A kind of cemented carbide and its manufacturing method

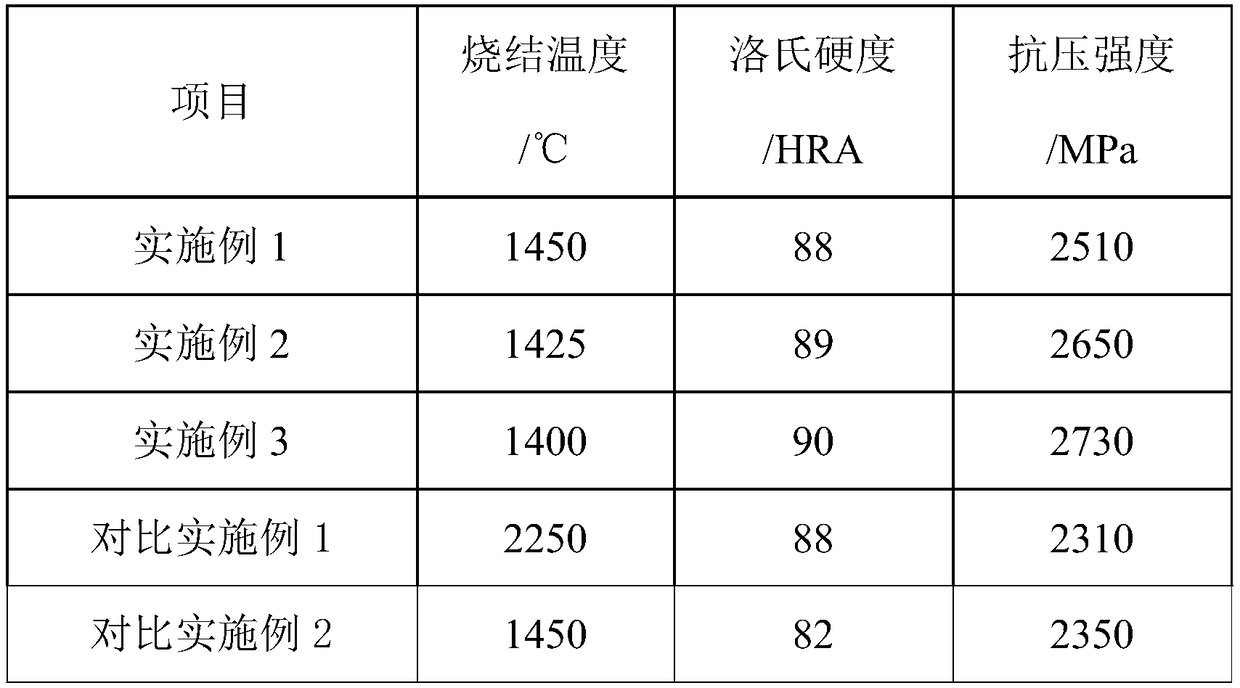

A technology of hard alloy and manufacturing method, which is applied in the field of alloy manufacturing, can solve problems such as insufficient hardness, holes, and high sintering temperature, and achieve the effect of increasing Rockwell hardness HRA and improving compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

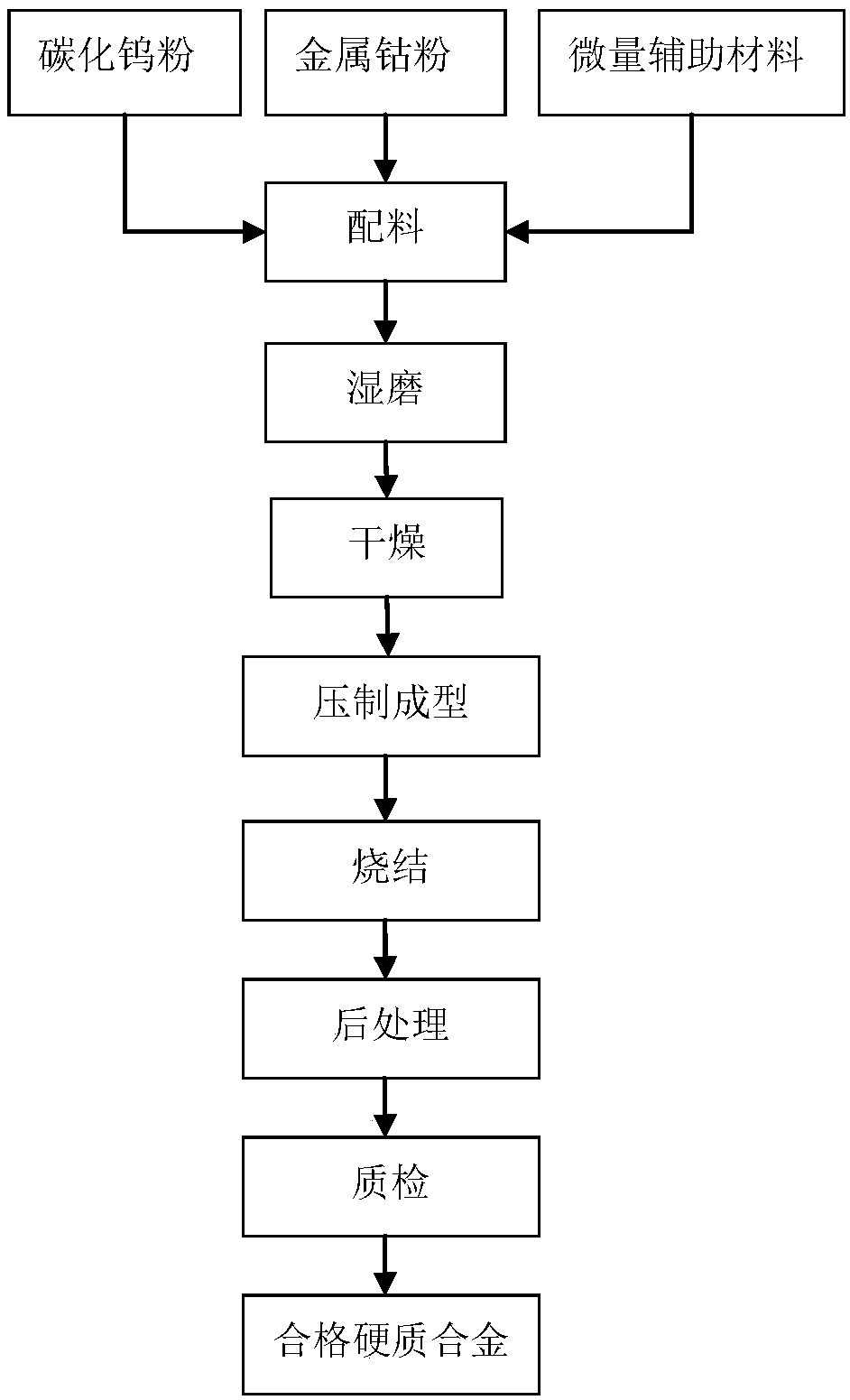

[0040] like figure 1 As shown, a kind of cemented carbide is provided in the embodiment, implement according to the following steps:

[0041] S1 ingredients: Take 85 parts of tungsten carbide powder, 15 parts of cobalt powder, and 0.6 part of tantalum carbide with the average particle size of the raw materials being 10 μm, and add them into the mixing chamber for preliminary mixing to obtain the ingredient mixture;

[0042] S2 Wet milling and sieving: transfer the ingredient mixture to a ball mill for wet milling, the ball mill rotating speed is 30r / min, add methanol with a mass fraction of 98% in 5 times while grinding, and the addition amount is 1 / 2 of the volume of the ingredient mixture 30%, during the wet grinding process, the exhaust operation is carried out at a frequency of every 2 hours. After grinding for 72 hours, pass through a 320-mesh sieve to obtain a sieved mixture;

[0043] S3 drying: the sieved mixture is preliminarily dried using a vacuum steam drier connec...

Embodiment 2

[0057] like figure 1 As shown, a kind of cemented carbide is provided in the embodiment, implement according to the following steps:

[0058] S1 ingredients: Take 86 parts of tungsten carbide powder, 14 parts of cobalt powder, and 0.4 part of niobium carbide with an average particle size of 10 μm and add them into the mixing chamber for preliminary mixing to obtain the batching mixture;

[0059] S2 Wet milling and sieving: transfer the ingredient mixture to a ball mill for wet milling, the ball mill speed is 40r / min, and add ethanol with a mass fraction of 98.8% in 4 times while grinding, and the addition amount is 2% of the volume of the ingredient mixture 40%, during the wet grinding process, the exhaust operation is carried out at a frequency of every 5 hours. After grinding for 54 hours, pass through a 320-mesh sieve to obtain a sieved mixture;

[0060] S3 drying: the sieved mixture is preliminarily dried using a vacuum steam drier connected to a dispersant recovery devic...

Embodiment 3

[0074] like figure 1 As shown, a kind of cemented carbide is provided in the embodiment, implement according to the following steps:

[0075] S1 ingredients: Take 87 parts of tungsten carbide powder, 13 parts of cobalt powder, and 0.2 part of chromium carbide with an average particle size of 8 μm and add them into the mixing chamber according to the proportion for preliminary mixing to obtain the batching mixture;

[0076] S2 Wet milling and sieving: transfer the ingredient mixture to a ball mill for wet milling, the ball mill speed is 50r / min, and add methanol with a mass fraction of 99% in 3 times while grinding, and the addition amount is the volume of the ingredient mixture 50%, during the wet grinding process, the frequency of processing once every 5 hours is used for exhaust operation. After grinding for 36 hours, pass through a 320-mesh sieve to obtain a sieved mixture;

[0077] S3 drying: the sieved mixture is preliminarily dried using a vacuum steam drier connected t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com