Modified SEBS (styrene-ethylene/butadiene-styrene block copolymer) alloy and preparation method thereof

An alloy and modification technology, applied in the field of modified SEBS alloy and its preparation, can solve problems such as poor mechanical properties, and achieve the effects of improving application effect, increasing crystallinity, good physical properties and anti-aging properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

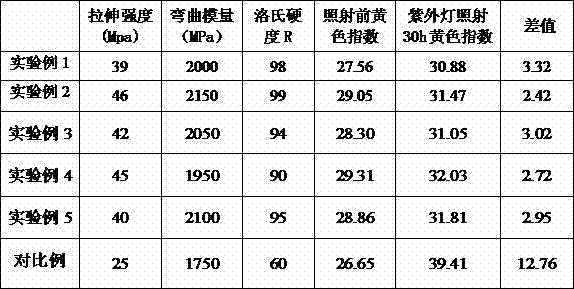

Examples

Embodiment 1

[0027] (1) First dissolve antimony nitrate and ammonium metachromate in nitric acid at a molar ratio of 1:1 to obtain a yellow solution; then add 3-nitro-1 with a molar ratio of 1:5:12 to antimony nitrate ,2,4-triazol-5-one (NTO), nano-TiO 2 Particles were further hydrothermally treated in a reactor at 160°C for 15 hours to obtain SbCrO 3 / TiO 2 nanocomposites.

[0028] (2) Mix 80 parts of SEBS resin, 2 parts of white oil, 25 parts of POE, SbCrO 3 / TiO 2 30 parts of nanocomposite materials were uniformly stirred in a high mixer for 10 minutes at room temperature.

[0029] (3) Melt the mixed material with a twin-screw extruder, extrude and pelletize, and then knead the pellets at 50°C to obtain a modified SEBS alloy. Among them, the temperature of zone 1 of the twin-screw extruder is 100°C, the temperature of zone 2 is 100°C, the temperature of zone 3 is 100°C, the temperature of zone 4 is 120°C, the temperature of zone 5 is 120°C, the temperature of zone 6 is 120°C, and t...

Embodiment 2

[0031] (1) First dissolve antimony nitrate and ammonium metachromate in nitric acid at a molar ratio of 1:1 to obtain a yellow solution; then add 3-nitro-1 with a molar ratio of 1:5:12 to antimony nitrate ,2,4-triazol-5-one (NTO), nano-TiO 2 Particles were further hydrothermally treated in a reactor at 180°C for 12 hours to obtain SbCrO 3 / TiO 2 nanocomposites.

[0032] (2) 100 parts of SEBS resin, 5 parts of white oil, 35 parts of POE, SbCrO 3 / TiO 2 40 parts of nanocomposite materials were uniformly stirred in a high mixer for 11 minutes at room temperature.

[0033] (3) Melt the mixed material with a twin-screw extruder, extrude and pelletize, and then knead the pellets at 60°C to obtain a modified SEBS alloy. The temperature of zone 1 of the twin-screw extruder is 120°C, the temperature of zone 2 is 120°C, the temperature of zone 3 is 120°C, the temperature of zone 4 is 160°C, the temperature of zone 5 is 160°C, and the temperature of zone 6 is 160°C. The temperature...

Embodiment 3

[0035] (1) First dissolve antimony nitrate and ammonium metachromate in nitric acid at a molar ratio of 1:1 to obtain a yellow solution; then add 3-nitro-1 with a molar ratio of 1:5:12 to antimony nitrate ,2,4-triazol-5-one (NTO), nano-TiO 2 Particles were further hydrothermally treated in a reactor at 170°C for 13h to obtain SbCrO 3 / TiO 2 nanocomposites.

[0036] (2) 85 parts of SEBS resin, 4 parts of white oil, 30 parts of POE, SbCrO 3 / TiO 2 35 parts of nanocomposite materials were uniformly stirred in a high mixer for 12 minutes at room temperature.

[0037] (3) Melt the mixed material with a twin-screw extruder, extrude and pelletize, and then knead the pellets at 60°C to obtain a modified SEBS alloy. The temperature of zone 1 of the twin-screw extruder is 110°C, the temperature of zone 2 is 120°C, the temperature of zone 3 is 110°C, the temperature of zone 4 is 140°C, the temperature of zone 5 is 150°C, and the temperature of zone 6 is 140°C The temperature in Zon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com