Microalloying chromium-nickel austenitic heat-resistant steel, as well as preparation method and application thereof

An austenitic heat-resistant steel and micro-alloying technology, applied in the field of alloys, can solve problems such as hot cracks, poor casting performance, complex structure of exhaust pipe and turbine casing castings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention provides a method for preparing the microalloyed chromium-nickel series austenitic heat-resistant steel described in the above scheme, comprising the following steps:

[0042] The alloy raw material is smelted to obtain a feed liquid; the alloy raw material includes the following components in mass percentage: carbon 0.30%-0.60%, silicon 2.00%-3.00%, manganese≤1.00%, phosphorus≤0.04%, sulfur≤0.3% %, chromium 23.00%~28.00%, nickel 27.00%~30.00%, niobium 0.50%~1.50%, molybdenum ≤0.6%, nitrogen 0.20%~0.50%, vanadium 0.20%~0.50%, boron 0.01%~0.05%, rare earth Elements 0.005% ~ 0.100%, the balance of iron;

[0043] After the feed solution is left to stand, it is poured and formed to obtain a micro-alloyed chromium-nickel system austenitic heat-resistant steel.

[0044] The invention melts alloy raw materials to obtain feed liquid. In the present invention, the composition and content of the elements in the alloy raw material are consistent with the ab...

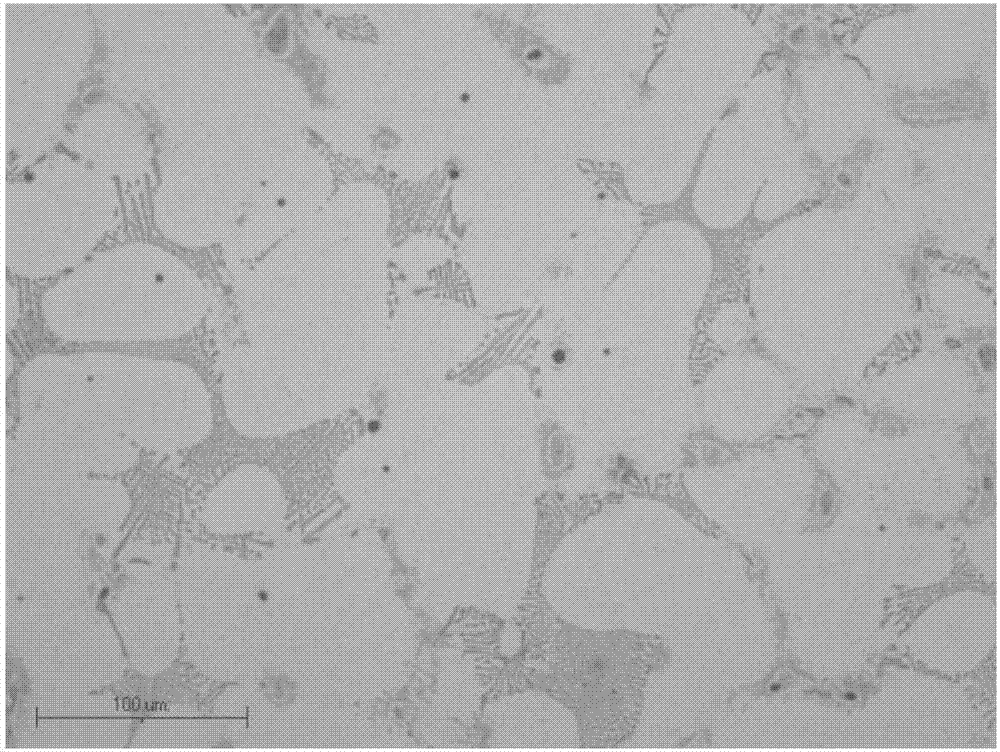

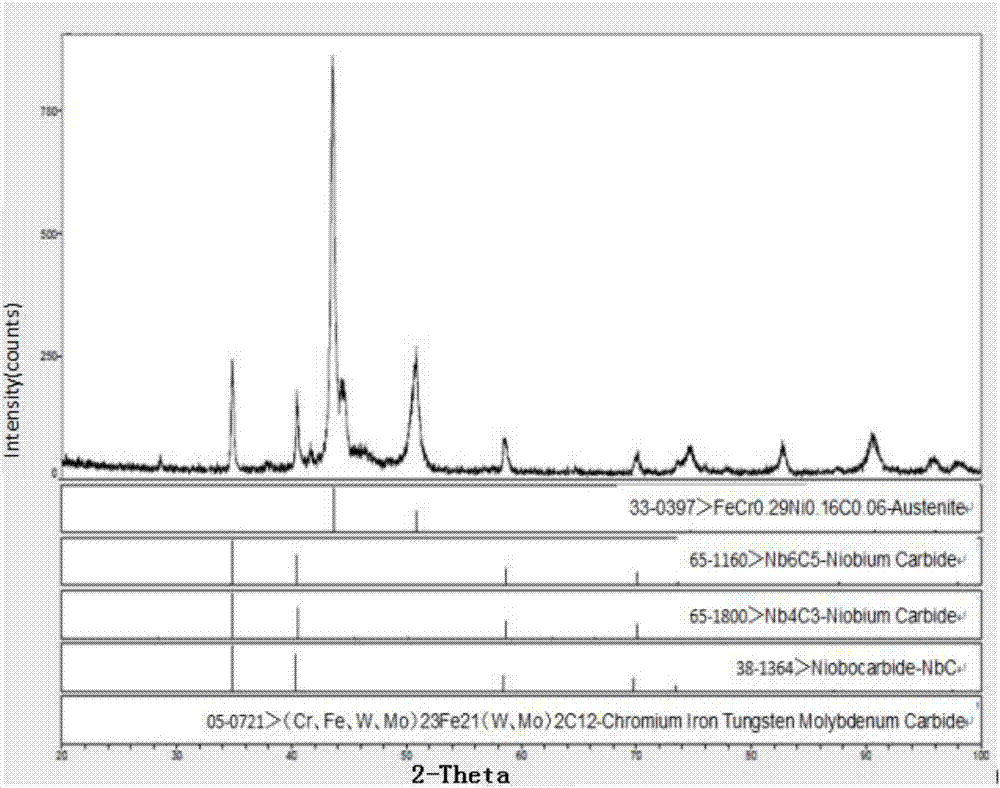

Embodiment 1

[0057] Ingredients: The weight percentage distribution of main raw materials is: recarburizer = 0.50%, scrap steel = 22.72%, chromium nitride (FeNCr10-A) = 4.20%, micro-carbon ferrochrome (ZKFeCr65C0.03) = 38.30%, niobium Iron (FeNb-60) = 1.40%, ferrosilicon (FeSi75-B) = 3.25%, nickel plate (99.9% high-purity nickel plate) = 29.00%, vanadium iron (FeV50-A) = 0.45%, boron iron (FeB23C0. 05) = 0.11%, dense cerium alloy = 0.025%;

[0058] Melting: The smelting equipment adopts a medium-frequency induction furnace. Firstly, steel scrap, nickel plate, ferro-vanadium, ferro-boron, and recarburizer are put into the medium-frequency induction furnace, and the temperature is raised to 1580°C by power transmission. After the material is melted, the remaining material is added to the furnace and continued Heat preservation smelting, control the total smelting time to 2 hours; when the input materials are completely melted, raise the temperature in the intermediate frequency induction fur...

Embodiment 2

[0071] Ingredients: The weight percentage distribution of main raw materials is: recarburizer = 0.48%, scrap steel = 21.782%, chromium nitride (FeNCr10-A) = 4.63%, micro-carbon ferrochromium (ZKFeCr65C0.03) = 37.55%, niobium Iron (FeNb-60) = 2.71%, ferrosilicon (FeSi75-B) = 2.93%, nickel plate (99.9% high-purity nickel plate) = 29.00%, vanadium iron (FeV50-A) = 0.80%, boron iron (FeB23C0. 05) = 0.10%, dense cerium alloy = 0.018%;

[0072] Melting: The smelting equipment adopts a medium-frequency induction furnace. Firstly, steel scrap, nickel plate, ferro-vanadium, ferro-boron, and recarburizer are put into the medium-frequency induction furnace, and the temperature is raised to 1620°C by power transmission. After the materials are melted, the remaining materials are added to the furnace and continue Heat preservation smelting, control the total smelting time to 2 hours; when the input materials are completely melted, continue to raise the temperature in the intermediate frequ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com