Blade part efficient and precise grinding microcrystal ceramic corundum grinding wheel and machining method thereof

A technology of precision grinding and microcrystalline ceramics, applied in the direction of grinding devices, metal processing equipment, grinding/polishing equipment, etc., can solve the problems of low grinding efficiency and poor grinding precision, and achieve good grinding stability , long service life, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The grinding wheel of the present invention comprises a non-grinding layer part and a grinding layer part, and the parts by weight of each raw material of the non-grinding layer part are:

[0037]

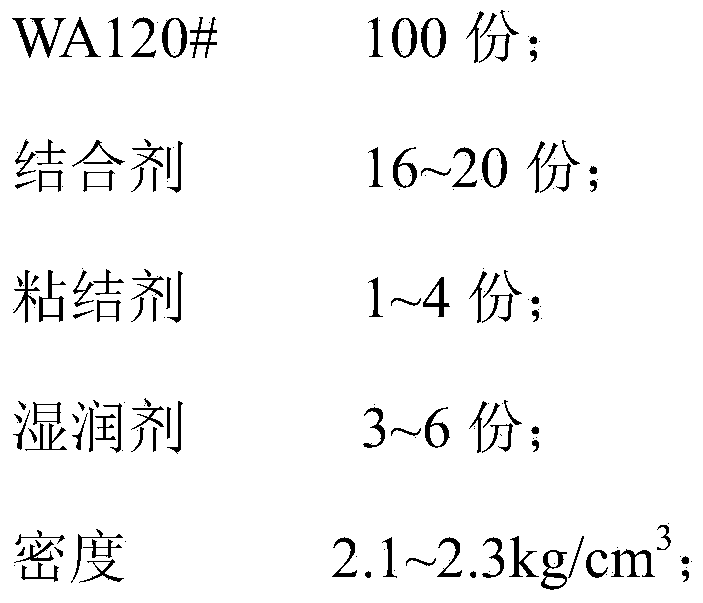

[0038] The parts by weight of each raw material of the grinding layer part are:

[0039]

[0040]

[0041] The parts by weight of each raw material component of described binding agent are:

[0042] 30 parts of clay;

[0043] Boron glass 40 parts;

[0044] 30 parts of glass frit containing lithium oxide;

[0045] The chemical composition and refractoriness of the above binder are:

[0046]

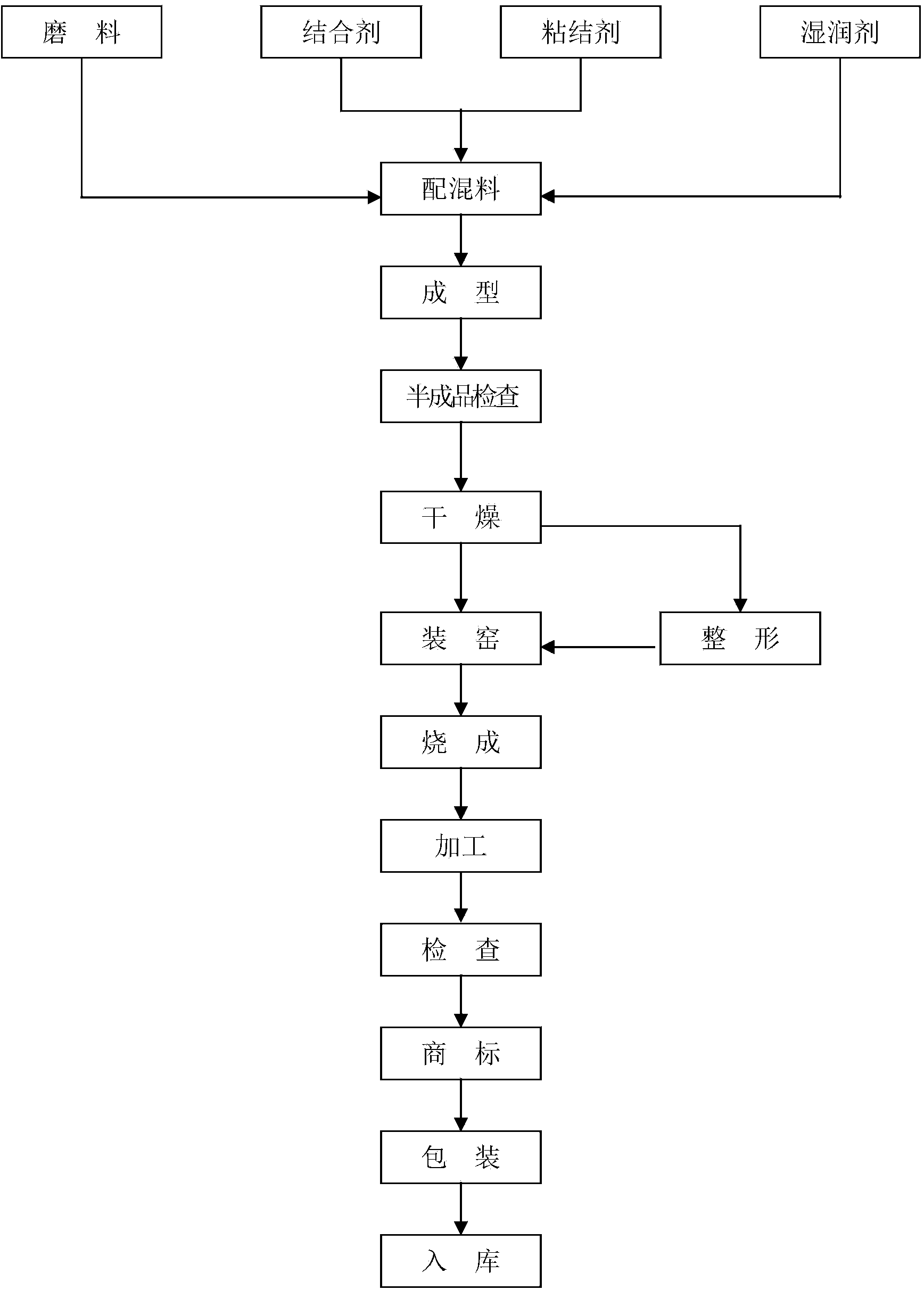

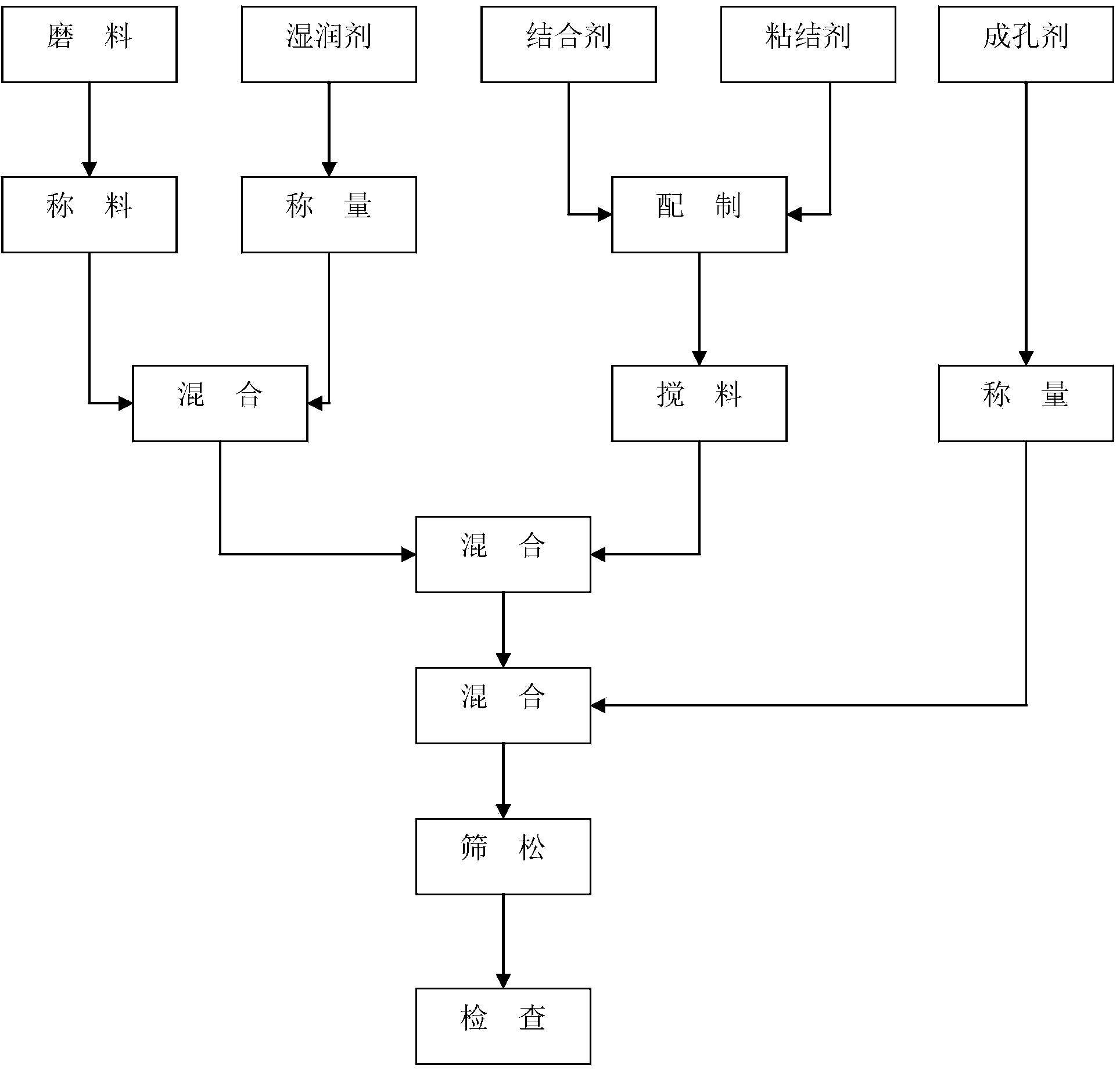

[0047] When the present invention is made as figure 1 , figure 2 The process shown is carried out, and the specific operation is as follows:

[0048] 1) Mixed material: first put the abrasive into the mixing pot, then add the weighed wetting agent, start the agitator, and mix well; while mixing the abrasive and wetting agent, put the prepared binder and binder well mi...

Embodiment 2

[0058] The grinding wheel of the present invention comprises a non-grinding layer part and a grinding layer part, and the parts by weight of each component of the non-grinding layer part are:

[0059]

[0060]

[0061] The parts by weight of each component of the grinding layer part are:

[0062]

[0063]The parts by weight of each raw material of the binding agent are:

[0064] 35 parts of clay;

[0065] 40 parts of boron glass;

[0066] 25 parts of glass frit containing lithium oxide;

[0067] The chemical composition and refractoriness of the above binder are:

[0068]

[0069]

[0070] When the present invention is made as figure 1 , figure 2 The process shown is carried out, and the specific operation is as follows:

[0071] 1) Mixed material: first put the abrasive into the mixing pot, then add the weighed wetting agent, start the agitator, and mix well; while mixing the abrasive and wetting agent, put the prepared binder and binder well mixed. Af...

Embodiment 3

[0081] The grinding wheel of the present invention comprises a non-grinding layer part and a grinding layer part, and the parts by weight of each component of the non-grinding layer part are:

[0082]

[0083] The parts by weight of each component of the grinding layer part are:

[0084]

[0085] The parts by weight of each raw material of the binding agent are:

[0086] 28 parts of clay;

[0087] Boron glass 40 parts;

[0088] 32 parts of glass frit containing lithium oxide;

[0089] The chemical composition and refractoriness of the above binder are:

[0090]

[0091]

[0092] When the present invention is made as figure 1 , figure 2 The process shown is carried out, and the specific operation is as follows:

[0093] 1) Mixed material: first put the abrasive into the mixing pot, then add the weighed wetting agent, start the agitator, and mix well; while mixing the abrasive and wetting agent, put the prepared binder and binder well mixed. After the abrasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com