Diamond grinding wheel with ceramic binders and production method thereof

A vitrified bond and diamond grinding wheel technology, which is applied in metal processing equipment, manufacturing tools, grinding/polishing equipment, etc., can solve the problem that the particle size and porosity of the pores cannot meet the processing requirements, and achieve good self-sharpening and not easy to block , the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of vitrified bond diamond grinding wheel is as follows:

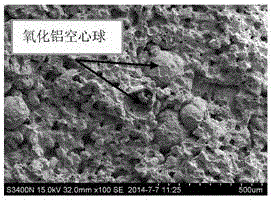

[0031] Step (1): Sieve the alumina hollow spheres to obtain ceramic hollow spheres with a particle size of 100-800 μm and a density of 0.5 g / cm 3 .

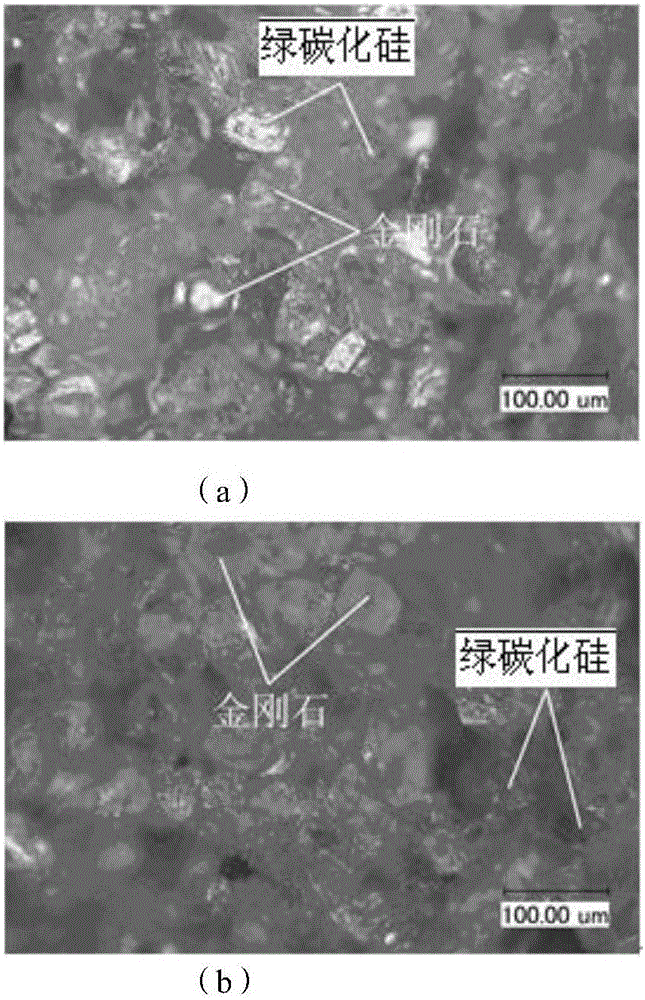

[0032] Step (2): 6.24g diamond powder (1-50μm), 10.92g green silicon carbide powder (2-60μm), 4.68g alumina hollow sphere, 9.36g vitrified bond (G068 of Foshan Tao Yise Glaze Co., Ltd. , 1-20 μm) was put into the filling mill and mixed for 2 hours to obtain the mixed powder;

[0033] Step (3): Sieve the mixed powder of step (2), pour it into a grinding bowl, use the solution obtained by mixing phenolic resin and ethanol at a mass ratio of 1:1 as a pre-adhesive, add 3g of pre-adhesive, Stir fully and evenly, and sieve to obtain pre-adhesive powder;

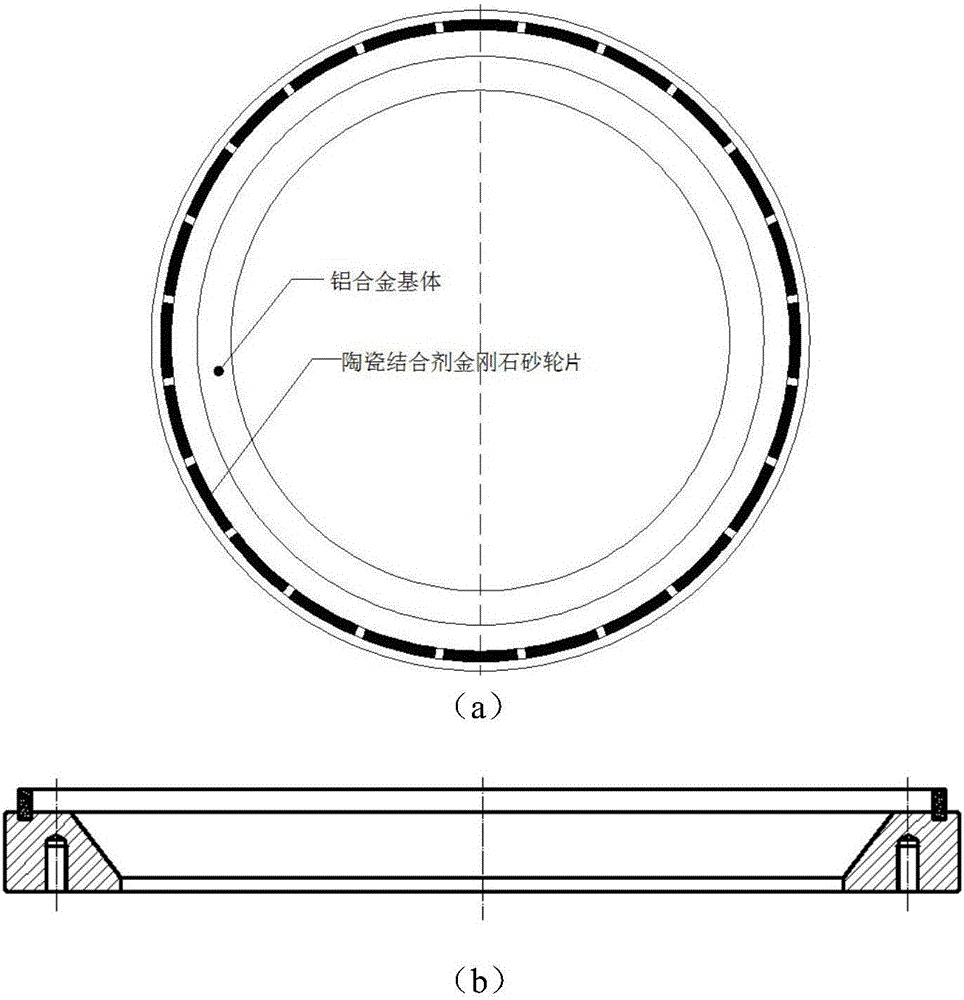

[0034] Step (4): Weigh 1.3g of the pre-bonded powder in step (3) and put it into a forming abrasive tool, and cold press it at room temperature at 5Mpa to obtain a grinding wheel sheet with a th...

Embodiment 2

[0038] The preparation method of vitrified bond diamond grinding wheel is as follows:

[0039] Step (1): Sieve the alumina hollow spheres to obtain ceramic hollow spheres with a particle size of 100-800 μm and a density of 0.8 g / cm 3 .

[0040] Step (2): 15.6g diamond powder (1-50μm), 7.8g green silicon carbide powder (2-60μm), 1.56g aluminum oxide hollow sphere, 6.24g vitrified bond (G068 of Foshan Tao Yise Glaze Co., Ltd. , 1-20 μm) was put into the filling mill and mixed for 2 hours to obtain the mixed powder;

[0041] Step (3): Sift the mixed powder of step (2), pour it into a grinding bowl, use the solution obtained by mixing phenolic resin and ethanol at a mass ratio of 1:1 as a pre-adhesive, and add 2.5g of pre-adhesive , fully stirred evenly, and sieved to obtain pre-adhesive powder;

[0042] Step (4): Weigh 1.3g of the pre-bonded powder in step (3) and put it into a forming abrasive tool, and cold press it at room temperature at 5Mpa to obtain a grinding wheel shee...

Embodiment 3

[0045] The preparation method of vitrified bond diamond grinding wheel is as follows:

[0046] Step (1): Sieve alumina hollow spheres to obtain ceramic hollow spheres with a particle size of 100-800 μm and a density of 1 g / cm 3 .

[0047] Step (2): 14.04g diamond powder (1-50μm), 9.36g green silicon carbide powder (2-60μm), 3.12g aluminum oxide hollow spheres, 4.68g vitrified bond (G068 of Foshan Tao Yise Glaze Co., Ltd. , 1-20 μm) was put into the filling mill and mixed for 2 hours to obtain the mixed powder;

[0048] Step (3): Sieve the mixed powder of step (2), pour it into a grinding bowl, use the solution obtained by mixing phenolic resin and ethanol at a mass ratio of 1:1 as a pre-adhesive, add 2g of pre-adhesive, Stir fully and evenly, and sieve to obtain pre-adhesive powder;

[0049] Step (4): Weigh 1.3g of the pre-bonded powder in step (3) and put it into a forming abrasive tool, and cold press it at room temperature at 5Mpa to obtain a grinding wheel sheet with a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com