Patents

Literature

51results about How to "High Rockwell hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

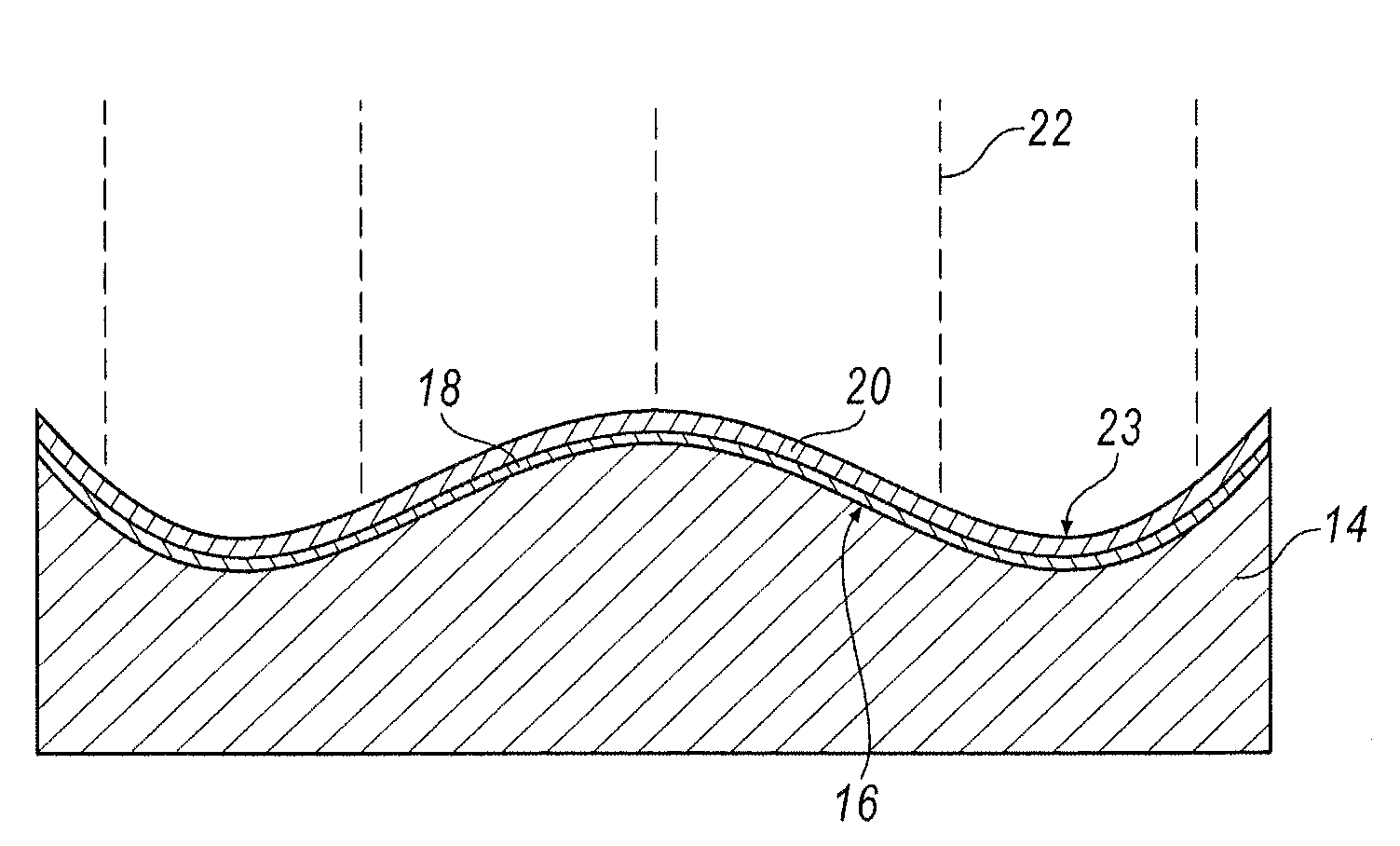

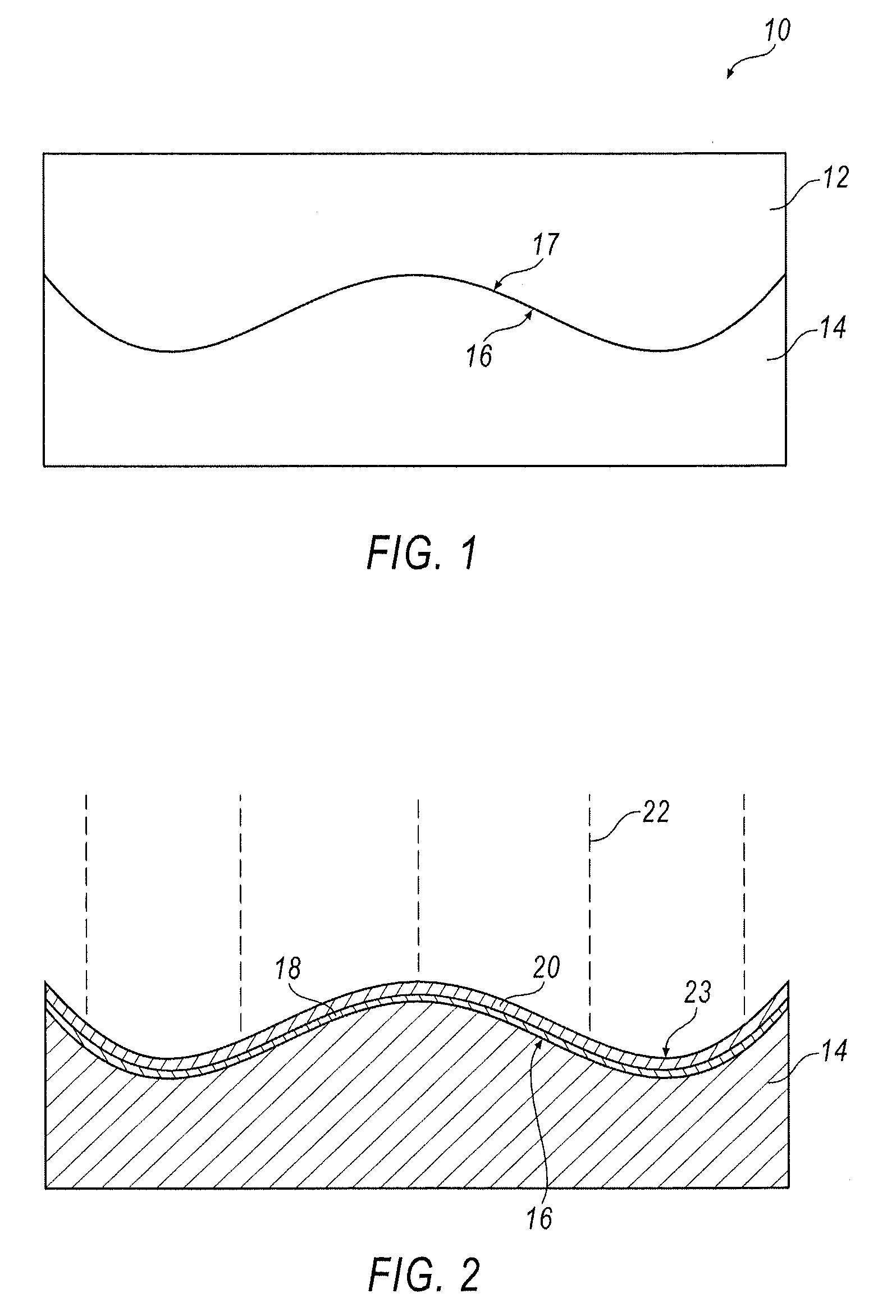

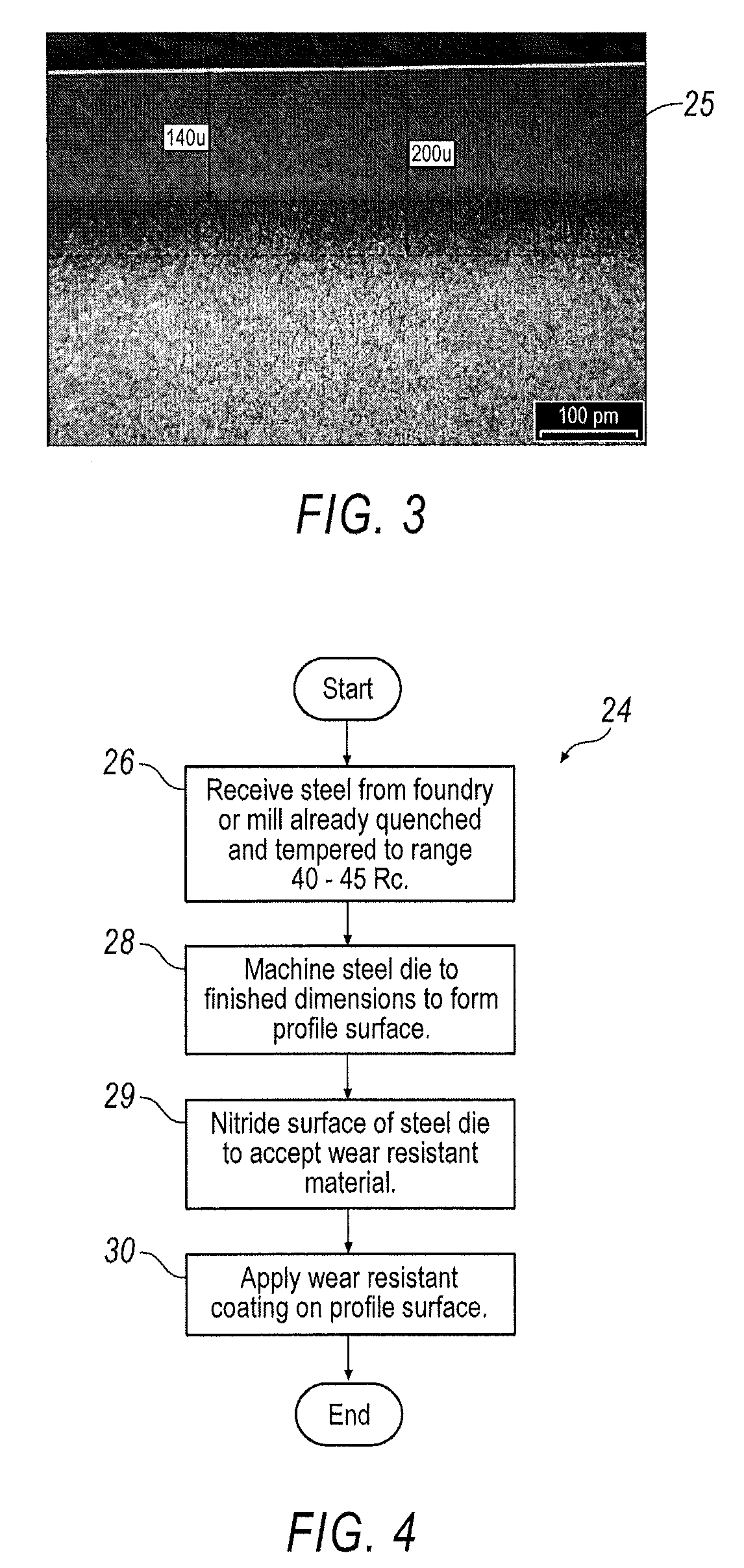

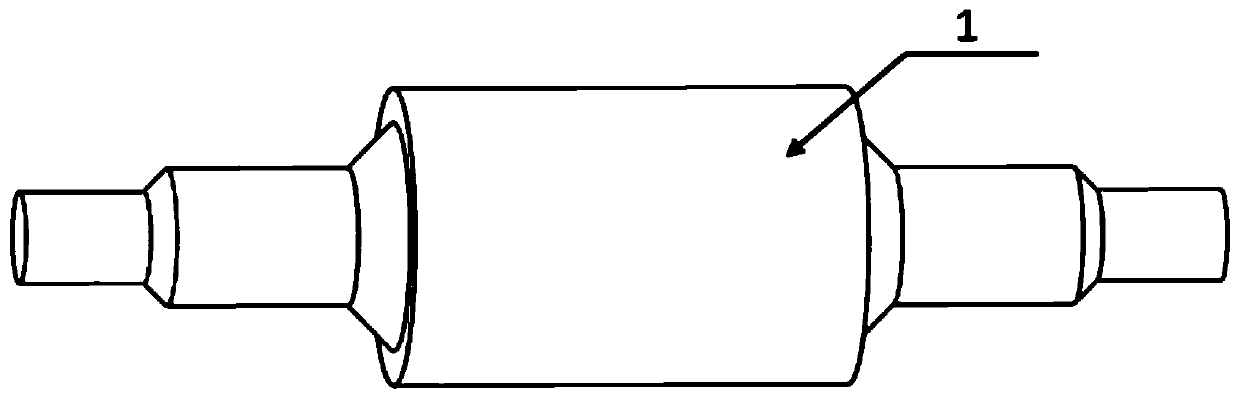

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS7587919B1Impart wear resistanceAvoid insufficient thicknessShaping toolsCutting toolsMetal formingGas phase

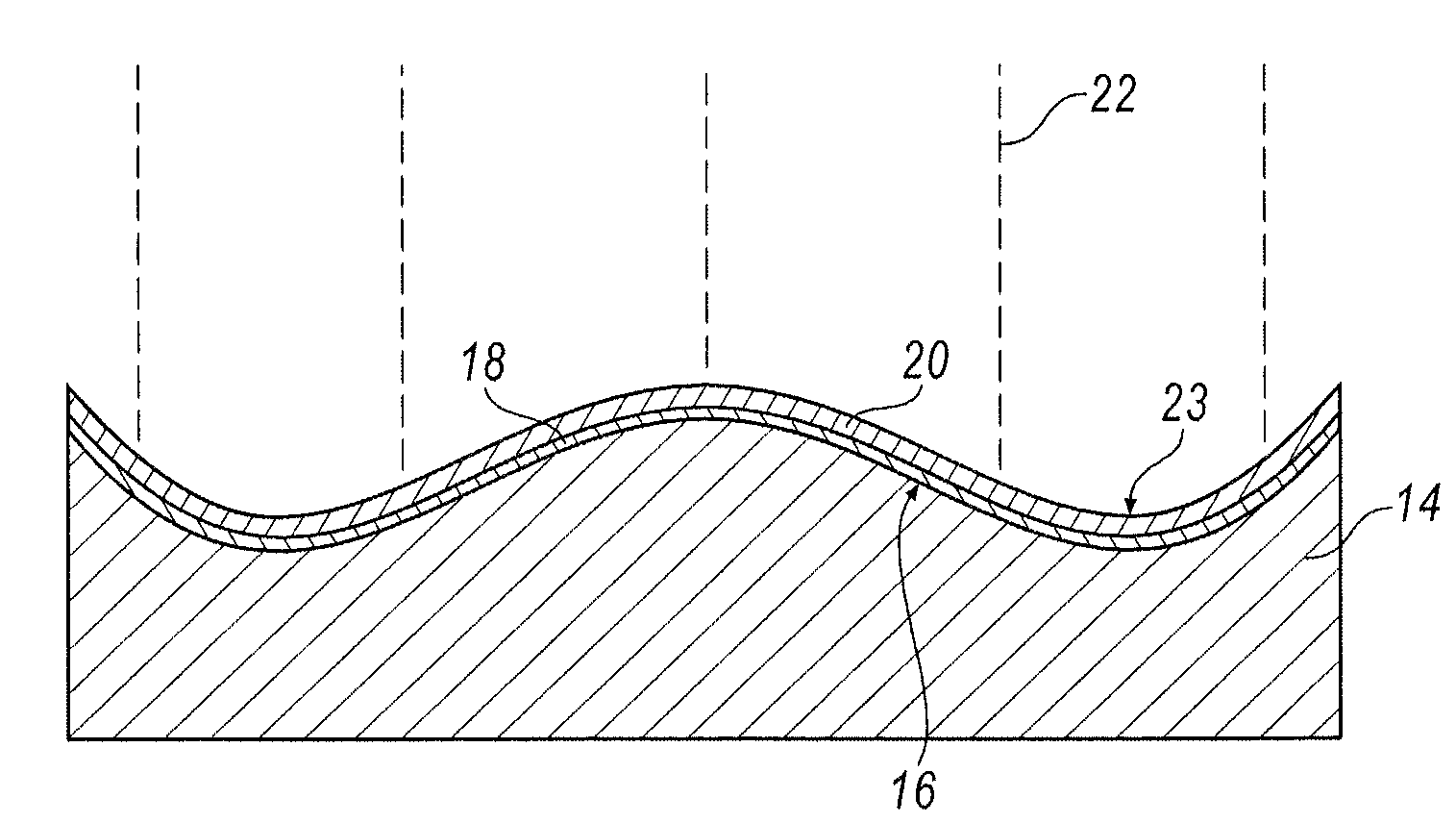

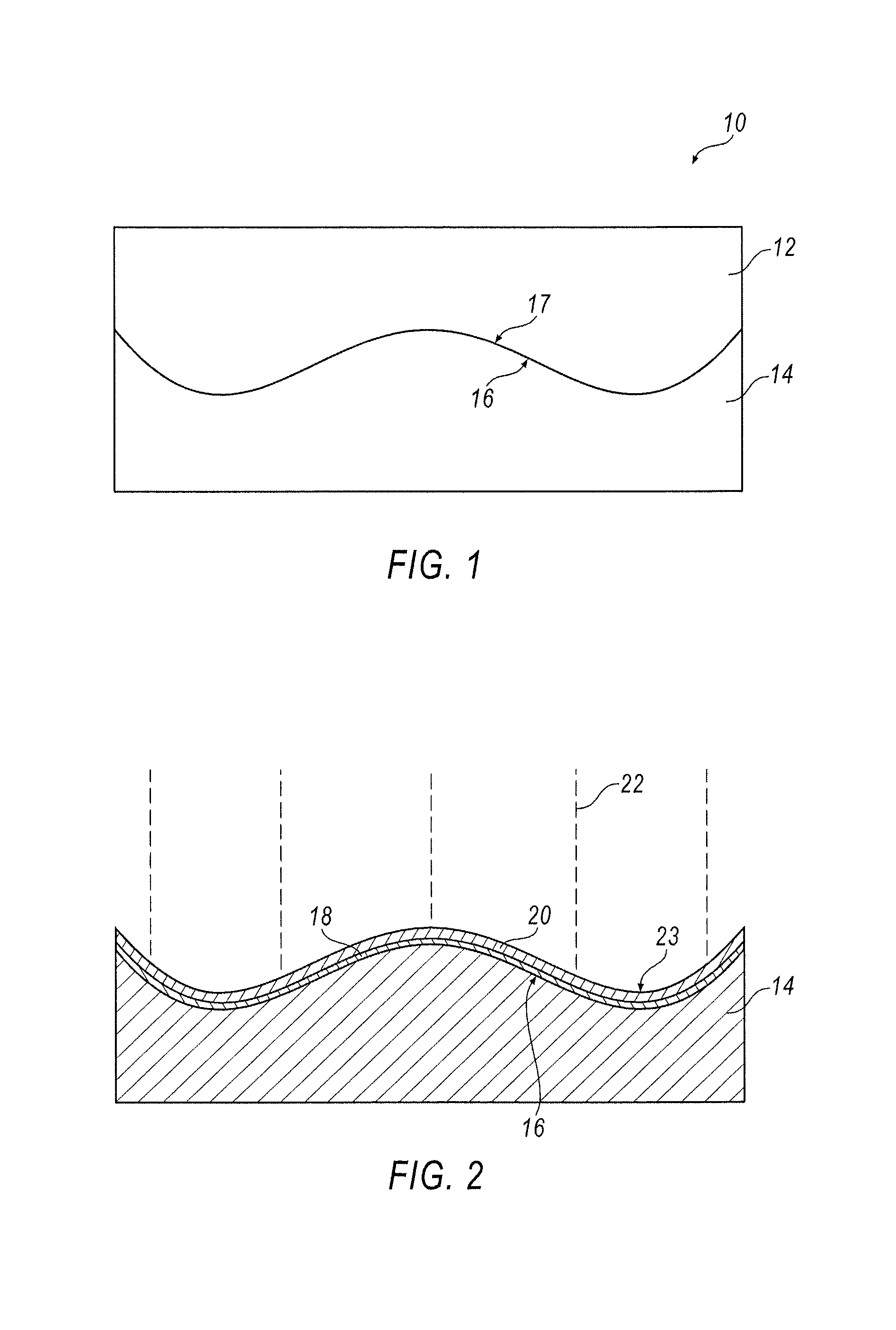

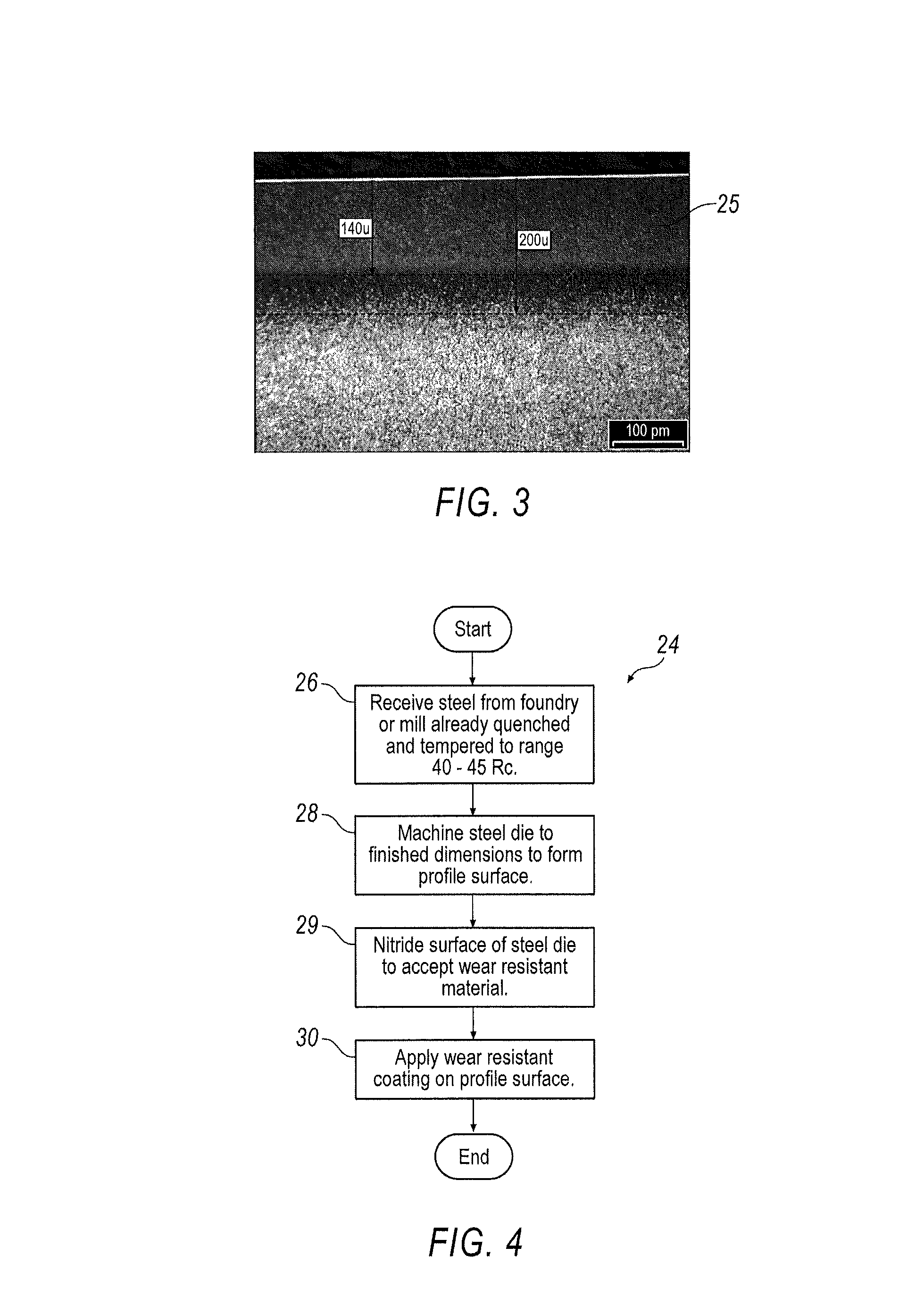

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

High heat-intensity hot-work die steel material

ActiveCN1924069AImprove metallurgical qualityImprove organizationHeat treatment process controlSlagHot work

The invention discloses a heat mould steel material in the alloy steel material manufacturing technological domain, which comprises the following parts: 3.5-4.0%Cr, 2.0-2.5% Mo, 1.0-1.5% V,1.0-1.5% W , 0.1-0.5% Mn, 0.1-0.25% Ni, 0.3-0.35% C, 0.1-0.5% Si, 0.005-0.01% S, 0.01-0.02% P and Fe. The preparing method comprises the following steps: (1) fusing; (2) refusing electric slag; (3) evening at high temperature; (4) forging; (5) annealing; (6) forging blank; (7) annealing to obtain the product with hardness between 48-54HRC and impaction flexibility more than 300J.

Owner:SHANGHAI UNIV

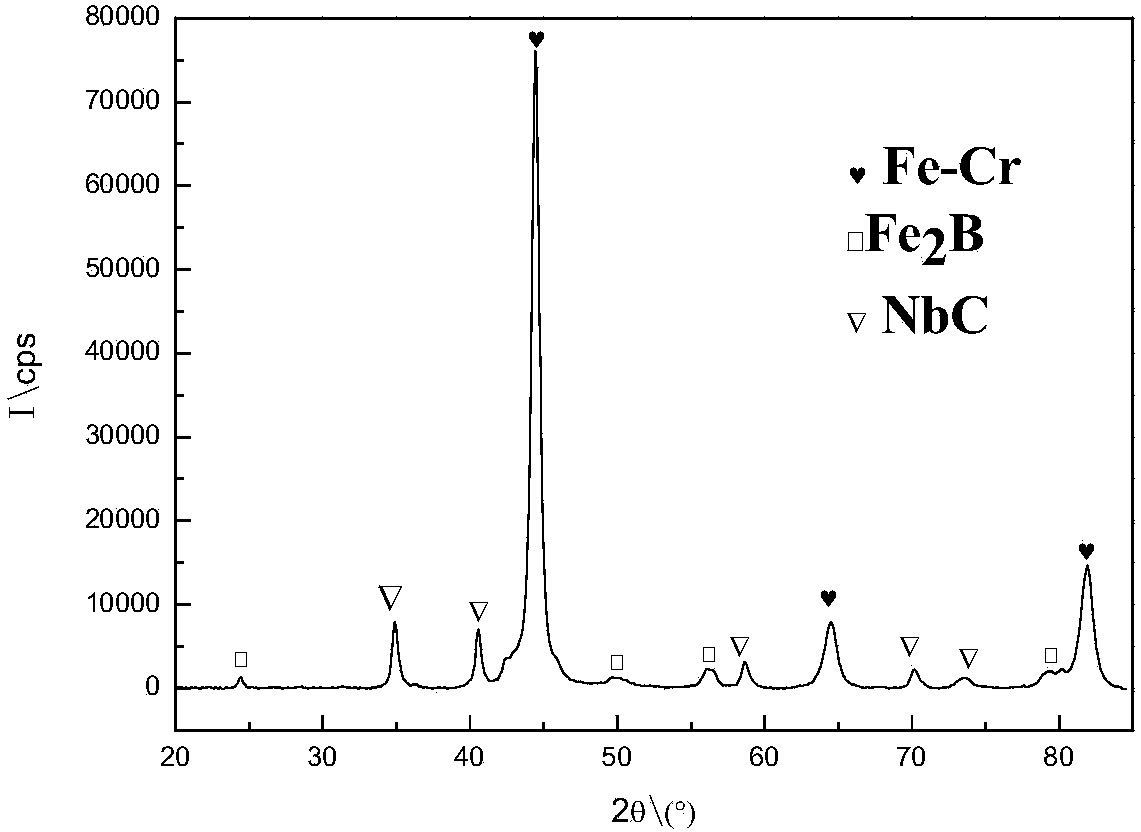

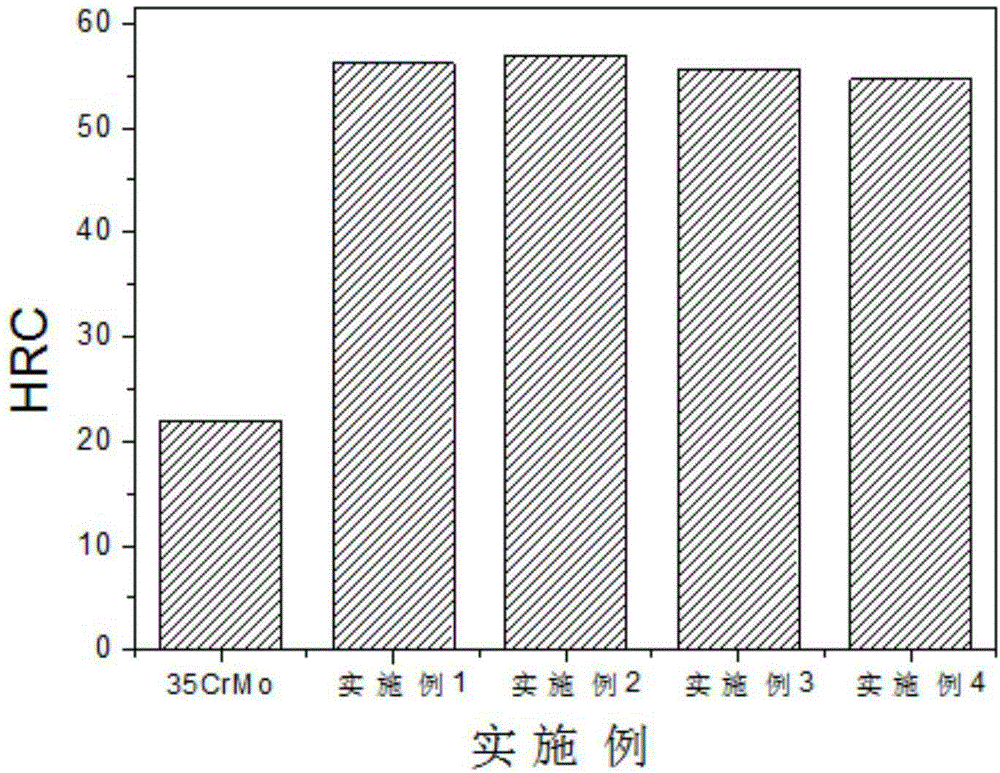

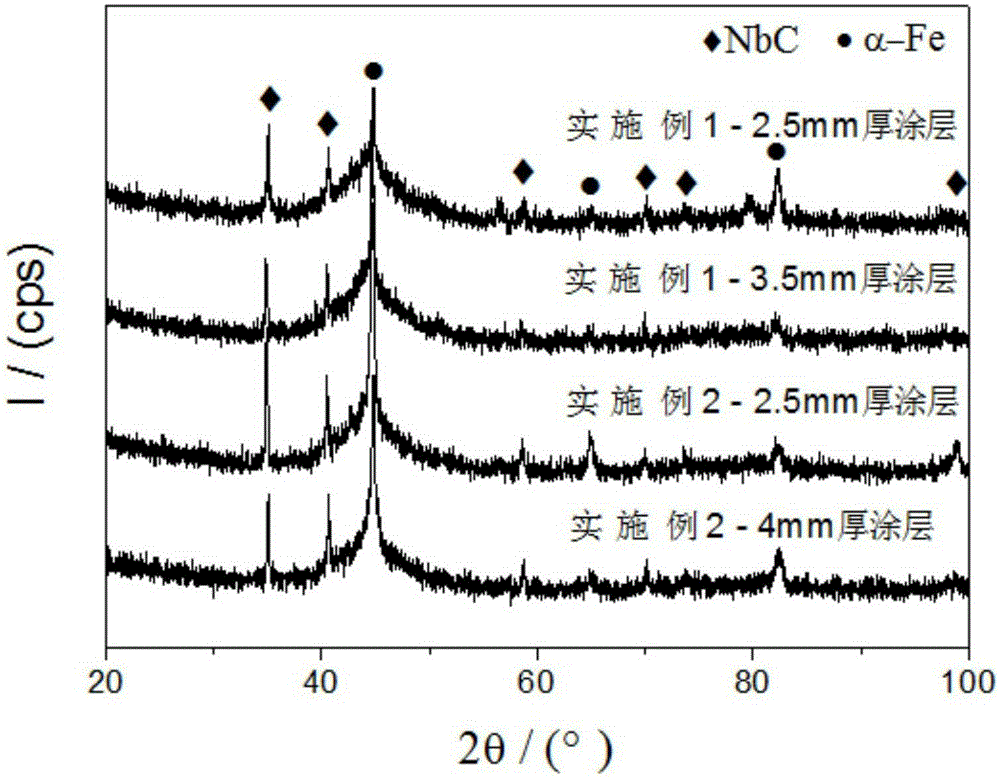

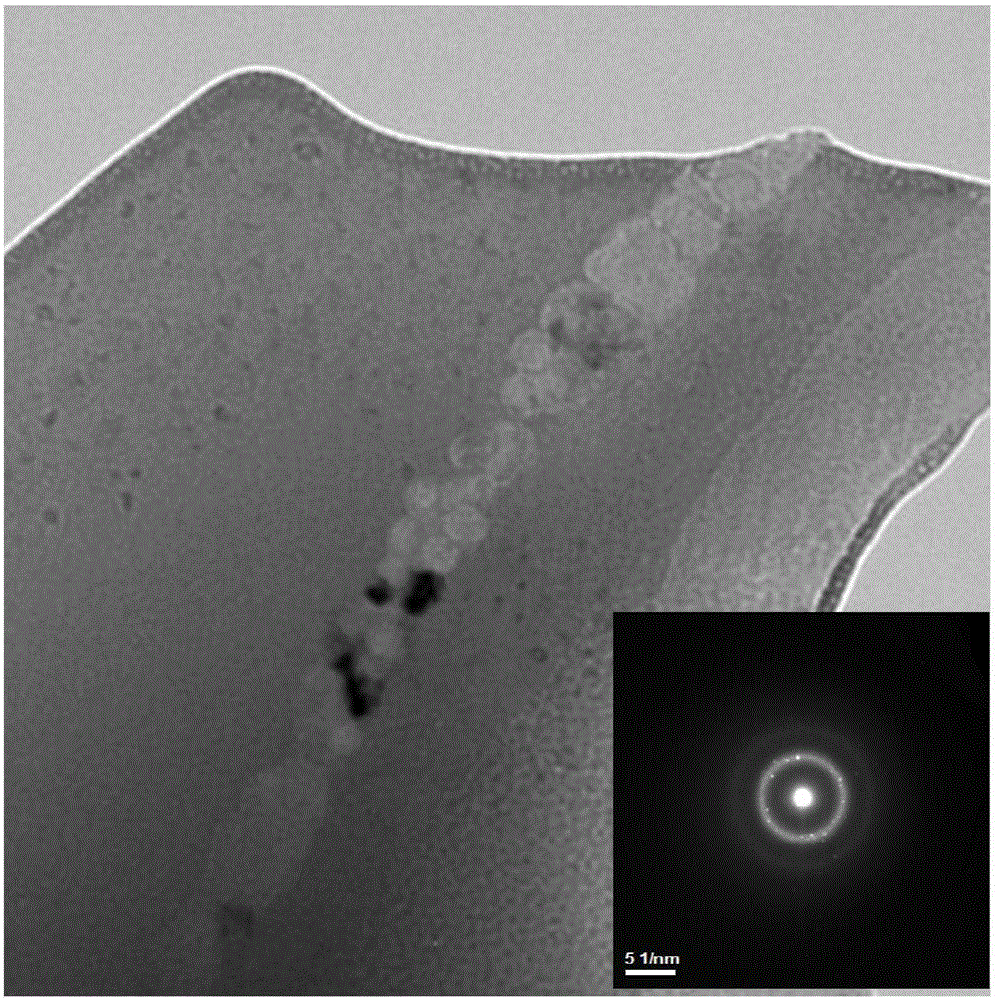

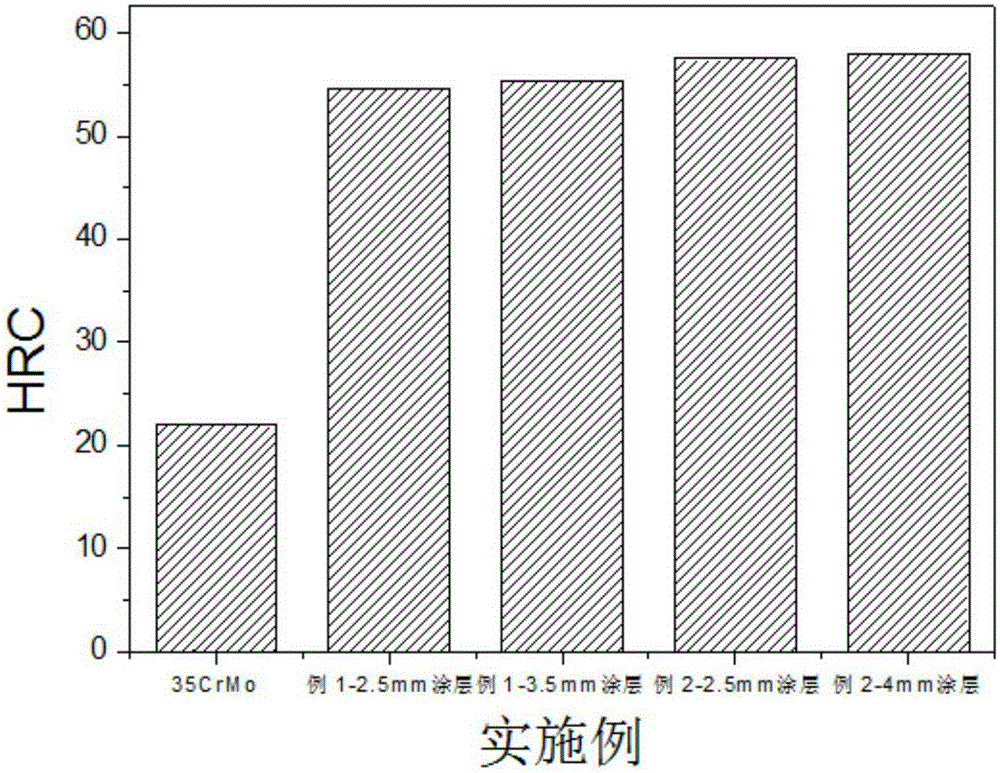

Fe-Nb-Mo-Cr-Mn-B iron-based surfacing flux-cored wire for wear-resistant strip of drill rod joint

InactiveCN103894756AImprove wear resistanceImprove crack resistanceArc welding apparatusWelding/cutting media/materialsBorideCrack resistance

The invention relates to an Fe-Nb-Mo-Cr-Mn-B iron-based surfacing flux-cored wire for a wear-resistant strip of a drill rod joint, and belongs to the technical field of welding materials. A carbon steel strip is adopted to coat flux core powder, filling rate of the flux-cored wire is 20-26%, and alloying elements of the flux-cored wire powder include, by mass, 0.6-1.2% C, 0.8-1.2% of B, 2-9% of Cr, 10-19% of Nb, 4-10% of Mo, 4-10% of Mn, 3-8% of Si, 1-4% of Ti and the balance Fe. Grain structures generated by a coating, carbide and boride after wire surfacing are closely arrayed into a hard metallographic phase to be dispersed in martensite, the size of an NbC hard phase is quite small and is about 1-2 micrometers. No crack exists after welding, average Rockwell hardness is more than 60HRC, and the flux-cored wire has reasonable wear resistance and crack resistance matching performance; surfacing manufacturability is good, weld joints are beautiful in formation, the wear-resistant strip is smooth, the flux-cored wire is few in splash, free of peeling, high in cohesiveness, reusable for surfacing and excellent in compatibility.

Owner:BEIJING UNIV OF TECH

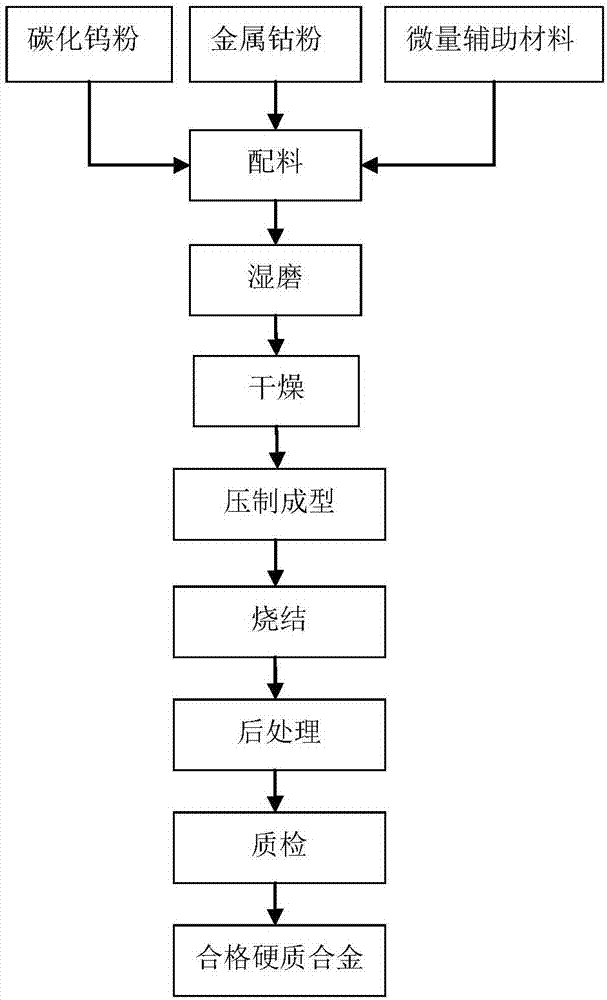

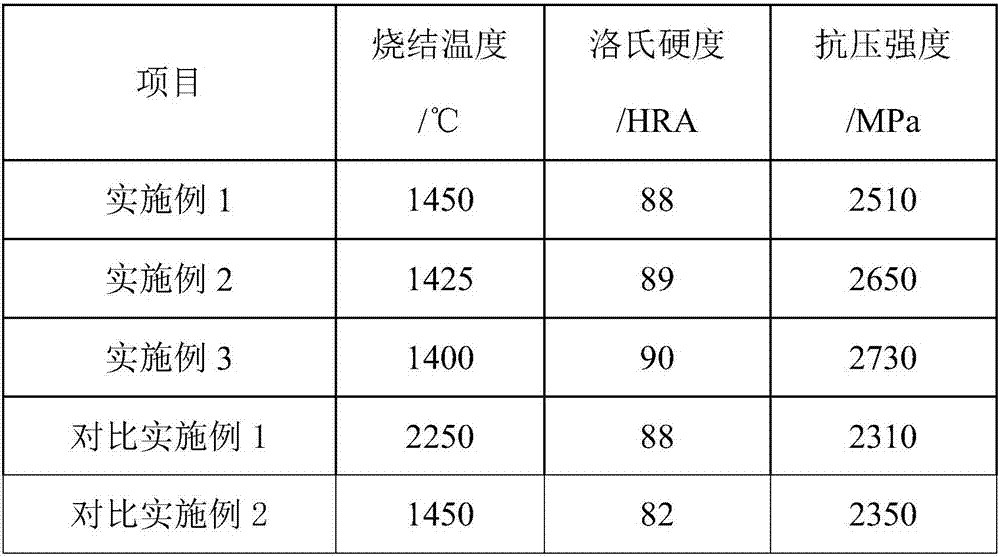

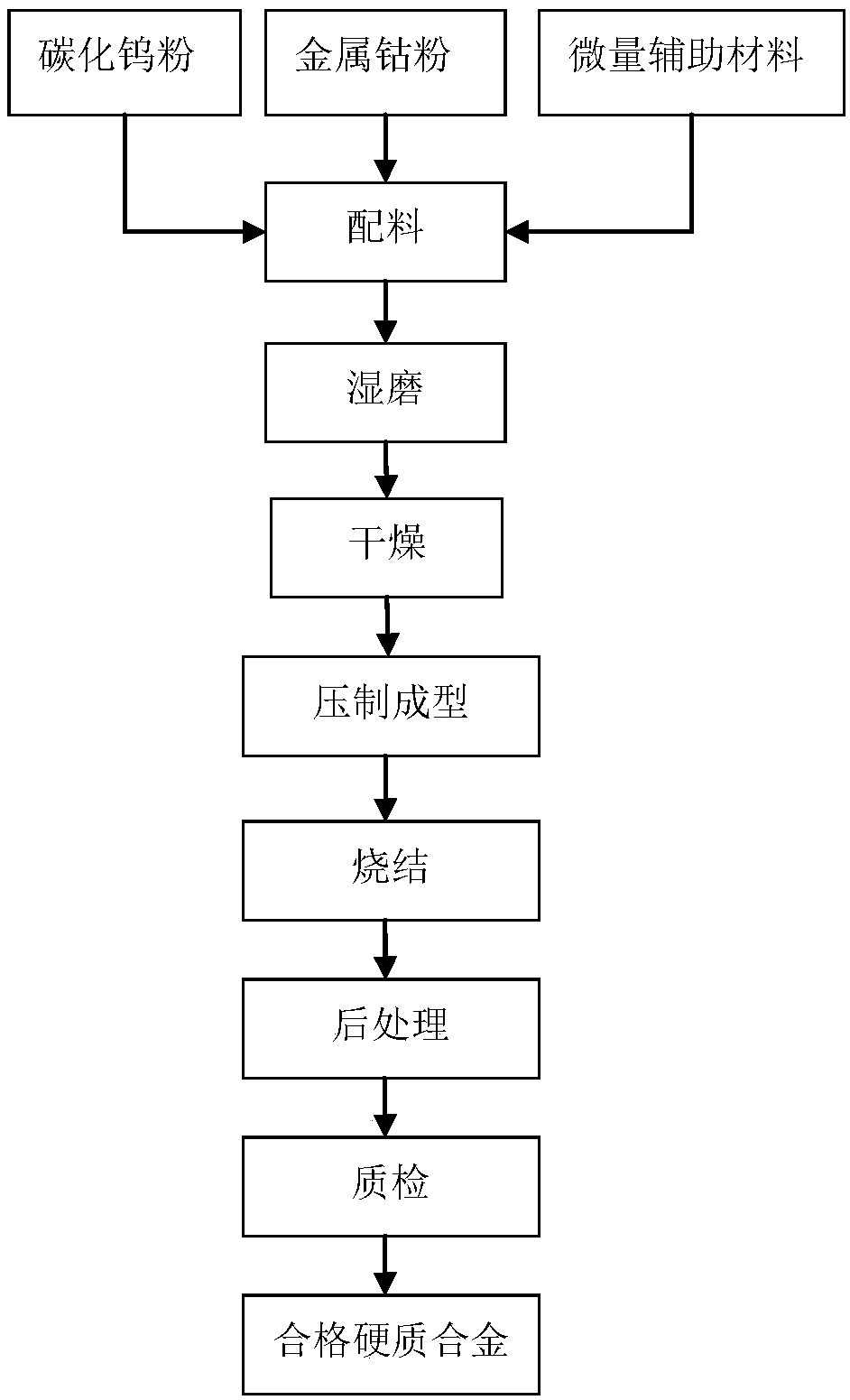

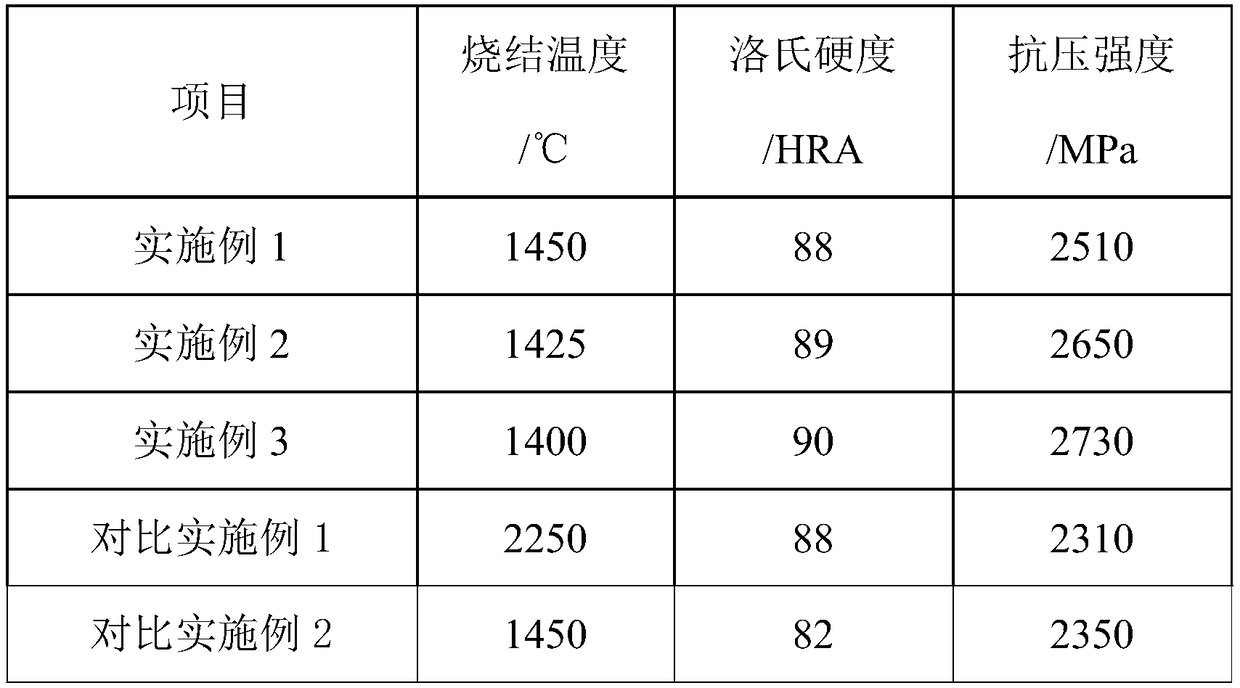

Hard alloy and manufacturing method thereof

ActiveCN107385304ALower sintering temperatureHigh Rockwell hardnessTransportation and packagingMetal-working apparatusTemperature controlGasoline

The invention discloses a manufacturing method of a hard alloy, and in particular, belongs to the field of alloy manufacturing. The manufacturing method is performed according to the steps of: (S1) batching; (S2) wet grinding and screening; (S3) drying: a screened mixture is primarily dried by using a vacuum steam dryer; molding agent gasoline solution is added in the drying process; the primary drying temperature is 60-100 DEG C; the drying time is 3-10 h; and primarily dried mixture powder is dried by 0.5 or more h at a temperature of 100-150 DEG C in a steam drying cabinet; (S4) molding by pressing; (S5) sintering: the mixture powder molded by pressing is sintered by heating through five phase procedures; and (S6) aftertreatment. The invention discloses the hard alloy. The manufacturing method of the hard alloy machines the hard alloy with the Rockwell hardness HRA of at least increasing by 6, the sintering temperature of reducing by at least 800 DEG C and the compressive strength of at least increasing by 200 MPa through the temperature control in the sintering process.

Owner:GANZHOU WHISKAS ALLOY

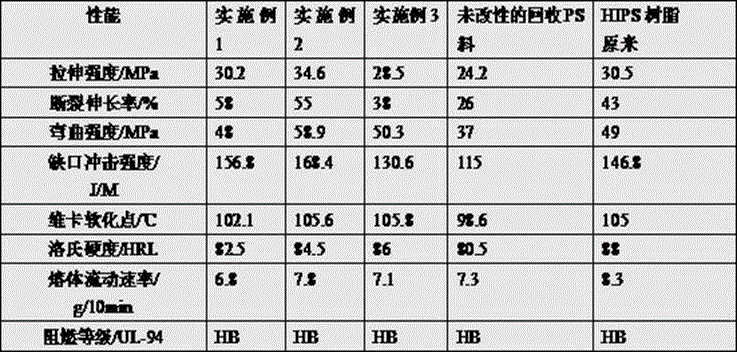

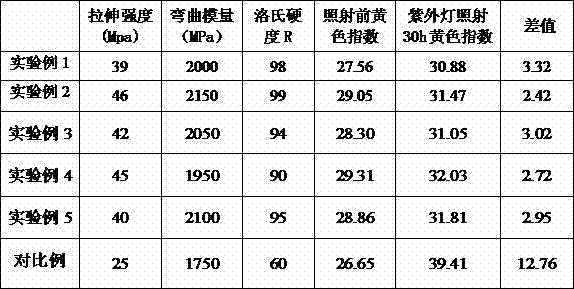

Method for recycling polystyrene shell materials of waste electrical appliances

InactiveCN102719030ASimple processAvoid secondary pollutionPlastic recyclingEquipment usePolystyrene

The invention discloses a method for recycling polystyrene shell materials of waste electrical appliances. The method comprises the following steps of: 1) weighing waste polystyrene shell materials and other raw materials according to a formula; 2) adding the raw materials into a high-speed mixing machine and mixing for 3 to 5 minutes to obtain premix; 3) adding the premix obtained in the step 2) into a granulator and granulating at the temperature of between 180 and 210 DEG C to obtain modified particles; and 4) feeding the modified particles obtained in the step 3) into an injection molding machine and performing injection molding. Equipment used by the method for recycling the polystyrene shell materials and the process are simple, and secondary pollution is avoided; the adding amount of flexibilizer is reduced, so that the processability of the materials is improved, and the modification cost is reduced; according to the formula of the method for recycling the polystyrene shell materials, additives which are strong in volatility and have peculiar smell are avoided, and working environment is improved; and the performance of the modified product is improved, the application field of the modified particles is widened, the white pollution is reduced, and environment is protected.

Owner:TPV DISPLAY TECH (XIAMEN) CO LTD

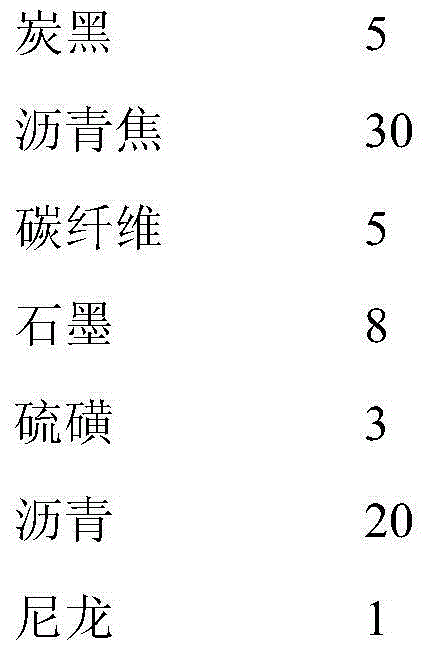

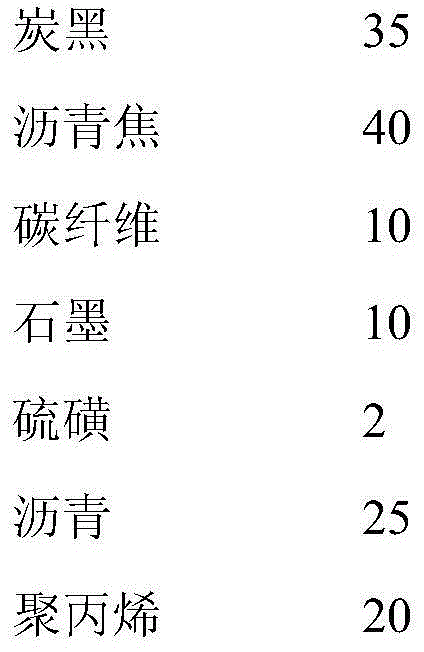

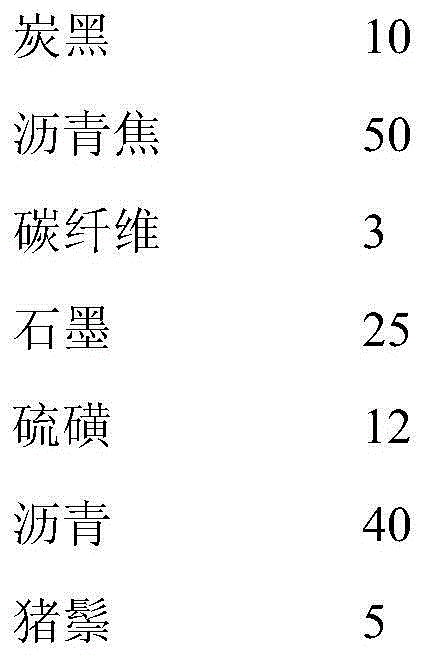

Method for making carbon-fiber-reinforced pantograph carbon slide plate carbon strip

The invention provides a method for making a carbon-fiber-reinforced pantograph carbon slide plate carbon strip, and the method comprises the following steps: uniformly mixing a pantograph carbon slide plate carbon strip raw material and a pore forming agent to obtain a mixture; pressing the mixture to obtain a carbon slide plate carbon strip initial blank containing the pore forming agent; calcining the carbon slide plate carbon strip initial blank to burn out the pore forming agent in the carbon slide plate carbon strip initial blank to form pores in uniform distribution in the carbon slide plate carbon strip so as to obtain a carbon slide plate carbon strip with a pore structure; and performing metal impregnation treatment on the carbon slide plate carbon strip with the pore structure to obtain the carbon slide carbon strip having a uniformly-distributed metal. The prepared carbon strip has the advantages of low resistivity, strong electric conductivity, high strength and long service life by addition of the pore-forming agent to control the number and shape of the pores in the carbon strip so as to make the impregnated metal in a uniformly-distributed net structure.

Owner:SUZHOU DONEKA NEW MATERIALS CORP LTD

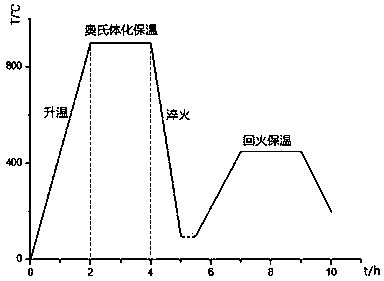

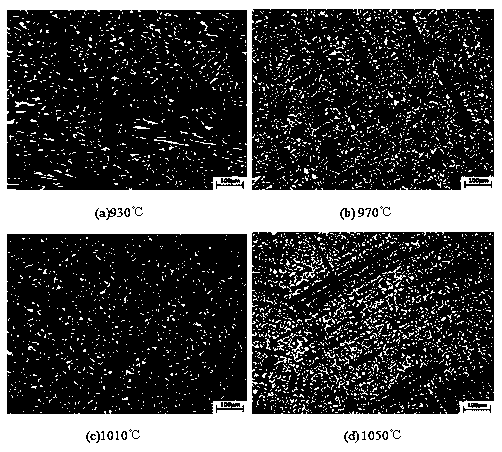

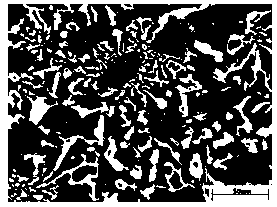

High-chromium cast iron heat treatment process

The invention relates to a high-chromium cast iron heat treatment process. The process includes steps: heating high-chromium cast iron in a heating furnace for 1.5-2, and after the heating temperaturereaches 1010-1050DEG C, keeping the temperature for 1.5-2h to realize austenization; discharging the high-chromium cast iron, and quenching; reheating the quenched high-chromium cast iron in the furnace for 1.5-2h, and after the heating temperature reaches 450-460DEG C, keeping the temperature for 1.5-2h; discharging the high-chromium cast iron, and performing air cooling to the room temperature.By reasonable optimization of the quenching temperature and the temper temperature, the quenched high-chromium cast iron structure is appropriate in content of martensite, retained austenite and carbides, and Rockwell hardness, impact toughness and comprehensive mechanical properties are greatly improved as compared with those of a cast sample.

Owner:ANHUI FENGXING WEAR RESISTANT MATERIALS CO LTD +1

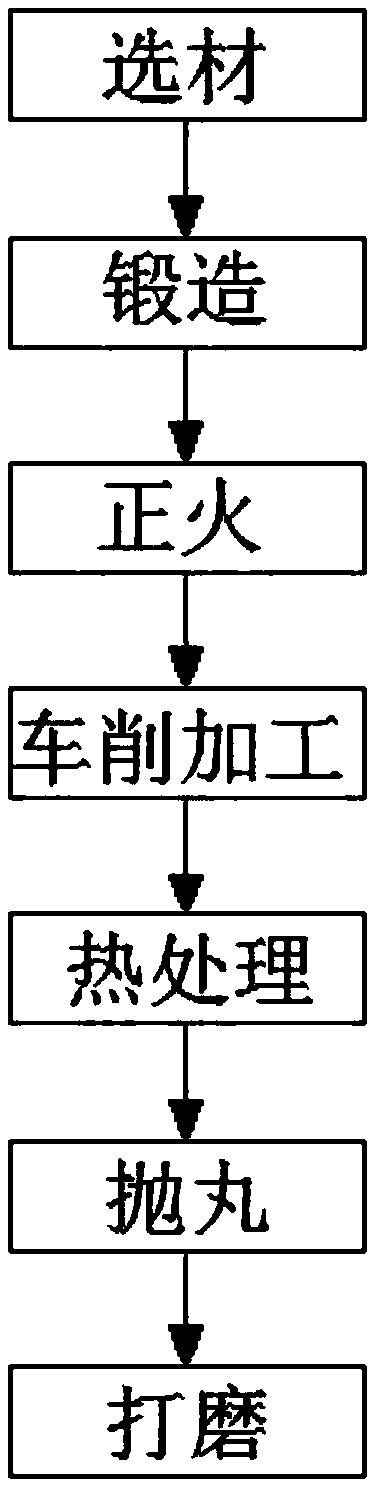

Machining method of spline gear shaft

The invention discloses a machining method of a spline gear shaft in the technical field of machining. The machining method of the spline gear shaft comprises the following steps: S1: material selection: selecting a workblank of which the material adopts 20CrMnTi and the hardness is HB277-348; S2: forging: forging the workblank by adopting a horizontal forging machine; S3: normalizing; S4: turningmachining; S5: heat treatment; S6: shot blasting: mounting and fixing the spline gear shaft on a rotary table of a rotary table type shot blasting machine by adopting a positioning pin after quenching molding on the spline gear shaft is carried out, closing a shot blasting room door, and carrying out a shot blasting strengthening process; and S7: grinding: sequentially performing cylindrical grinding, gear grinding and spline grinding on the spline gear shaft after the shot blasting strengthening process is carried out. According to the machining method of the spline gear shaft disclosed by the invention, the Rockwell hardness of the spline gear shaft is greatly improved, the assembly pressure meets the assembly requirement, deformation of the spline can be effectively prevented, and thequality of the spline gear shaft is improved.

Owner:JIANGYIN YONGXING MACHINERY MFG

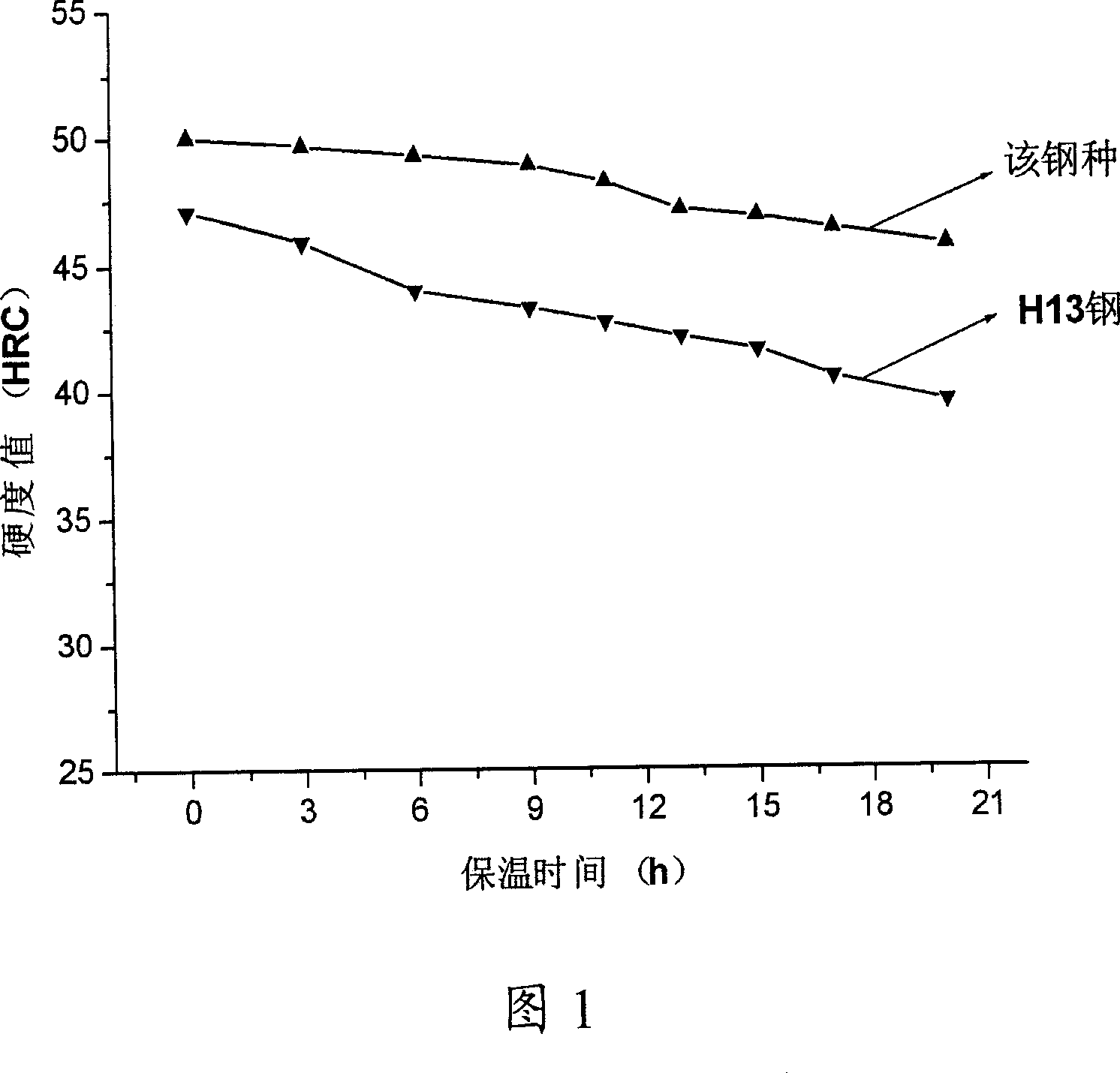

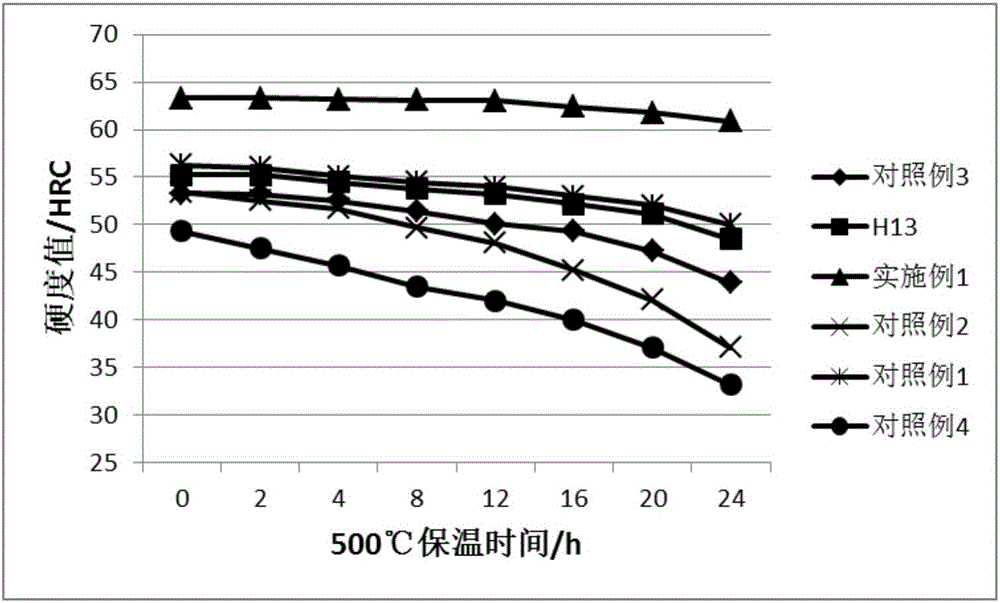

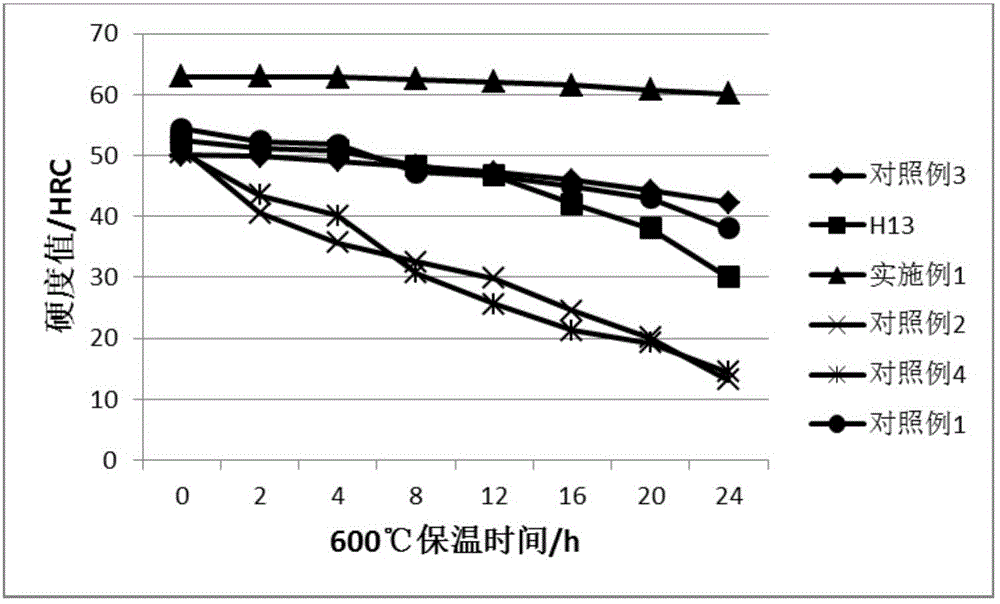

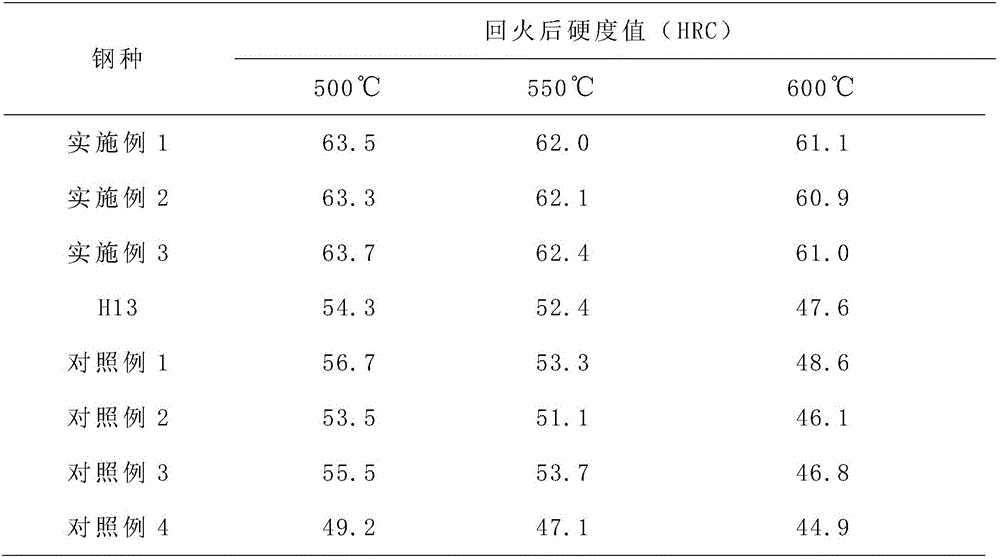

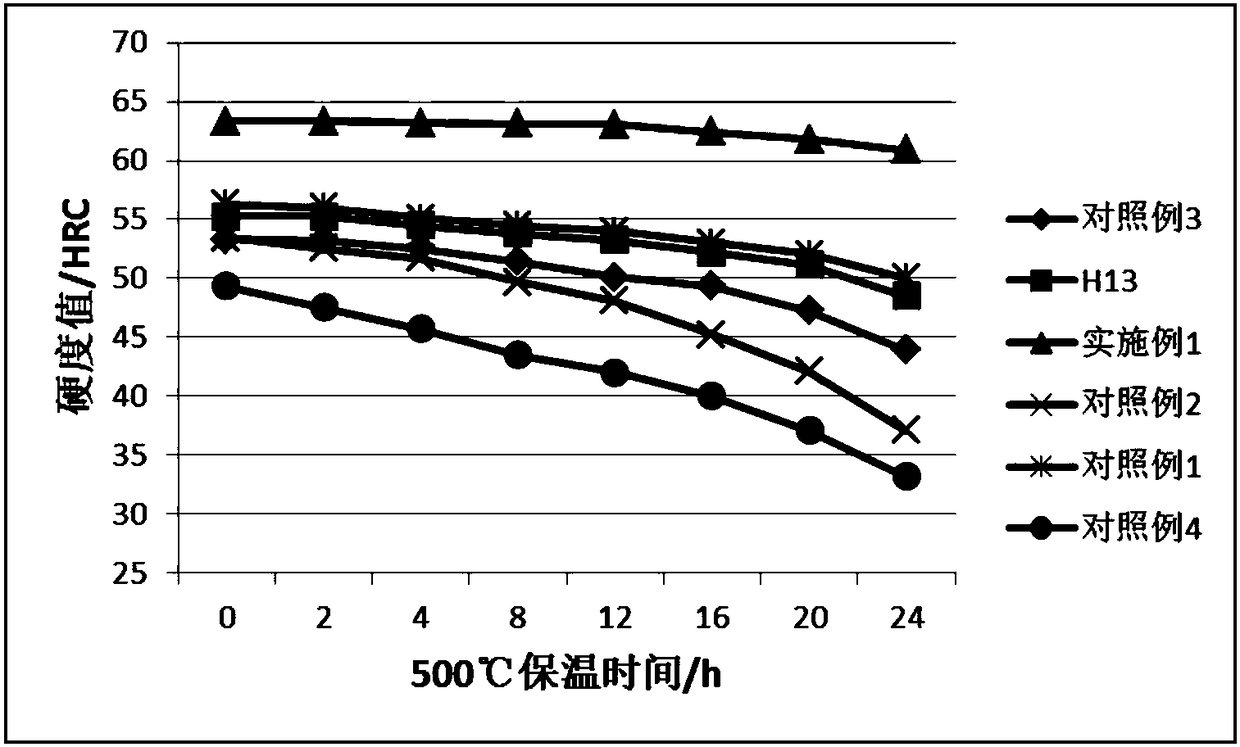

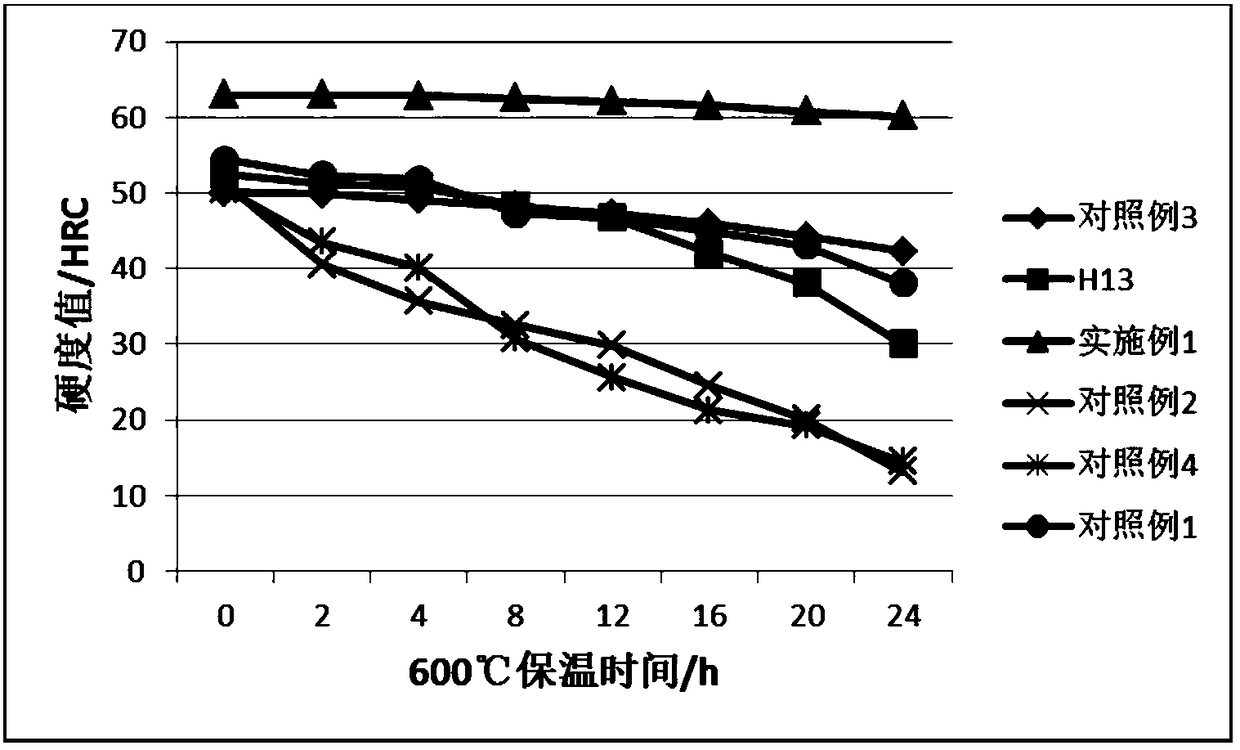

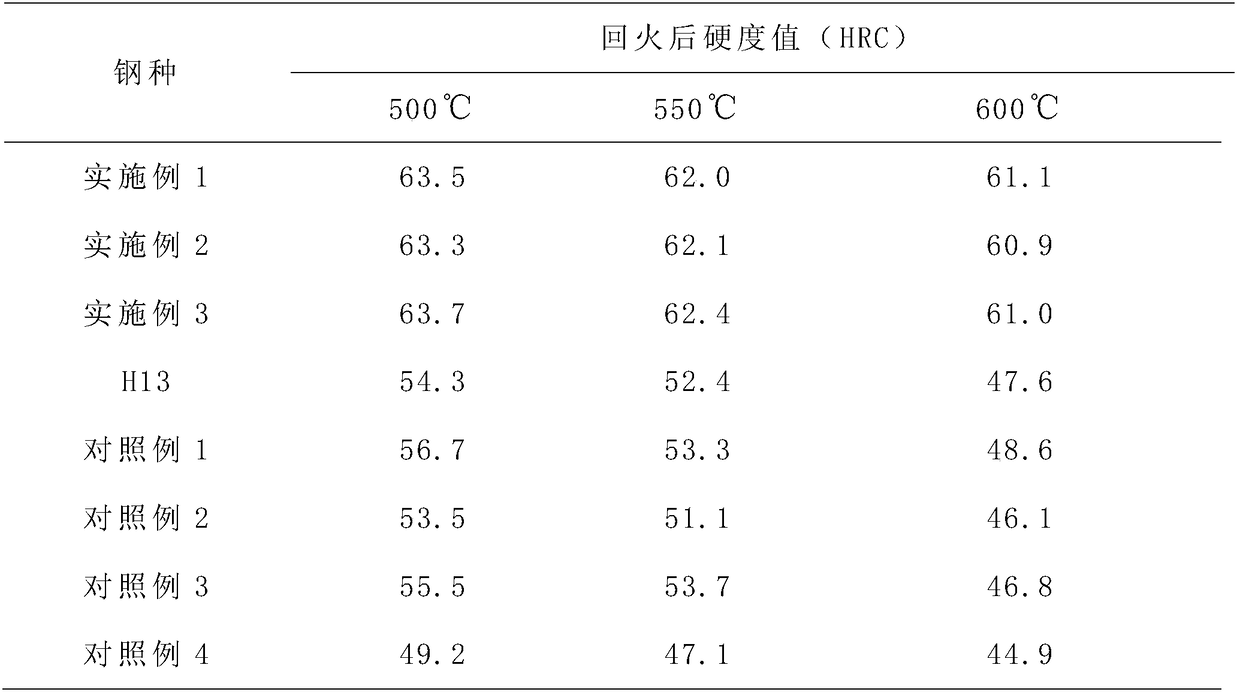

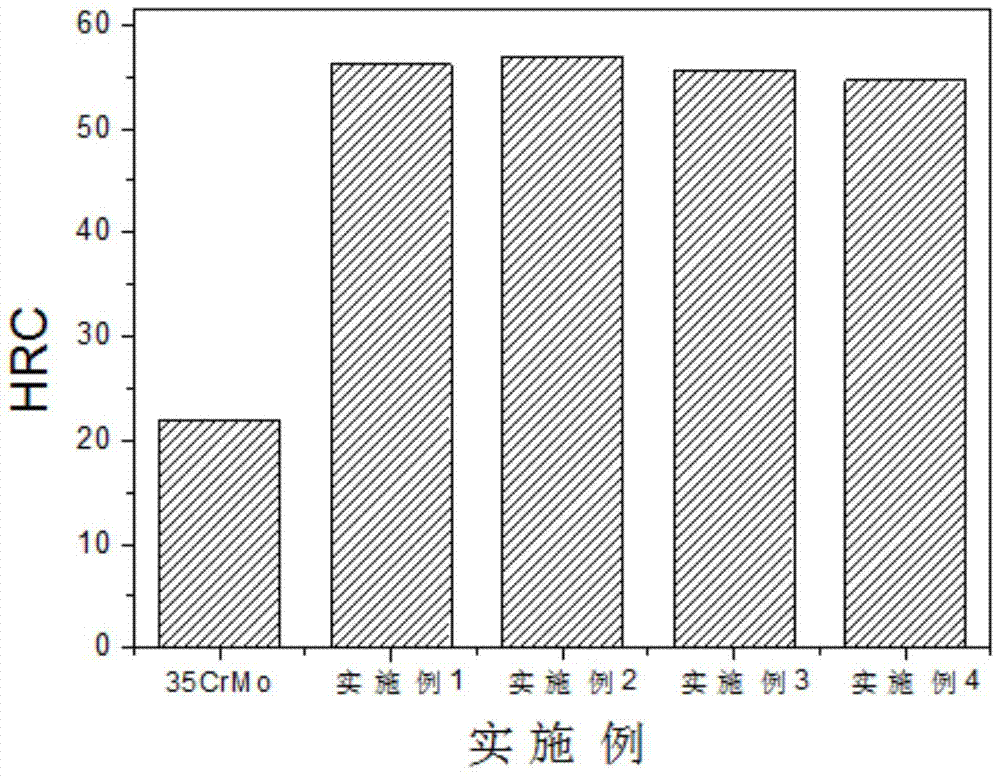

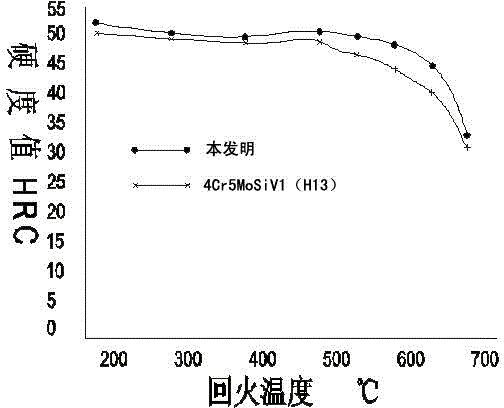

High-temperature-resistant and high-toughness hot work die steel and preparation method thereof

The invention relates to high-temperature-resistant and high-toughness hot work die steel and a preparation method thereof. The hot work die steel is mainly composed of, by mass, 0.50-0.65% of C, 0.7-1.3% of Si, 0.6-1.0% of Mn, 2.5-4.5% of Cr, 2.7-4.5% of Mo, 0.5-1.1% of V, 0-0.02% of P, 0-0.0005% of S, and the balance Fe. According to the hot work die steel, the use amounts of all components of H13 die steel are improved, so that the weight percentage of C is increased to 0.50-0.65%, the weight percentage of Mn is increased to 0.6-1.0%, the content of Cr is decreased to 2.5-4.5%, and the weight percentage of Mo is increased to 2.7-4.5%; and the four chemical components are adjusted at the same time, the optimal proportion is achieved, and accordingly the prepared die steel is excellent in hardness and high-temperature resistance and high in toughness.

Owner:TIANJIN CISRI HARDER MATERIALS & TECH

Wear resistant coated sheet metal die and method to manufacture a wear resistant coated sheet metal forming die

InactiveUS20090241632A1Increased longevityHigh hardnessShaping toolsCutting toolsMetal formingWear resistant

A method to manufacture a steel die having a Physical Vapor Deposition wear resistant coating on a profile surface and a steel die formed thereby is disclosed. The steel die is subjected to quenching and tempering to achieve a Rockwell hardness in the range of about 40-45 Rc and then subjected to machining to form a profile surface. The surface is then subjected to Physical Vapor Deposition of a wear resistant coating that may be multiple layers of CrN, AlCrN, TiCrN, TiN, TiCN or TiAlN, and preferably is alternating layers of TiN—TiCN—TiN. The coating is applied at a sufficient thickness to impart wear resistance to the steel die. The steel dies are useful in sheet metal stamping operations.

Owner:FORD MOTOR CO

Preparation method of ceramic particle metal composite material

ActiveCN107598136APacked tightlyPrevent peelingFoundry mouldsLiquid/solution decomposition chemical coatingChemical platingLost-foam casting

The invention provides a preparation method of a ceramic particle metal composite material. The preparation method comprises the following steps that ceramic particles are subjected to surface pretreatment and then placed into a chemical plating solution, and thus nickel-plated ceramic particles are obtained; an electric heating resistance wire is used for cutting a foam plate; the nickel-plated ceramic particles are washed and dried, and then coats the surface of a foam specimen, after drying, the foam specimen is bonded with a cross gate, a sprue and an ingate, and thus a lost foam casting white foam is obtained; the prepared lost foam casting white foam is placed into a sand box filled with dry sand, the dry sand is vibrated to be compacted and scraped to be flat, a plastic thin film isused for covering, a pouring cup is placed, and the negative pressure is pumped; after the dry sand is firm and is formed, metal liquid is cast; and after casting, vacuum relief, cooling and solidification then polishing are conducted. According to the preparation method of the ceramic particle metal composite material, the Rockwell hardness, impact toughness and overall abrasion resistance of the prepared composite material are greatly improved, no element diffusion exists between the ceramic particles and a metal substrate at the composite interface, and the bonding strength between the ceramic particles and metal is high.

Owner:安徽省凤形新材料科技有限公司 +1

Laser repairing method of damaged roller

ActiveCN109706448ASolve associativitySolve crackingMetallic material coating processesLaser beam welding apparatusWear resistantAlloy

The invention belongs to the technical field of roller repairing, particularly relates to the technical field of laser welding repairing, in particular to a laser repairing method of a damaged roller.The laser repairing method includes the following steps: a wear failure layer on the surface of the roller is removed first, and then the roller is turned and ground to achieve the consistency with afinished roller body; then a chrome-contained steel plate is selected, a layer of high-hardness wear-resistant material is coated on the surface of the chrome-contained steel plate, the chrome-contained steel plate is heated, then rolled on the roller in the form of an insert bush to form a C ring, and a joint of the C ring is welded through a laser; and finally, a layer of self-melting alloy powder is coated on the surface of the insert bush through the laser. According to the laser repairing method of the damaged roller, the problems that the bonding strength between a repairing layer and aroller base body is low, cladding materials are difficult to accumulate on a roller carrying a cylinder, and since the volume of the roller is large and heat dissipation is fast, cracks are producedby the pressure caused by rapid cooling when laser spots leave are solved, and the Rockwell hardness of the repaired roller can be improved to be 65 HRC or above.

Owner:江苏镭电嘉成激光科技有限公司

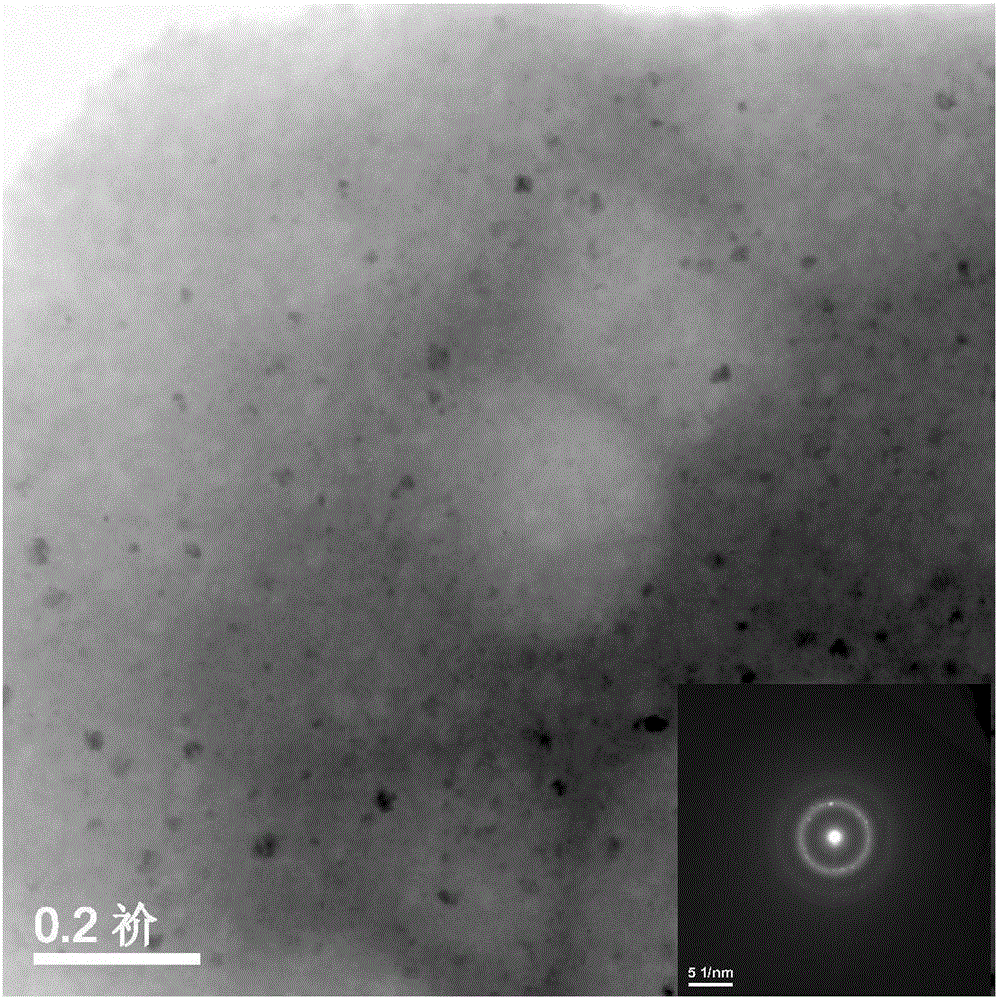

Iron-based amorphous coating and preparation method thereof

The invention discloses an iron-based amorphous coating and a preparation method of the iron-based amorphous coating through a plasma surfacing method. Alloy powder is prepared after being made up according to a specific proportion, and an alloy coating is formed on the surface of a substrate through surfacing conducted by a plasma surfacing machine, and technological parameters are as follows, the welding voltage is 25-30 V, the welding current is 140-200 A, the welding speed is 35-40 mm / min, the shielding gas flow speed is 10-12 L / min, the powder feeding speed is 15-25 g / min, and the swing amplitude is 20-30 mm; and after the plasma surfacing is completed, the coating is awaited to be naturally cooled to the room temperature, and the preparation of the iron-based amorphous coating is completed. An iron-based surfacing coating prepared through the plasma surfacing method is high in hardness, good in abrasion resistance, and can be widely applied to the manufacturing and restoring of metallurgical machinery and petrochemical equipment. In addition, the plasma surfacing method for preparing the coating is simple in process, easy and convenient to operate and free of weld preheating and post-weld slow cooling; the coating after being subjected to the surfacing is free of cracks and peeling, and the coating is formed well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

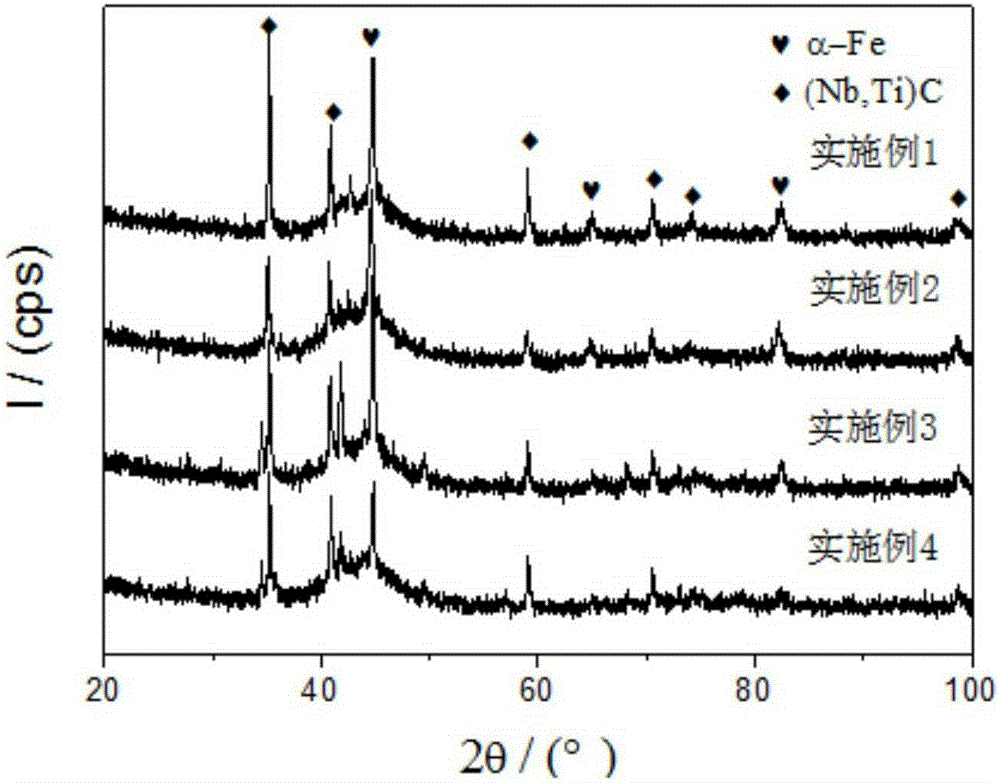

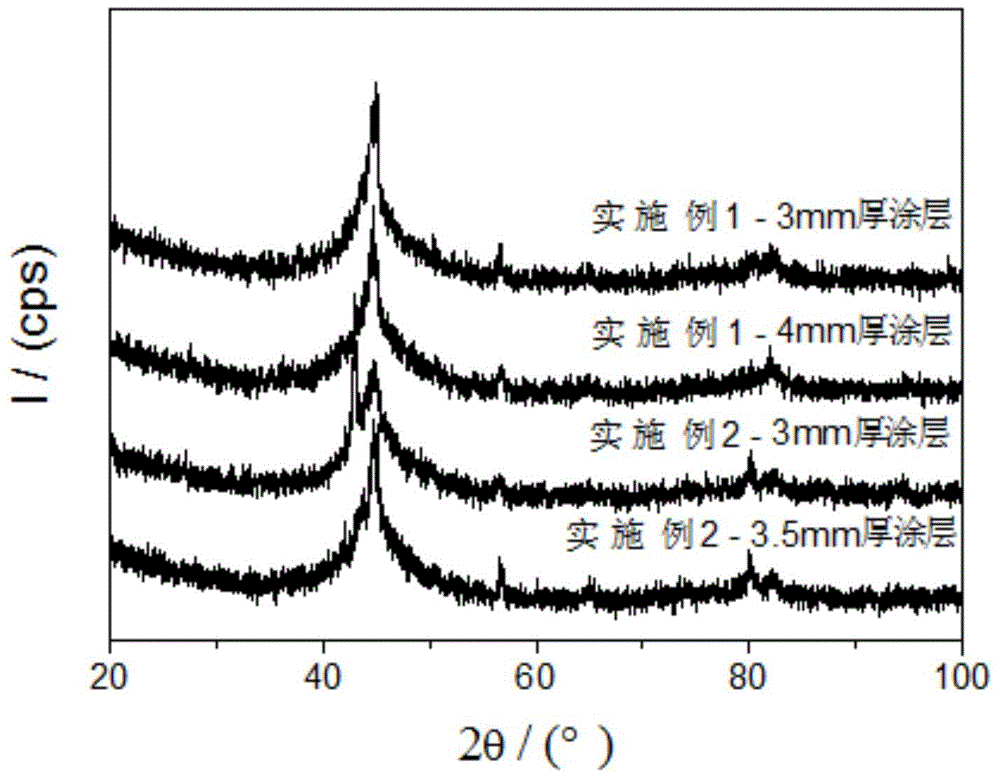

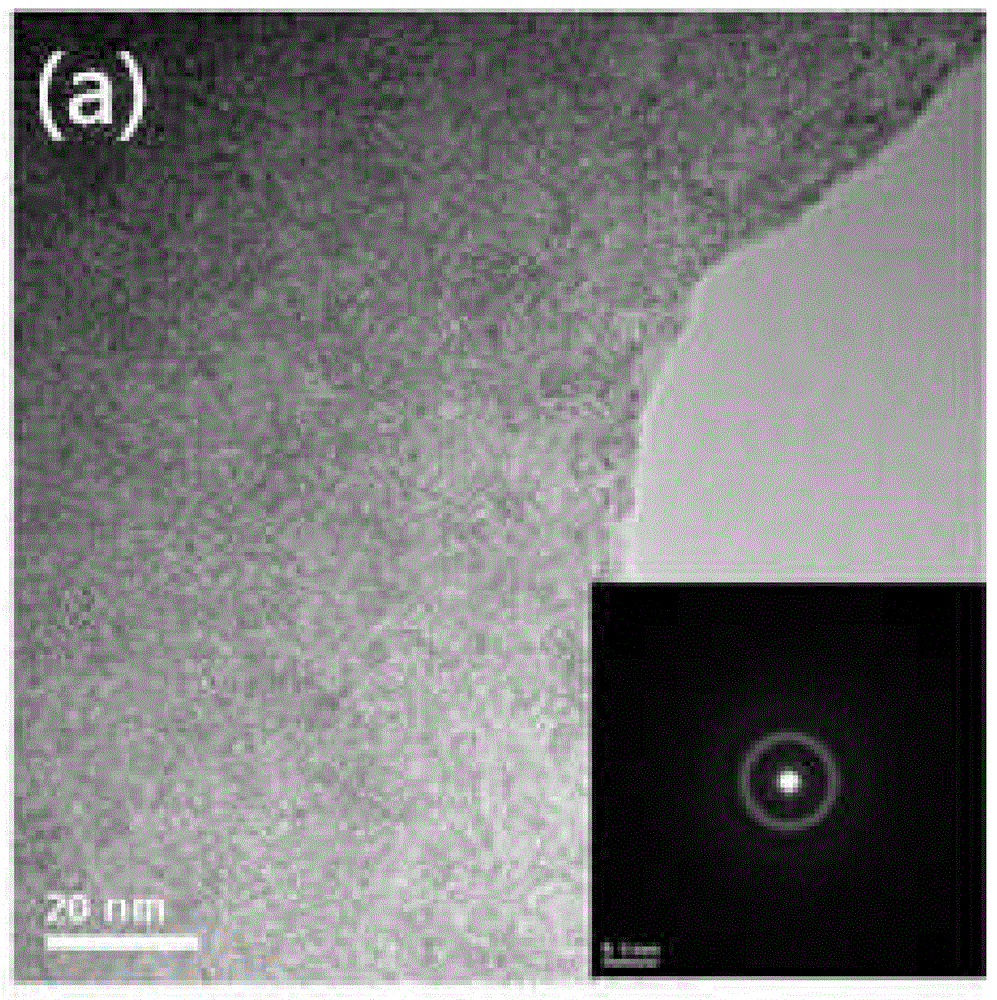

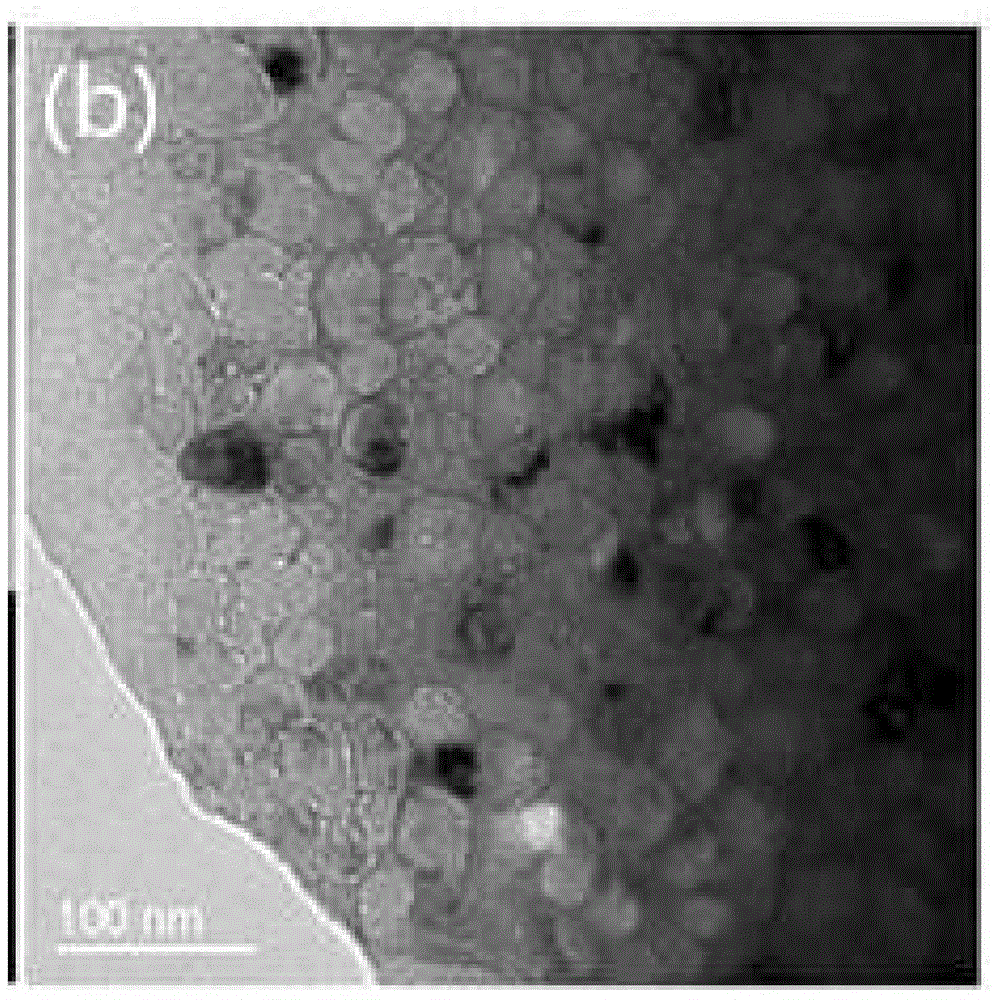

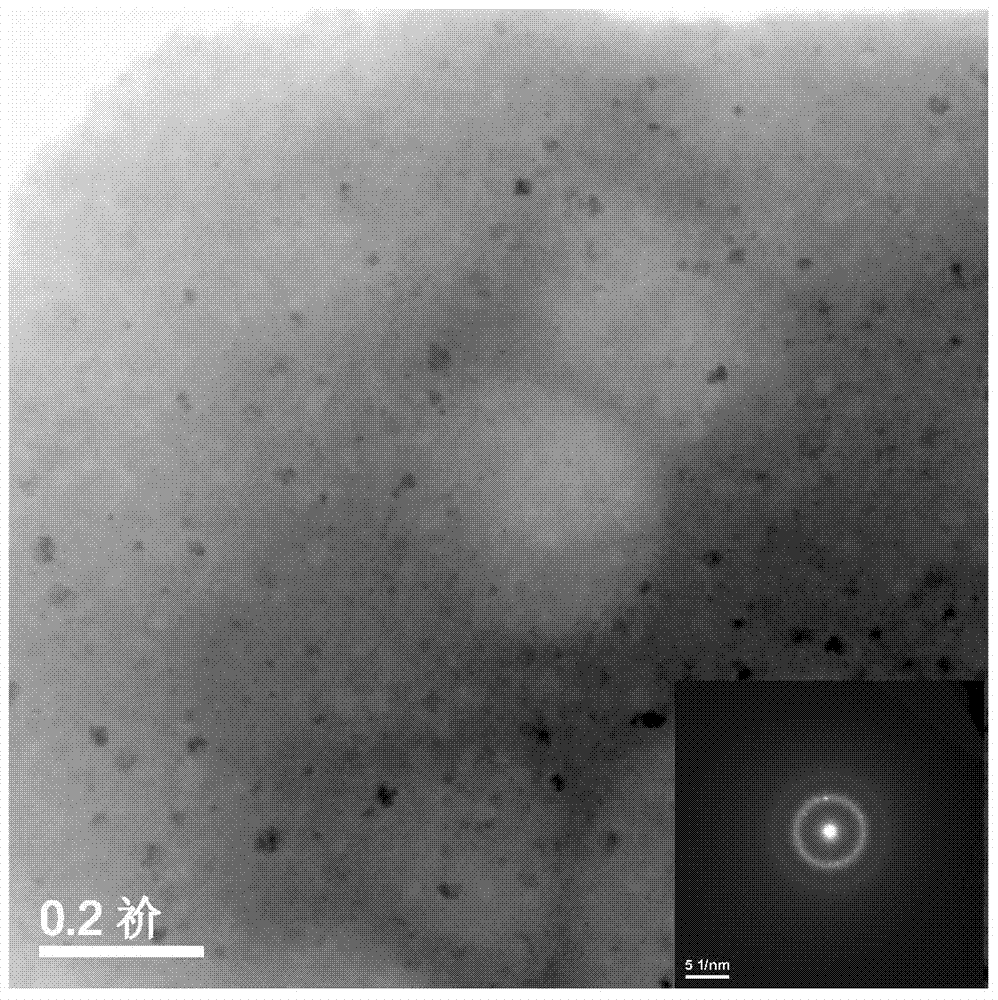

Iron-based amorphous nanocrystalline composite coating and preparation method thereof

The invention discloses an iron-based amorphous nanocrystalline composite coating and a preparation method of preparing the iron-based amorphous nanocrystalline composite coating by adopting a plasma surfacing method. Alloy powder which is prepared according to the specified proportion is subjected to surfacing on the surface of a base material by adopting a plasma surfacing machine to form an alloy coating, wherein the technical parameters comprise: the welding voltage is 25-30 V, the welding current is 140-190 A, the welding speed is 35-40 mm / min, the shielding gas flow is 10-12 L / min, the powder feed speed is 15-25 g / min and the amplitude of swing is 20-30 mm. when the plasma surfacing ends, after the coating is naturally cooled to the room temperature, the preparation of the iron-based amorphous nanocrystalline composite coating is completed. The iron-based amorphous nanocrystalline composite coating which is prepared by the plasma surfacing method is high in rigidity and good in wear-resisting property and can be widely applied to manufacturing and repair of metallurgical machinery and petrochemical engineering apparatuses. In addition, the coating prepared by the plasma surfacing method has the advantages that the technology is simple; the operation is simple and easy; no preheating before welding and no slow cooling after welding are needed; after surfacing, the coating has no cracks and no peeling, and the forming of the coating is excellent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Modified SEBS (styrene-ethylene/butadiene-styrene block copolymer) alloy and preparation method thereof

The invention discloses a modified SEBS (styrene-ethylene / butadiene-styrene block copolymer) alloy and a preparation method thereof. The SEBS alloy is prepared from the following components in parts by weight: 80-100 parts of styrene block copolymer, 2-5 parts of white oil, 25-35 parts of polyolefin elastomer and 30-40 parts of antimony chromate / titanium dioxide nano composite material, wherein the antimony chromate / titanium dioxide nano composite material is synthesized by antimony nitrate, ammonium metachromate, 3-nitro-1, 2, 4- triazole-5-ketone and nano TiO2. According to the invention, the antimony chromate / titanium dioxide nano composite material is added, thus, degree of crystallinity of the SEBS alloy material is improved, and flexural modulus, hardness, tensile strength and other properties of the modified SEBS alloy are all improved to a greater extent.

Owner:滁州格美特科技有限公司

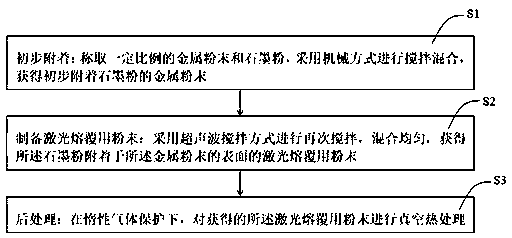

Powder for laser cladding, preparation method and application thereof

InactiveCN110846660AImprove performanceImprove wear resistanceTransportation and packagingMetal-working apparatusGraphiteMetal powder

The invention relates to the technical field of laser surface treatment, and discloses a powder for laser cladding and a preparation method and application thereof. The powder for laser cladding comprises metal powder and graphite powder, wherein the graphite powder is attached to the surface of the metal powder; and by the mass of the powder for laser cladding, the mass ratio of the metal powderto the graphite powder is 100: (0.2-10). The powder for laser cladding can improve the strength, hardness and wear resistance of the workpiece surface after laser cladding.

Owner:西安鑫精合智能制造有限公司

Manufacturing method for bearing with Rockwell hardness improved

The invention discloses a manufacturing method for a bearing with the Rockwell hardness improved. The method includes the following processes that a steel material is melted in a high-frequency vacuum melting furnace, then casting is conducted, the cooling speed in the casting process is 1.2 DEG C / min, and an ingot material is formed; the ingot material is maintained for 10 hours at the temperature of 950 DEG C and then is maintained for 90 minutes at the temperature of 500 DEG C; afterwards, a hammer forging machine 500 tons in weight is used for hot forging, and bearing steel is manufactured; and the bearing steel is pressed and formed in the forging machine, and therefore the bearing is manufactured. The steel material comprises, by weight, 0.25%-0.29% of carbon, 0.10%-1.20% of manganese, 0.09%-0.13% of phosphorus, 0.10%-0.19% of sulfur, 0.60%-1.00% of silicon, smaller than or equal to 0.09% of aluminum, smaller than or equal to 0.01% of nitrogen, 0.45%-0.83% of chromium, 0.04%-0.07% of niobium, smaller than or equal to 0.50% of copper, 0.05%-0.60% of nickel, 0.2%-2.00% of molybdenum, 0.2%-0.4% of vanadium, 0.0030%-0.0065% of boron, 0.010%-0.050% of titanium and the balance iron and inevitable impurities. By means of the method, the bearing with the Rockwell hardness improved can be manufactured.

Owner:徐文萍

Bearing steel with enhanced Rockwell hardness

The present invention relates to bearing steel with the enhanced Rockwell hardness. The bearing steel with the enhanced Rockwell hardness is composed of (by weight percentage): 0.25%-0.29% of carbon; 0.10%-1.20% of manganese; 0.09%-0.13% of phosphorus; 0.10%-0.19% of sulfur; 0.60%-1.00% of silicon; 0.09% or less of aluminum; 0.01% or less of nitrogen; 0.45%-0.83% of chromium; 0.04%-0.07% of niobium; 0.50% or less of copper; 0.05%-0.60% of nickel; 0.2%-2.00% of molybdenum; 0.2%-0.4% of vanadium; 0.0030%-0.0065% of boron; 0.010%-0.050% of titanium; and the residual of iron and unavoidable impurities. The bearing steel has the enhanced Rockwell hardness and can be widely applied to the field of bearings.

Owner:徐文萍

Iron-based amorphous nanocrystalline composite coating with high amorphous content and preparation method thereof

The invention discloses an iron-based amorphous nanocrystalline composite coating with high amorphous content and a preparation method of preparing the iron-based amorphous nanocrystalline composite coating with high amorphous content by adopting a plasma surfacing method. Alloy powder which is prepared according to the specified proportion is subjected to surfacing on the surface of a base material by adopting a plasma surfacing machine to form an alloy coating, wherein the technical parameters comprise: the welding voltage is 25-30 V, the welding current is 140-190 A, the welding speed is 35-40 mm / min, the shielding gas flow is 10-12 L / min, the powder feed speed is 15-25 g / min and the amplitude of swing is 20-30 mm. when the plasma surfacing ends, after the coating is naturally cooled to the room temperature, the preparation of the iron-based amorphous nanocrystalline composite coating with high amorphous content is completed. The iron-based amorphous nanocrystalline composite coating with high amorphous content, which is prepared by the plasma surfacing method, is high in rigidity and good in wear-resisting property and can be widely applied to manufacturing and repair of metallurgical machinery and petrochemical engineering apparatuses. In addition, the coating prepared by the plasma surfacing method has the advantages that the technology is simple; the operation is simple and easy; no preheating before welding and no slow cooling after welding are needed; after surfacing, the coating has no cracks and no peeling, and the forming of the coating is excellent.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

A kind of cemented carbide and its manufacturing method

ActiveCN107385304BLower sintering temperatureHigh Rockwell hardnessTransportation and packagingMetal-working apparatusTemperature controlGasoline

Owner:GANZHOU WHISKAS ALLOY

A hot work die steel with high temperature resistance and high toughness and its preparation method

The invention relates to high-temperature-resistant and high-toughness hot work die steel and a preparation method thereof. The hot work die steel is mainly composed of, by mass, 0.50-0.65% of C, 0.7-1.3% of Si, 0.6-1.0% of Mn, 2.5-4.5% of Cr, 2.7-4.5% of Mo, 0.5-1.1% of V, 0-0.02% of P, 0-0.0005% of S, and the balance Fe. According to the hot work die steel, the use amounts of all components of H13 die steel are improved, so that the weight percentage of C is increased to 0.50-0.65%, the weight percentage of Mn is increased to 0.6-1.0%, the content of Cr is decreased to 2.5-4.5%, and the weight percentage of Mo is increased to 2.7-4.5%; and the four chemical components are adjusted at the same time, the optimal proportion is achieved, and accordingly the prepared die steel is excellent in hardness and high-temperature resistance and high in toughness.

Owner:TIANJIN CISRI HARDER MATERIALS & TECH

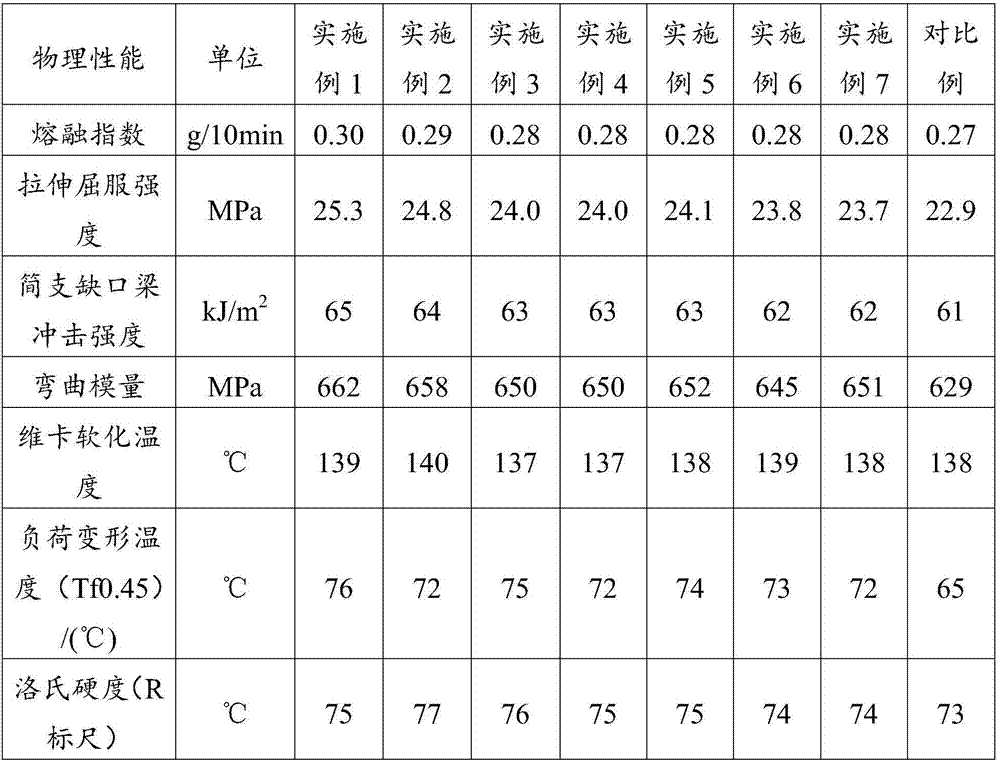

Compound additive for polypropylene random copolymer tubular product

The invention discloses a compound additive for a polypropylene random copolymer tubular product. The compound additive is prepared from the following components in parts by weight: 10 to 20 parts ofa processing auxiliary agent, 10 to 30 parts of a long-acting antioxidant, 40 to 60 parts of an antioxidant and 10 to 30 parts of stearate. According to the compound additive for the polypropylene random copolymer tubular product, disclosed by the invention, the processing auxiliary agent is added so that the processing performance of materials is easy to improve; the surface evenness and smoothness of a product are improved and the abrasion of equipment is reduced; the long-acting antioxidant is added so that the hot water washing resisting performance of the product is improved and the long-period weather resisting performance of the product is kept; properties including the melt index, the tensile yield strength, the impact strength of a simply supported notch beam, the bending modulus,the load deformation temperature, the Rockwell hardness and the like of the materials are effectively improved.

Owner:广州赫尔普化工有限公司

A kind of modified sebs alloy and preparation method thereof

The invention discloses a modified SEBS (styrene-ethylene / butadiene-styrene block copolymer) alloy and a preparation method thereof. The SEBS alloy is prepared from the following components in parts by weight: 80-100 parts of styrene block copolymer, 2-5 parts of white oil, 25-35 parts of polyolefin elastomer and 30-40 parts of antimony chromate / titanium dioxide nano composite material, wherein the antimony chromate / titanium dioxide nano composite material is synthesized by antimony nitrate, ammonium metachromate, 3-nitro-1, 2, 4- triazole-5-ketone and nano TiO2. According to the invention, the antimony chromate / titanium dioxide nano composite material is added, thus, degree of crystallinity of the SEBS alloy material is improved, and flexural modulus, hardness, tensile strength and other properties of the modified SEBS alloy are all improved to a greater extent.

Owner:滁州格美特科技有限公司

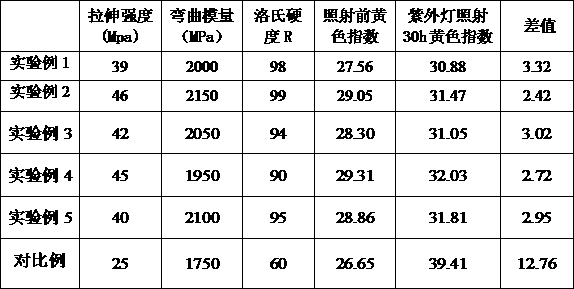

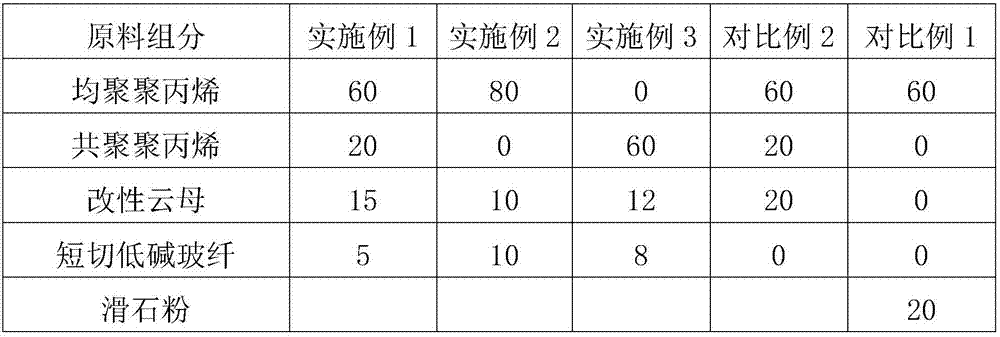

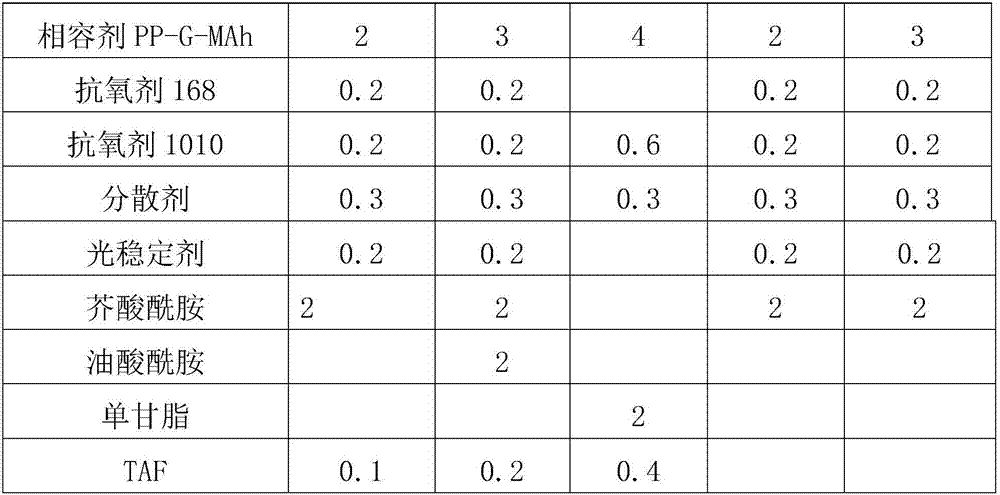

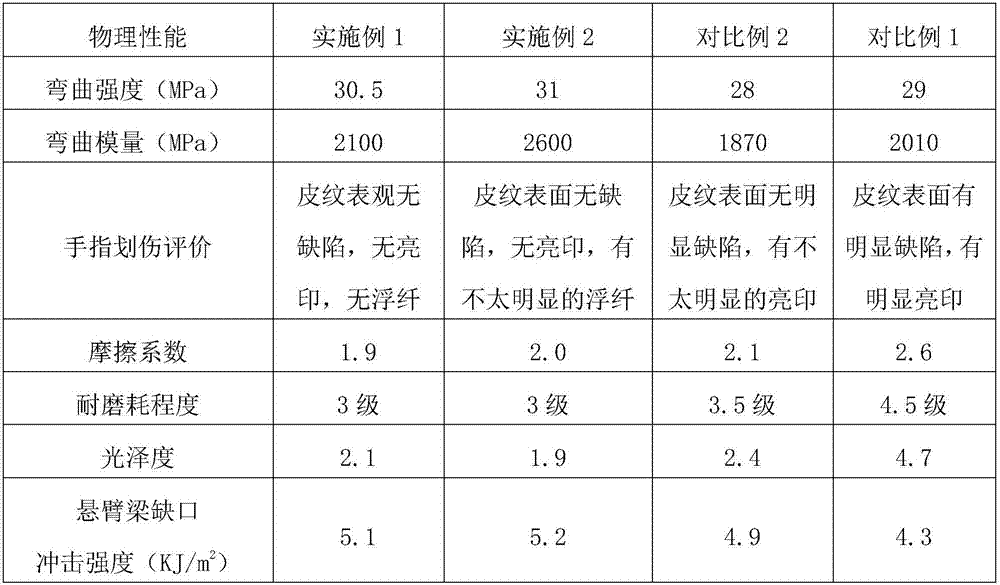

Modified polypropylene composite material with high wear resistance and preparation method of modified polypropylene composite material

InactiveCN107501727AHigh Rockwell hardnessImproved finger scratch resistanceGlass fiberPolypropylene composites

The invention discloses a modified polypropylene composite material with high wear resistance. The modified polypropylene composite material is prepared from raw materials in parts by weight as follows: 60-75 parts of polypropylene, 10-15 parts of modified mica, 5-10 parts of glass fibers, 2-4 parts of a compatilizer, 2 parts of a surface slipping agent, 0.2-0.4 parts of a surface floating fiber resisting auxiliary and 0.9 parts of other auxiliaries. With addition of modified mica, the glass fibers, the compatilizer and the other auxiliaries, the dispersion condition of the modified mica and the glass fibers in a matrix is better, and the matrix is combined with the material more stably, so that finger scratching resistance of the material is improved; the finger scratching resistance of the surface of the composite material is excellent, the surface has no obvious change after being scratched, notch impact strength is higher than 5 KJ / m<2>, bending modulus is higher than 2000 MPa, and the use range of the material is wide.

Owner:ORINKO NEW MATERIAL CO LTD

Preparation process of metal wear-resistant alloy flange

The invention discloses a preparation process of a metal wear-resistant alloy flange, and particularly relates to the technical field of flange manufacturing. The preparation process comprises the following steps of raw material preparation and casting raw material preparation, specifically, raw materials comprise 0.8-1.2% of carbon, 0.6-0.8% of silicon, 18-22% of chromium, 2.2-3.2% of manganese,0.2-0.6% of vanadium, 0.01-0.03% of phosphorus, 0.4-0.8% of nickel, 0.2-0.5% of molybdenum, 0.2-0.4% of nitrogen, 0.06-0.08% of zinc and the balance copper, iron and inevitable impurities. According to the preparation process, an inner core layer and a high-chromium cast iron shell are arranged, so that the weight of the flange manufactured through the preparation process can be obviously reducedwithin a certain range on the premise that the hardness and the strength of the flange are not affected, moreover, carbon fibers can be selected from some leftover materials in a carbon fiber production workshop, and the material cost is low; and compared with a traditional metal flange preparation method at present, the flange prepared through the preparation process is formed by combining the high-chromium cast iron shell and the inner core layer, so that the flange has the advantages of being high in strength, toughness and wear resistance, low in manufacturing cost, small in weight and convenient to carry and transport.

Owner:湖北恩腾机械有限公司

A kind of preparation method of ceramic particle metal composite material

ActiveCN107598136BLarge real surface areaHigh bonding strengthFoundry mouldsLiquid/solution decomposition chemical coatingChemical platingParticulate metal

The invention provides a preparation method of a ceramic particle metal composite material. The preparation method comprises the following steps that ceramic particles are subjected to surface pretreatment and then placed into a chemical plating solution, and thus nickel-plated ceramic particles are obtained; an electric heating resistance wire is used for cutting a foam plate; the nickel-plated ceramic particles are washed and dried, and then coats the surface of a foam specimen, after drying, the foam specimen is bonded with a cross gate, a sprue and an ingate, and thus a lost foam casting white foam is obtained; the prepared lost foam casting white foam is placed into a sand box filled with dry sand, the dry sand is vibrated to be compacted and scraped to be flat, a plastic thin film isused for covering, a pouring cup is placed, and the negative pressure is pumped; after the dry sand is firm and is formed, metal liquid is cast; and after casting, vacuum relief, cooling and solidification then polishing are conducted. According to the preparation method of the ceramic particle metal composite material, the Rockwell hardness, impact toughness and overall abrasion resistance of the prepared composite material are greatly improved, no element diffusion exists between the ceramic particles and a metal substrate at the composite interface, and the bonding strength between the ceramic particles and metal is high.

Owner:安徽省凤形新材料科技有限公司 +1

Novel slag melting agent, preparation method and application of novel slag melting agent in preparation of high-purity hypereutectic niobium-chromium-containing 28 cast iron

PendingCN114507767AStrong alkalinityIncrease surface adsorption capacityProcess efficiency improvementNiobiumSesbania gum

The invention discloses a novel slag melting agent, a preparation method of the novel slag melting agent and application of the novel slag melting agent to preparation of high-purity hypereutectic niobium-chromium-containing 28 cast iron. Comprising the following raw materials: 9-13 parts of perlite powder, 3-5 parts of aluminum powder, 14-18 parts of montmorillonite powder, 3-6 parts of fluorite powder, 10-16 parts of talcum powder, 4-8 parts of passivated lime powder, 6-10 parts of magnesium carbonate powder, 4-7 parts of medical stone powder, 2-5 parts of quartz powder, 2.6-4.8 parts of sesbania gum and 18-25 parts of water. According to the high-purity hypereutectic niobium-chromium-containing 28 cast iron prepared through the technology, the oxygen content is 10.8 ppm, the hydrogen content is 3.1 ppm, the Rockwell hardness value (HRC) is 64.1, the high-purity hypereutectic niobium-chromium-containing 28 cast iron can be used for overflowing part pump bodies, impellers, various powder conveying pipelines, liners and the like of small pumps (8 inches), and the use effect is good.

Owner:广西长城机械股份有限公司

A kind of iron-based amorphous coating and preparation method thereof

The invention discloses an iron-based amorphous coating and a preparation method of the iron-based amorphous coating through a plasma surfacing method. Alloy powder is prepared after being made up according to a specific proportion, and an alloy coating is formed on the surface of a substrate through surfacing conducted by a plasma surfacing machine, and technological parameters are as follows, the welding voltage is 25-30 V, the welding current is 140-200 A, the welding speed is 35-40 mm / min, the shielding gas flow speed is 10-12 L / min, the powder feeding speed is 15-25 g / min, and the swing amplitude is 20-30 mm; and after the plasma surfacing is completed, the coating is awaited to be naturally cooled to the room temperature, and the preparation of the iron-based amorphous coating is completed. An iron-based surfacing coating prepared through the plasma surfacing method is high in hardness, good in abrasion resistance, and can be widely applied to the manufacturing and restoring of metallurgical machinery and petrochemical equipment. In addition, the plasma surfacing method for preparing the coating is simple in process, easy and convenient to operate and free of weld preheating and post-weld slow cooling; the coating after being subjected to the surfacing is free of cracks and peeling, and the coating is formed well.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

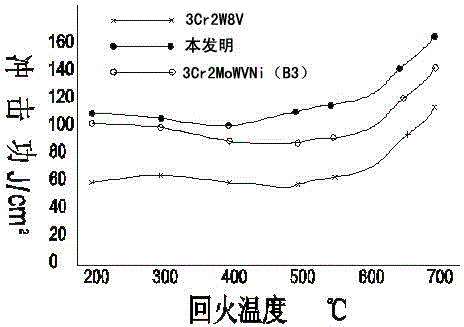

B3R hot work die steel with high strength and toughness and resistance to tempering, and preparation process thereof

The invention provides 4Cr3MoWVNi (B3R) hot work die steel with high strength and toughness and resistance to tempering, and a preparation process thereof. Raw materials for preparing the B3R hot work die steel comprise, by weight, C 0.35 to 0.42%, Si 0.15 to 0.35%, Mn 0.3 to 0.5%, Cr 2.50 to 3.50%, Mo 1.00 to 1.50%, W 0.50 to 0.80%, V 0.50 to 0.80%, Ni 1.45 to 1.85%, S 0.003 to 0.010% and P 0.008 to 0.018%, with the balance being Fe. The preparation process comprises the following steps: smelting at intermediate frequency--remelting (refining) of electroslag-diffusion hydrogen of electroslagingots, annealing treatment of electroslag ingots--forging--annealing of forging stocks--rough machining--vacuum heat treatment, and secondary tempering so as to obtain the novel product of die steel. The hot work die steel prepared in the invention has high Rockwell hardness, excellent impact toughness and tempering (thermal fatigue) resistance, and the advantages of optimized collocation of components, pure steel quality, a uniform structure, high strength, strong toughness, good tempering resistance, etc.

Owner:SHANDONG YUANDA MATERIAL TECH CO LTD

Reinforced and antifriction ultra-high molecular weight polyethylene composite material

The invention relates to a strength reinforced and antifriction ultrahigh molecular weight polyethylene composite material. The composite material comprises ultrahigh molecular weight polyethylene and superfine inorganic powder. The composite material adopts the coupling agent processed superfine inorganic powder for filling, and is prepared through solid phase grafting technology, thereby obviously improving the compatibility of components and functionally modifying the surface of the composite material. The solid phase grafting technology has little solvent consumption, simple production equipment, convenience for the industrialized production, and good development prospect.

Owner:SHANGHAI RES INST OF CHEM IND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com