Patents

Literature

42results about How to "Less impurity elements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electroslag remelting method for difficult-processing high alloy stainless steel and electroslag remelting slag system adopting electroslag remelting method

InactiveCN102925712AImprove or increase thermoplasticityHigh yieldIncreasing energy efficiencySlagAlloy

The invention relates to an electroslag remelting method for difficult-processing high alloy stainless steel and an electroslag remelting slag system adopting the electroslag remelting method. The slag system comprises the components in parts by weight: 46-72 parts of CaF2, 15-28 parts of CaO, 24-10 parts of Al2O3 and 8-2 parts of MgO, wherein the content of impurities is less than 1.0%. The electroslag remelting slag system and the electroslag remelting method reduce the contents of harmful elements in steel, improve the purity, optimize the organization, particularly and remarkably improve the processing performance of the difficult-processing high alloy stainless steel and greatly improve the material yield.

Owner:CHONGQING MATERIALS RES INST

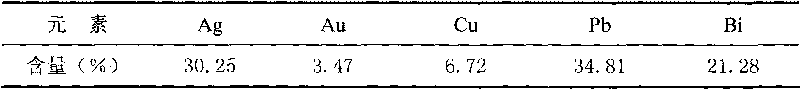

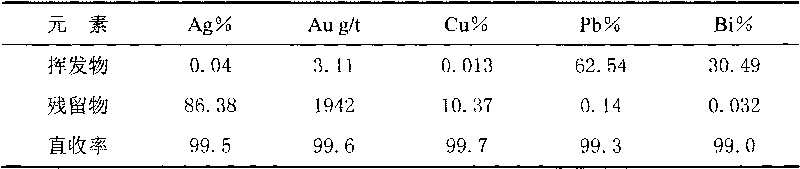

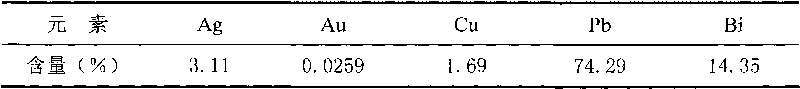

Method for separating multi-element alloy of lead, bismuth, gold, silver and copper

The invention relates to a method for separating a multi-element alloy of lead, bismuth, gold, silver and copper, which adopts a vacuum distillation method to treat the multi-element alloy, wherein the distillation temperature is 1,050 to 1,100 DEG C, the distillation time is 60 to 80min and the vacuum degree in a furnace is 5 to 15 Pa. Materials can be separated into a volatile (an alloy of lead and bismuth) and a residue (an alloy of gold, silver and copper). In the separated product, noble metals are gathered in 6 to 7 times; the recovery rate of each noble metal is over 99 percent; the loss of the noble metals is low; and the recovery rates of the lead and the bismuth are 98 percent and 98.5 percent respectively.

Owner:KUNMING UNIV OF SCI & TECH +1

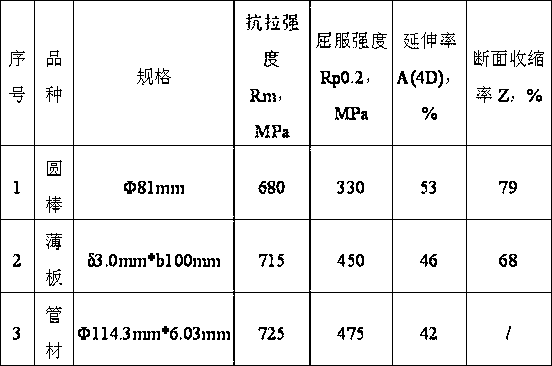

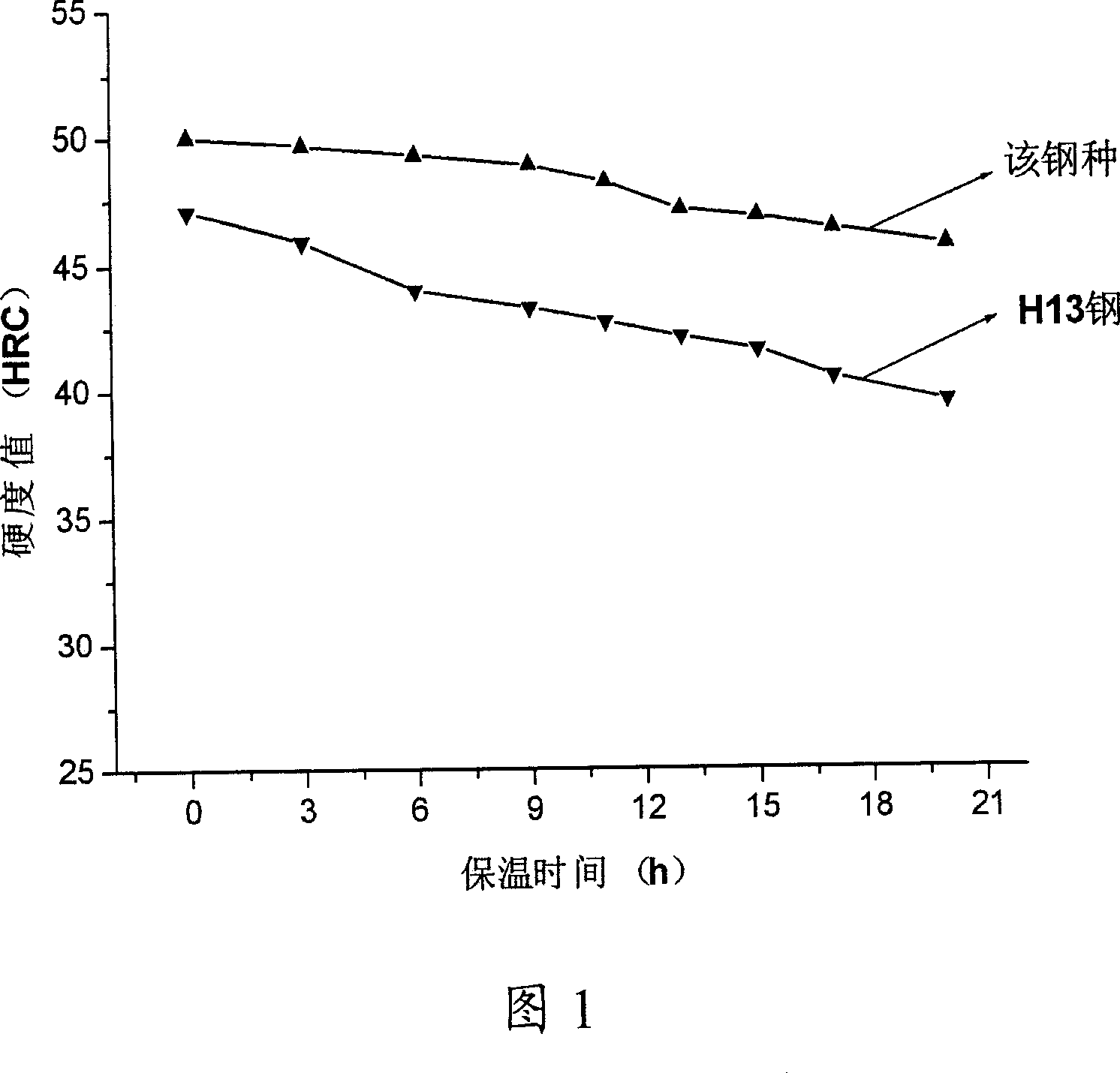

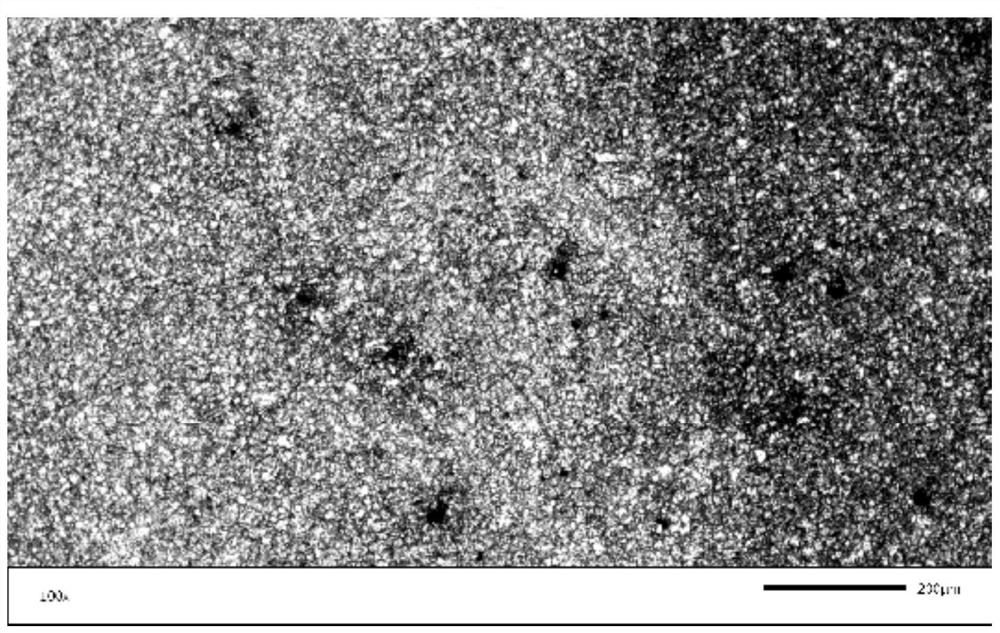

High heat-intensity hot-work die steel material

ActiveCN1924069AImprove metallurgical qualityImprove organizationHeat treatment process controlSlagHot work

The invention discloses a heat mould steel material in the alloy steel material manufacturing technological domain, which comprises the following parts: 3.5-4.0%Cr, 2.0-2.5% Mo, 1.0-1.5% V,1.0-1.5% W , 0.1-0.5% Mn, 0.1-0.25% Ni, 0.3-0.35% C, 0.1-0.5% Si, 0.005-0.01% S, 0.01-0.02% P and Fe. The preparing method comprises the following steps: (1) fusing; (2) refusing electric slag; (3) evening at high temperature; (4) forging; (5) annealing; (6) forging blank; (7) annealing to obtain the product with hardness between 48-54HRC and impaction flexibility more than 300J.

Owner:SHANGHAI UNIV

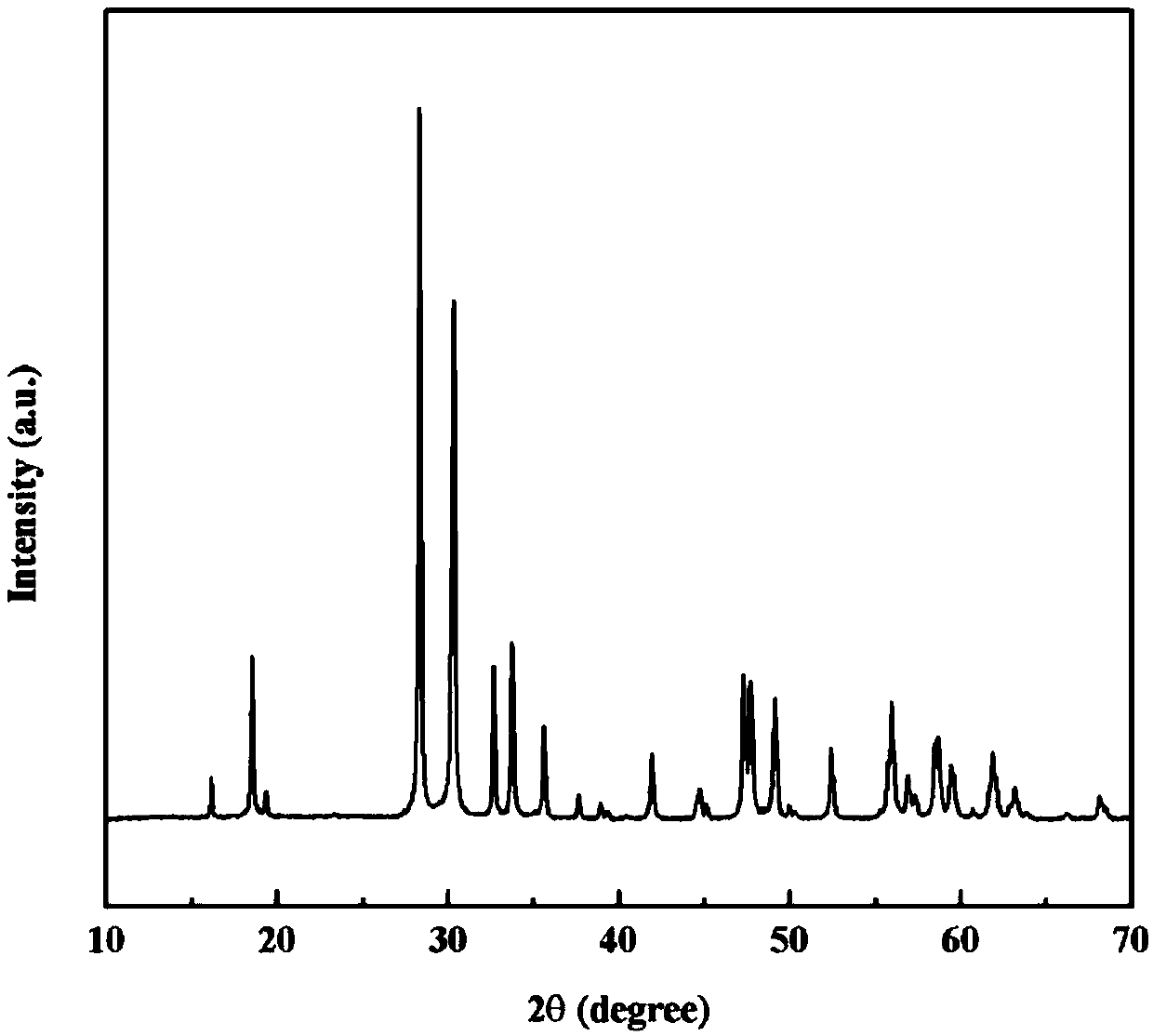

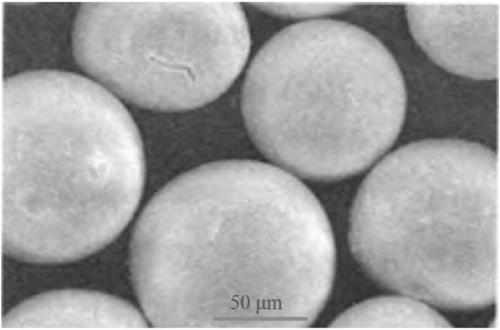

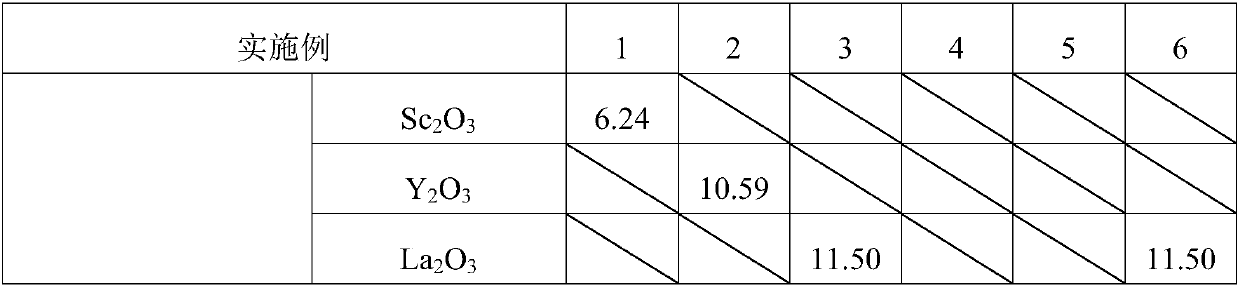

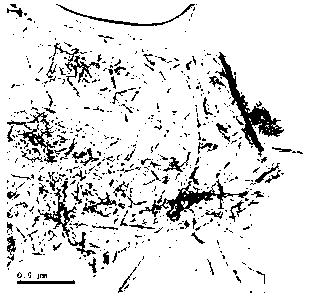

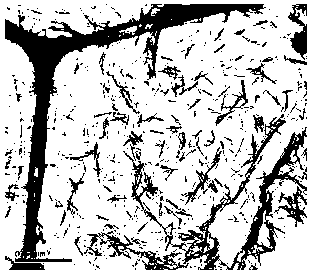

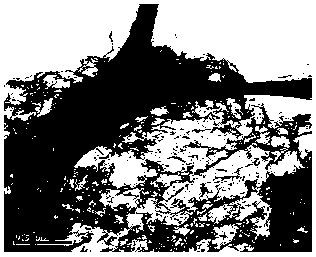

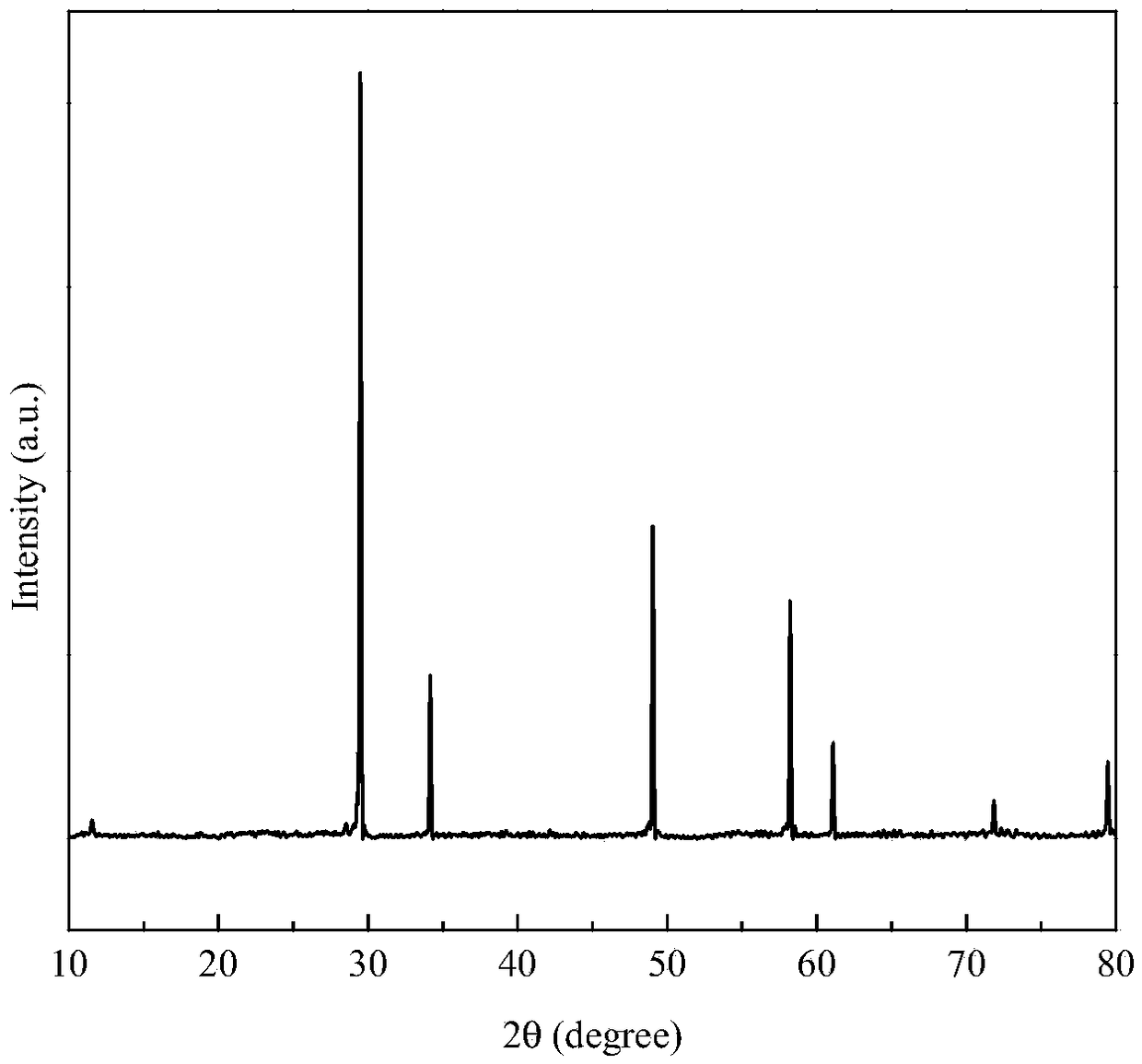

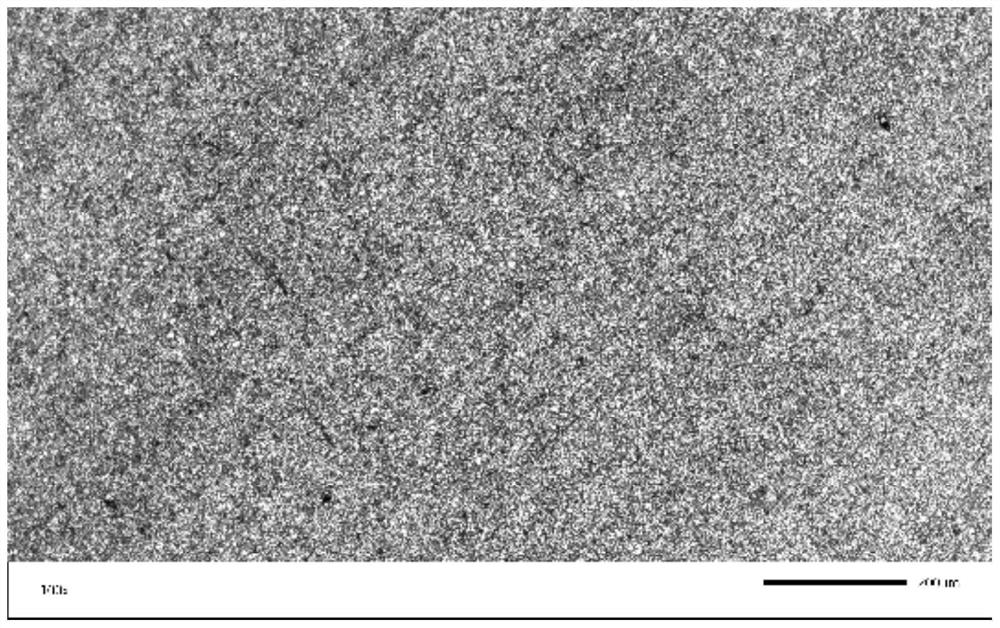

Rare earth tantalum/niobate (RETa/NbO4) ceramic powder and preparation method thereof

The invention relates to the technical field of preparation of ceramic powder, and discloses rare earth tantalum / niobate (RETa / NbO4) ceramic powder and a preparation method thereof. The chemical general formula of the rare earth tantalum / niobate (RETa / NbO4) ceramic powder is RETa / RENbO4, the crystal structure of the ceramic powder is the orthorhombic phase, the crystal lattice space group is C2221, the particle size is 10-70 microns, and the ceramic powder is spherical. In the preparation process, raw materials are subjected to ball milling, after a high temperature solid phase method is adopted for a reaction the processed raw materials, a solvent and an organic adhesive are mixed to obtain paste C, after centrifugal atomization, dry material particles are obtained, resintering is conducted, and the rare earth tantalum / niobate (RETa / NbO4) ceramic powder meeting the requirements of an APS technology for ceramic powder is obtained.

Owner:KUNMING UNIV OF SCI & TECH

Method for preparing composite of grapheme with different oxidation degrees and manganese dioxide

InactiveCN102709057AHigh purityLess impurity elementsElectrolytic capacitorsPotassium manganateManganese oxide

The invention discloses a method for preparing composite of grapheme with different oxidation degrees and manganese dioxide. The method comprises the processes of: respectively carrying out low-temperature, intermediate-temperature and high-temperature subsection reactions on original graphite, and concentrated sulfuric acid with a mass concentration of 98% and potassium permanganate so as to obtain graphite oxide; dispersing the graphite oxide in de-ionized water, and reducing the prepared graphite oxide with hydrazine hydrate so as to obtain the grapheme oxide with different oxidation degrees by controlling reduction time; and mixing the grapheme oxide with MnCl2*4H2O in an isopropyl alcohol solution, and adding a water solution of the potassium permanganate to prepare the composite of the grapheme with the different oxidation degrees and the manganese dioxide through oxidation reduction. The method provided by the invention has the advantages as follows: materials used in the method are rich in storage amount and low in cost, so that the method is good in commercialization; an dispersing agent, a stabilizer and the like do not need to be added, and a pure chemical technology is used, so that simple operation, no pollution and low energy consumption can be realized; and the prepared composite material of the grapheme and the manganese dioxide has high purity and good stability.

Owner:TIANJIN UNIV

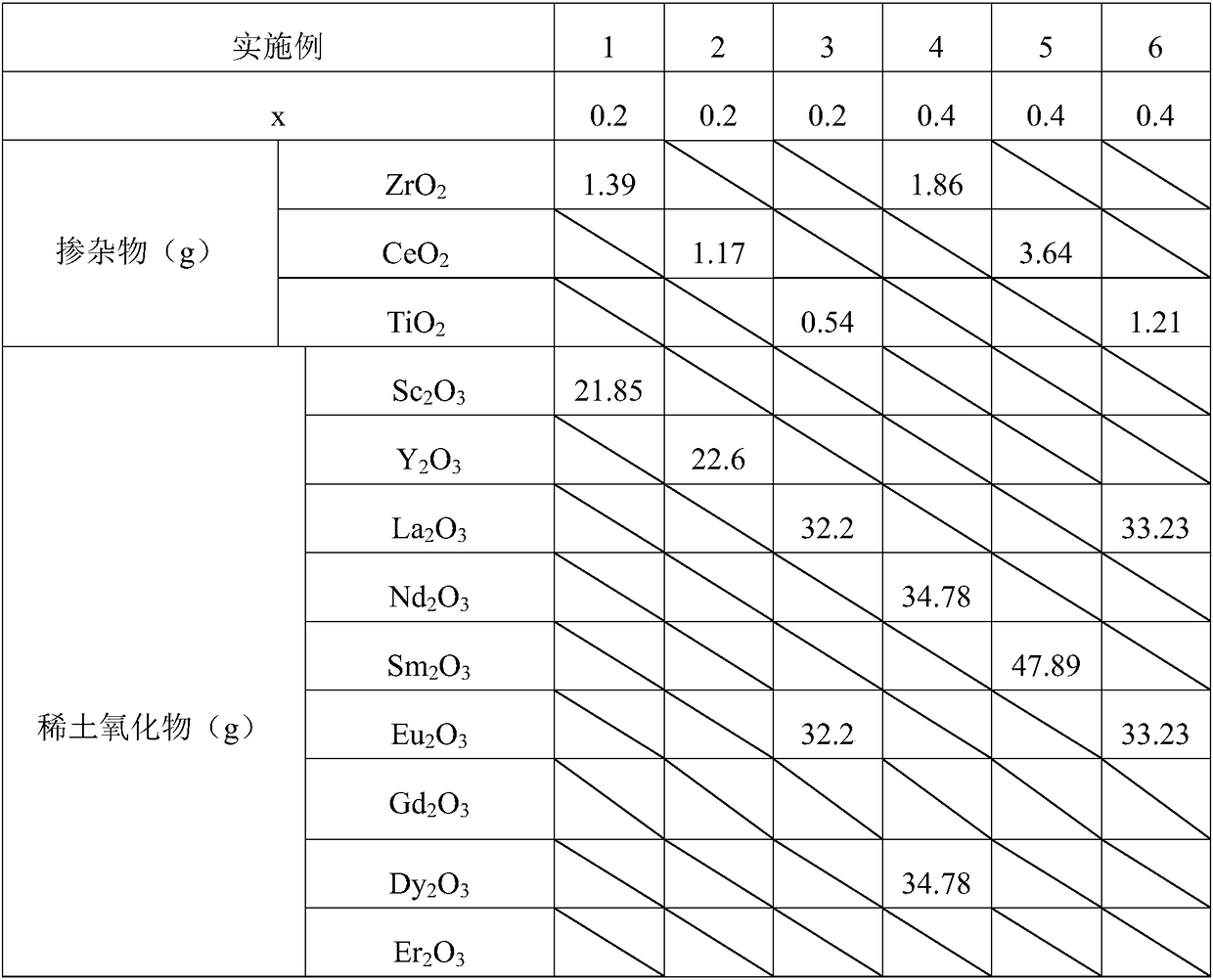

ZrO2/TiO2/CeO2 doped RE3Ta/NbO7 (Rare-Earth Tantalite/Niobate) ceramic powder and preparation method thereof

The invention relates to the technical field of ceramic powder preparation, and specifically discloses ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 (Rare-Earth Tantalite / Niobate) ceramic powder. The preparation method comprises the following steps: carrying out ball milling on a dopant (ZrO2 / TiO2 / CeO2), RE2O3 powder, Ta2O5 powder or Nb2O5 powder, and carrying out solid-phase reaction, thus obtaining a target phase; mixing the target phase with an organic adhesive, thus forming slurry; drying by adopting a high-temperature spray pyrolysis method, thus obtaining sphere-like powdery particles; sintering, thusobtaining the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder. A chemical general formula of the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder is RE(3-x)(Ta / Nb)(1-x)(Zr / Ce / Ti)2xO7, wherein x is greater than 0 and is smaller than 1. A crystal structure of the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder is an orthorhombic phase, the space group of a crystal lattice is C2221, the particle diameter is 10 to 50 mum, and the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powder is spherical. By adopting the technical scheme disclosed by the invention, the ZrO2 / TiO2 / CeO2 doped RE3Ta / NbO7 ceramic powderwhich can meet APS (Atmospheric Plasma Spraying) technical requirements can be obtained.

Owner:KUNMING UNIV OF SCI & TECH

Electroslag remelting slag system of super duplex stainless steel

The invention relates to an electroslag remelting slag system of super duplex stainless steel. The electroslag remelting slag system comprises the following ingredients by weight percentage: 55-74% ofCaF2, 5-20% of CaO, 5-20% of Al2O3, 5-15% of MgO and 1-15% of SiO2. According to the electroslag remelting slag system, optimal slag alkalinity is achieved by adjusting contents of basic oxides, namely CaO and MgO, and acidic oxides, namely SiO2 and Al2O3; and the electroslag remelting slag system is particularly applicable to electroslag remelting of the super duplex stainless steel, improves purity of the super duplex stainless steel, reduces a content of harmful impurity elements, optimizes an ingot structure, greatly improves processability of the stainless steel increases a hot processing yield and contributes to achieving excellent mechanical properties and corrosion resistance.

Owner:CHONGQING MATERIALS RES INST

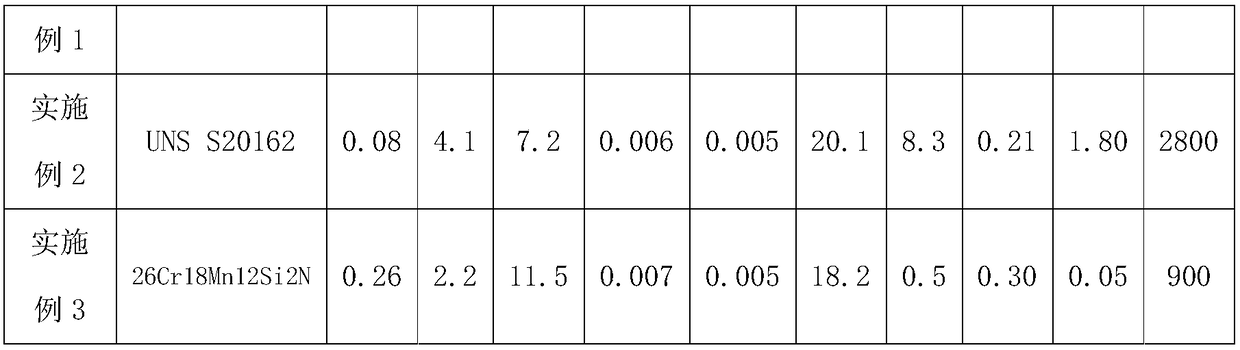

High-nitrogen austenitic stainless steel smelting method

The invention relates to a high-nitrogen austenitic stainless steel smelting method. The high-nitrogen austenitic stainless steel smelting method comprises the following steps of (1) blast-furnace molten iron pretreatment, (2) refining in a top-bottom combined blowing TSR stainless steel refining furnace, (3) refining outside a ladle refining furnace and (4) continuous casting. Compared with the prior art, the high-nitrogen austenitic stainless steel smelting method has the characteristics that the smelting cost is low, and the plate blank surface and interior quality meets the steel type requirements of the high-nitrogen austenitic stainless steel.

Owner:SHANDONG TAISHAN STEEL GROUP

Iron-rich phase modifier as well as preparation method and modification method thereof

The invention relates to the technical field of iron-rich phase modification. An iron-rich phase modifier comprises the following components by mass: 4.5-7.0% of Si, 2.5-5.0% of Fe, 0.7-1.4% of Mn, 0.03-0.1% of B, 0-0.15% of impurity elements and the balance of Al, wherein a preparation method of the iron-rich phase modifier comprises the following steps: placing Al, Al-Si, Al-Fe and Al-Mn in a melting furnace at a proportion for melting, then adding an Al-B intermediate alloy, and pouring the melt to form round ingots after degassing, impurity removal, heat preservation and standing, and slagging; the ingots are thermally extruded and processed to prepare an alloy rod after turning, sectioning and homogenizing treatment; and a modification method comprises the following steps: melting aniron-containing aluminum alloy, then adding the modifier, stirring, and then refining, standing, slagging and pouring to form ingots or performing production. According to the invention, a modification process is simplified, the impurity elements are reduced, and the dosage of the modifier is reduced.

Owner:GUANGDONG INST OF NEW MATERIALS

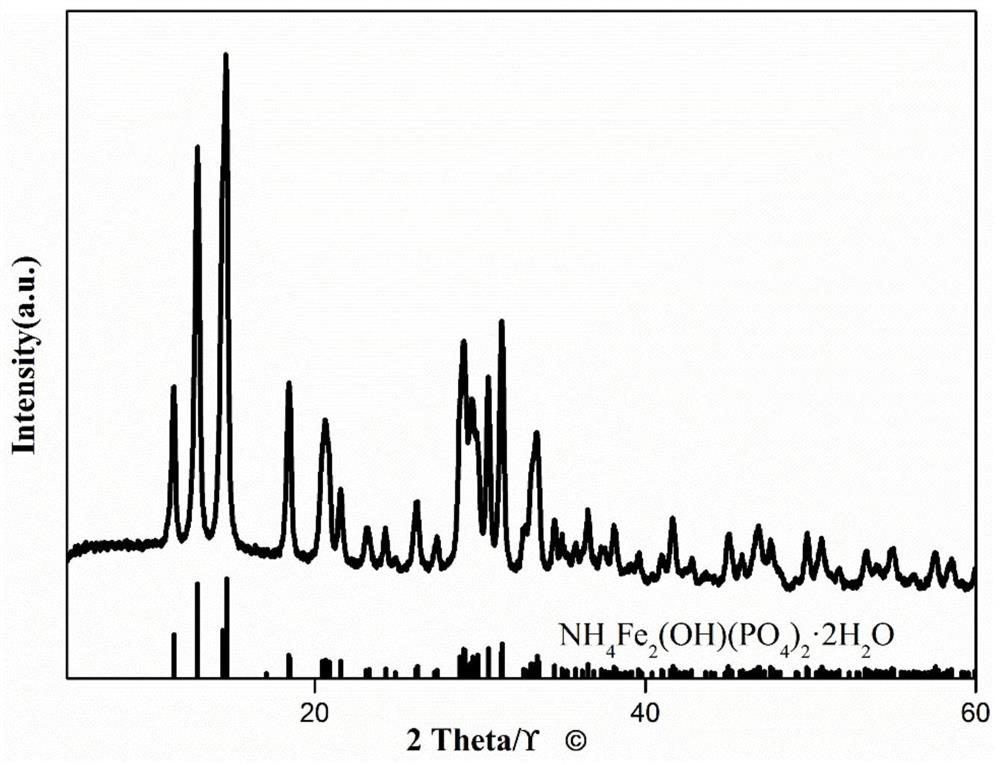

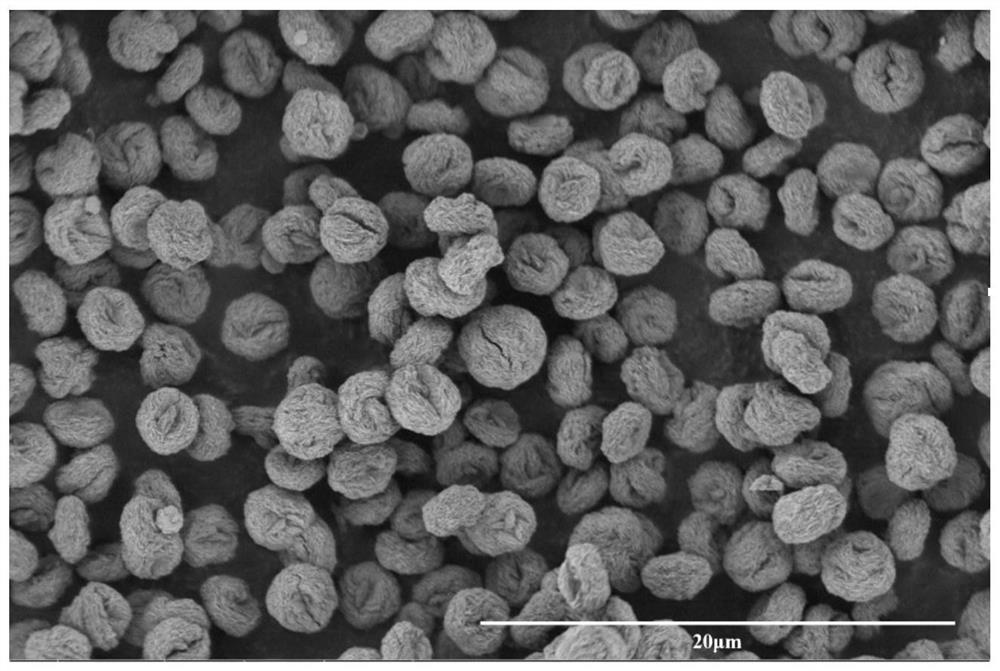

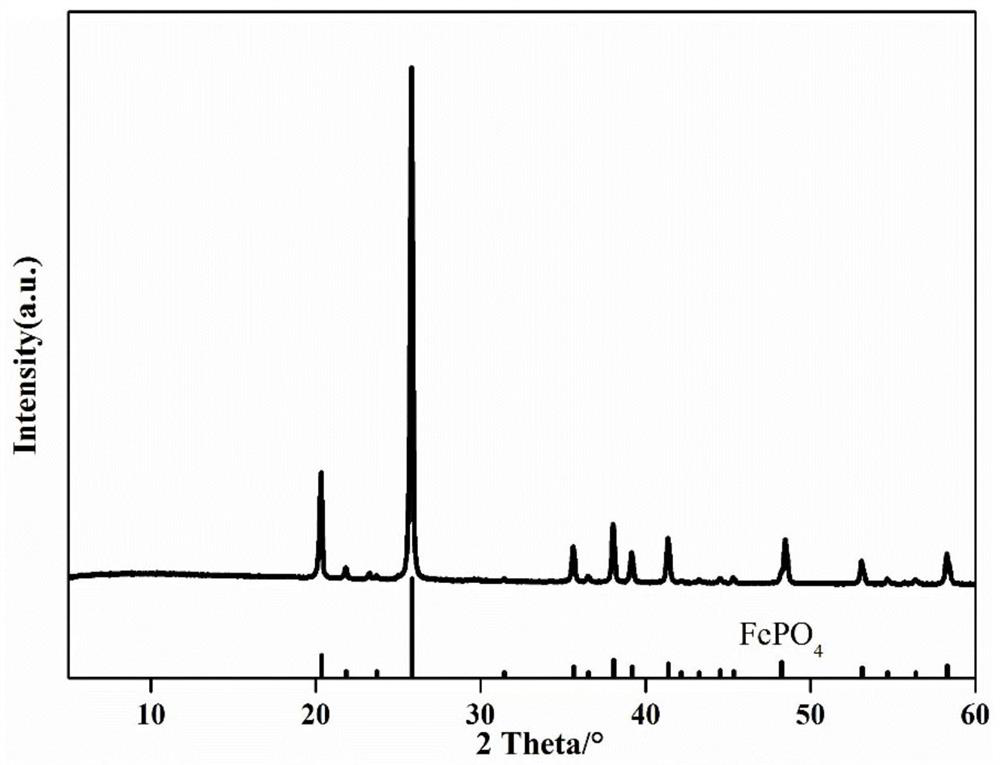

Preparation method and application of iron phosphate

ActiveCN112624076ALow costTo achieve the purpose of controllable crystallizationCell electrodesPhosphorus compoundsO-Phosphoric AcidPhosphate crystals

The invention belongs to the field of battery materials, and discloses a preparation method and application of iron phosphate. The preparation method comprises the following steps: roasting iron phosphate waste, adding into an acid solution, dissolving, filtering, and taking the filtrate to obtain a solution A containing iron and phosphorus elements; stirring the solution A and alkali liquor, adjusting the pH value to be acidic, reacting, washing, filtering, and taking filter residues to obtain an amorphous iron phosphate yellow filter cake; aging, pulping and heating the iron phosphate yellow filter cake, adding phosphoric acid and alkali liquor, washing, filtering, taking filter residues to obtain a basic ammonium iron phosphate filter cake, and drying to obtain basic ammonium iron phosphate crystal powder; and roasting, dehydrating and cooling the basic ammonium ferric phosphate crystal powder to obtain the iron phosphate. According to the invention, recycled ferrophosphorus waste is used as a raw material, amorphous iron phosphate is precipitated by adopting alkali liquor, and ammonia water and phosphoric acid are used as an aging agent under a high-temperature stirring condition, so that the purpose of controllable crystallization of basic ammonium ferric phosphate is achieved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

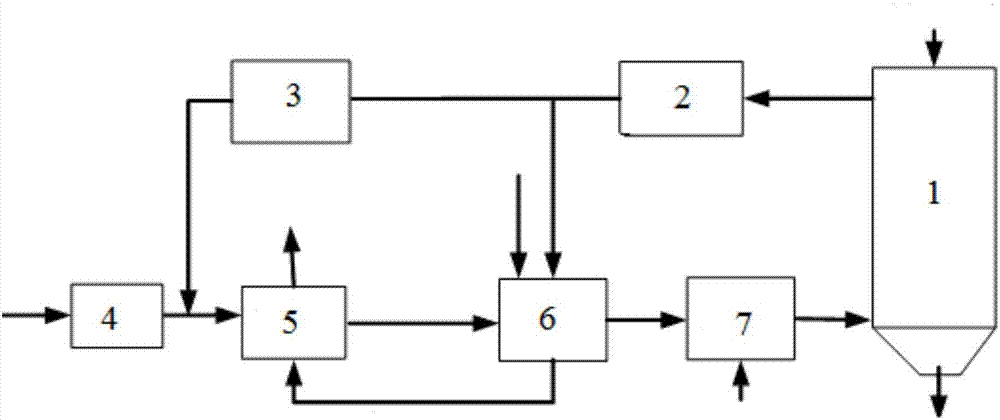

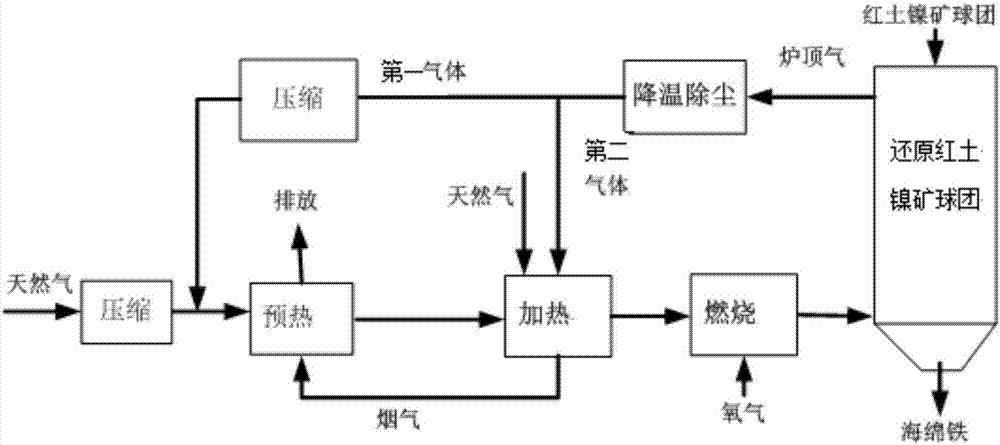

Natural gas tri-reforming red earth nickel ore pellet reducing system and method

PendingCN107043861AReduce consumption costsControllable reduction abilityShaft furnaceGas emission reductionProduct gasShaft furnace

The invention relates to a natural gas tri-reforming red earth nickel ore pellet reducing system and method. In the system, a shaft furnace is provided with a red earth nickel ore pellet inlet, a reducing gas inlet, a sponge iron outlet and a furnace top gas outlet; a cooling dust remover is provided with a furnace top gas inlet, a first gas outlet and a second gas outlet; the furnace top gas inlet is connected with the furnace top gas outlet of the shaft furnace; a preheater is provided with a mixed gas inlet and a preheating mixed gas outlet; the mixed gas inlet is connected with the first gas outlet of the cooling dust remover; a heater is provided with a preheating mixed gas inlet and a heating mixed gas outlet; the preheating mixed gas inlet is connected with the preheating mixed gas outlet of the preheater; a combustor is provided with an oxygen inlet, a heating mixed gas inlet and a reduced gas outlet; the heating mixed gas inlet is connected with the heating mixed gas outlet of the heater; and the reduced gas outlet is connected with the reduced gas inlet of the shaft furnace. The natural gas tri-reforming red earth nickel ore pellet reducing system and method can selectively reduce red earth nickel ore pellets, prepare high-grade ferro-nickel alloys and achieve recycling of energy.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

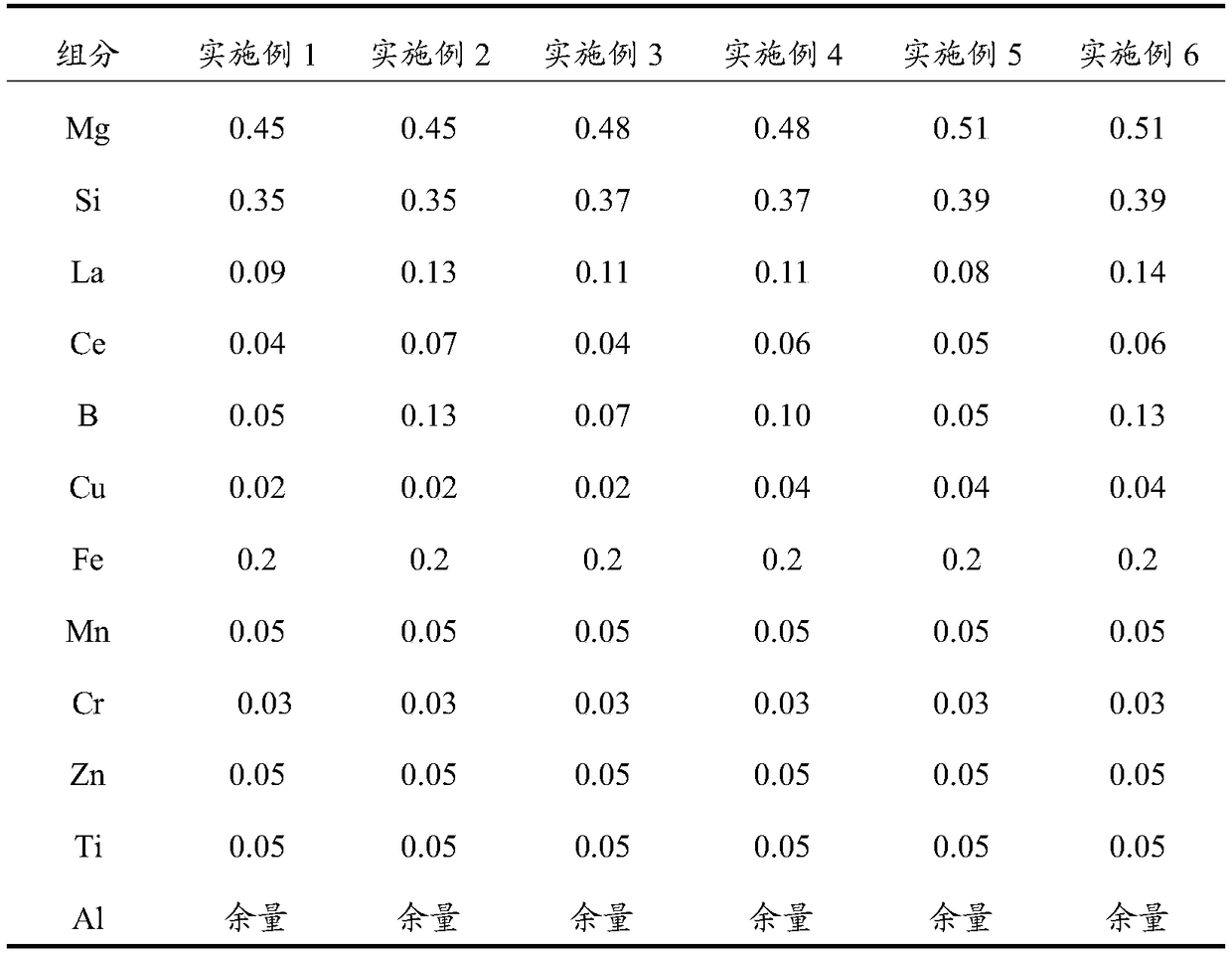

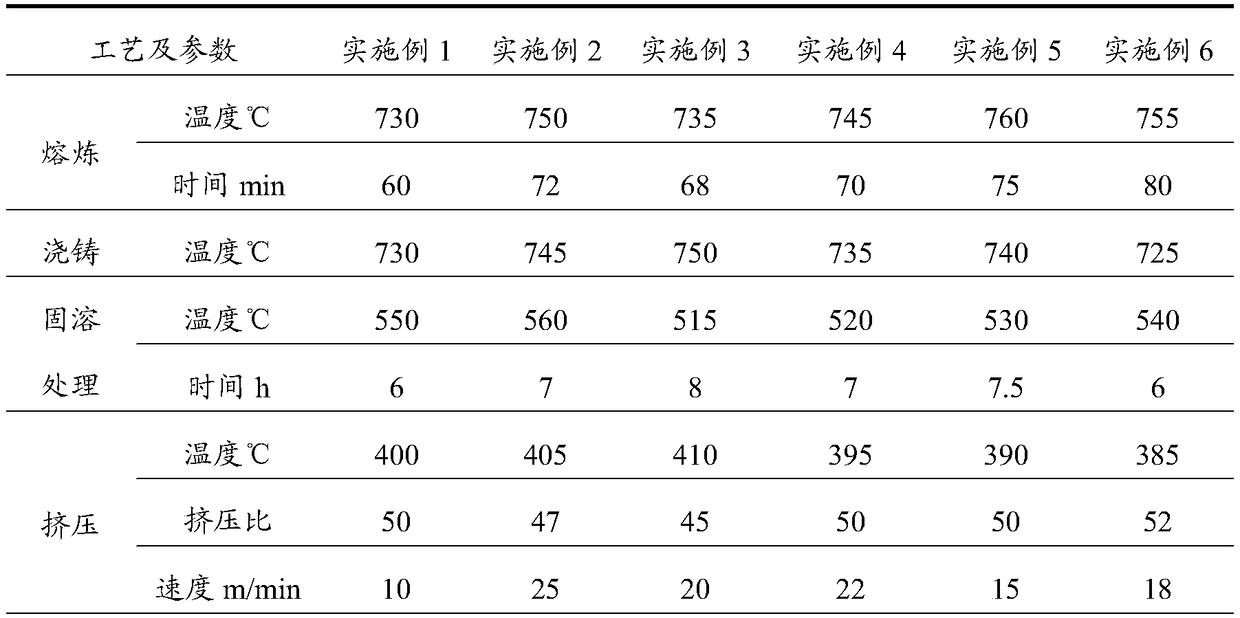

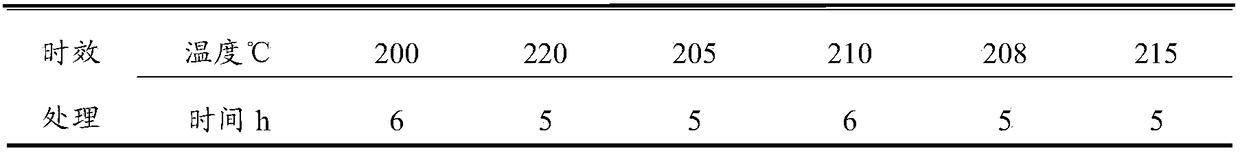

Thermal conductive aluminum alloy, and preparation method and application thereof

The invention belongs to the technical field of metal material heat conduction, in particular to thermal conductive aluminum alloy, and a preparation method and application thereof. According to the invention, mixed rare earth and boron refined alloy grains are utilized to reduce the content of harmful trace elements in the alloy, so that the aluminum alloy has excellent thermal conductivity underthe premise of high strength and plasticity. Embodiment results show that the aluminum alloy provided by the invention has a thermal conductivity of 236 W / m*K or more and a tensile strength of 199 MPa or more, and can be used as a heat dissipating material for electronic devices.

Owner:GUANGXI UNIV

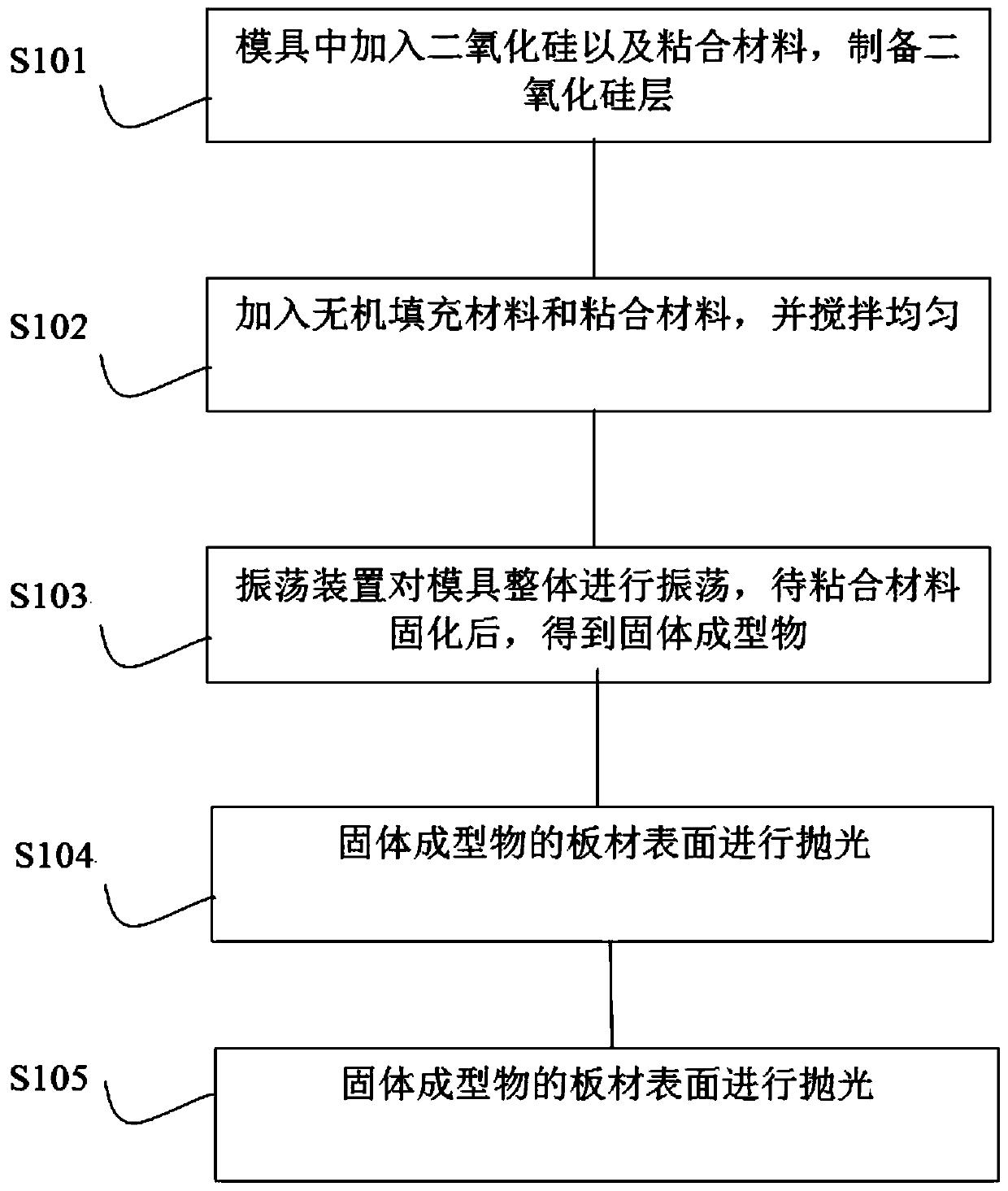

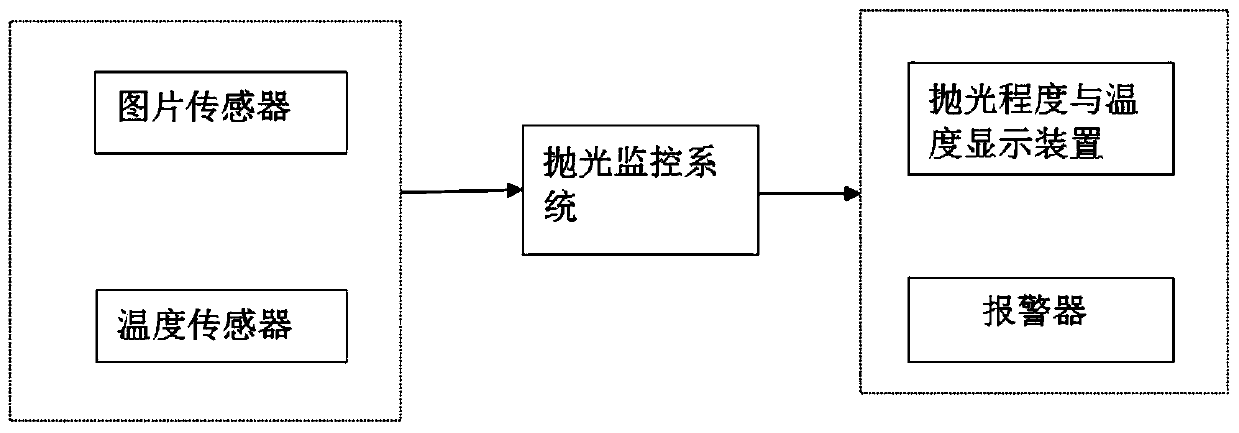

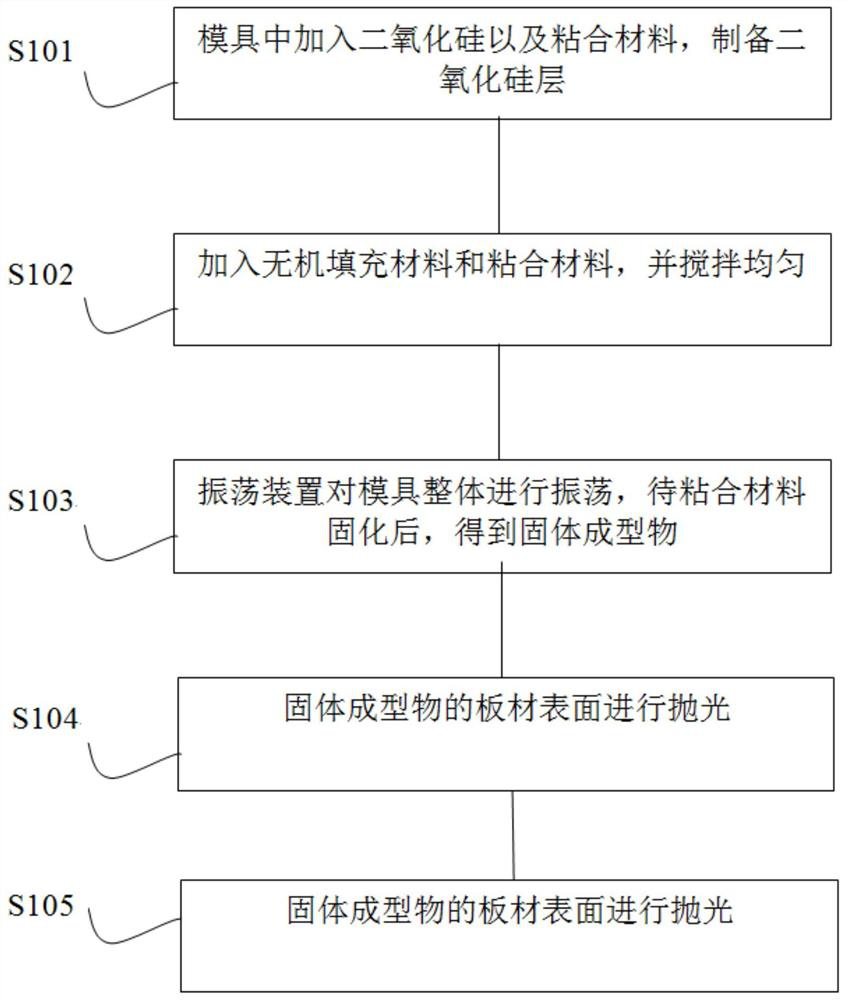

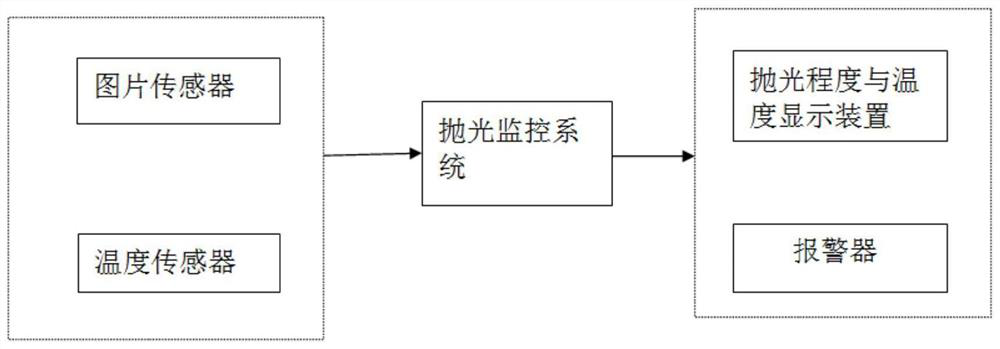

Preparation method of stone material and polishing system thereof

ActiveCN110078430ALong-lasting glossGood bonding propertiesCeramic shaping apparatusAbrasive machine appurtenancesWeather resistanceFilling materials

The invention provides a preparation method of a stone material and a polishing system thereof. According to the preparation method, a silica layer is prepared, an inorganic filler material and a binder are added for stirring, mixing and forming, then processing is preformed through a polishing system, and finally, the surface of the stone material is coated with a transparent ultraviolet-curablecoating of modified composite tourmaline powder for clean and anti-dirty treatment. The prepared stone material contains the silica layer and can have better bonding performance with the curable coating containing the modified composite tourmaline powder, a polishing media are silicon, silica gel and silica, the impurity elements are few, the polishing of the stone material is uniform, and the glossiness is remarkable. By coating the surface of the stone material with the transparent ultraviolet-curable coating of the modified composite tourmaline powder for clean and anti-dirty treatment, theglossiness of the surface of the stone material is further improved, and the corrosion resistance and weather resistance of the surface of the stone material are further increased; combined with a polishing monitoring system arranged in the polishing system, the polishing degree of the stone material can be controlled more accurately.

Owner:佛山市高明成丽厨饰有限公司

Purifying and nitriding process for producing manganese alloy with very low impurity content

InactiveCN1122727CHigh nitrogen contentLess impurity elementsNitrogen-metal/silicon/boron binary compoundsSteel tubeNitrogen gas

A treatment method for purifying manganese nitride alloy with ultra-low impurity content. The steps are to desulfurize metal manganese, carbon, and phosphorus, so that the content of sulfur, carbon, and phosphorus in manganese is reduced to C<0.02, S<0.01, P<0.01; Crush the above manganese metal into particles smaller than Φ2 and place it in a stainless steel container; put it into an electric furnace, connect the stainless steel tubes on the stainless steel container to the pure nitrogen source and the water container respectively; fill with pure nitrogen, observe the flow of nitrogen, and give Power is supplied to the electric furnace, the temperature is raised to 450-1100°C, and the temperature is maintained for 20-200 hours; the electric furnace is powered off, and nitrogen gas is continued until the temperature of the stainless steel container cools down to room temperature. The invention has high nitrogen content and low impurity elements.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

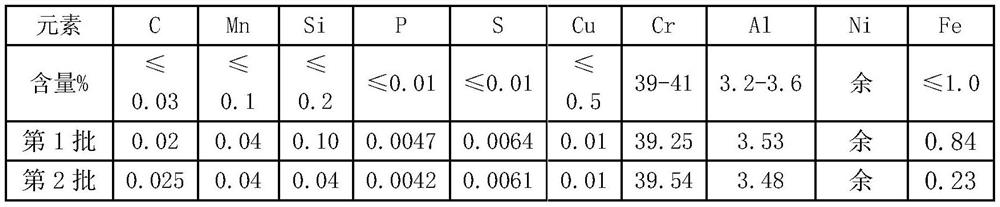

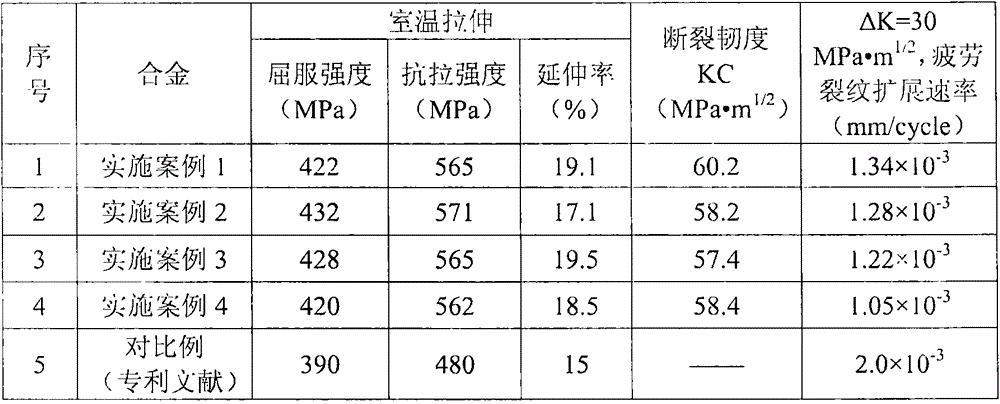

High-hardness 3J40 alloy bar for air valve and manufacturing method of high-hardness 3J40 alloy bar

The invention relates to a high-hardness 3J40 alloy bar for an air valve and a manufacturing method of the high-hardness 3J40 alloy bar. The grain size of the high-hardness 3J40 alloy bar for the air valve is smaller than the grade 5, the grade difference is within grade 2, and strip grains do not exist; and meanwhile, the bar is stable in mechanical property, and the hardness HV is larger than or equal to 370.

Owner:JIANGSU TOLAND ALLOY

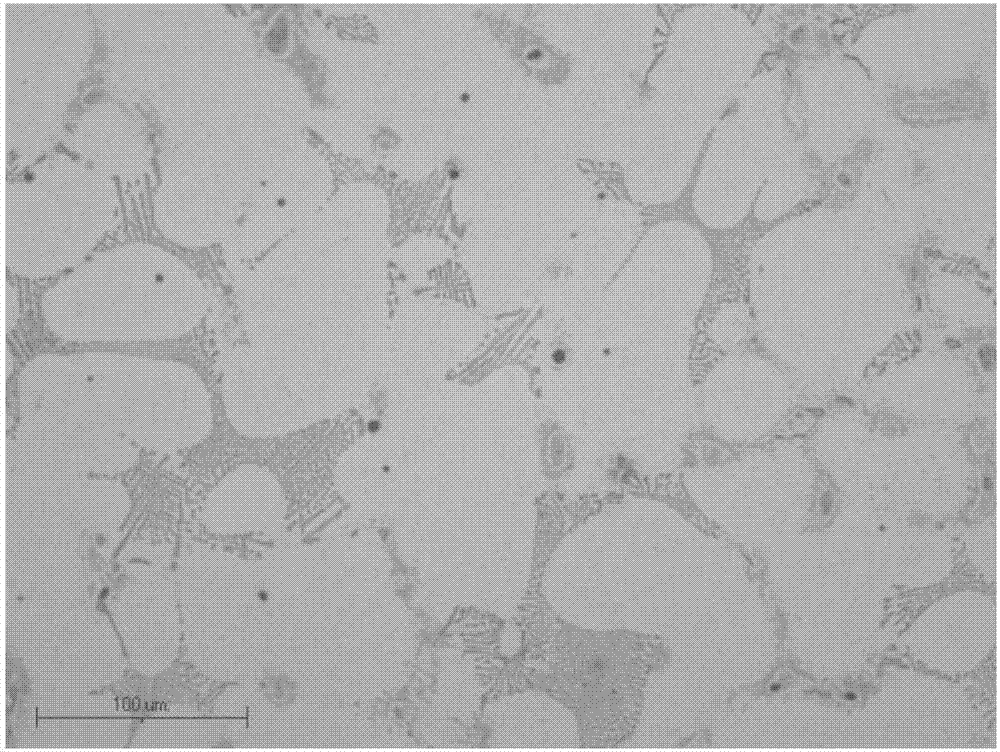

Microalloying chromium-nickel austenitic heat-resistant steel, as well as preparation method and application thereof

The invention provides microalloying chromium-nickel austenitic heat-resistant steel. The microalloying chromium-nickel austenitic heat-resistant steel comprises the following components in percentage by mass: 0.30-0.60% of carbon, 2.00-3.00% of silicon, not more than 1.00% of manganese, not more than 0.04% of phosphorus, not more than 0.3% of sulfur, 23.00-28.00% of chromium, 27.00-30.00% of nickel, 0.50-1.50% of niobium, not more than 0.6% of molybdenum, 0.20-0.50% of nitrogen, 0.20-0.50% of vanadium, 0.01-0.05% of boron, 0.005-0.100% of rare-earth elements, and the balance iron. The microalloying chromium-nickel austenitic heat-resistant steel provided by the invention is high in strength, good in heat resistance and low in cost, has high capacity for resisting the tendency of generating hot cracks in the solidifying process of a casting, can be widely applied in the casting of a turbine case and an exhaust pipe of an automobile, and meets requirements for high-performance engines.

Owner:TIANJIN DA SHIANG PRECISION IND CO LTD

Manufacturing process of high-fin cupronickel alloy efficient pipe

ActiveCN112296122AHigh process feasibilityHigh yieldFurnace typesHeat treatment furnacesForeign matterCupronickel

The invention relates to a manufacturing process of a high-fin cupronickel alloy efficient pipe. The manufacturing process comprises the following steps of casting, hot extrusion, first annealing, rolling, cogging, heading and stretching, second annealing, empty drawing, fin rolling, cleaning, rinsing, purging and drying, stress relief heat treatment, straightening, sizing, inspection and detection, and packaging and warehousing. According to the manufacturing process, the plasticity of a BFe10-1-1 copper alloy pipe blank is improved, the probability of foreign matter pressing in the large-deformation stretching process is reduced, the cracking situation during fin rolling is greatly reduced, the manufacturing selectivity of the efficient pipe with different finished product performance requirements is improved, and the process is high in feasibility and high in yield.

Owner:江苏隆达超合金股份有限公司

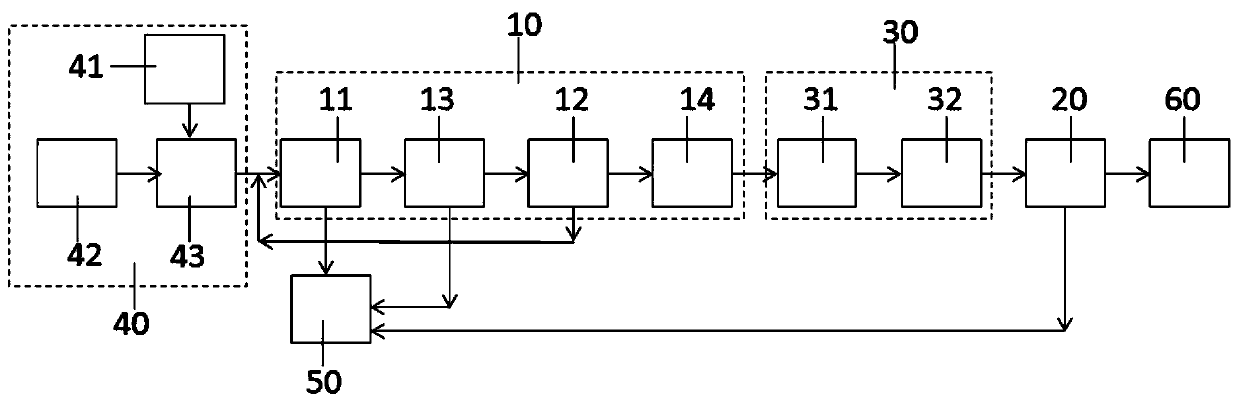

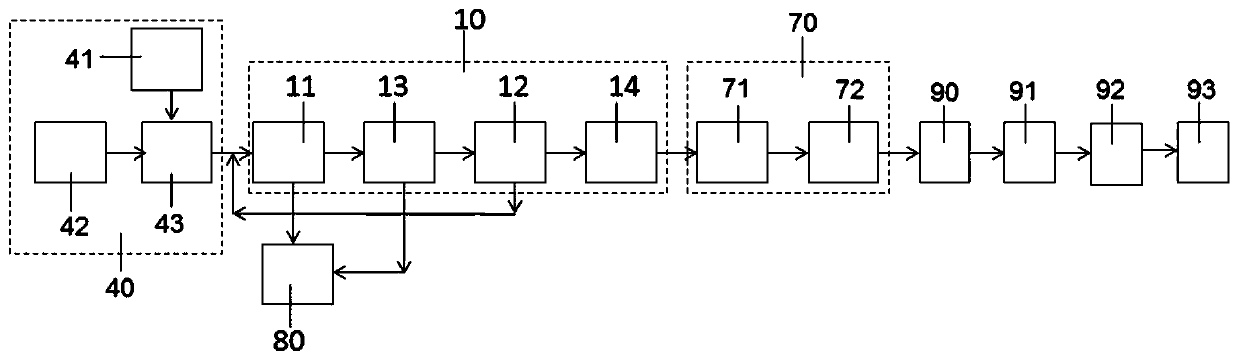

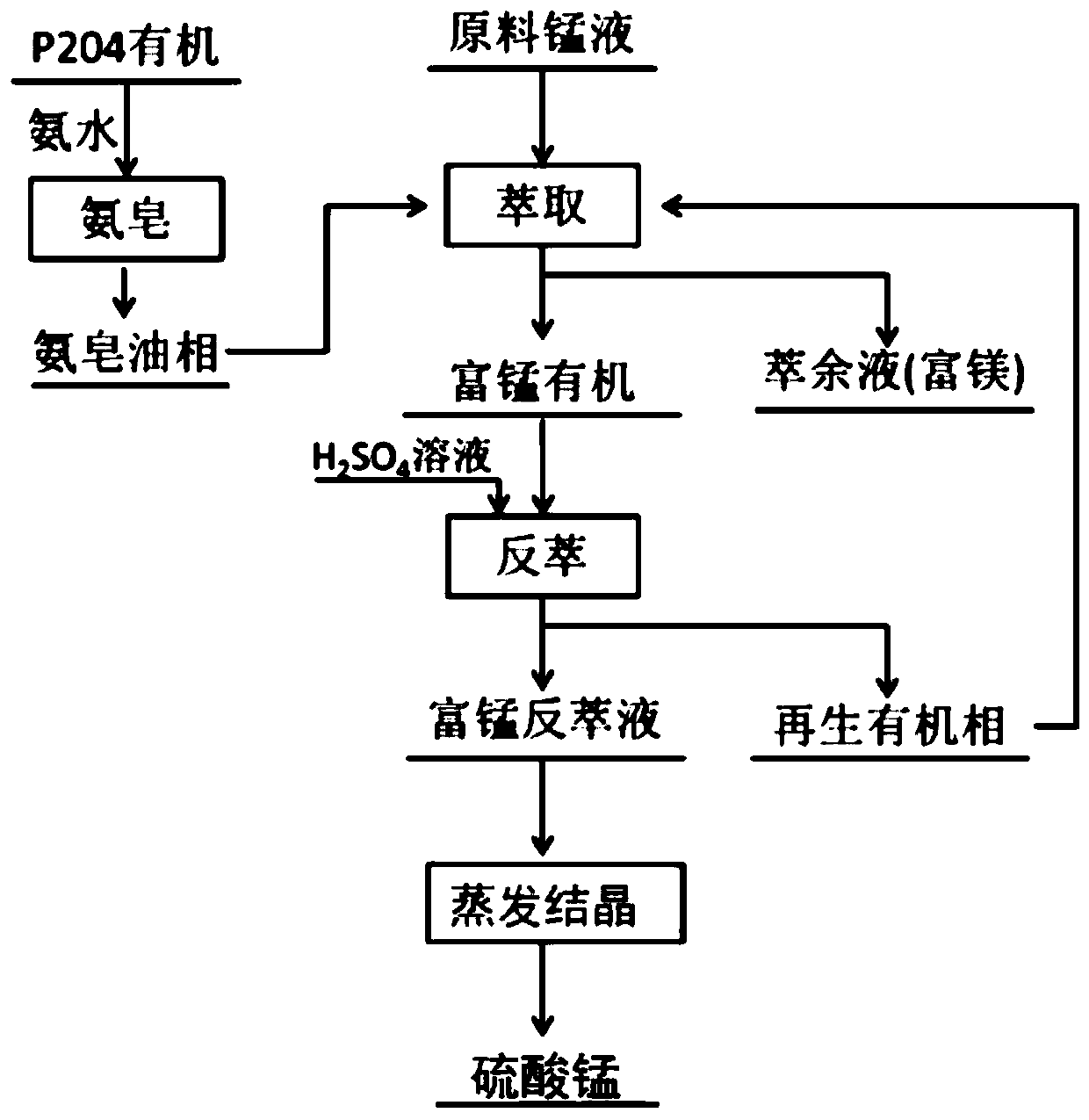

Treatment system and treatment method for reducing content of impurities in soluble manganese sulfate solution

PendingCN111170368AIncrease the content of manganeseSimple structureManganese compounds preparationManganese sulfatesManganese sulphateSulfate

The invention provides a treatment system and a treatment method for reducing the content of impurities in a soluble manganese salt solution. The impurities comprise calcium ions and magnesium ions, the treatment system comprises an extraction unit and an evaporative crystallization device or a precipitation unit, the extraction unit is used for removing the magnesium ions, and the extraction unitis provided with a soluble manganese salt solution inlet, an extraction agent inlet and a primary purified product outlet; the evaporative crystallization device is provided with a primary purified product inlet, and the primary purified product inlet is communicated with the primary purified product outlet through a primary purified product conveying pipeline; the precipitation unit is providedwith a primary purification product inlet and a precipitant inlet, and the primary purification product inlet is communicated with the primary purification product outlet through a primary purification product conveying pipeline. By adopting the treatment system, the impurity content in the soluble manganese salt solution can be greatly reduced. The treatment system and a treatment method for reducing the content of impurities in a soluble manganese salt solution have the advantages of being simple in structure, small in solid slag and hazardous waste discharge amount and the like, and therefore good environmental friendliness is achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

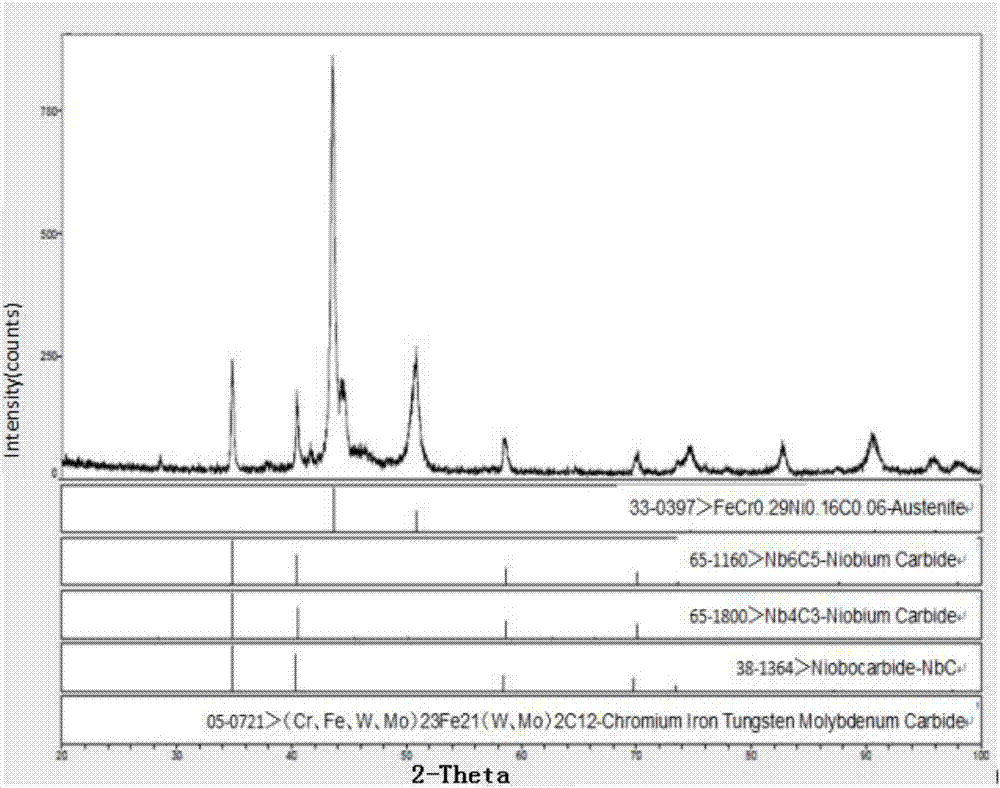

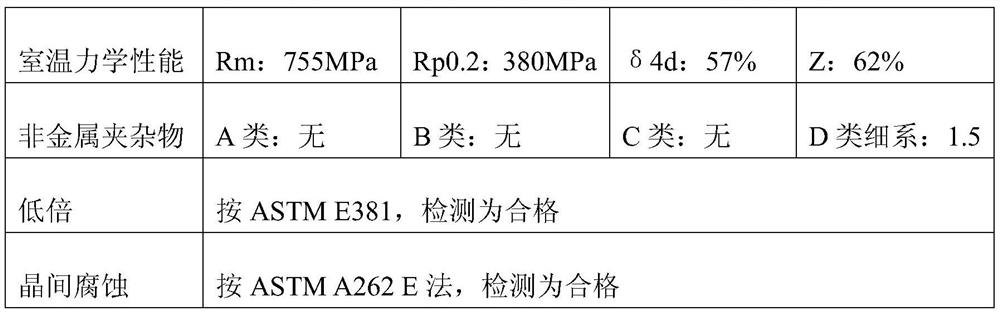

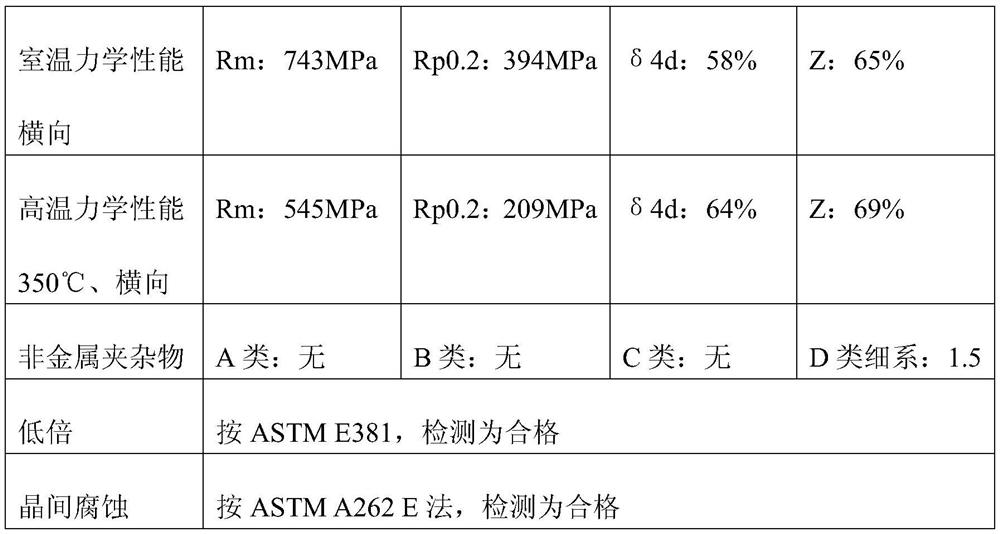

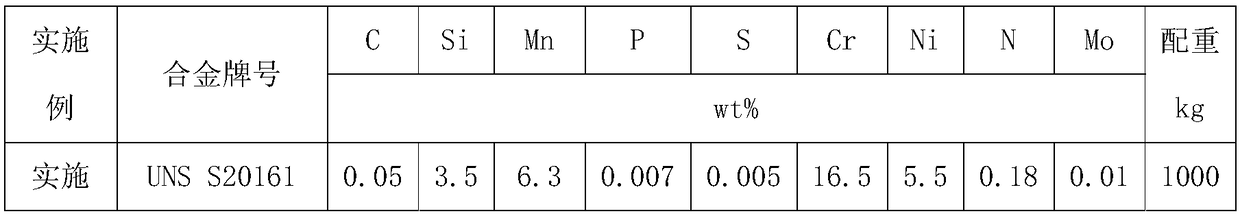

Microalloyed high-silicon-manganese nitrogen-containing austenitic stainless steel material and preparation method

ActiveCN109280842BHigh purityComposition is stableIncreasing energy efficiencyManganeseSS - Stainless steel

The invention relates to a microalloyed high-silicon-manganese nitrogen-containing austenitic stainless steel material and a preparation method thereof. The weight percentage of each component of the high-silicon-manganese nitrogen-containing stainless steel material is: C: 0.03-0.06% , Cr: 16.0~17.5%, Ni: 8.0~9.0%, Si: 3.5~4.5%, Mn: 7.5~9.0%, N: 0.10~0.18%, Mo: 0.1~0.6%, V: 0.05~0.2%, Nb: 0.05 to 0.2%, Cu: 0.1 to 0.5%, and Fe as the balance. The high-silicon-manganese-nitrogen-containing austenitic stainless steel prepared by the method of the present invention has good cold and hot workability, excellent horizontal and vertical room temperature, high temperature mechanical properties, toughness and plasticity, and good corrosion resistance. , greatly improving the yield of the alloy.

Owner:CHONGQING MATERIALS RES INST

High-Al electrical steel square billet for automobile generator pole claw and production method of high-Al electrical steel square billet

ActiveCN107460409AReduce noiseMeet production needsManufacturing convertersElectrical steelChemical composition

The invention discloses a high-Al electrical steel square billet for an automobile generator pole claw and a production method of the high-Al electrical steel square billet. The electrical steel square billet comprises chemical components including, by mass, 0-0.010% of C, 0-0.10% of Si, 0-0.10% of Mn, 0-0.010% of P, 0-0.010% of S, 0.30%-0.40% of Alt and the balance Fe and inevitable impurities. The production method comprises the steps of molten iron pretreatment, converter smelting, LF furnace treatment, RH furnace treatment, continuous casting and cogging. A small square billet product produced through the production method is stable and uniform in component and small in impurity element amount, and production requirements of users for the automobile generator pole claw for export are met; and through the product, the generating capacity can be improved by 5%-8%, meanwhile, the overall thickness of the pole claw can be decreased by 0.5 mm, the magnetic resistance is effectively reduced, a remarkable effect on dynamic balance and light weight is achieved, the quality requirements for stable generating capacity and low noise of the export generator pole claw can be met, and the using effect is great.

Owner:XINGTAI IRON & STEEL

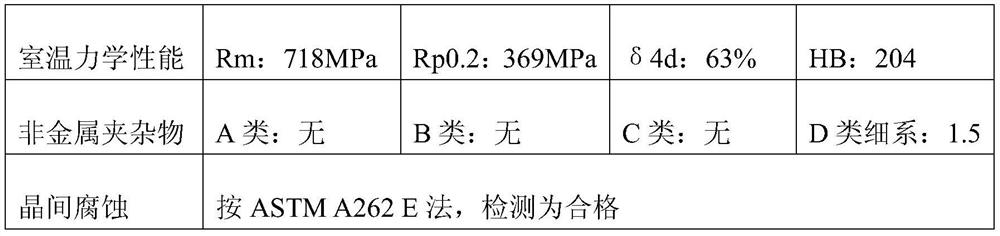

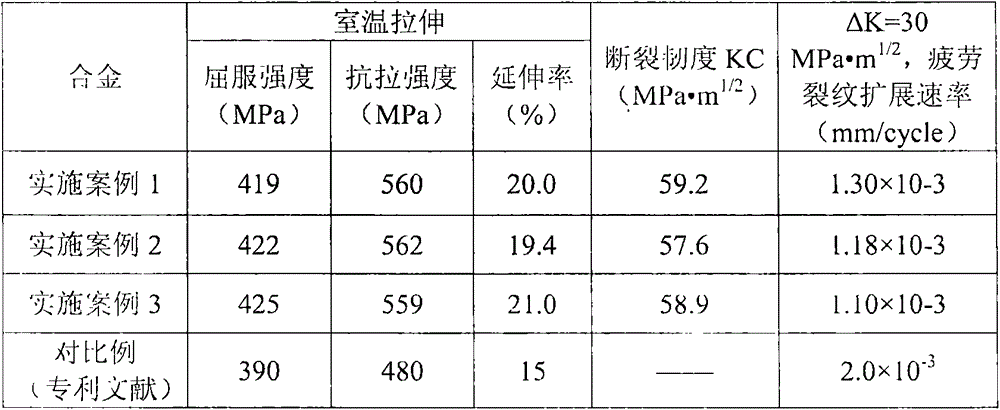

Damage-resistant aluminum alloy and preparation method thereof

The invention provides a damage-resistant aluminum alloy and a preparation method thereof. The damage-resistant aluminum alloy comprises the following components by mass percent: 3.6-4.3%of Cu, 1.0-1.6% of Mg, 0.3-0.8% of Mn, 0.1-0.15% of Zr, 0.1-0.2% of Er, and the balance Al and trace impurity elements, wherein the total content of the trace impurity elements is less than 0.1%. Through adjusting the content of a main alloy element and adding new alloy elements, the aluminum alloy having high resistance to fatigue crack extension and excellent mechanical property is obtained, and the problem that the comprehensive performance of the conventional damage-resistant aluminum alloy is difficult to improve is solved. With the adoption of a water atomization and steam heating mode for homogenizing treatment, the homogenizing time is shortened, the size of a second-phase particle is reduced, and significant effect is exerted on the improvement of the material fracture toughness. The damage-resistant aluminum alloy is simple in technology and low in cost, and large-scale industrial production can be realized easily.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

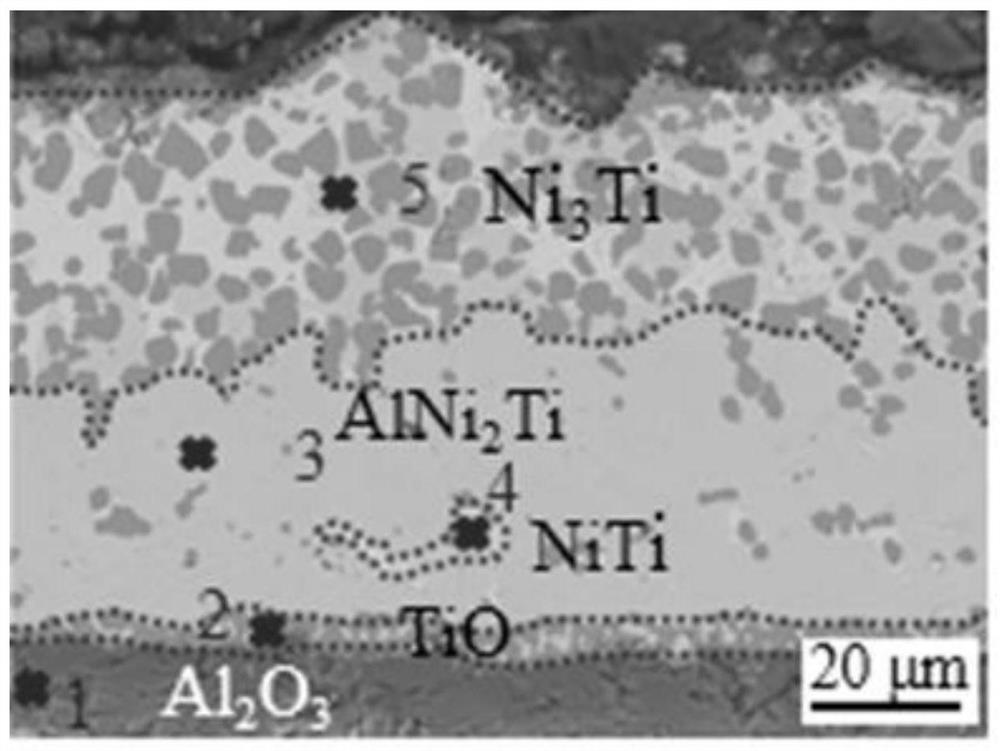

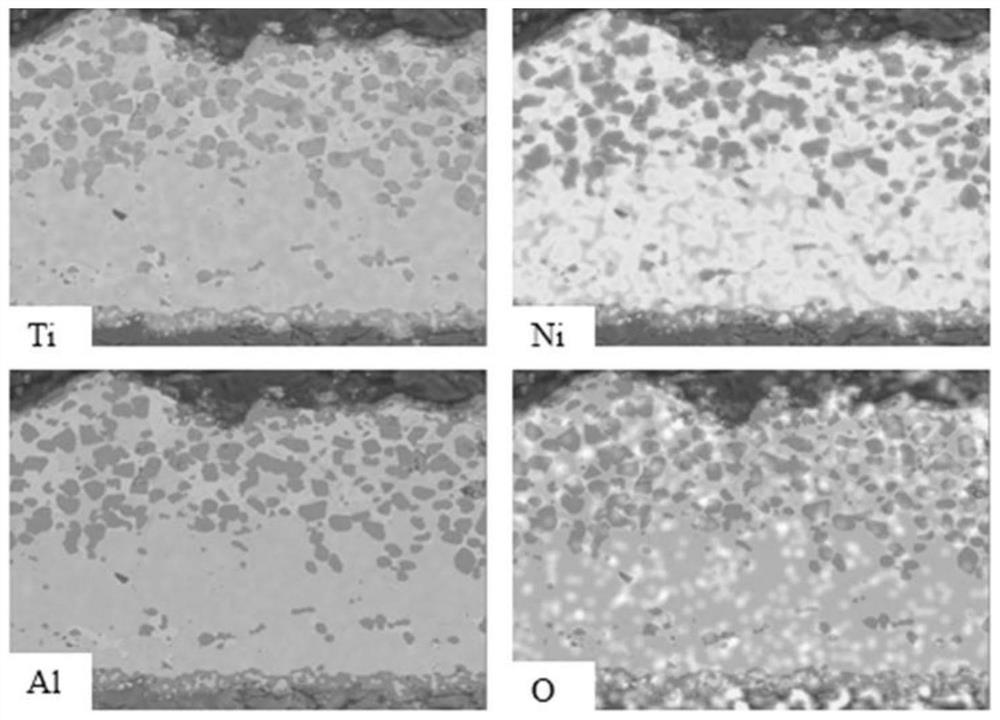

Aluminum oxide/nickel-titanium alloy/aluminum oxide composite material prepared through diffusion bonding and method thereof

ActiveCN112109393ASpread evenlyLess impurity elementsLamination ancillary operationsLaminationAluminum compositesTitanium nickelide

The invention discloses an aluminum oxide / nickel-titanium alloy / aluminum oxide composite material prepared through diffusion bonding and a method of the composite material. Nickel-titanium alloy sheets and aluminum oxide sheets are used as raw materials, and the nickel-titanium alloy sheets are placed between the two aluminum oxide sheets to prepare a sample with a sandwich structure; the obtainedsandwich structure sample is placed in a graphite mold and fastened; and the graphite mold is put into a vacuum carbon tube furnace to be subjected to annealing treatment, and the aluminum oxide / nickel-titanium alloy / aluminum oxide sandwich layered composite material is prepared. According to the invention, the ceramic toughness of Al2O3 is improved, and reliable connection between Al2O3 ceramicand metal is realized.

Owner:XI AN JIAOTONG UNIV

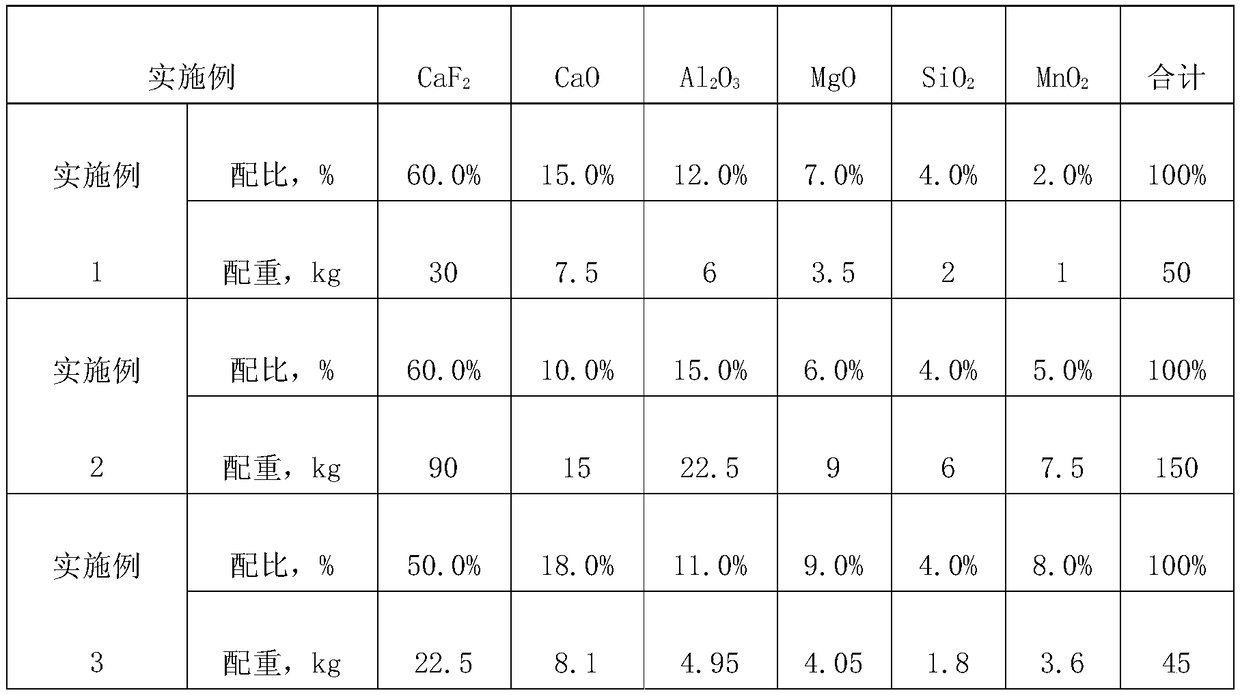

Electroslag remelting slag material for preparing high silicomanganese nitrogen-containing stainless steel

The invention relates to an electroslag remelting slag material for preparing high silicomanganese nitrogen-containing stainless steel. The electroslag remelting slag material is characterized in thatthe slag material comprises components including, by weight, 50-70 parts of CaF2, 8-20 parts of CaO, 5-20 parts of Al2O3, 5-15 parts of MgO, 1-10 parts of SiO2 and 1-8 parts of MnO2. The silicon element and the manganese element in a high silicomanganese nitrogen-containing stainless steel alloy prepared through the slag material are stable and controllable, a matrix structure is stable, harmfulimpurity elements and nonmetal inclusions are reduced, the structure is optimized, the hot working performance of the alloy is greatly improved, the yield is increased, and excellent mechanical performance and corrosion resistance are obtained.

Owner:CHONGQING MATERIALS RES INST

A kind of high Al electrical steel square billet for pole claw of automobile generator and its production method

ActiveCN107460409BReduce noiseMeet production needsManufacturing convertersLow noiseChemical composition

The invention discloses a high-Al electrical steel square billet for an automobile generator pole claw and a production method of the high-Al electrical steel square billet. The electrical steel square billet comprises chemical components including, by mass, 0-0.010% of C, 0-0.10% of Si, 0-0.10% of Mn, 0-0.010% of P, 0-0.010% of S, 0.30%-0.40% of Alt and the balance Fe and inevitable impurities. The production method comprises the steps of molten iron pretreatment, converter smelting, LF furnace treatment, RH furnace treatment, continuous casting and cogging. A small square billet product produced through the production method is stable and uniform in component and small in impurity element amount, and production requirements of users for the automobile generator pole claw for export are met; and through the product, the generating capacity can be improved by 5%-8%, meanwhile, the overall thickness of the pole claw can be decreased by 0.5 mm, the magnetic resistance is effectively reduced, a remarkable effect on dynamic balance and light weight is achieved, the quality requirements for stable generating capacity and low noise of the export generator pole claw can be met, and the using effect is great.

Owner:XINGTAI IRON & STEEL

A kind of stone preparation method and polishing system thereof

ActiveCN110078430BLong-lasting glossGood bonding propertiesCeramic shaping apparatusAbrasive machine appurtenancesWeather resistancePolishing

The invention provides a stone preparation method and a polishing system thereof. By preparing a silicon dioxide layer, adding an inorganic filler material and a binder, stirring and mixing molding, after being processed by a polishing system, and finally coating the surface of the stone with modified The transparent UV-curable coating of permanent composite tourmaline powder is used for clean and anti-fouling treatment. The silicon dioxide-containing layer of the prepared stone has better bonding performance with the cured coating containing the modified composite tourmaline powder, and the polishing medium is silicon, silica gel and silicon dioxide, with few impurity elements, and the stone is polished evenly. The glossiness is remarkable; the present invention further improves the glossiness of the stone surface and also increases the durability of the stone surface Corrosion and weather resistance; combined with the polishing monitoring system set in the polishing system, it can more accurately control the polishing degree of the stone.

Owner:佛山市高明成丽厨饰有限公司

Damage-resistant aluminum alloy and preparation method thereof

The invention provides a damage-resistant aluminum alloy and a preparation method thereof. The damage-resistant aluminum alloy comprises the following components by mass percent: 3.6-4.3%of Cu, 1.0-1.6% of Mg, 0.3-0.8% of Mn, 0.1-0.15% of Zr, 0.1-0.2% of Er, and the balance Al and trace impurity elements, wherein the total content of the trace impurity elements is less than 0.1%. Through adjusting the content of a main alloy element and adding new alloy elements, the aluminum alloy having high resistance to fatigue crack extension and excellent mechanical property is obtained, and the problem that the comprehensive performance of the conventional damage-resistant aluminum alloy is difficult to improve is solved. With the adoption of a water atomization and steam heating mode for homogenizing treatment, the homogenizing time is shortened, the size of a second-phase particle is reduced, and significant effect is exerted on the improvement of the material fracture toughness. The damage-resistant aluminum alloy is simple in technology and low in cost, and large-scale industrial production can be realized easily.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

A lithium battery tab metal strip treatment solution and tab treatment process

ActiveCN106435630BWill not corrodeReduce pollutionMetallic material coating processesCell component detailsElectrolytic agentMetal strips

A lithium battery tab metal strip treatment solution and tab treatment process, the treatment solution is obtained from the compounding of alkylphenol polyoxyethylene ether, glycol, alcohol amine and polyquaternary ammonium salt, the alkyl group in the treatment solution The molar concentration of phenol polyoxyethylene ether is 0.001~0.01mol / L, the molar concentration of diol is 0.0005~0.005mol / L, the molar concentration of alcohol amine is 0.001~0.01mol / L, the molar concentration of polyquaternium 0.005-0.05mol / L. The invention can effectively remove impurities on the surface of the tab metal strip without corroding the tab of the metal strip, can improve the bonding effect of the tab glue and the metal strip, and improve the electrolyte resistance and penetration resistance of the tab.

Owner:GREAT POWER BATTRY ZHUHAI

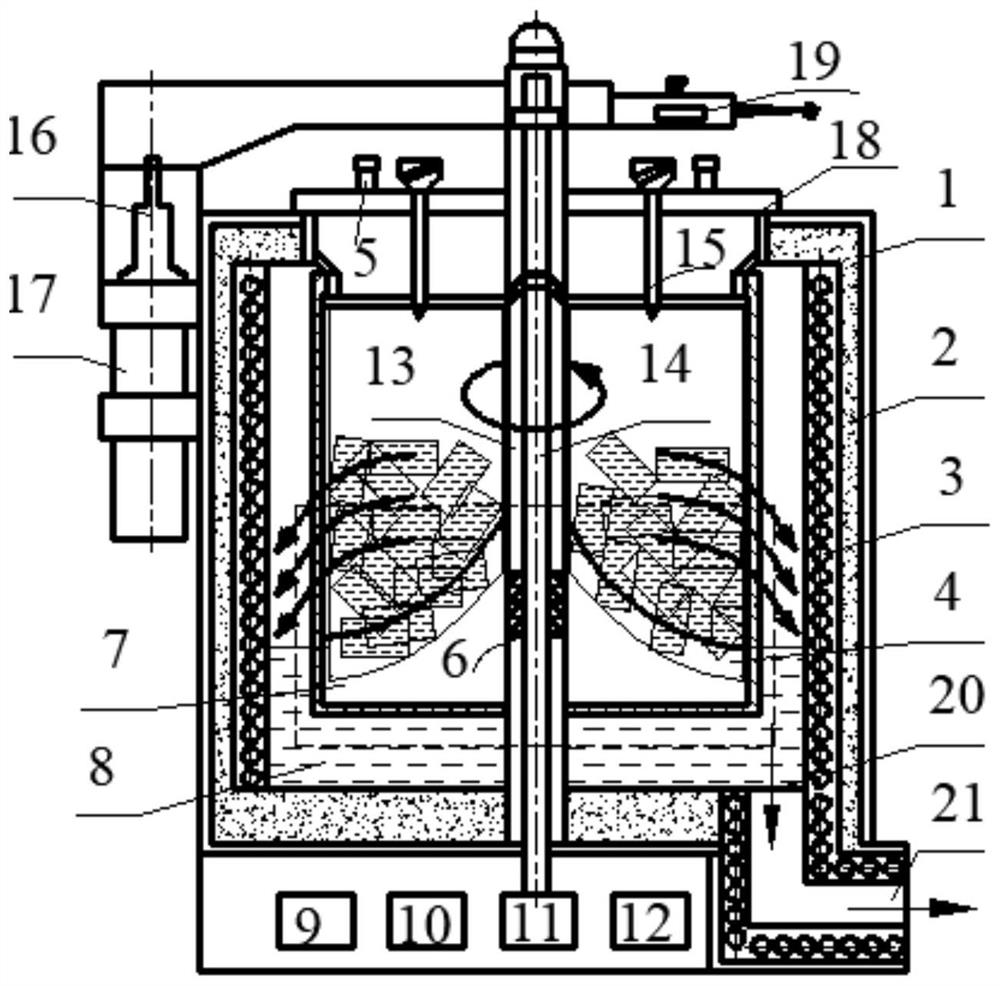

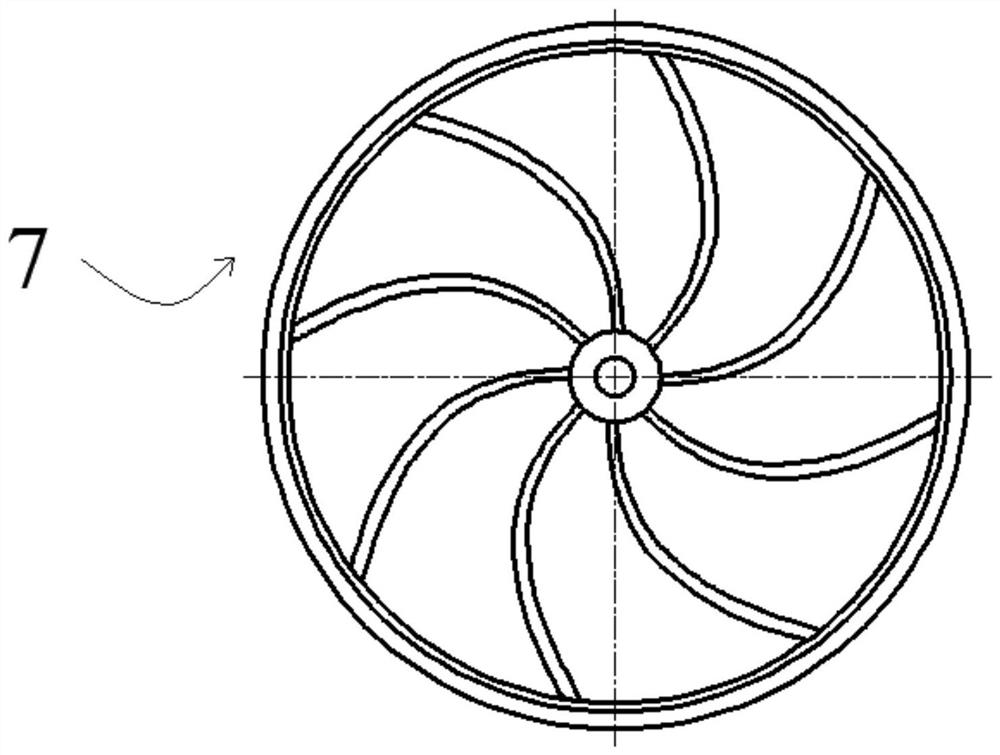

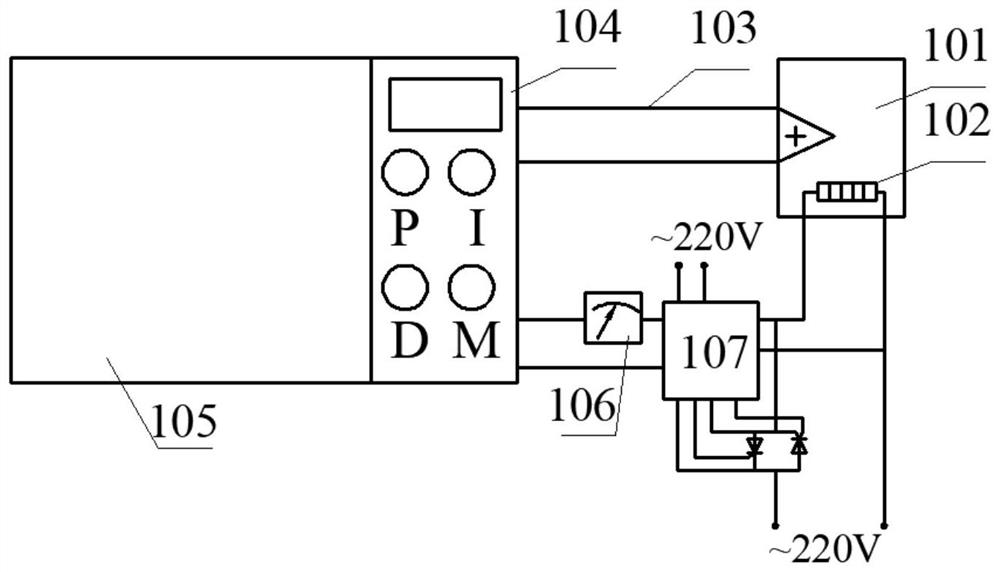

Method and device for separating 434 aluminum alloy composite plates

PendingCN114653486ALess impurity elementsQuality improvementRotary centrifugesFurnace temperatureNonferrous metal

The invention discloses a method and device for separating 434 aluminum alloy composite plates, belongs to the field of nonferrous metallurgy, and mainly solves the problem of recycling of the 434 aluminum alloy composite plates. The preparation method comprises the following steps: firstly, melting a coating alloy of the 434 aluminum alloy at 574-643 DEG C in a high-temperature centrifugal machine; then centrifugally separating the molten alloy, discharging the molten alloy through a liquid phase outlet pipe, closing a centrifugal mechanism, and taking out the unfused alloy; and finally, the molten alloy and the incomplete alloy are smelted in a smelting furnace and poured into cast ingots. The device comprises a shell, a heat preservation layer, a PID furnace temperature self-adjusting system, a centrifugal mechanism, a liquid outlet mechanism, a melt deposition tank, a liquid phase outlet pipe, a furnace cover lifting mechanism, a feeding and discharging mechanism and a tool. According to the method, a temperature field and a centrifugal force field are used for achieving same-grade recovery after a coating layer and a core layer of the 434 aluminum alloy composite plate are effectively separated, and 3003 aluminum alloy and 4004 aluminum alloy with the same-grade quality are obtained through separation.

Owner:HARBIN UNIV OF SCI & TECH

Electroslag remelting slag system of a super duplex stainless steel

The invention relates to an electroslag remelting slag system of super duplex stainless steel. The electroslag remelting slag system comprises the following ingredients by weight percentage: 55-74% ofCaF2, 5-20% of CaO, 5-20% of Al2O3, 5-15% of MgO and 1-15% of SiO2. According to the electroslag remelting slag system, optimal slag alkalinity is achieved by adjusting contents of basic oxides, namely CaO and MgO, and acidic oxides, namely SiO2 and Al2O3; and the electroslag remelting slag system is particularly applicable to electroslag remelting of the super duplex stainless steel, improves purity of the super duplex stainless steel, reduces a content of harmful impurity elements, optimizes an ingot structure, greatly improves processability of the stainless steel increases a hot processing yield and contributes to achieving excellent mechanical properties and corrosion resistance.

Owner:CHONGQING MATERIALS RES INST

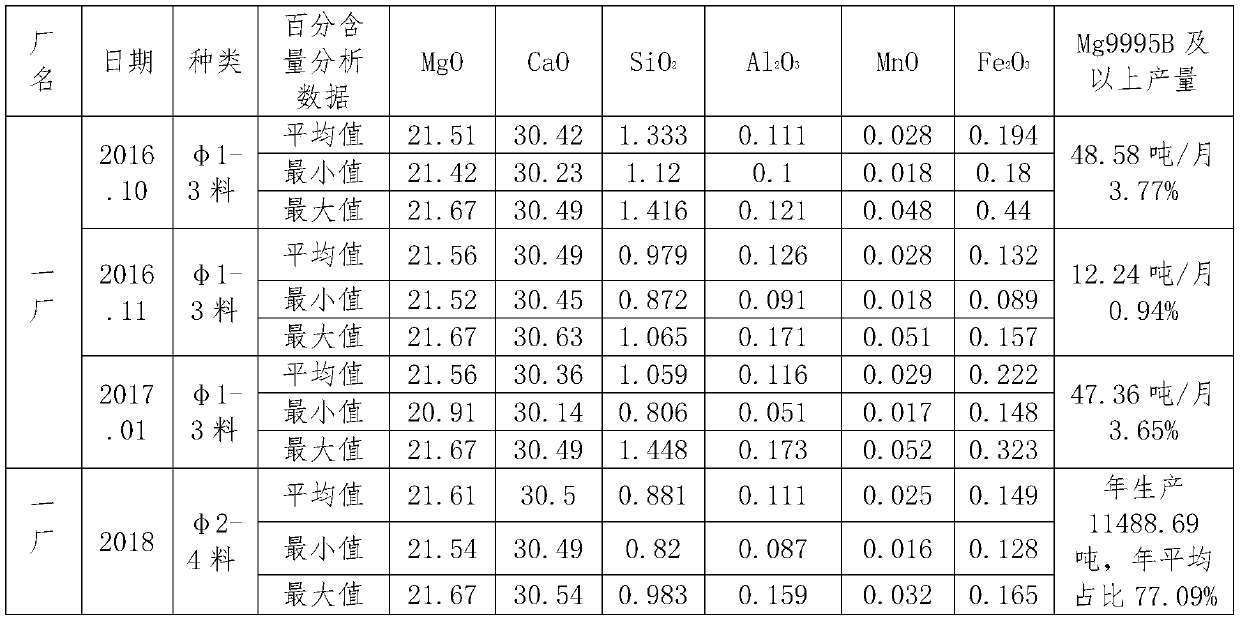

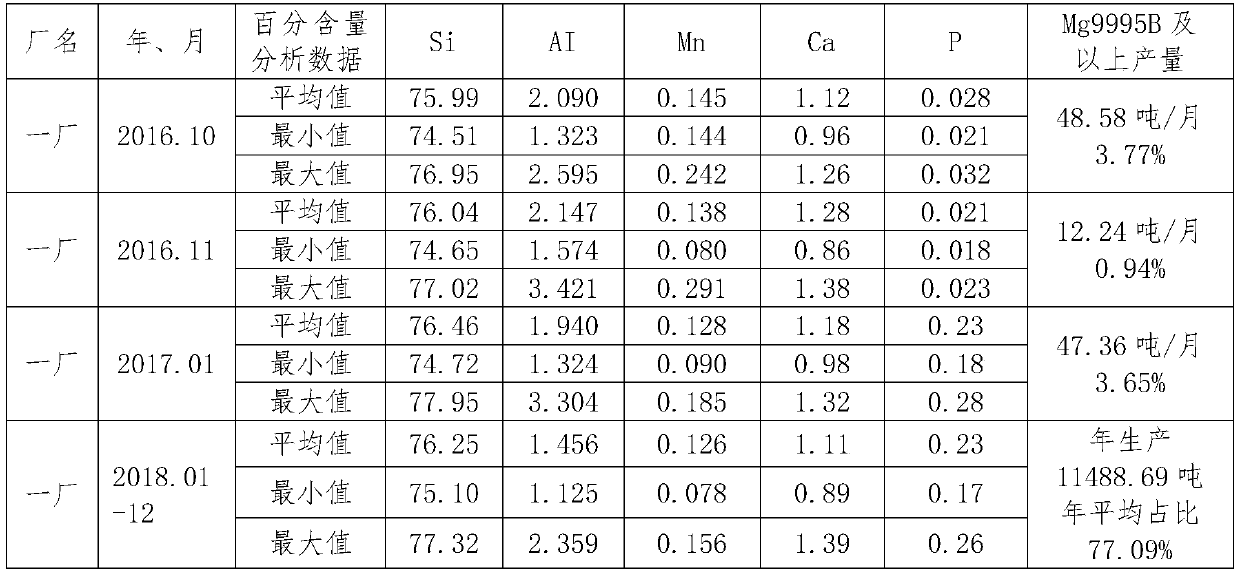

Production technology of Mg 9995B and above protogenetic magnesium ingot

The invention provides a production technology of Mg 9995B and above protogenetic magnesium ingot. The production technology comprises the following steps: S1, calcining dolomite to obtain calcined dolomite; S2, mixing calcined dolomite, fluorite powder and ferrosilicon to obtain a mixture, and carrying out ball-milling and pelletizing on the mixture to obtain pellet material; S3, filling the pellet material in a reducing tank, carrying out high temperature heat reduction reaction under the vacuum condition to obtain crystallized magnesium, wherein the reducing temperature is 1235-1245 DEG C;and S4, carrying out refining and pouring on the crystallized magnesium to obtain the protogenetic magnesium ingot. With adoption of the production technology, the percentage content of Mg in the protogenetic magnesium ingot is increased, the impurity element is reduced, large-scale production of Mg 9995B and above protogenetic magnesium ingot is realized, and master batch is provided for production of magnesium alloy.

Owner:FUGU TAIDA COAL CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com