Hammer based on functionally graded composite material and preparation method thereof

A composite material, functional gradient technology, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of poor wear resistance and low service life of hammers, achieve low production costs, improve hardness and wear resistance, and save steel Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with specific embodiments.

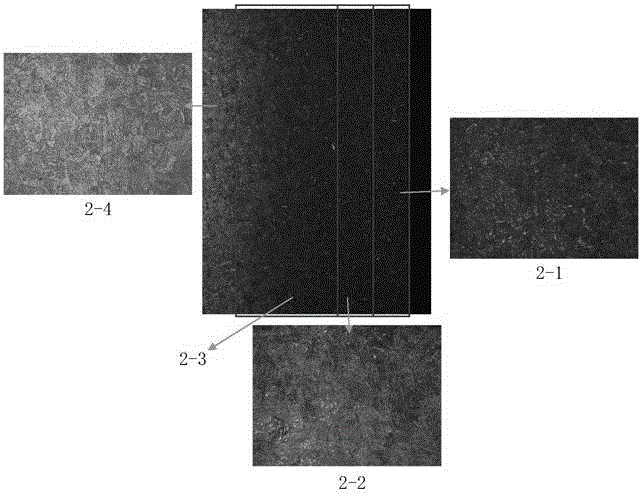

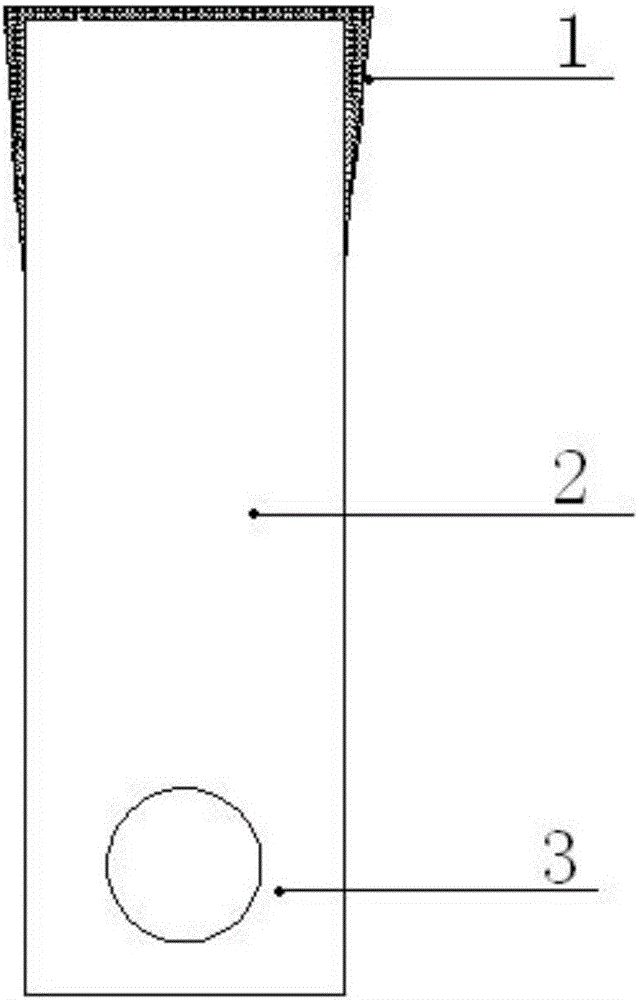

[0021] A hammer based on a functionally graded composite material, comprising a hammer matrix, such as figure 1 As shown, the working end 1 of the hammer is equipped with a ceramic particle reinforced composite layer with a WC content of more than 50% as a wear-resistant layer; 0.8%-1.0%; the transition layer structure is fine acicular tempered martensite plus lath tempered martensite, and the core structure is lath tempered martensite with a carbon content of 0.2%; the hammer is fixed The structure of the end pin hole is mainly tempered sorbite.

[0022] The hardness of the above-mentioned working end is 63-65HRC, the surface hardness of the middle part is 48-53HRC, and the surface hardness of the pin hole part is lower than 48HRC.

[0023] In the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com