Method for recycling polystyrene shell materials of waste electrical appliances

A technology of waste polystyrene and polystyrene, which is applied in recycling technology, plastic recycling, etc., can solve the problems of low performance of blended modified products, easy delamination of blends, and limited practical application, and achieves improved Tensile strength, reduce white pollution, and expand the effect of application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

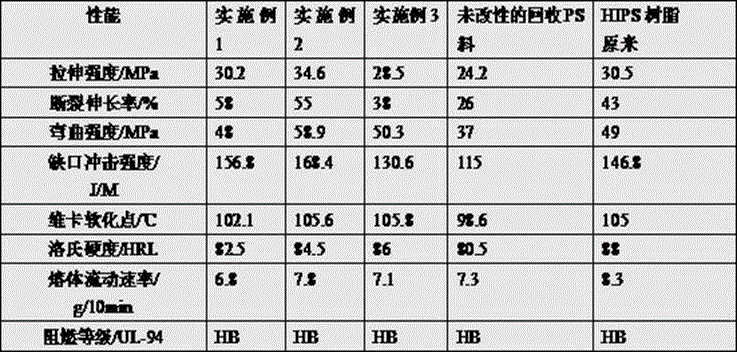

Examples

Embodiment 1

[0052] 1) Weigh each raw material according to the following parts:

[0053] 70 pieces of waste polystyrene shell material;

[0054] Resin raw material HIPS original rice 10 copies;

[0055] Toughening agent methyl methacrylate-butadiene-styrene graft copolymer (MBS) 10 parts;

[0056] 6 parts of reinforced filler nano-montmorillonite;

[0057] 0.1 part of coupling agent KH550;

[0058] Antioxidant 1010 0.5 parts;

[0059] Diffusion agent ethylene bis-stearate (EBS) 1.2 parts;

[0060] Lubricant barium stearate 0.8 part;

[0061] 1 part white oil;

[0062] 2) Add the above raw materials to the high-speed mixer, and mix for 3 minutes to obtain the premix;

[0063] 3) Add the premix obtained in step 2) into a granulator, and granulate at 180-210°C to obtain modified granules;

[0064] 4) The modified pellets obtained in step 3) are put into an injection molding machine to be injected into a test strip.

Embodiment 2

[0066] 1) Weigh each raw material according to the following parts:

[0067] 78 pieces of waste polystyrene shell material;

[0068] Resin raw material K resin: 6 parts;

[0069] Toughening agent styrene-[ethylene-butylene copolymer]-styrene (SEBS) 8 parts;

[0070] 3 parts of reinforcing filler nano calcium carbonate;

[0071]0.8 part of coupling agent KH550;

[0072] Antioxidant 168 0.1 part;

[0073] Diffusion agent polyethylene wax 3 parts;

[0074] 1 part of lubricant sodium stearate;

[0075] 1 part white oil;

[0076] 2) Add the above raw materials to a high-speed mixer, and mix for 5 minutes to obtain a premix;

[0077] 3) Add the premix obtained in step 2) into a granulator, and granulate at 180-210°C to obtain modified granules;

[0078] 4) The modified pellets obtained in step 3) are put into an injection molding machine to be injected into a test strip.

Embodiment 3

[0080] 1) Weigh each raw material according to the following parts:

[0081] 85 pieces of waste polystyrene shell material;

[0082] Resin raw material K resin: 5 parts;

[0083] Toughening agent thermoplastic polyurethane (TPU) 5 parts;

[0084] 2 parts of reinforcing filler talc;

[0085] 0.5 part of coupling agent KH550;

[0086] Antioxidant 2264 0.5 parts;

[0087] Diffusion agent ethylene bis-stearate (EBS) 1 part;

[0088] Lubricant zinc stearate 0.5 part;

[0089] 0.5 part of white oil;

[0090] 2) Add the above raw materials to the high-speed mixer, and mix for 4 minutes to obtain the premix;

[0091] 3) Add the premix obtained in step 2) into a granulator, and granulate at 180-210°C to obtain modified granules;

[0092] 4) The modified pellets obtained in step 3) are put into an injection molding machine to be injected into a test strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com