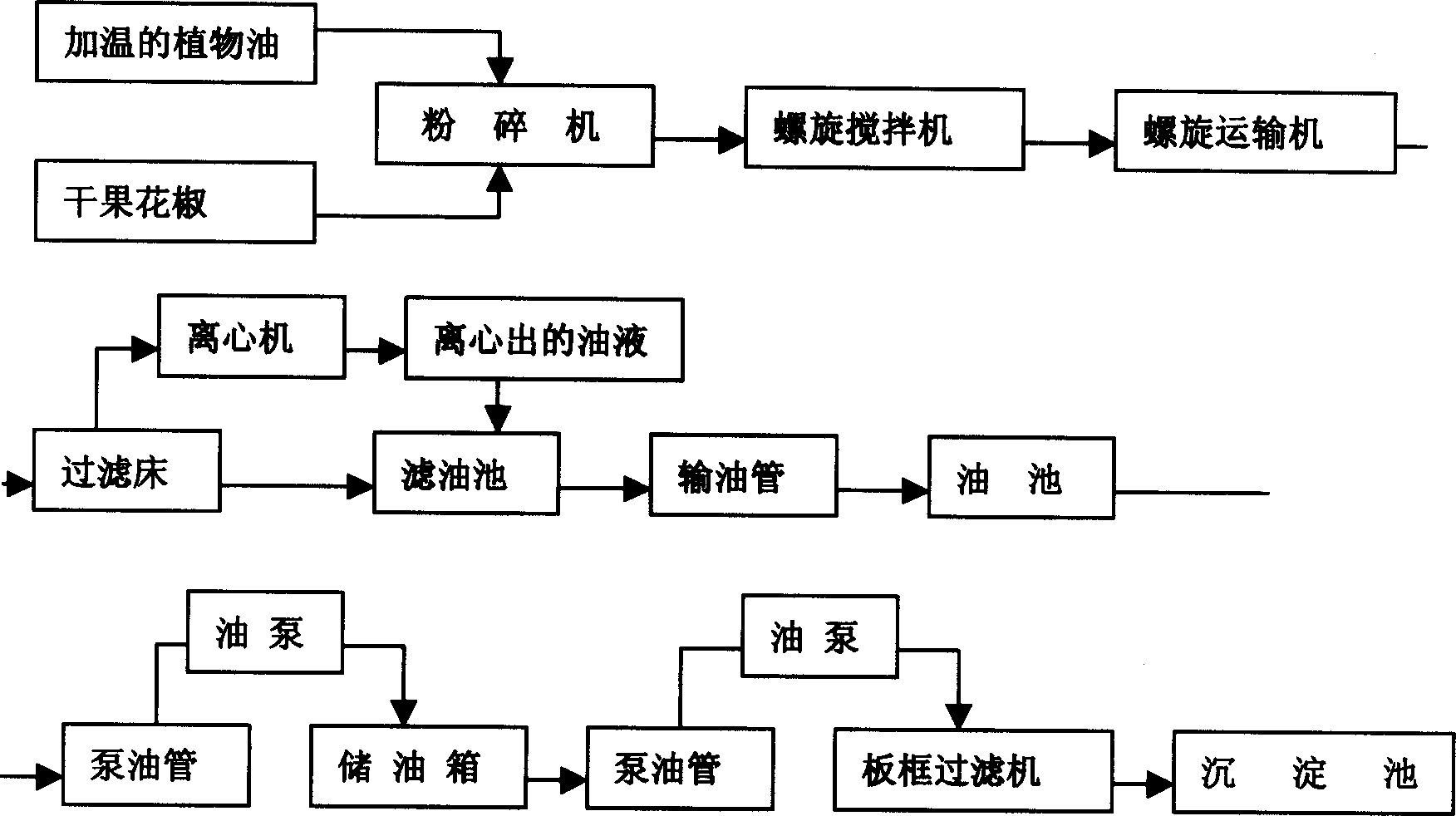

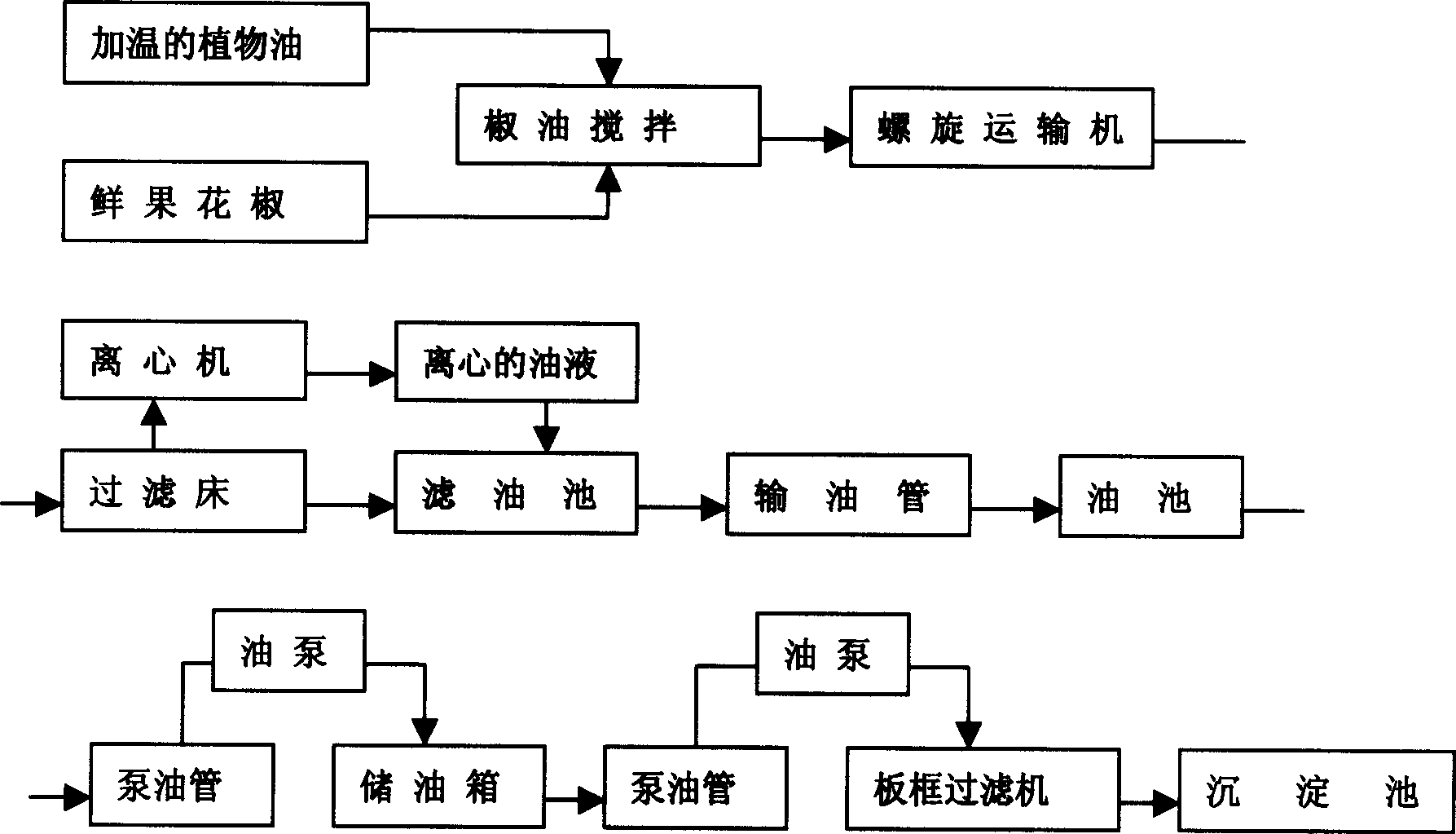

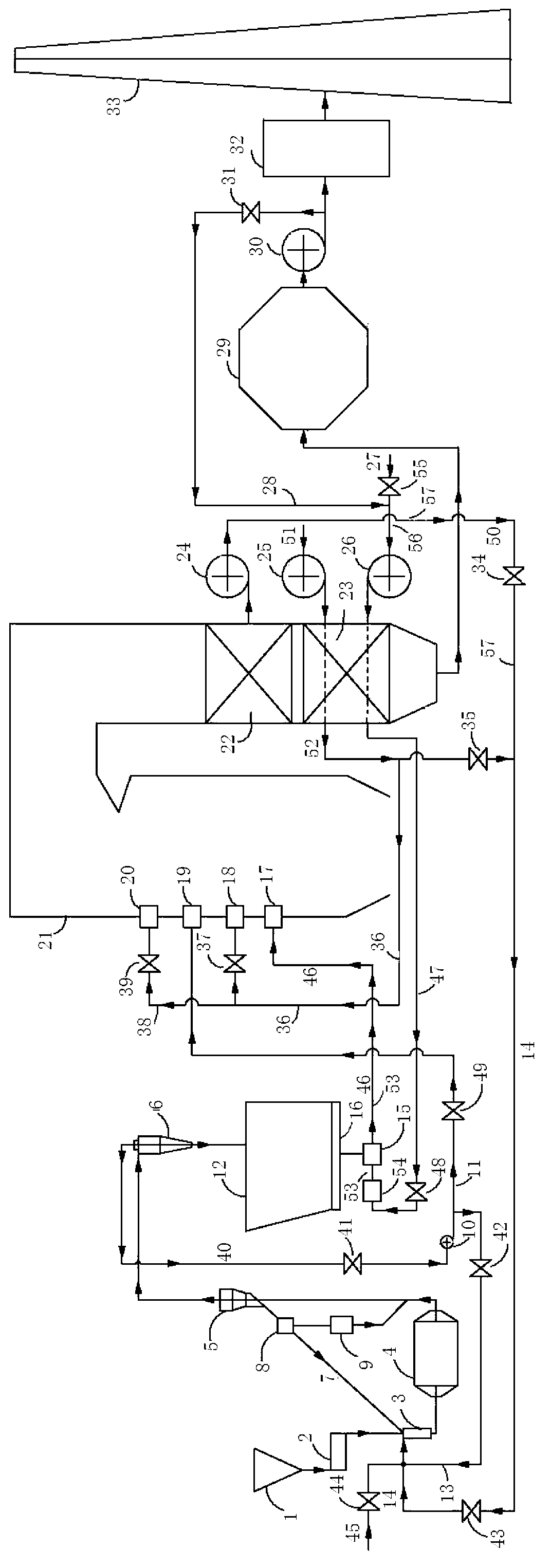

Pepper oil, preparing method thereof and producing apparatus therefor

InactiveCN1490389AFragrant and rich in numbnessEasy to useFatty-oils/fats productionFood sciencePulverizerBiology

A process for preparing the wild pepper oil includes such steps as adding wild pepper in rape seed oil, pulverizing, stirring, immersing, filtering, separating, filtering, and depositing. Its equipment is composed of pulverizer, screw stirrer, centrifugal separator, oil delivering pipe, and frame-type filter.

Owner:SICHUAN WUFENG LIHONG FOOD

Storage-type super-low nitric oxide system in coal fired boiler coal mill

ActiveCN103216840ANot easy to explodeIncrease delivery temperatureLump/pulverulent fuel feeder/distributionLump/pulverulent fuel preparationPowder mixtureNitric oxide

The invention relates to a storage-type super-low nitric oxide system in a coal fired boiler coal mill. On the basis of the existing low-nitrogen burning technology, the superfine coal powder preparation technology and the smoke circulating technology are adopted. The smoke circulating technology adopts cold furnace smoke to be mixed with primary air to be supercharged by a primary fan, the heating and powder feeding technology of an air preheater and the hot air and high-temperature furnace smoke drying technology of the powder production system are adopted, i.e. superfine coal powder can be prepared, the hot furnace smoke enters a primary air large air bellow, the hot furnace smoke is mixed with superfine coal powder prepared by a superfine coal powder preparation device in a coal powder blender and supplied by a powder supply machine from a coal powder cabin to be heated, and the air-powder mixture is fed into a low-nitrogen burner through a primary air pipe. In the main burning area of the boiler, since the air content of the furnace smoke is little, a lower residual air coefficient can be realized, the emission of the nitric oxide can be reduced.

Owner:南京佛莱斯特环保科技有限公司

Ceramic microwave absorbing material and preparation method and application thereof

InactiveCN101665350AHigh surface hardnessScratch resistantScreening apparatusCooking vesselsMicrowaveUtilization rate

The invention discloses a ceramic microwave absorbing material and a preparation method and an application thereof. The ceramic microwave absorbing material comprises ceramic material powder and microwave absorbing powder, and the weight percentage of the components is as follows: 40 to 80 percent of ceramic material powder and 20 to 60 percent of microwave absorbing powder. The preparation methodof the ceramic microwave absorbing material comprises the following steps: 1) respectively weighing the ceramic material powder and the microwave absorbing powder according to weight percentage; 2) evenly mixing the ceramic material powder with the microwave absorbing powder to obtain compound wave-absorbing powder; 3) evenly mixing the compound wave-absorbing powder with methylcellulose and water to obtain the pulp of the ceramic microwave absorbing material; 4) forming the pulp to obtain a green body; and 5) drying the green body, and then sintering at high temperature to obtain the ceramicmicrowave absorbing material. The ceramic microwave absorbing material can be used for manufacturing ceramic microwave absorbing cooking equipment. The cooking equipment has high microwave utilization rate and heating efficiency; and food is not easy to be coked and is heated more uniformly. The preparation method of the ceramic microwave absorbing material has simple technique and low cost of raw material and processing.

Owner:MIDEA GRP CO LTD

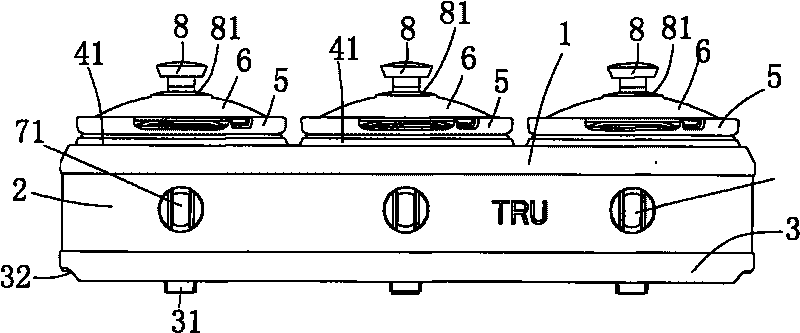

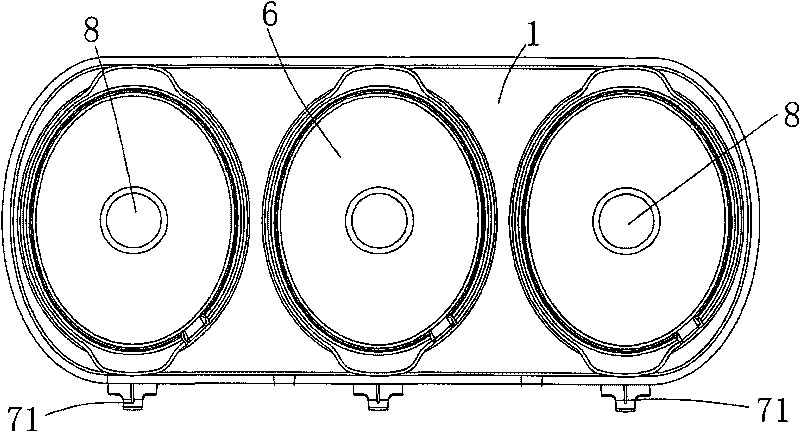

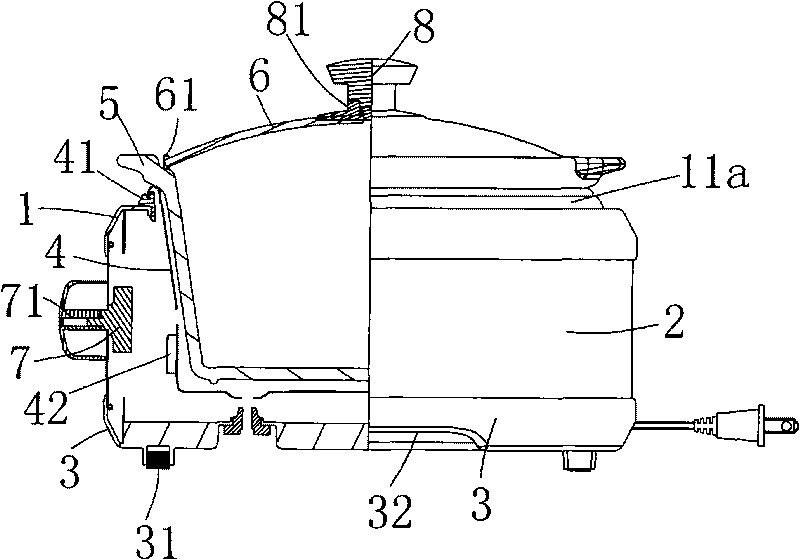

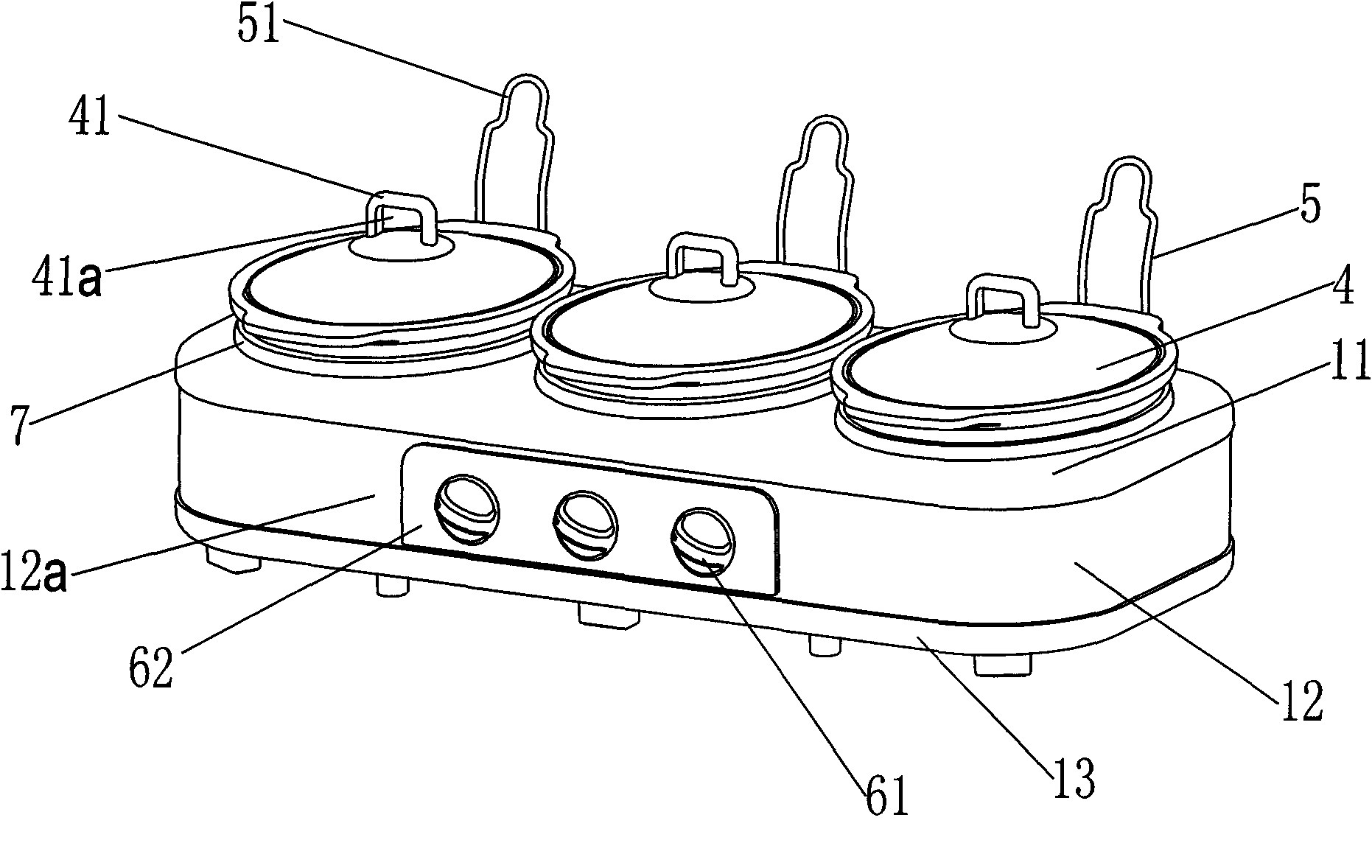

Multi-cooker site slow cooker

InactiveCN101695429AIncrease contact surfaceNot easy to burnMultiple-unit cooking vesselsPressure castingEngineering

The invention discloses a multi-cooker site slow cooker comprising an upper cover, a shell and a lower cover. Three linear parallel cooker holes running through the inner chamber of the shell are arranged on the upper cover, and a heating bladder is respectively inlaid in the cooker holes; a ceramic bladder is inlaid in each heating bladder; the cooker cover covers above the ceramic bladder; the lower ring edge of the upper cover is provided with an upper fastening edge, and the upper fastening edge and the upper ring edge of the shell are in coupling connection; the upper ring edge of the lower cover is provided with a lower fastening edge, and the lower fastening edge and the lower ring edge of the shell are in coupling connection; the side surface of the shell is provided with three linear parallel rotating switches, and the rotating switches are corresponding to the heating bladders one to one and independently control the heating operation of each heating bladder; three parallel ceramic bladders are arranged, and thereby, the cooking diversification can be realized; the upper cover and the lower cover have a plastic housing respectively, thereby having beautiful and elegant appearance and low surface temperature; the cooker cover is made of pressure casting tempering glass, thereby being safe to use and not easy to break; an operation panel has a rotating switch structure, being convenient to operate; and a right grip and a left grip are connected into a whole with a base, being durable.

Owner:浙江亿达控股集团有限公司

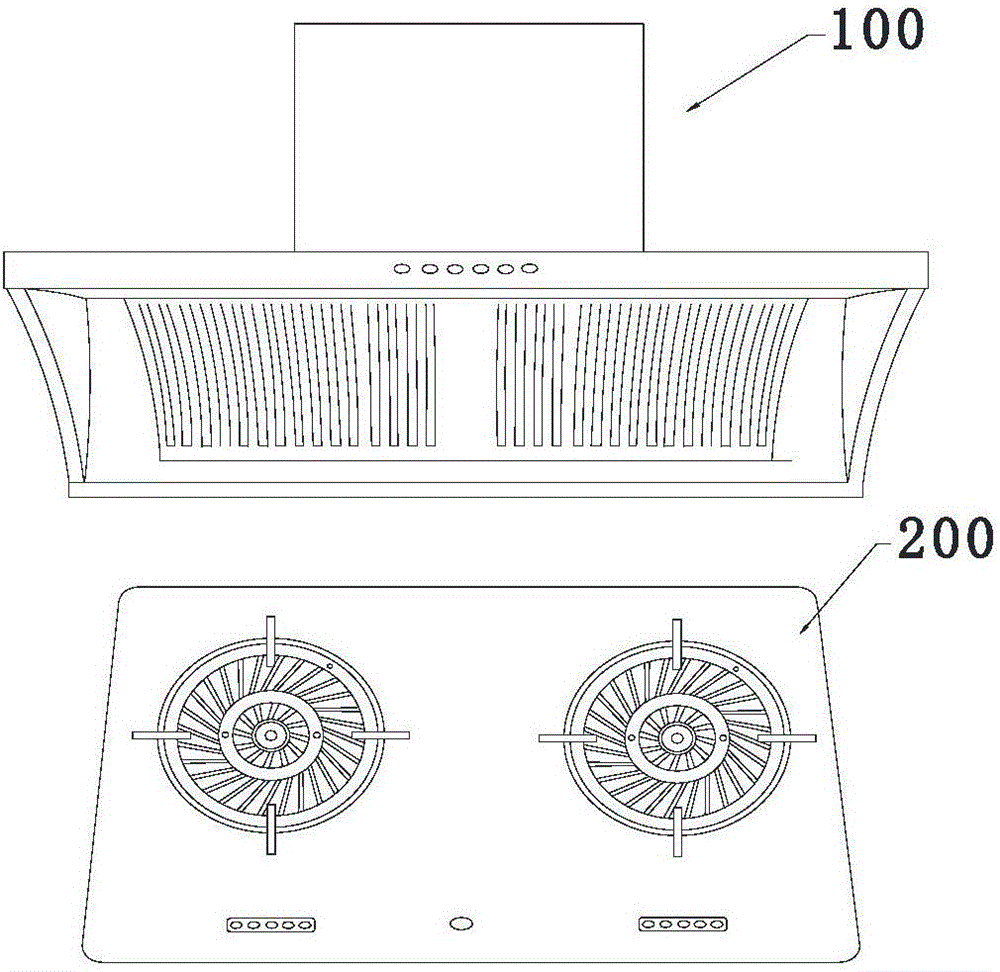

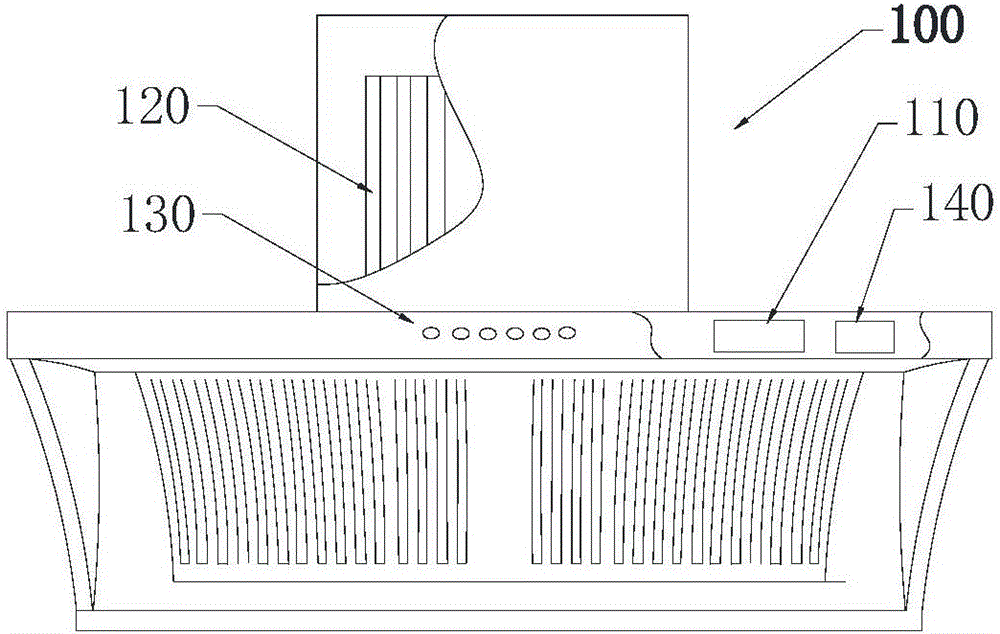

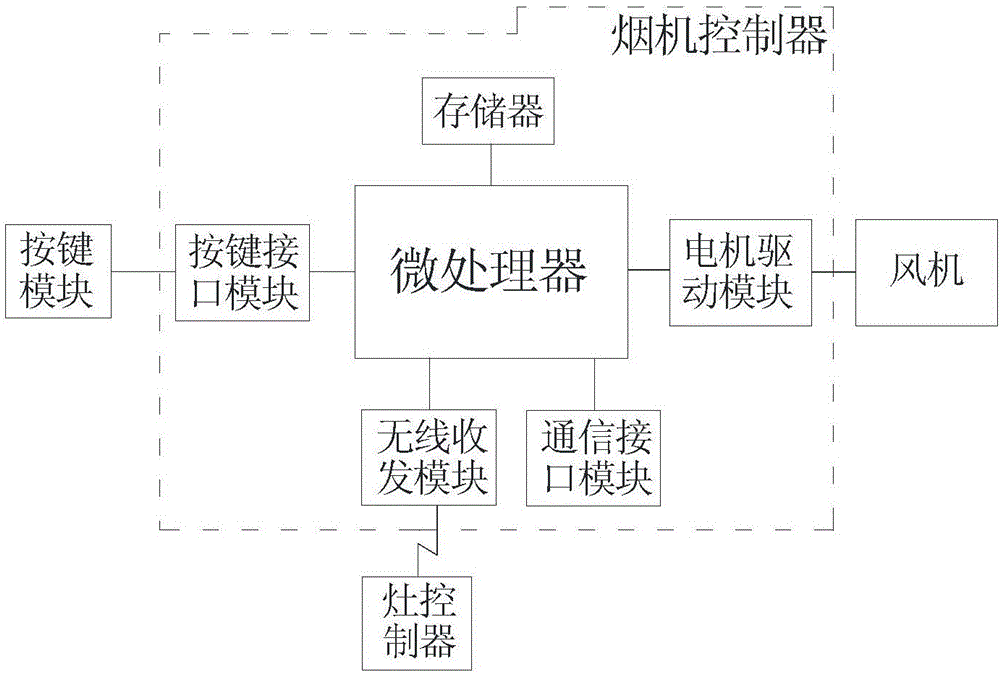

Intelligent system of integrated gas cooker

ActiveCN106839005AHeating evenlyUniform colorDomestic stoves or rangesLighting and heating apparatusCombustorProcess engineering

The invention belongs to the field of cookers and discloses an intelligent system of an integrated gas cooker. The intelligent system comprises the gas cooker and a range hood, and the gas cooker comprises burners, temperature sensors, ignition needles, electric control flow valves and a cooker controller. The electric control flow valves include a first electric control flow valve and a second electric control flow valve and are arranged on gas inlet pipelines of the burners respectively and used for controlling heat power of inner fire and outer fire. A range hood controller and a fan are arranged in the range hood. The temperature sensors and the burners fit together to detect bottom temperatures of pots. In cooking, the cooker controller acquires a corresponding cooking mode to control starting of the range hood and ignition of the gas cooker, the electric control flow valves are controlled to adjust heat power of the burners on the basis of a measuring value and a set value of pot temperature in the cooking mode so as to make the measuring valve of the pot temperature reach the set value until the cooking mode is completed, and finally the gas cooker is controlled to flame out while the range hood stops. The intelligent system of the integrated gas cooker is suitable for automatic soup cooking, rice cooking, porridge cooking and pancake making without user participation.

Owner:李明守

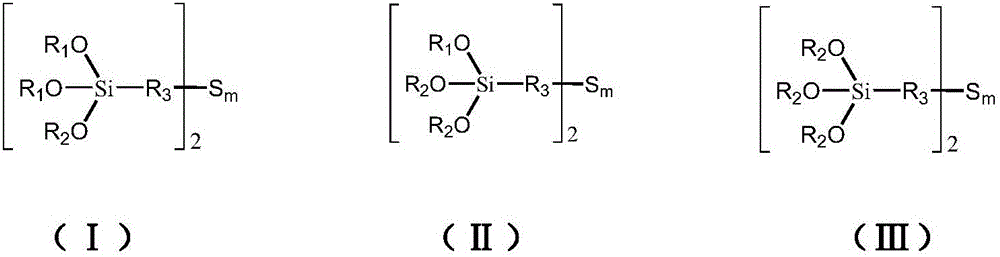

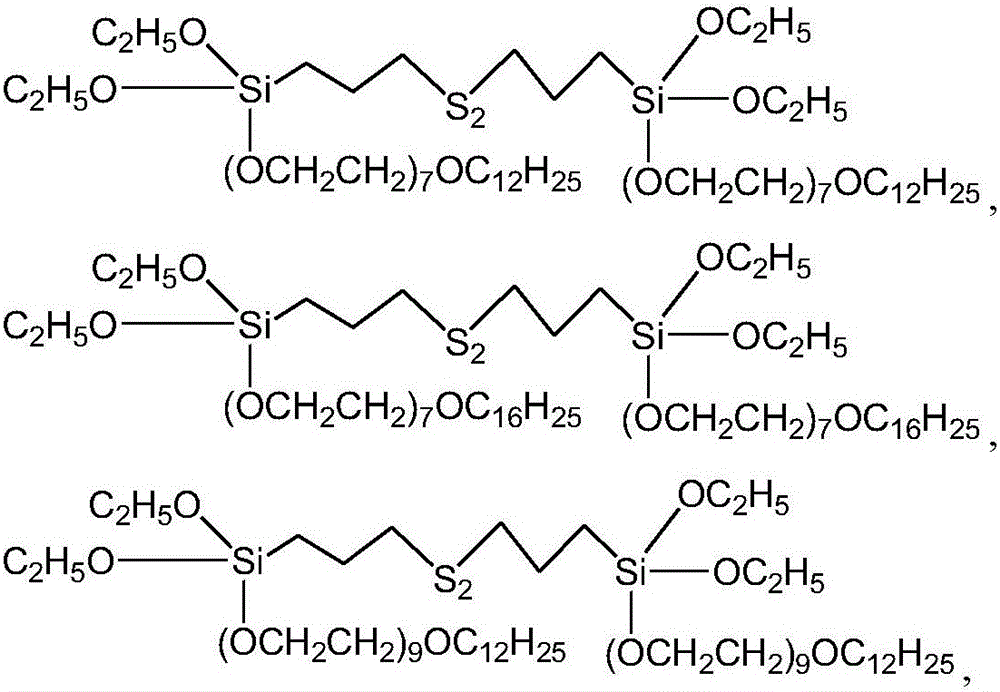

Silane coupling agent containing vinyl ether chain segment, and preparation method and application thereof

InactiveCN106674593AGood dispersionNot easy to burnPigment treatment with organosilicon compoundsVinyl etherAlcohol

The invention discloses a silane coupling agent containing a vinyl ether chain segment, and a preparation method and an application thereof. The silane coupling agent is a novel silane coupling agent. The silane coupling agent is acquired through the catalytic reaction of the traditional coupling agent with a formula (IV) structure and fatty alcohol-polyoxyethylene ether or alicyclic alcohol polyoxyethylene ether. The application of the silane coupling agent disclosed by the invention in preparing a high-performance tread rubber by in situ modifying white carbon black can effectively reduce the VOC discharge in the size mixing process and in the use process of rubber products. The silane coupling agent disclosed by the invention also can be used for modifying the liquid phase of the white carbon black; the wet-process mixing can be realized; the problems of single method for modifying the white carbon black with the traditional silane coupling agent, large energy consumption in the processing process and serious pollution can be effectively solved; and the traditional coupling agent with the formula (IV) structure and the fatty alcohol-polyoxyethylene ether in low cost are taken as the synthesis raw materials, so that the use cost of the coupling agent is lowered.

Owner:BEIJING UNIV OF CHEM TECH +1

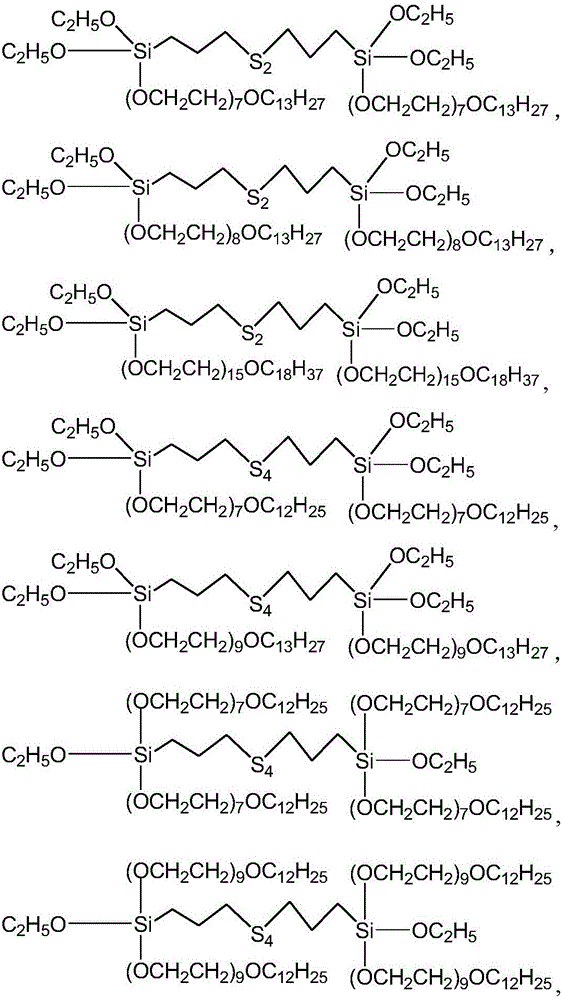

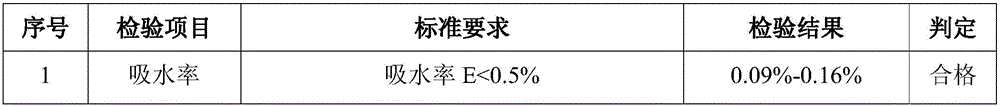

Bright red nanometer glaze slip for ceramic sanitary wares as well as preparation method and application of bright red nanometer glaze slip

The invention discloses a bright red nanometer glaze slip material for ceramic sanitary wares, as well as a preparation method and application of the bright red nanometer glaze slip material. The bright red nanometer glaze slip material specifically comprises water as a medium, and the following components in percentage: 20-25% of feldspar, 40-45% of quartz, 16-20% of calcium carbonate, 2-3% of dolomite, 3-5% of zinc oxide, 2-4% of kaolin, 2-5% of nanometer zirconium, 3.5-6% of nanometer aluminum oxide, 9-12% of 060 bright red chromophoric materials, 1-3% of Z309 claret chromophoric materials and an appropriate amount of CMC for ceramics. The bright red nanometer glaze slip material disclosed by the invention is resistant to high temperature and can bear long-time high-temperature calcination, so that the application of bright red nanometer glaze for the ceramic sanitary wares in the production of the ceramic sanitary wares comes true, and the defects that color becomes black and pigments are volatilized after high-temperature calcination are overcome.

Owner:JOMOO KITCHEN & BATHROOM

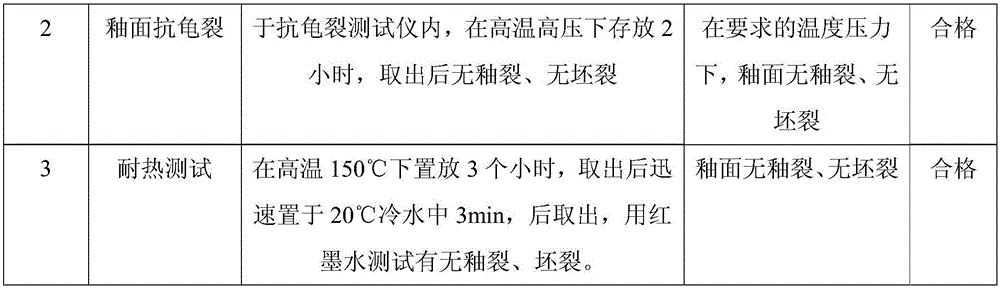

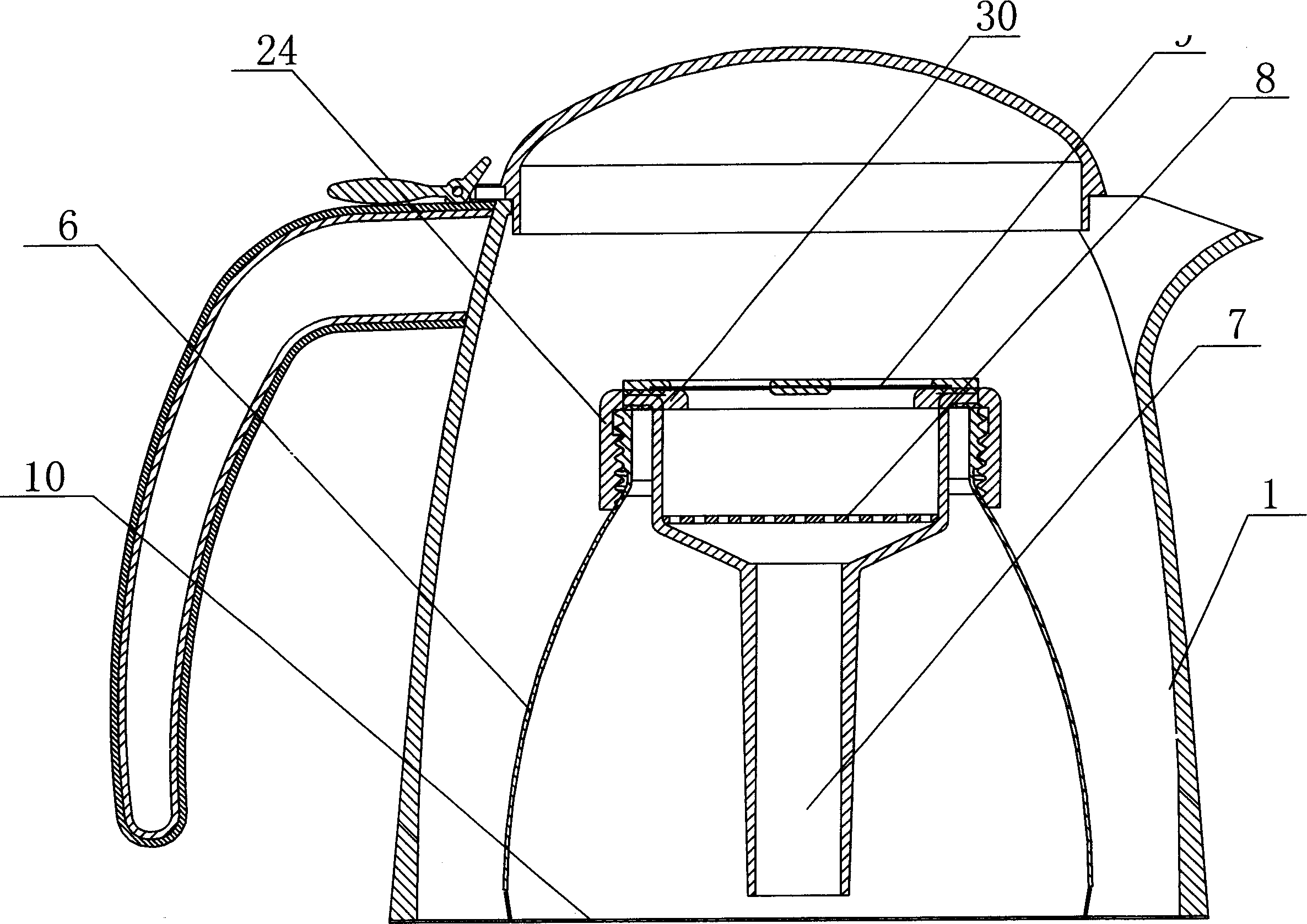

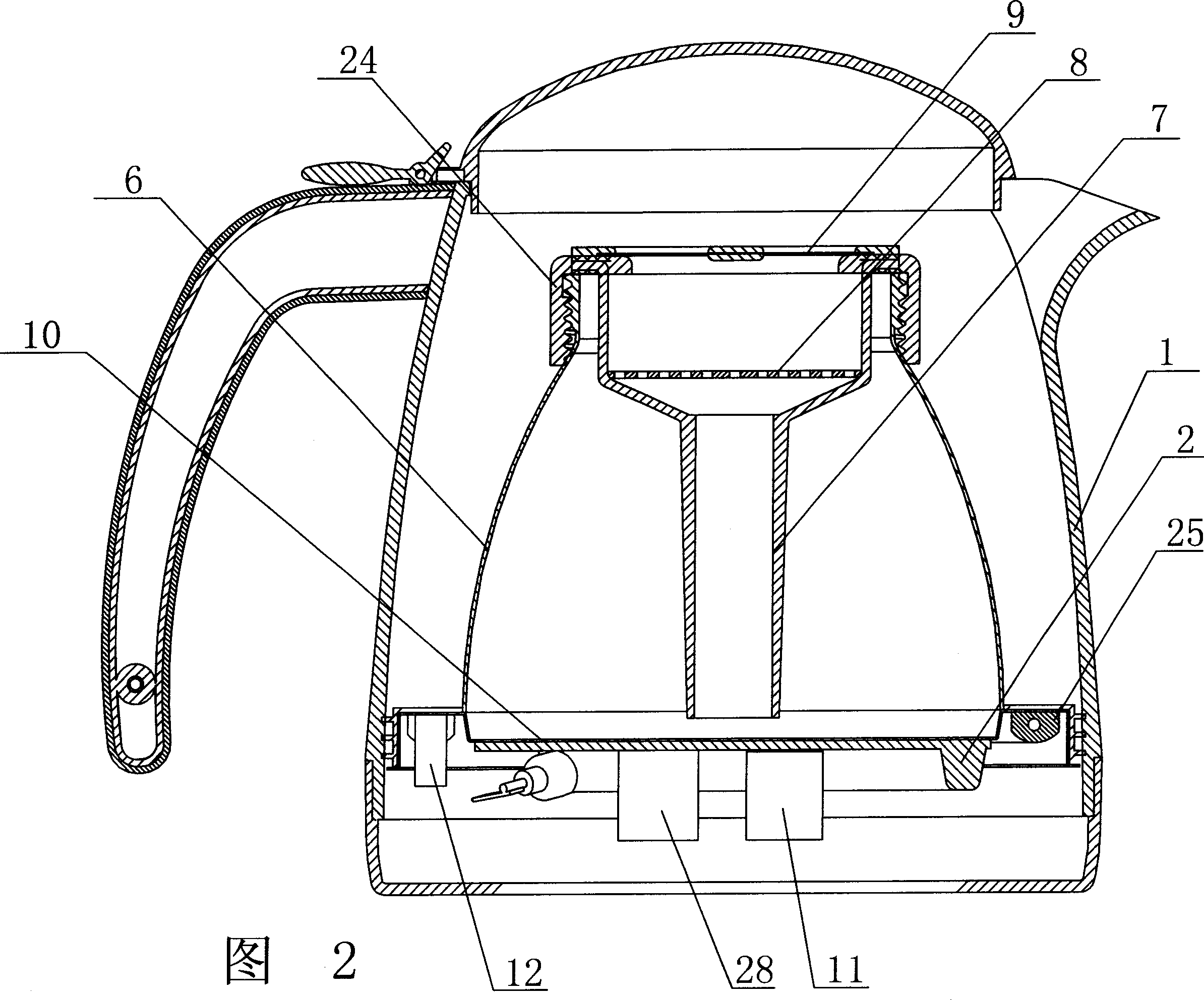

Kettle for boiling beverge, electric kettle and wireless electric kettle

InactiveCN1483374AGuaranteed fragranceNot easy to burnWater-boiling vesselsBeverage vesselsWater bottleElectric heating

The present invention relates beverage-boiling kettle, electroheating kettle and cordless electroheating kettle. The beverage-boiling kettle include a kettle body, an internal container on the bottom surface of the kettle body, the upper end hole of said internal container is equipped with a hopper in which a lower filtering layer and an upper filtering layer are set, and the beverage-boiling electroheating kettle is characterized by that an electroheater is added on the kettle body on the basis of the above-mentioned beverage-boiling kettle, and the beverage-boiling cordless electroheating kettle is characterized by adding kettle seat on the basis, and on the kettle body and kettle seat an electrically-connected plug and socket are set.

Owner:邵志成

Ceramic material prepared from red mud, and preparation method of ceramic material

InactiveCN105693210AIncrease incorporationNot easy to burnCeramic materials productionClaywaresCeramic sinteringRed mud

The invention relates to a ceramic material prepared from red mud, and a preparation method of the ceramic material, belonging to the field of comprehensive utilization of resources of solid wastes. The ceramic material is prepared by mixing the following raw materials by mass percent: 10-70% of red mud, 0-60% of clay, 5-35% of silicon-rich aluminum raw material, 5-40% of quartz raw material and 0-30% of magnesium-rich raw material; the preparation method adopts the traditional ceramics preparation technology, and comprises the steps of crushing the raw materials, blending, grinding, granulating, molding and carrying out other technologies to form a ceramic green body, drying the ceramic green body, enabling the dried ceramic green body to enter a ceramic kiln, and firing to obtain the ceramic material product, wherein the sintering temperature is 1060-1180 DEG C, the sintering time is 35-70 minutes, the breaking strength value of the prepared ceramic material exceeds 35MPa, the water absorption value of the prepared ceramic material is less than 1%, and if a optimal ratio is adopted, the breaking strength value of the ceramic material exceeds 100MPa, and the water absorption value of the ceramic material is less than 0.5%. After the preparation method is adopted, the red mud can be used for producing general construction ceramics / ceramic sintered bricks and high-strength industrial ceramic materials; the preparation method is easy and feasible, and is beneficial to industrial production.

Owner:UNIV OF SCI & TECH BEIJING

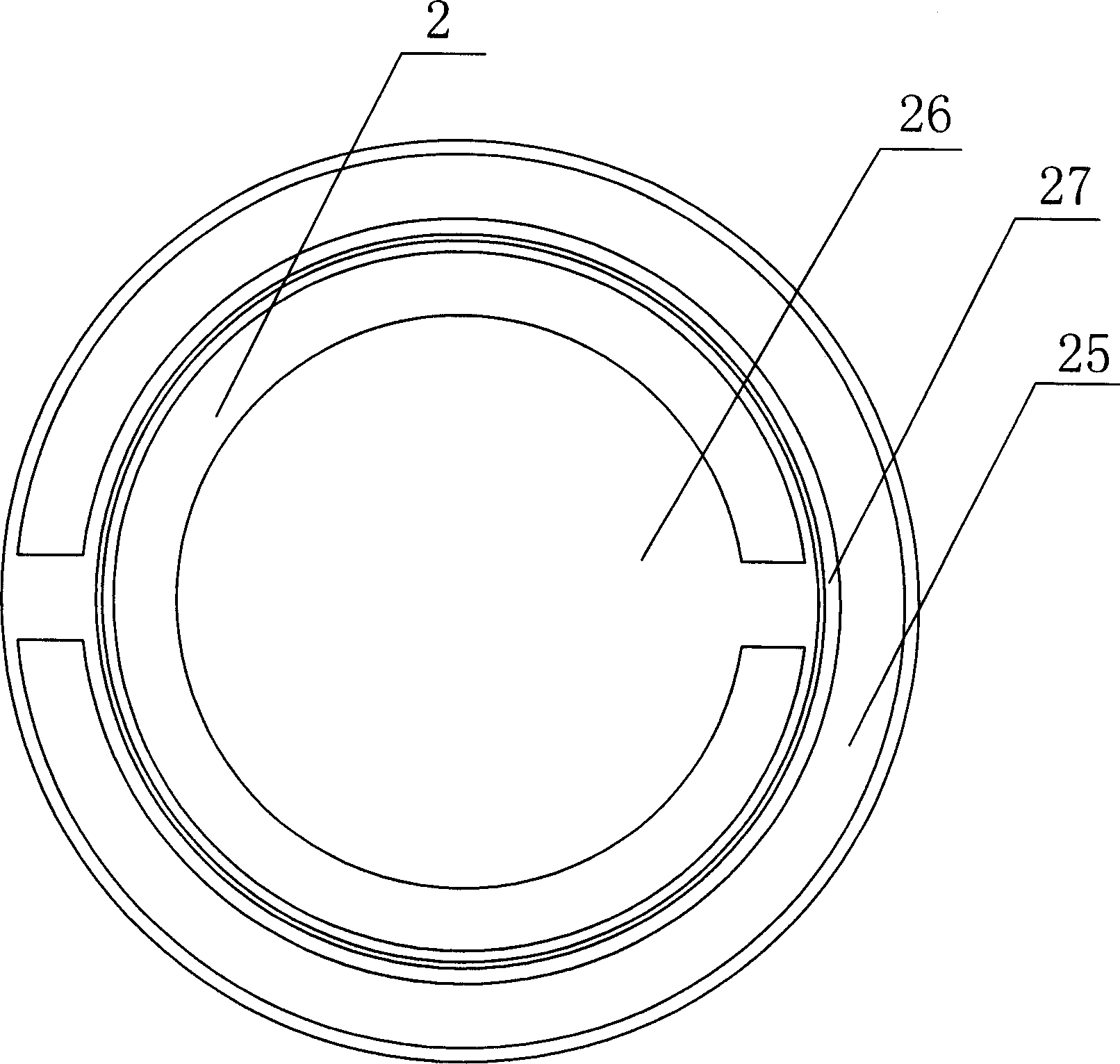

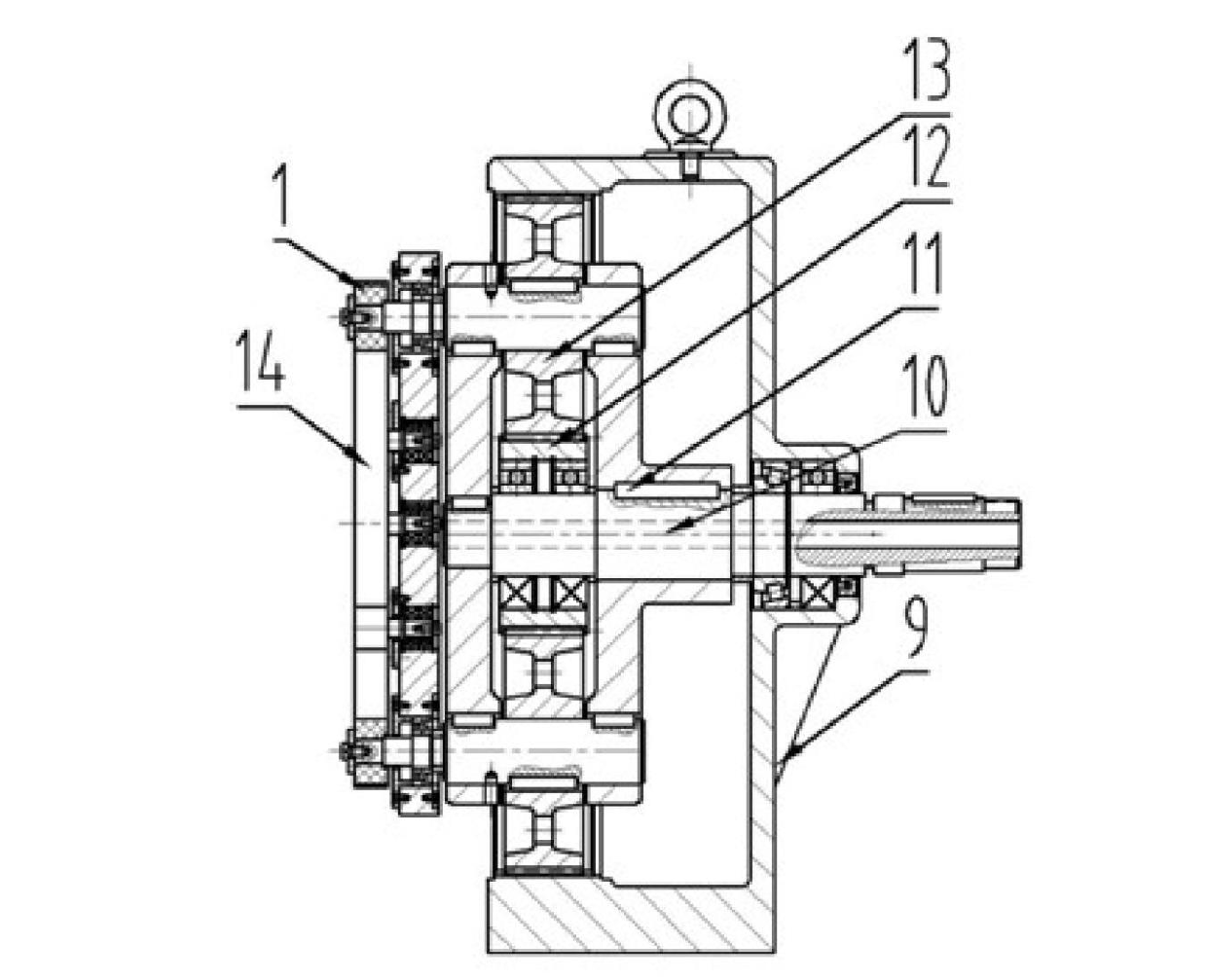

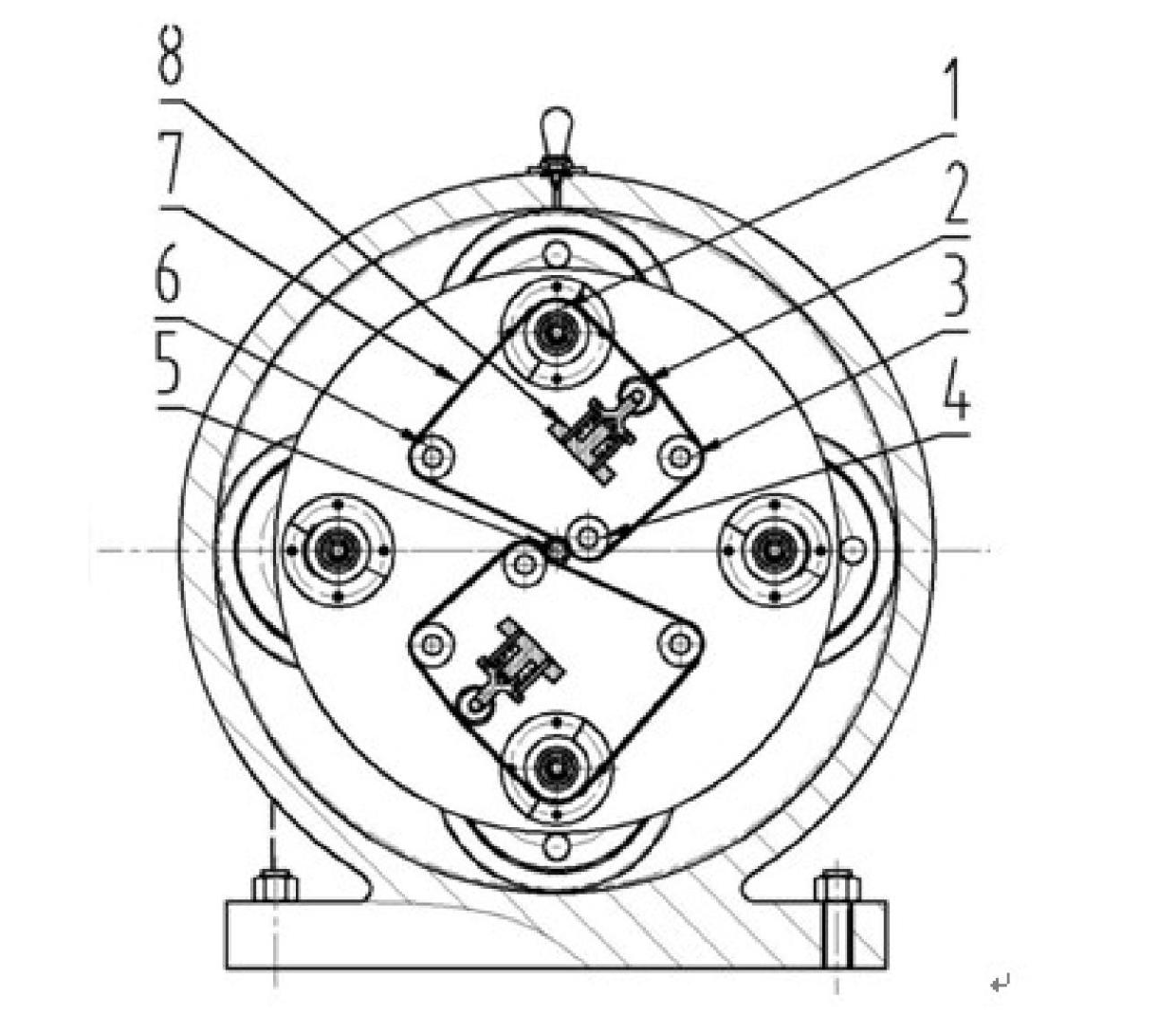

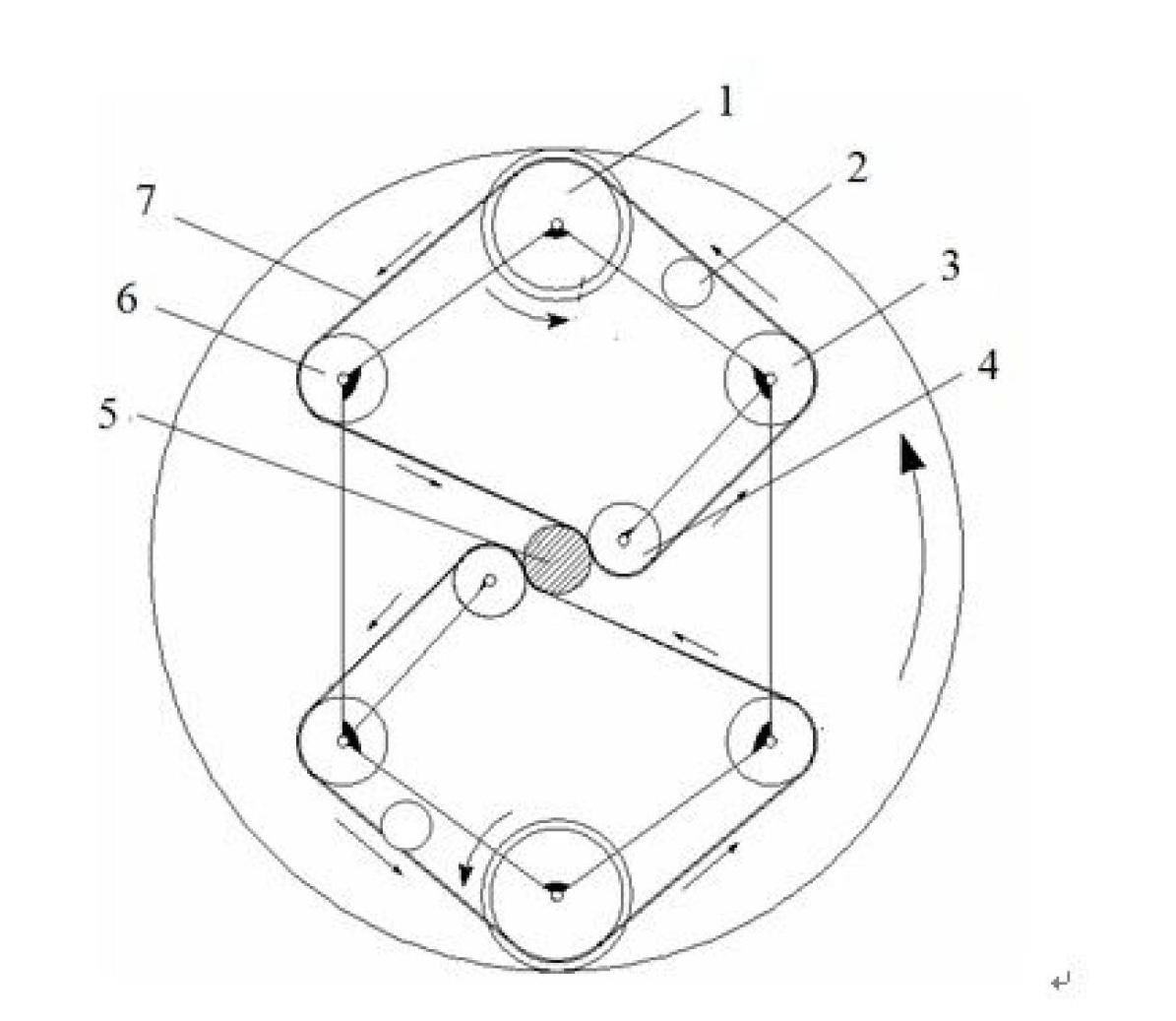

Abrasive belt wire polisher

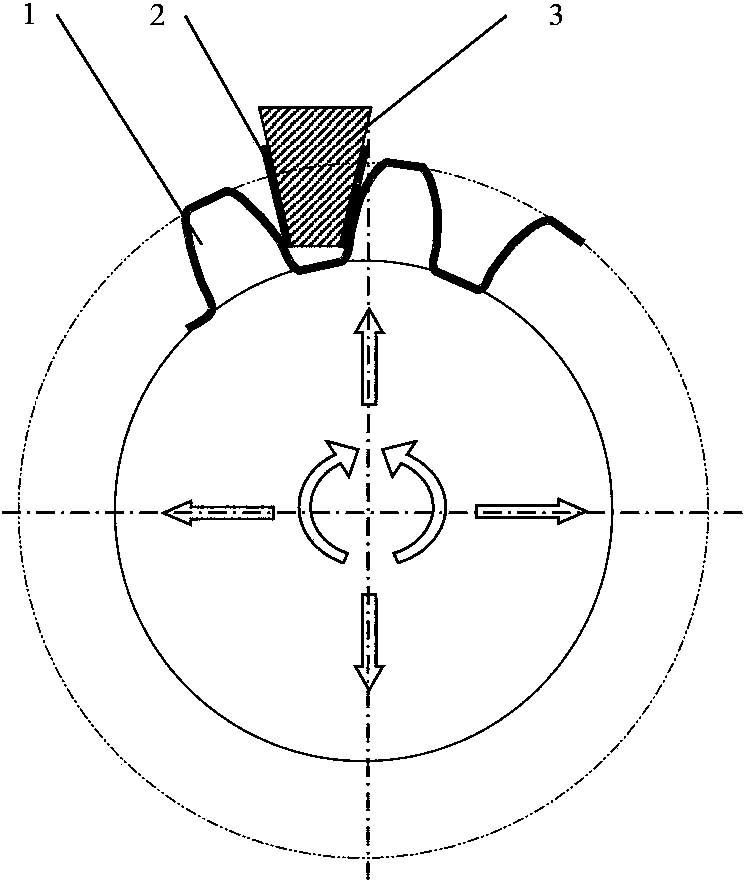

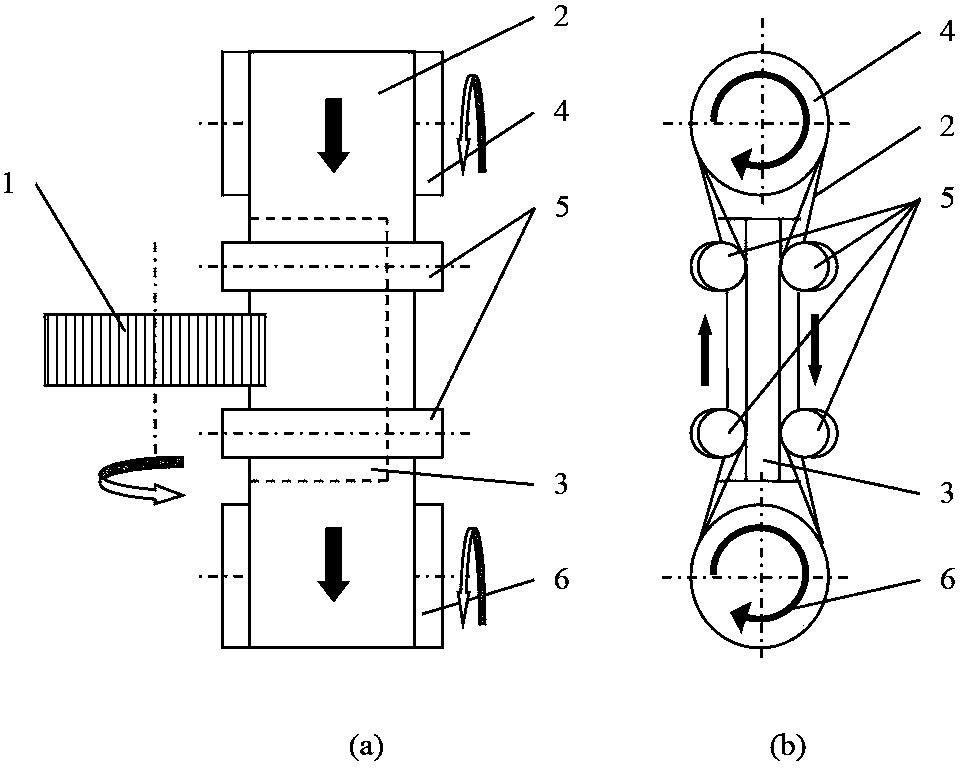

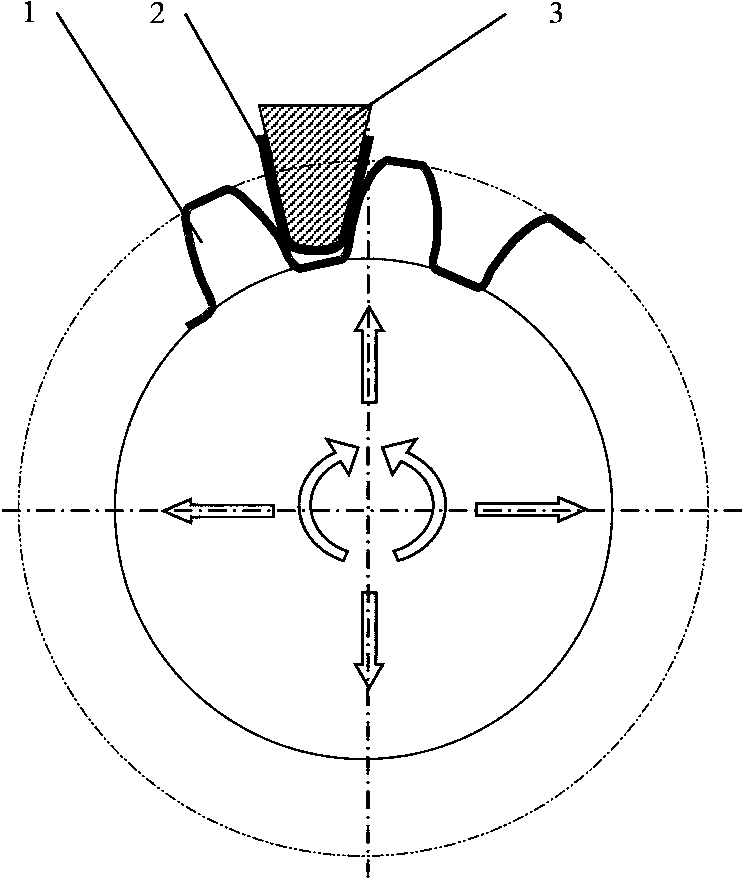

The invention relates to an abrasive belt wire polisher, which is characterized by comprising a polishing mechanism driven by a motor, wherein the polishing mechanism comprises two abrasive belts which are symmetrically tensioned on two driving wheels; and the two driving wheels rotate under the drive of planet gears and rotate around wires to drive the abrasive belts to polish the wires at full angle. Double planet gear mechanisms are symmetrically arranged, and the abrasive belts are driven to polish the wires at full angle by the driving wheels, so that the wires are quickly and efficiently polished, polishing efficiency and polishing quality are improved, and polishing uniformity is ensured.

Owner:XIAN UNIV OF TECH

Ceramic atomization element and smoke cartridge

InactiveCN105342010AHigh temperature resistantPromote absorptionTobacco devicesPackagingPorous ceramicsElectrical and Electronics engineering

The invention relates to a ceramic atomization element. The ceramic atomization element comprises a power supply positive terminal, a power supply negative terminal and a fixed base, wherein an air inlet is formed from the outer wall surface to the inner wall surface of the power supply positive terminal, the power supply negative terminal is mounted at the lower end of the power supply positive terminal, an insulation ring is mounted between the inner wall of the power supply positive terminal and the outer wall of the power supply negative terminal, a threaded hole is formed along the direction of the axis line of the fixed base, a ceramic liquid guide element is mounted in the threaded hole, and the inner wall of the ceramic liquid guide element contacts an atomization heating piece. The ceramic atomization element is made of porous ceramic, has the high-temperature resistance, has small possibility of generating charring, has the large smoke liquid contact area, and is high in liquid guide speed. The invention further provides a smoke cartridge which is simple in structure and convenient to process.

Owner:SHENZHEN SMACO TECHNOLOGY LIMITED

Isolating switch with quick break function

InactiveCN101527220ANot easy to burnStable jobSnap-action arrangementsAir-break switch detailsElectrical and Electronics engineering

The invention relates to an isolating switch with quick break function, comprising a moving contact, an operating mechanism which controls the moving contact to move and a fixed contact corresponding to the moving contact. The switch is characterized in that the switch further comprises a quick break moving contact, one side of which is sheathed in the moving contact, the other side of which is closely contacted with a conductive part of the fixed contact, a spring is arranged between the quick break moving contact and the moving contact, the quick moving contact is electrically connected with the moving contact. The isolating switch features short-time generation of voltaic arc when separating brake is carried out on the isolating switch, thus ensuring that the contact is not prone to be burnt by the voltaic arc.

Owner:浙江开关厂有限公司

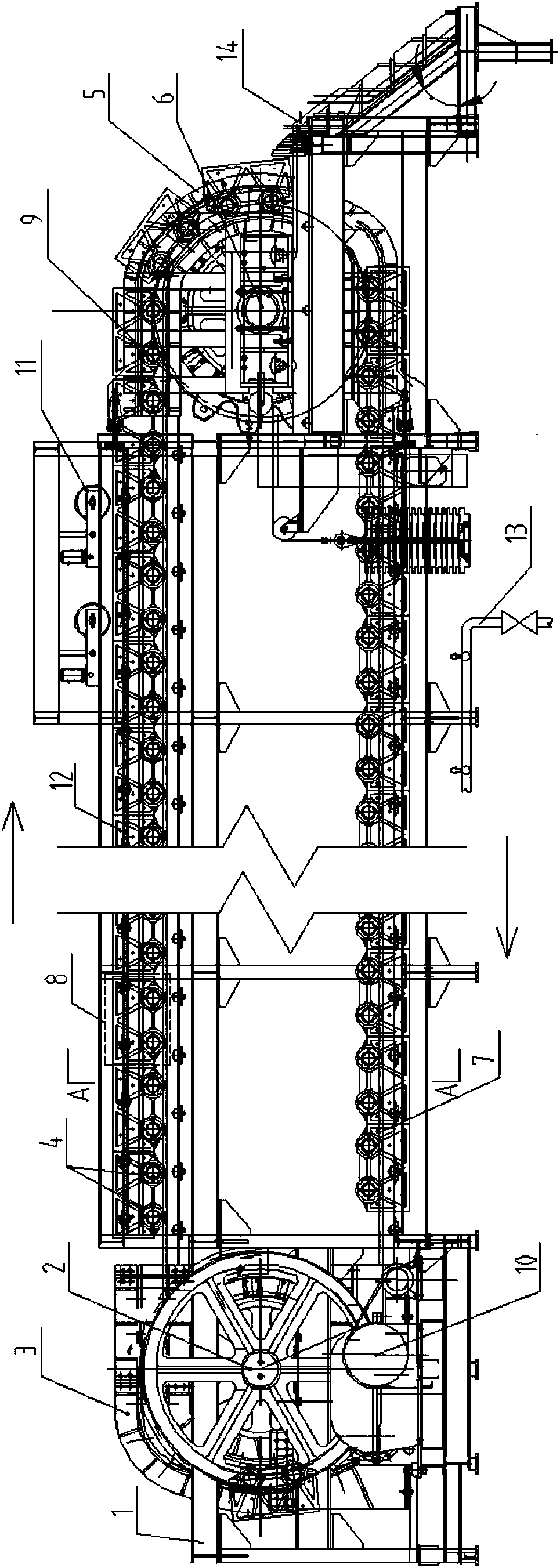

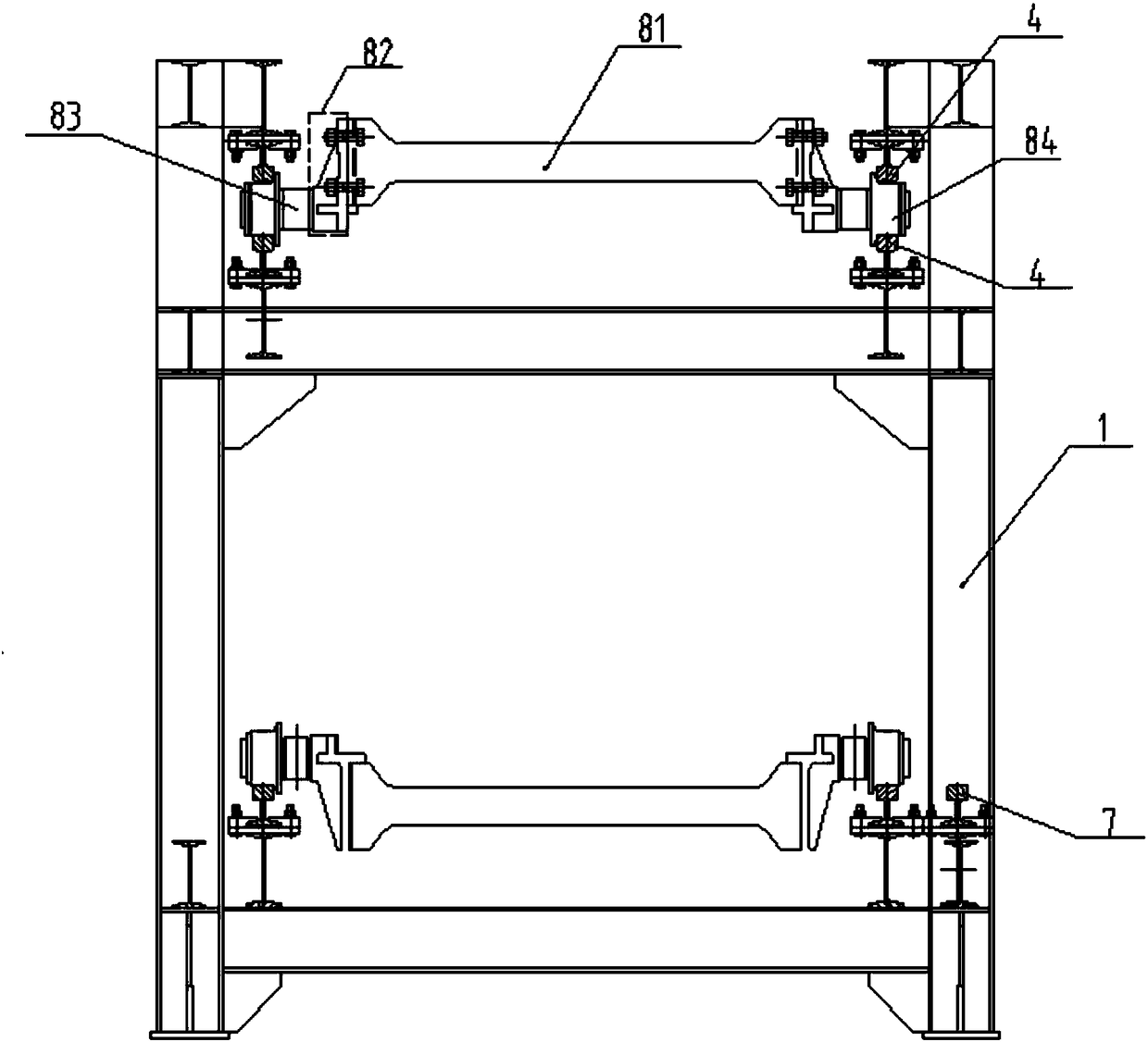

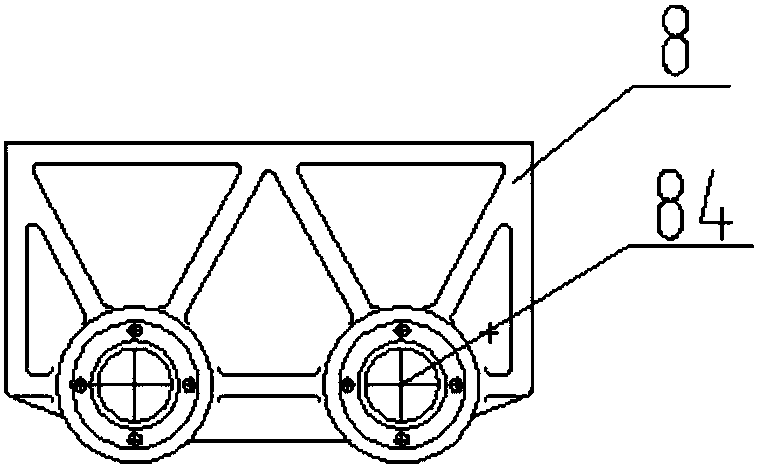

Novel ferroalloy continuous casting machine

PendingCN108247027ANot easy to burnConvenient for centralized processingIngot casting plantsMolten metal conveying equipmentsIngotSmall footprint

The invention discloses a novel ferroalloy continuous casting machine, and is applied to the field of ferroalloy production facilities. The novel ferroalloy continuous casting machine includes a rack,a head star wheel, a heat bent rail, an upper rail, a tail rail, a tail star wheel and a lower guide rail, wherein the head star wheel, the heat bent rail, the upper rail, the tail rail, the tail star wheel and the lower guide rail are sequentially arranged on the rack in a circular sealing mode; a plurality of freestanding trolley bodies are arranged on the guide rail; each trolley body includesa panel ingot mould, a transition part, a shaft sleeve and wheels, wherein the upper and lower faces of the panel ingot mould are symmetrically sunken inwards. The invention aims at eliminating the disadvantages of traditional shaping modes of pit casting, cast iron ingot mould casting and plate-chain pig machines and having the advantages of the better technical scheme. Particularly, compared with the traditional modes, the casting performance of the novel ferroalloy continuous casting machine is improved at all aspects; the novel ferroalloy continuous casting machine has the significant advantages that the yield and the quality are high, the labor strength is low, multispecies casting is achieved, centralized treatment is conveniently conducted on fume and gas, the occupied area is small, maintenance is convenient, the mould-iron ratio is large, and the ingot mould is not easily damaged by fire.

Owner:乌兰察布市旭峰新创实业有限公司

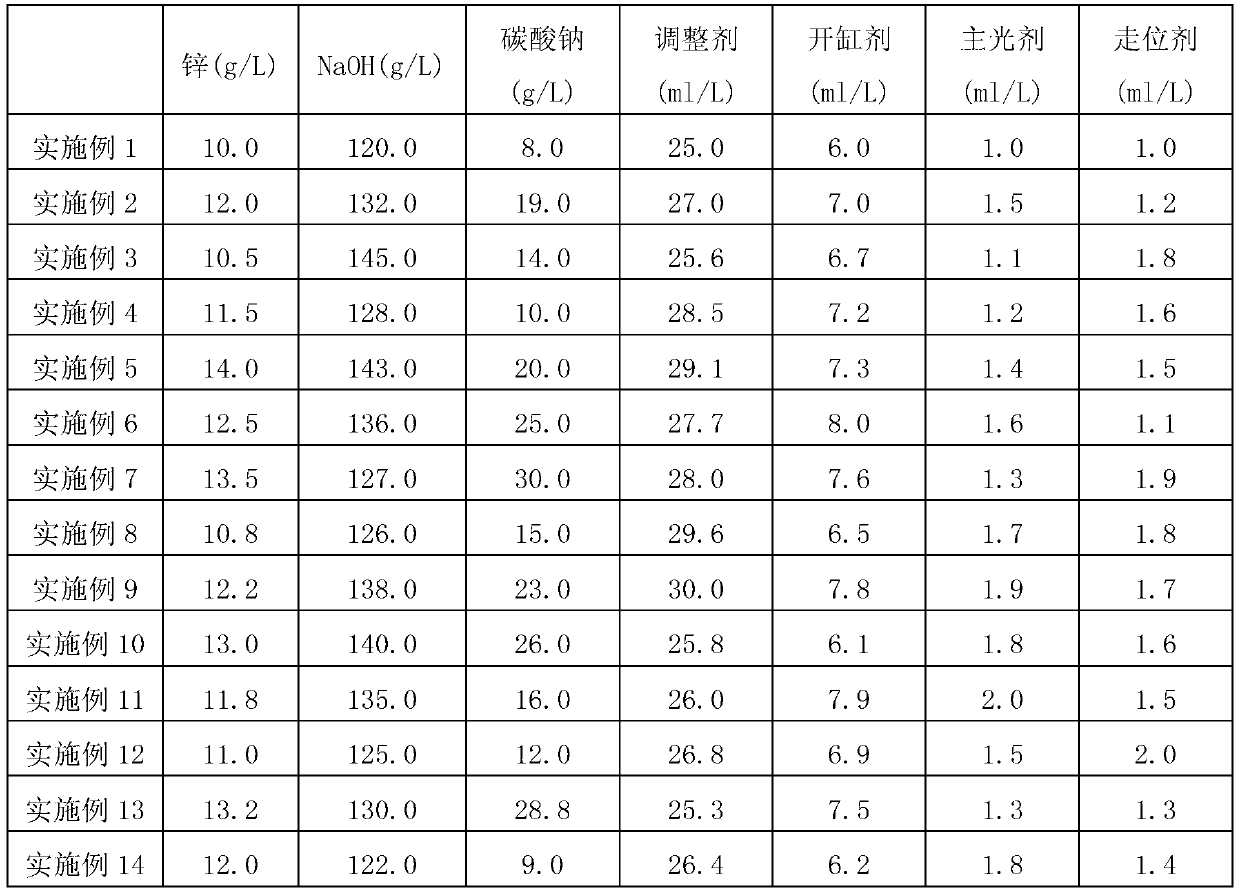

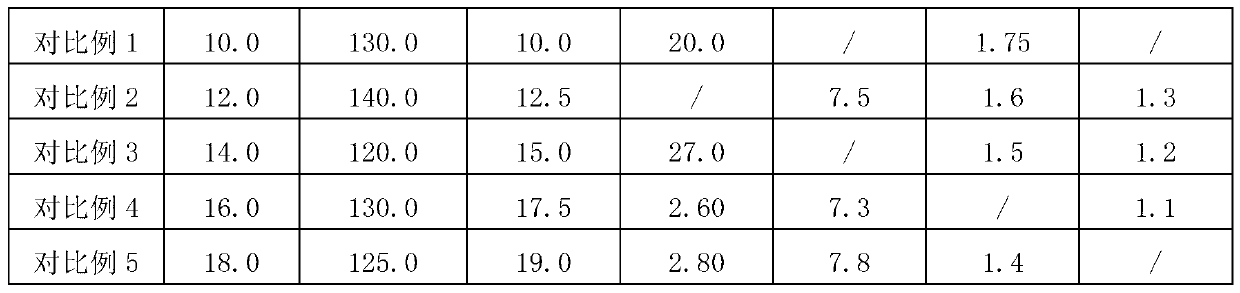

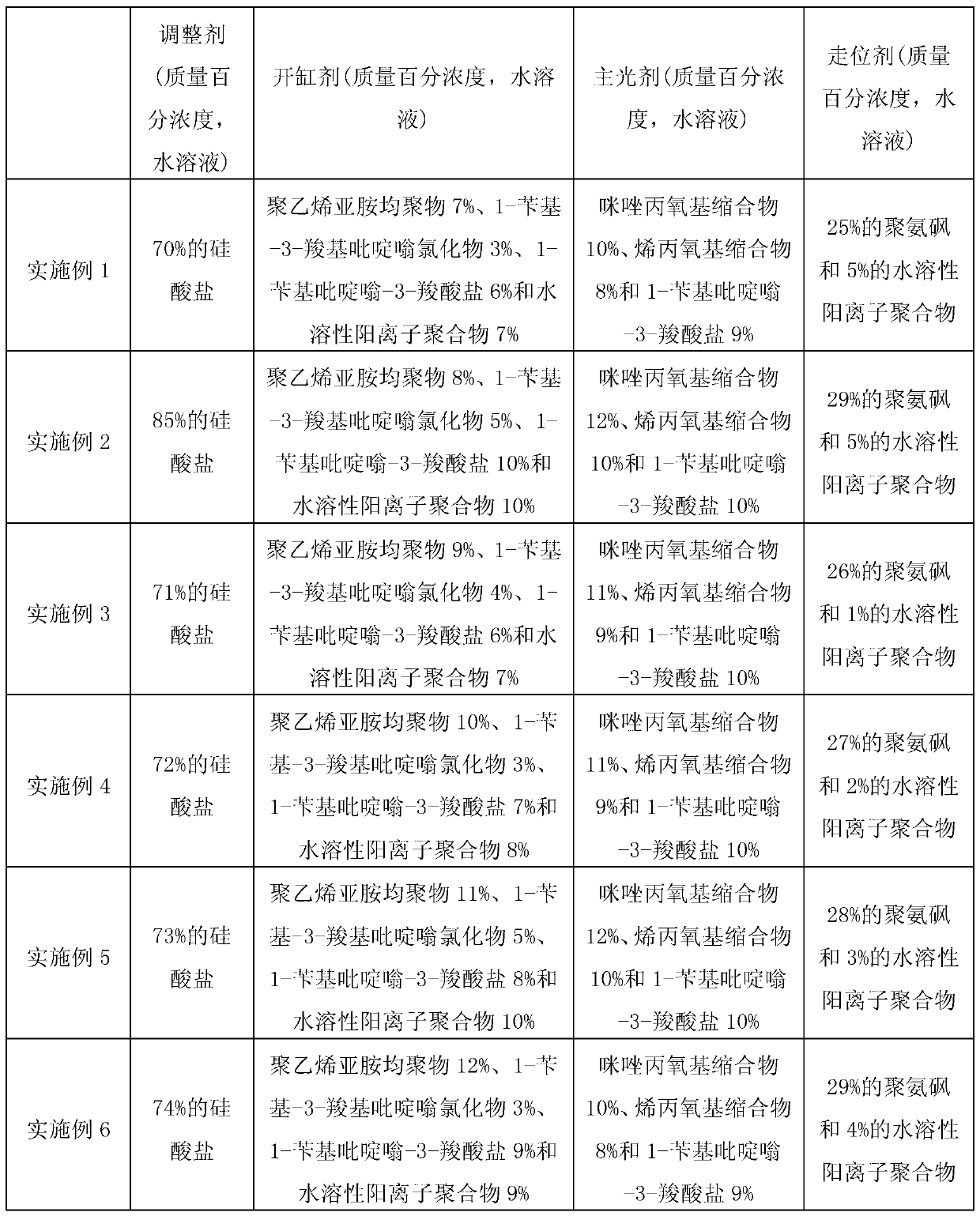

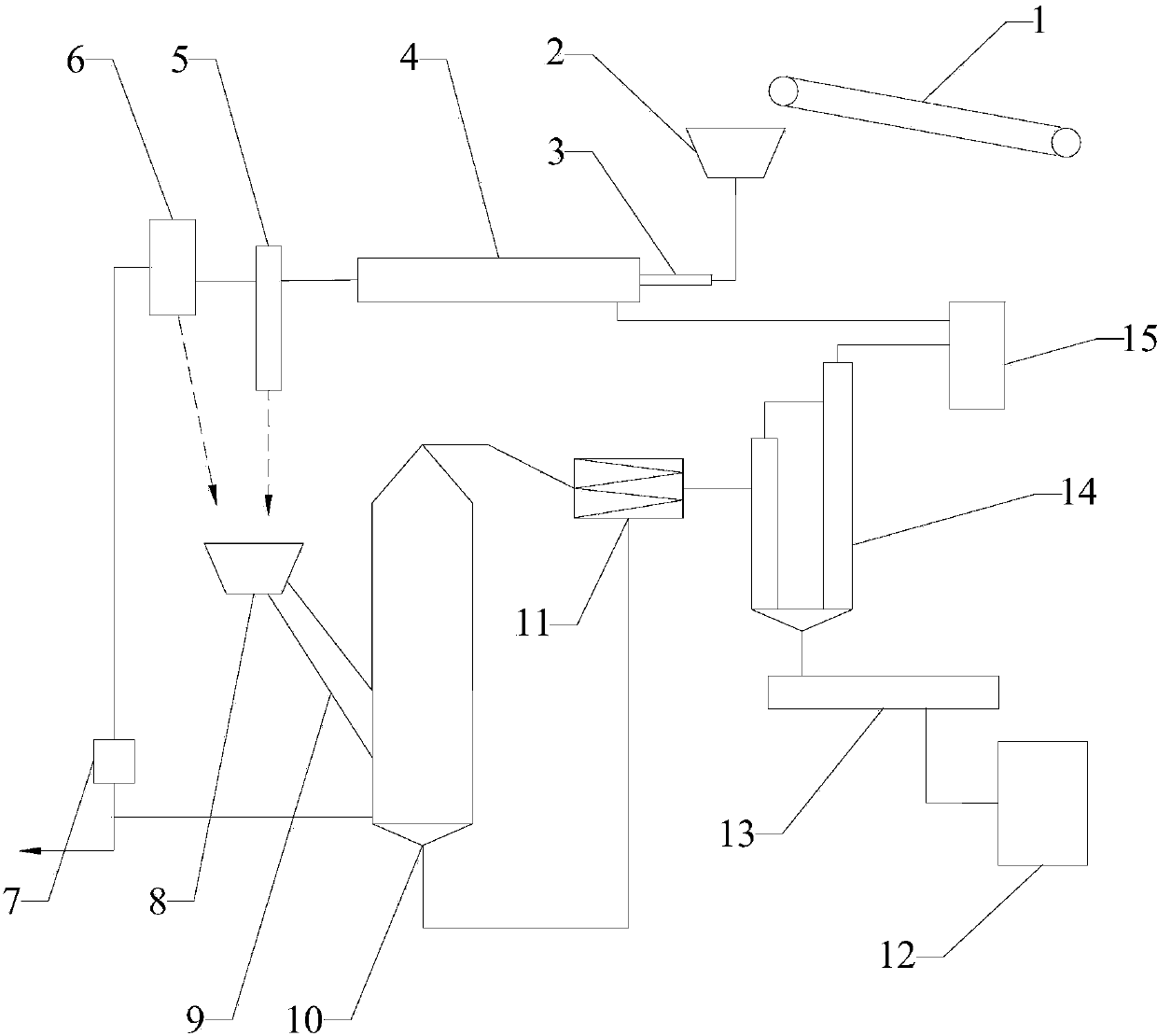

Electroplating solution, preparation method thereof and galvanization technique utilizing electroplating solution

The invention discloses an electroplating solution which mainly comprises an aqueous solution consists of the following substances: zinc, sodium hydroxide, sodium carbonate, a regulating agent, a plating bath solution, a secondary brightener and a bright-throwing power additive. According to the invention, some additives are added into the electroplating solution to adjust the proper zinc ion concentration and the current density, so that the electroplating solution has perfect throwing power; therefore, the electroplating solution has rather good current efficiency, throwing power and covering power. Thus a coating made of the electroplating solution has a better physical property and is more shiny, more full, more uniform and more exquisite with strong binding capability. The invention also discloses a preparation method of the electroplating solution and a galvanization technique using the electroplating solution.

Owner:江西博泉化学有限公司

Activated carbon regeneration device and method

ActiveCN104001488AHas an activation effectNot easy to burnOther chemical processesCombustible gas purificationActivated carbonBiological activation

The invention relates to the field of preparation for activated carbon, and in particular relates to an activated carbon regeneration device and method. The method comprises the following steps of feeding waste powdery activated carbon to a drying converter by using a feeding system, enabling the waste powdery activated carbon to pass through a carbon collector, a dust collector, a hopper and a charger, feeding dried powder into a boiling activation furnace, and activating the waste powdery activated carbon in the high-temperature boiling activation furnace; and enabling the formed powdery activated carbon and furnace gas to pass through a superheated steam heater in a pipeline, reheating steam, feeding the relatively high-temperature powdery activated carbon and furnace gas to a cyclone separator, and enabling the collected activated carbon to pass through a cooling feeder to be packaged or post-treated. According to the technical scheme, the activated carbon regeneration cost is low, the regeneration quality is high, a configured activated carbon drying and superheated steam boiling activation equipment system is reasonable in integral design, easy to run and environmentally-friendly, energy resources are recycled, the production cost is lowered, and the activated carbon can be automatically regenerated in a large scale.

Owner:FUJIAN XINSEN CARBON

Composite ceramic material and inner container of electric cooker prepared from composite ceramic material

ActiveCN105084905AExcellent thermal diffusivityImprove heat transfer efficiencyCooking-vessel materialsPtru catalystComposite ceramic

The invention discloses a composite ceramic material and an inner container of an electric cooker prepared from the composite ceramic material. The composite ceramic material is prepared from the following components in parts by weight: 3-8 parts of barium carbonate, 20-35 parts of calcite, 5-10 parts of kaolin, 35-55 parts of silica powder, 3-8 parts of potassium nitrate, 10-15 parts of paraffin, 3-8 parts of sodium carbonate, 7-8 parts of boric acid, 11-15 parts of quartz, 50-75 parts of aluminum nitride powder, 2-3 parts of yttrium oxide and 3-5 parts of lanthanum oxide, wherein the aluminum nitride powder is generated by reacting aluminum oxide powder serving as an aluminum source and carbon black powder in the flowing nitrogen atmosphere at the temperature of 1500-1700 DEG C; calcium oxide is added as a catalyst in the reaction process, and decarbonization is carried out in dry air with the temperature of 700-800 DEG C after the reaction is finished; the mass content of cation impurities in the aluminum oxide powder is lower than or equal to 0.02%, and the mass contents of silicon and iron impurities are respectively lower than 0.001%; and the average particle size of the carbon black powder is 35-40nm, and the specific surface area is smaller than or equal to 90m<2> / g.

Owner:GUANGDONG ENAITER ELECTRICAL APPLIANCES CO LTD

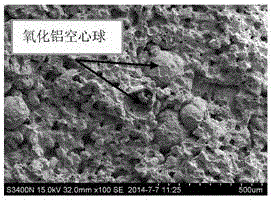

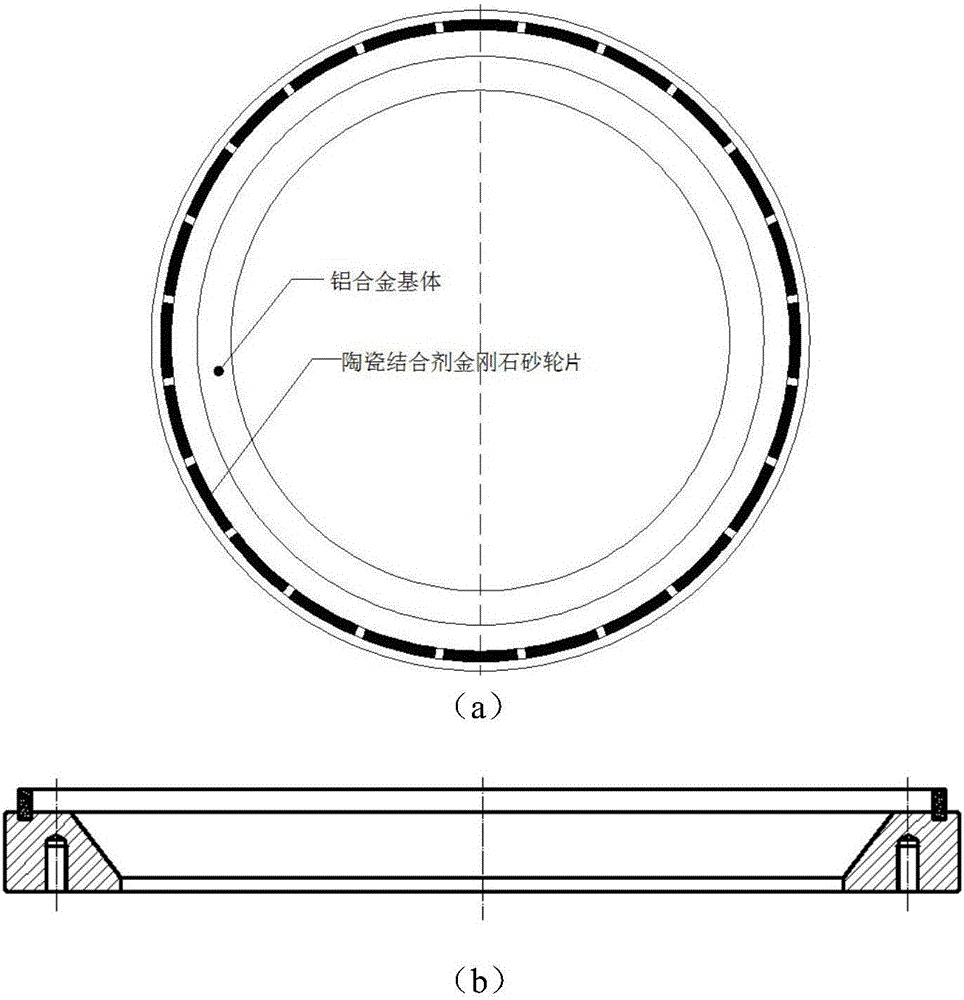

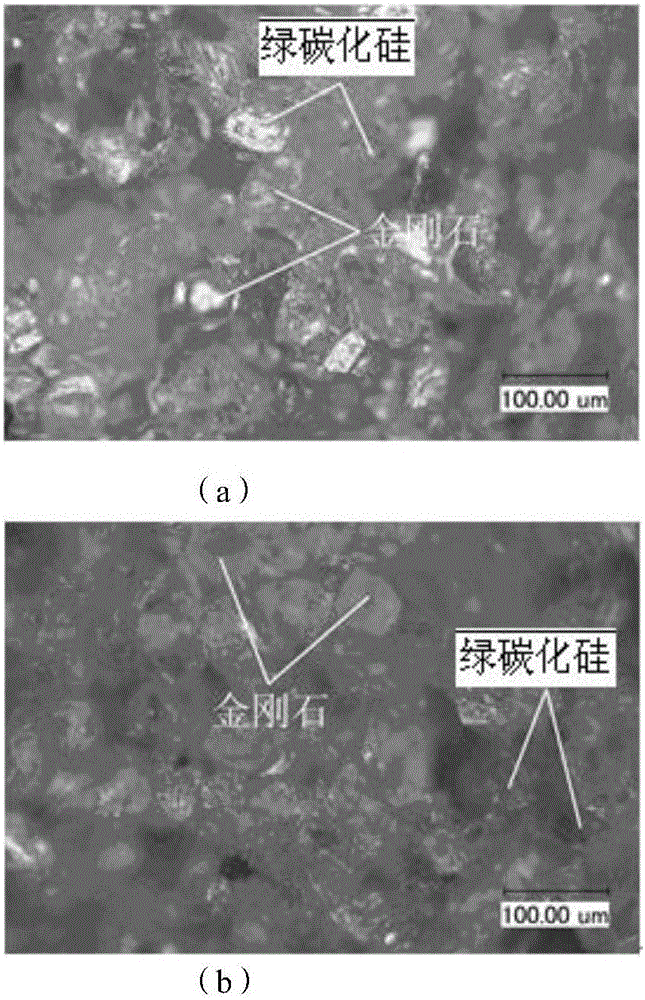

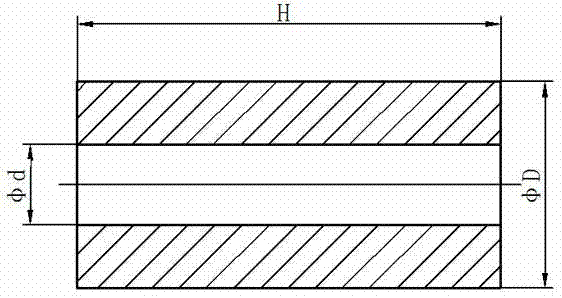

Diamond grinding wheel with ceramic binders and production method thereof

InactiveCN106392908AGood self-sharpeningHigh strengthAbrasion apparatusGrinding devicesAdamiteSilicon

The invention discloses a diamond grinding wheel with ceramic binders and a production method thereof. The diamond grinding wheel with the ceramic binders is composed of, by weight, 20-50% of diamond powder, 25-35% of green silicon carbide powder, 5-15% of ceramic hollow balls and 15-30% of the ceramic binders. According to the diamond grinding wheel with the ceramic binders and the production method thereof, the ceramic hollow balls are added, air holes are formed in the grinding wheel, the ceramic binders are used, and therefore the grinding wheel has the advantages that the self-sharpening property is good, the strength is high, the grinding efficiency is high, the rigidity is good, blocking and burning of work-pieces do not occur easily in the grinding process, machining of high-brittleness, hard and difficult-to-machine materials has high grinding efficiency and the application prospects are wide.

Owner:GUANGDONG UNIV OF TECH

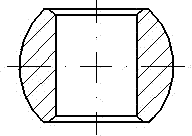

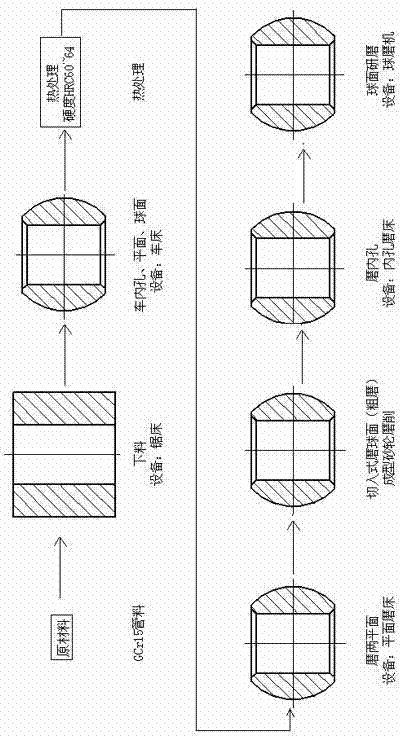

Joint bearing inner ring processing method

ActiveCN104295608AQuality improvementImprove processing efficiencyBearing componentsSurface roughnessEngineering

The invention relates to the technical field of mechanical processing, and especially relates to a joint bearing inner ring processing method. The method comprises the following steps: 1, lathing an inner pore, a plane surface and a spherical surface by using a joint bearing inner ring blank through a common lathe, wherein the joint bearing inner ring blank is a tube; 2, carrying out heat treatment on the joint bearing inner ring blank to make the hardness reaches a preset value; 3, milling the joint bearing inner ring blank plane surface through a surface grinder; 4, carrying out plunge surface grinding on the joint bearing inner ring blank through a formed grinding wheel, and carrying out coarse grinding on the joint bearing blank spherical surface; 5, grinding the joint bearing blank inner pore through an inner pore grinder; and 6, sequentially putting joint bearing inner rings in the V-shaped grooves of the lower mill plate of a grinder in a separate manner by using separators, and carrying out spherical surface grinding through a ball mill to ensure that the surface roughness reaches the preset value. The method reduces the processing cost of the joint bearing inner rings and improves the quality of the joint bearing inner rings.

Owner:台州科锦轴承有限公司

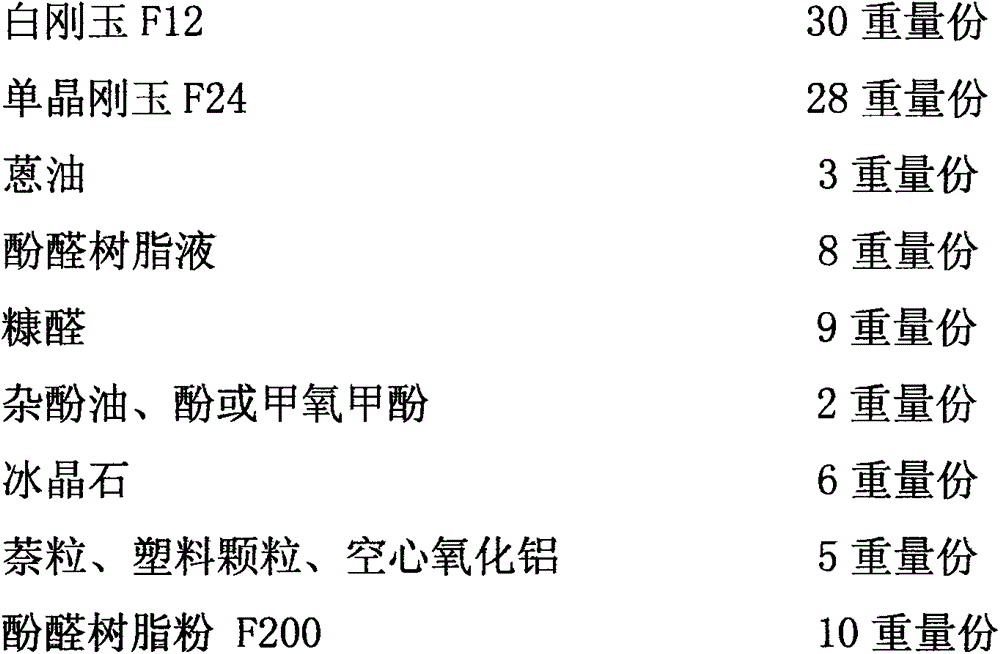

Resin grinding wheel preparation method

ActiveCN104128894AImprove production qualityGood chemical stabilityAbrasion apparatusGrinding devicesWettingPhenols

The invention provides a resin grinding wheel preparation method. A resin grinding wheel is prepared by combining multi-granularity white corundum, monocrystalline fused alumina, anthracene oil and phenolic resin liquid with furfural, kreosote, phenol or kreosol and cryolite, naphthalene grains, plastic particles and hollow alumina filling according to a certain weight ratio. By implementing the method, powder cannot be wrapped by wet materials in the process of mixing of materials, and influence on quality of a resin grinding wheel product due to the fact that the materials are not dispersed and cake is avoided. In addition, a certain weight part of silicon carbide is added in raw materials of mixed grinding materials, and grinding wheel cutting pieces different in performance can be acquired by controlling proportioning content of a silicon carbide grinding material, mixed white corundum and monocrystalline fused alumina and adjusting content of a wetting agent and phenolic resin powder within a certain range.

Owner:NINGBO DAHUA GRINDING WHEEL

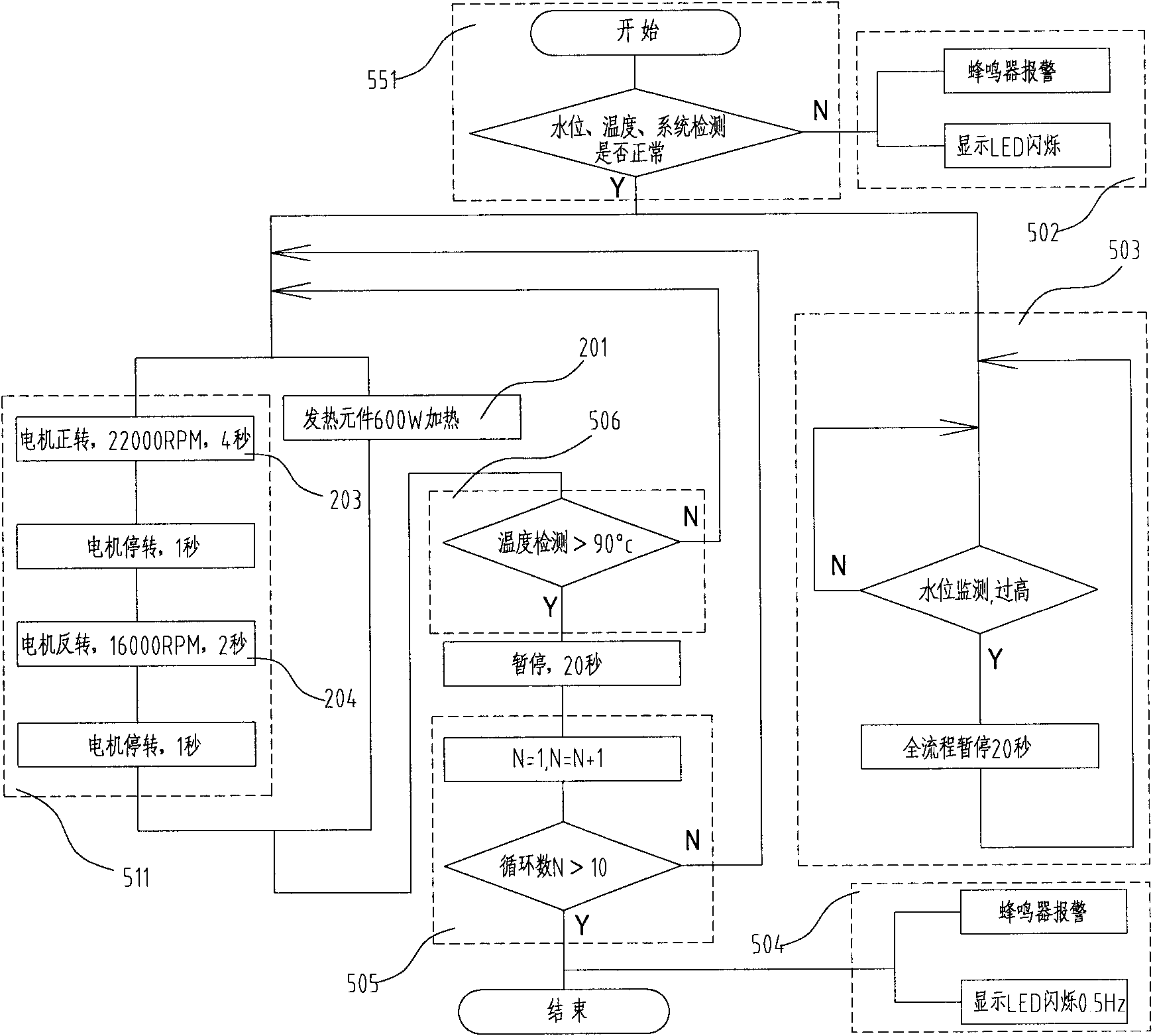

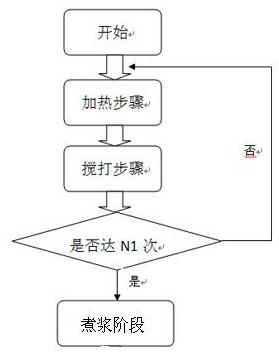

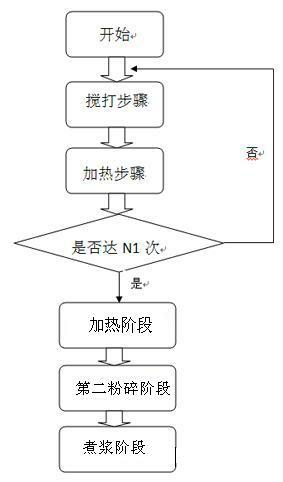

Method for crushing foods

The invention relates to the field of household appliances, in particular to a method for crushing foods. A household food crusher crushes the foods with a rotary cutter by a crushing step and a stirring step alternately. The rotation directions in the two steps are opposite, so relative speed between the cutter and the foods is increased and cutting efficiency is improved; the food crusher does not drive a liquid to form a big swirl and make the liquid overflow from a container; the flow direction of the liquid is complex and variable, so the food crusher contributes to the mixing of a solid and the liquid and prepared bean milk is thicker; and the crushing step and the stirring step are alternately performed, so the foods are uniformly turned and the crushed food particles are more uniform.

Owner:陈方舟

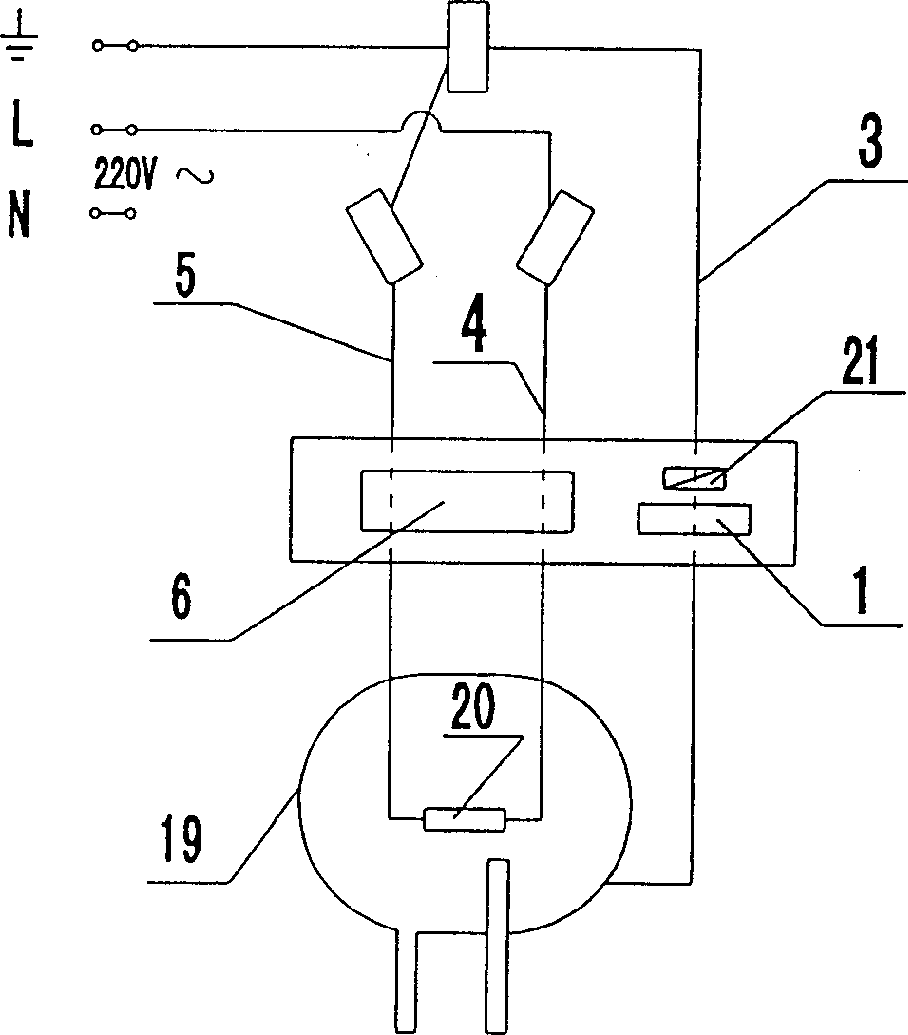

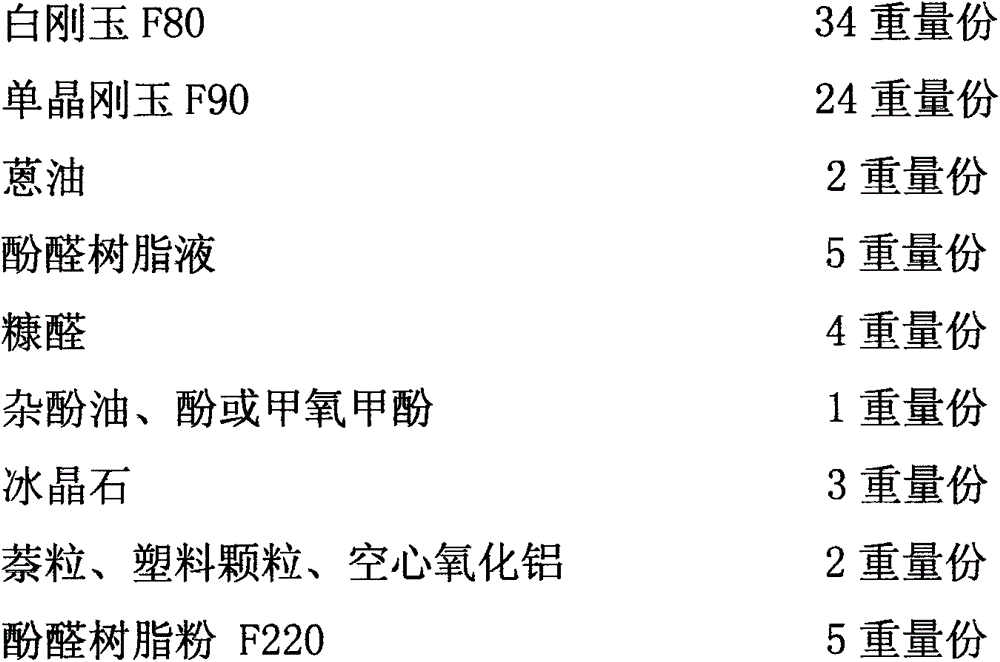

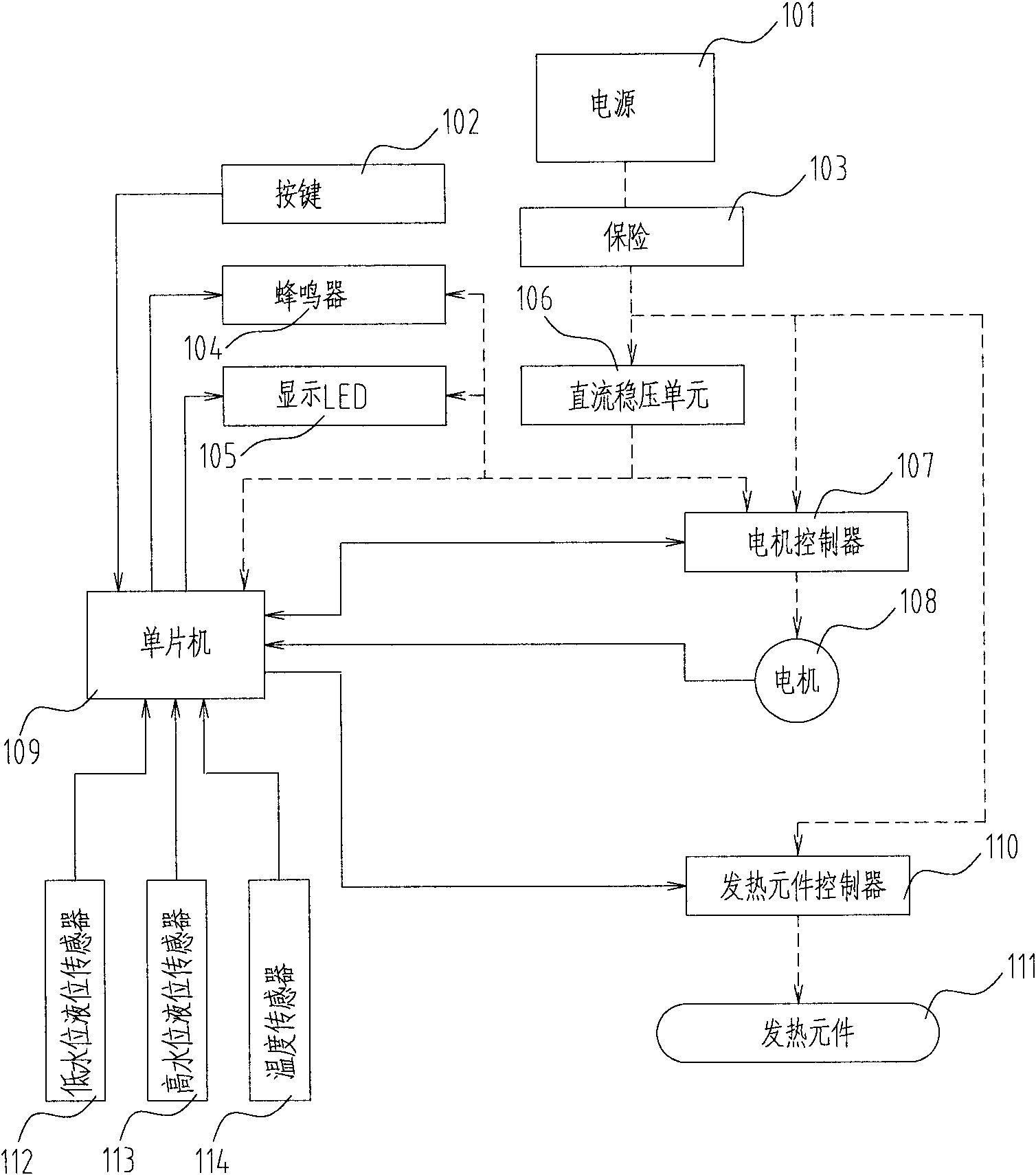

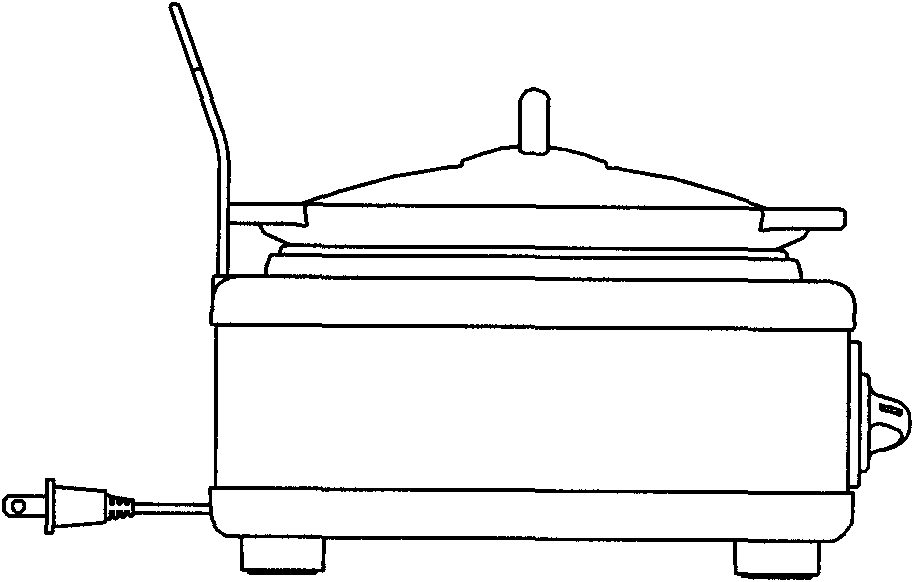

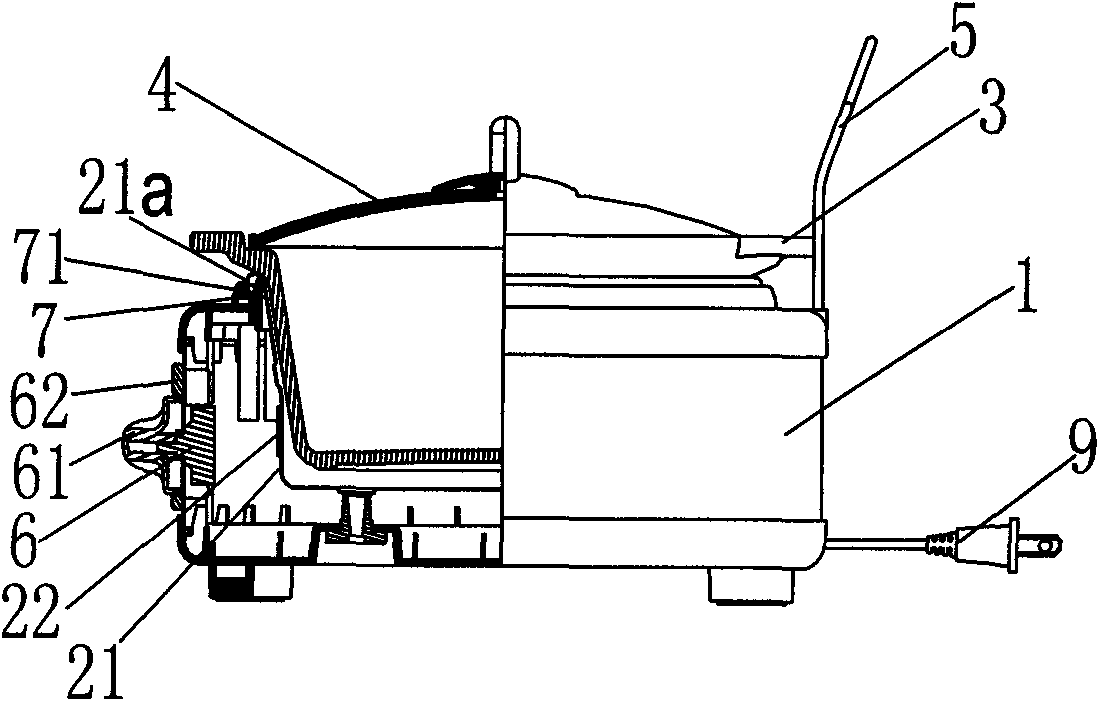

Originally ground soybean milk preparation method of soybean milk grinder and soybean milk grinder for preparing originally ground soybean milk

InactiveCN102144889ANot easy to burnImprove homogeneityBeverage vesselsMilk substitutesFlavorLiquid temperature

The invention relates to an originally ground soybean milk preparation method of a soybean milk grinder, which comprises: (a) a first grinding stage and (b) a boiling stage, wherein in the first grinding stage, materials for preparing soybean milk are ground by a grinding blade under the driving of an electric motor of the soybean milk grinder, and the liquid temperature during the first grinding stage is not more than 70 DEG C; and in the boiling stage, the soybean milk is heated by a heating component of the soybean milk grinder until the soybean milk is boiled up, and the heating component is used for persistently or interruptedly heating the materials in a cup during the first grinding stage. The soybean milk prepared according to the soybean milk preparation method has bean flavor and better mouthfeel.

Owner:JOYOUNG CO LTD

Novel slow cooker of combined structure

InactiveCN102172316ANice appearanceNot easy to burnWarming devicesEnergy consumptionHeating temperature

The invention discloses a novel slow cooker of a combined structure. The slow cooker comprises a stove body, wherein the stove body is equipped with three oval cooker site holes side by side which take the width direction of the stove body as long half shafts and the length direction of the stove body as short half shafts, and the inner chamber of the stove body is internally equipped with three heating elements matched with the shape of the cooker site holes through the three cooker site holes; and a pottery liner with an oval cross section is sheathed in each heating element in a suspension manner, each heating element is independently equipped with a switch knob for timing, regulating and controlling the operating time and heating temperature of the heating elements, and the circuit for the heating elements is connected with a power line. The novel slow cooker has the advantages of unique design, novel and beautiful appearance, controllable cooking time, constant temperature and less energy consumption, and can meet the dietary need of a plurality of persons at the same time.

Owner:宁波亿达电器有限公司

Pre-dispersion master colloidal particles of environment-friendly comprehensive promoter used for automobile sealing strips, and preparation thereof

The invention discloses pre-dispersion master colloidal particles of an environment-friendly comprehensive promoter used for automobile sealing strips. The pre-dispersion master colloidal particles comprises, by weight, 10-30 parts of a thiazole promoter, 10-30 parts of a zinc dialkyl dithiophosphate promoter, 10-30 parts of a thiocarbamate promoter, 1-10 parts of a scorch retarder, 2-5 parts of ethylene-propylene-diene monomers and 2-5 parts of cis-polyisoprene. The invention also discloses a preparation method for the pre-dispersion master colloidal particles of the environment-friendly comprehensive promoter used for the automobile sealing strips. The pre-dispersion master colloidal particles of the environment-friendly comprehensive promoter used for the automobile sealing strips are prepared by mixing powdery comprehensive promoters with a polymer carrier, so that during a use process, the pre-dispersion master colloidal particles have better dispersibility, more excellent vulcanization efficiency, are not easy to scorch and crock, do not generate carcinogenic nitrosamine, are environment-friendly, and can increase batch qualification rate of finished products.

Owner:NINGBO ACTMIX POLYMER

Gear grinding machining method and device

InactiveCN103737119AImprove grinding efficiencyAvoid easy cloggingGear-cutting machinesGear teethGear grindingGear wheel

The invention provides a gear grinding machining method and device. The method adopts an abrasive belt which is high in grinding efficiency, the abrasive belt is in high-speed motion along the tooth width direction of a gear to conduct grinding, and the abrasive belt is in generating motion relative to a gear blank to grind each tooth socket tooth surface sequentially and swings slightly relative to the generatrix of the tooth surface to achieve crowned tooth surface shape correction. The device for achieving the grinding machining method is provided and comprises a bed body, a lifting table, a gear blank rotation dividing head, a gear blank flat moving work table, a gear blank dip angle table, an abrasive belt feeding work table and an abrasive belt deflection rotary disc. A numerical control system controls all the portions to be in linkage and conducts complementation of abrasive belt abrasion loss, machining of various gears can be achieved by using suitable press grinding plates and belt guiding wheels or guiders, disc-shaped or worm-shaped grinding wheels are not required, and the method and device has high machining efficiency and machining quality.

Owner:湖北光辉节能科技有限公司

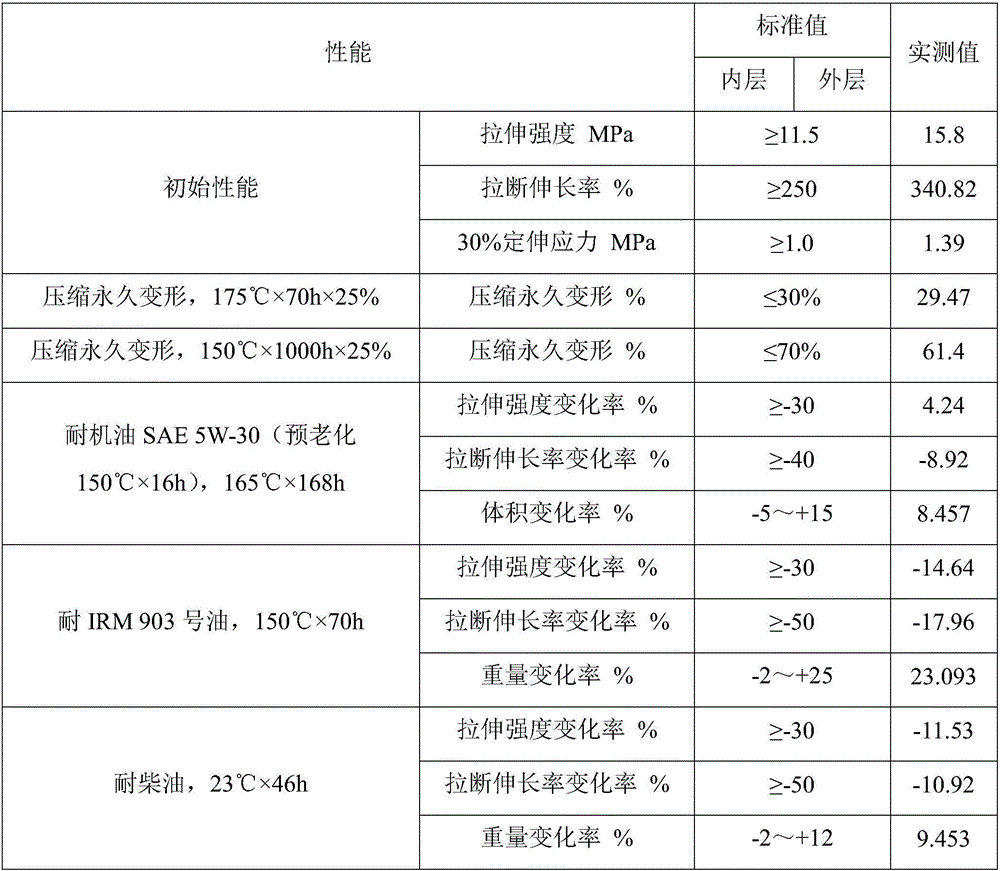

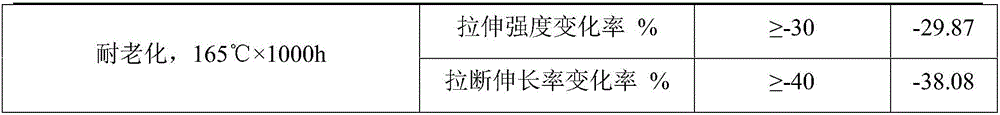

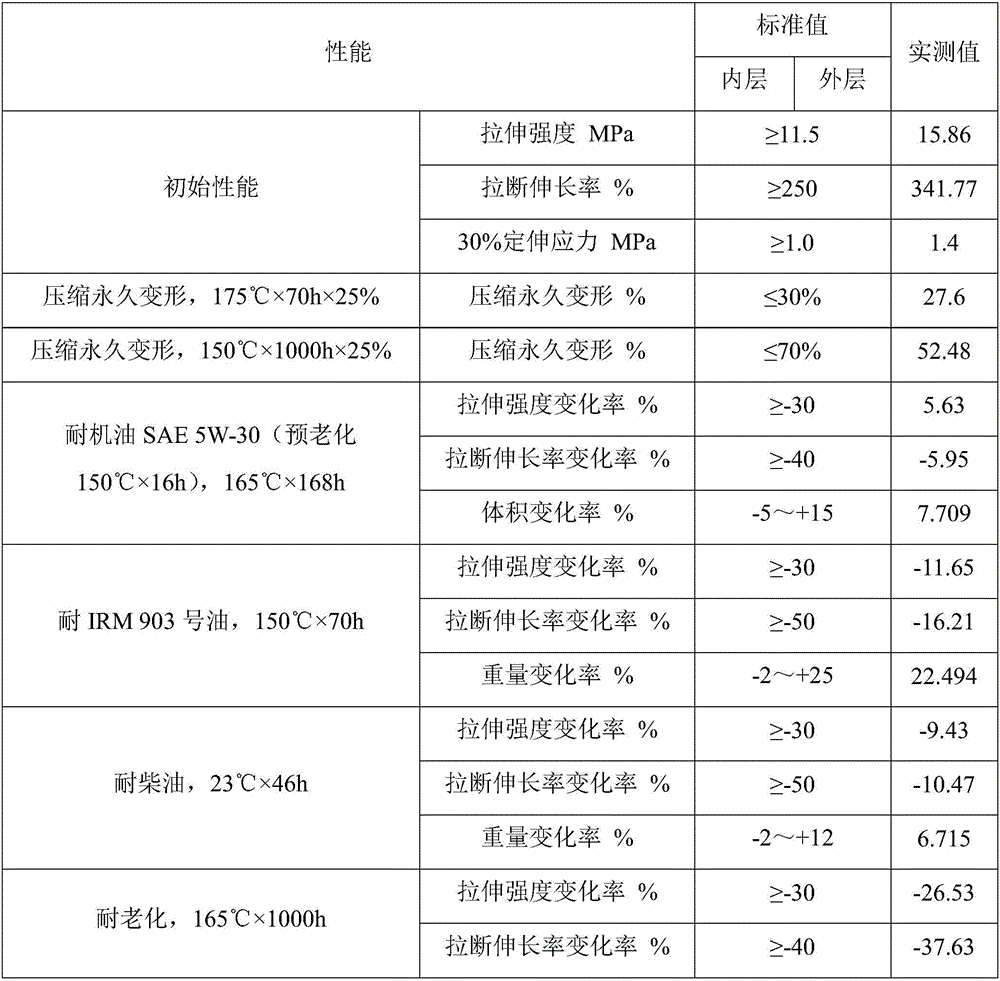

Rubber composition for preparing external and internal layers of automotive turbocharged hose and production method thereof

The invention relates to a rubber composition for preparing external and internal layers of an automotive turbocharged hose. The rubber composition comprises 100 parts of ethylene acrylate rubber, 1.0-3.0 parts of anti-aging agent, 1.0-3.0 parts of processing agent, 10.0-20.0 parts of plasticiser, 50.0-70.0 parts of carbon black, 0.5-1.5 parts of internal releasing agent, 2.0-3.0 parts of vulcanization activator and accelerator and 1.0-2.0 parts of vulcanizing agent. The invention further provides a preparation method for the rubber composition. The rubber composition improves high temperature resistance and oil resistance, reduce compression permanent sets, and is not prone to scorching, good in processing characteristics, and can serve as the external layer and the internal layer of the automotive turbocharged hose.

Owner:QINGDAO SUNSONG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com