Damage-resistant aluminum alloy and preparation method thereof

An aluminum alloy and damage-resistant technology, applied in the field of damage-resistant aluminum alloy and its preparation, can solve the problems of difficulty in improving the comprehensive performance of damage-resistant aluminum alloy profiles, and achieve the effects of realizing large-scale industrial production, reducing size, and reducing crack initiation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

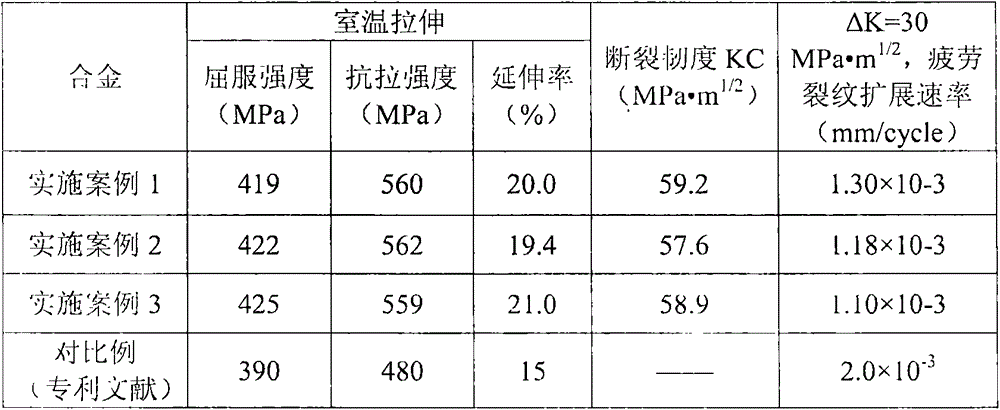

Examples

Embodiment 1

[0031] (1) The alloy composition is: Cu: 4.0%, Mg: 1.0%, Mn: 0.5%, Zr: 0.11%, Er: 0.15%, and the balance is Al and trace impurity elements, the total content of which is less than 0.1% .

[0032] (2) According to the designed components, get pure aluminum, pure magnesium, Al-Cu master alloy, Al-Mn master alloy, Al-Zr master alloy, Al-Er master alloy, remove the impurities on the surface and then dry it. The purity of the pure aluminum is ≥99.99%, and the purity of the pure magnesium is ≥99.99%.

[0033] (2) Raise the temperature of the metal aluminum to 793°C±5°C, when the charge begins to soften and settle down, then add a covering agent in an amount of 0.55% of the total weight of the metal to form an aluminum melt with a covering agent on the surface. The covering agent is composed of the following components by weight: 33% Al 2 o 3 , 7% CaO, 35% charcoal, 12% KCl, 8% NaCl, 5% Na 3 AlF 6 .

[0034] (3) Add Al-Zr master alloy, Al-Cu master alloy and Al-Mn master alloy ...

Embodiment 2

[0042] (1) The alloy composition is: Cu: 4.0%, Mg: 1.2%, Mn: 0.5%, Zr: 0.12%, Er: 0.15%, the balance is Al and trace impurity elements, the total content of the impurity elements is less than 0.1% %.

[0043] (2) Prepare pure aluminum, pure magnesium, Al-Cu master alloy, Al-Mn master alloy, Al-Zr master alloy, Al-Er master alloy respectively according to the designed components, remove the impurities on the surface and then dry it. The purity of the pure aluminum is ≥99.99%, and the purity of the pure magnesium is ≥99.99%.

[0044] (2) Raise the temperature of the metal aluminum to 793°C±5°C, when the charge begins to soften and settle down, then add a covering agent in an amount of 0.55% of the total weight of the metal to form an aluminum melt with a covering agent on the surface. The covering agent is composed of the following components by weight: 33% Al 2 o 3 , 7% CaO, 35% charcoal, 12% KCl, 8% NaCl, 5% Na 3 AlF 6 .

[0045] (3) Add Al-Zr master alloy, Al-Cu master ...

Embodiment 3

[0053] (1) The alloy composition is: Cu: 4.0%, Mg: 1.4%, Mn: 0.5%, Zr: 0.13%, Er: 0.13%, the balance is Al and trace impurity elements, the total content of the impurity elements is less than 0.1% %.

[0054] (2) According to the designed components, get pure aluminum, pure magnesium, Al-Cu master alloy, Al-Mn master alloy, Al-Zr master alloy, Al-Er master alloy, remove the impurities on the surface and then dry it. The purity of the pure aluminum is ≥99.99%, and the purity of the pure magnesium is ≥99.99%.

[0055] (2) Raise the temperature of the metal aluminum to 793°C±5°C, when the charge begins to soften and settle down, then add a covering agent in an amount of 0.55% of the total weight of the metal to form an aluminum melt with a covering agent on the surface. The covering agent is composed of the following components by weight: 33% Al 2 o 3 , 7% CaO, 35% charcoal, 12% KCl, 8% NaCl, 5% Na 3 AlF 6 .

[0056] (3) Add Al-Zr master alloy, Al-Cu master alloy and Al-Mn ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com