Patents

Literature

31results about How to "Homogenization time shortened" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

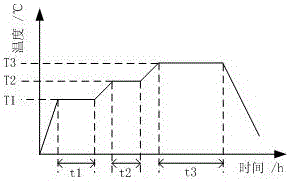

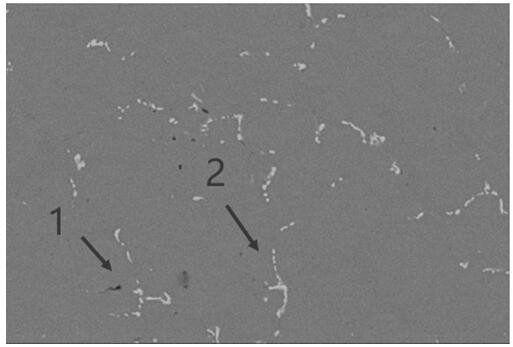

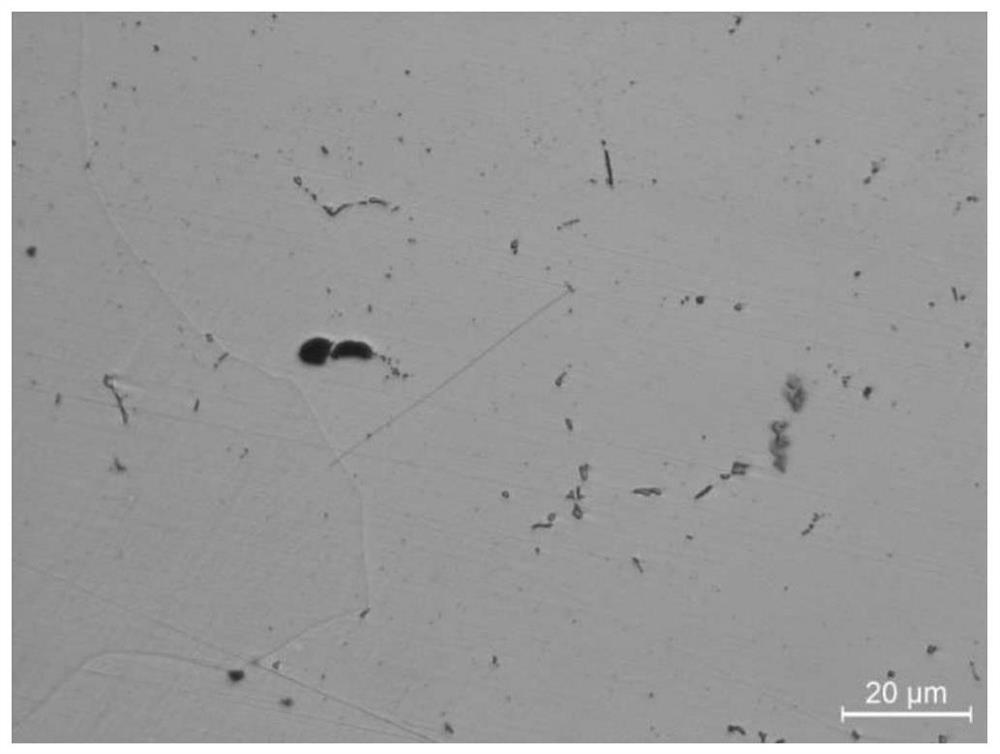

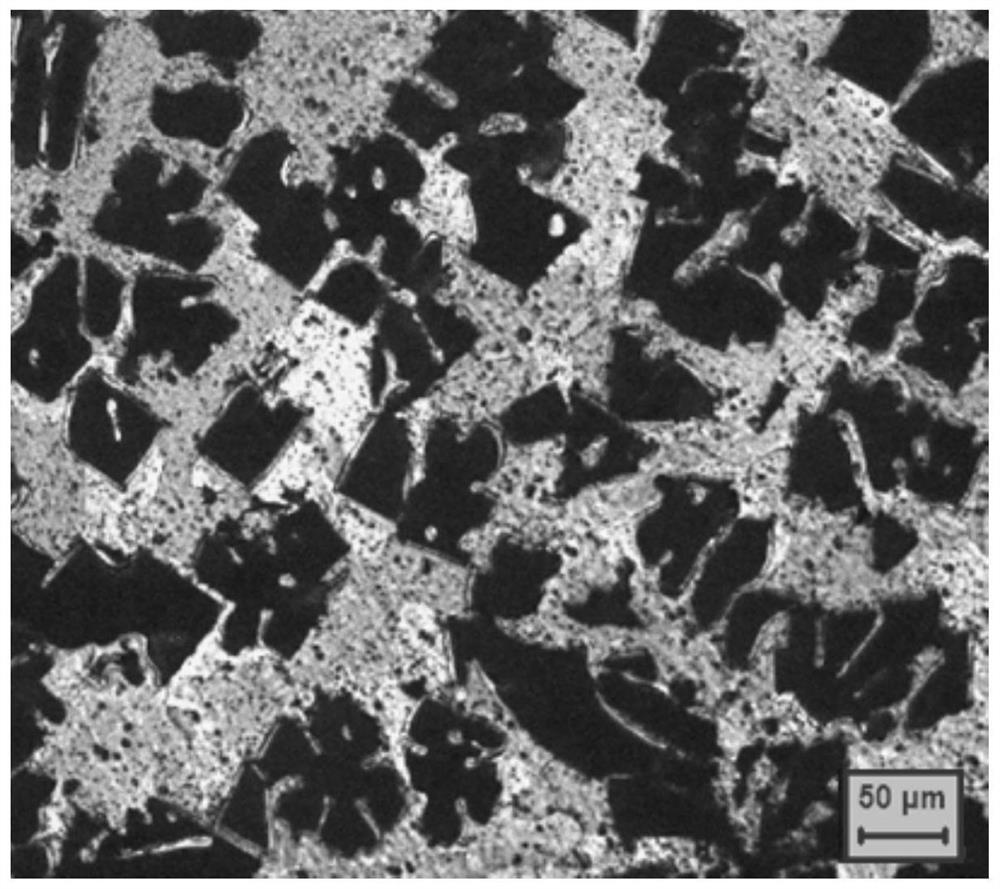

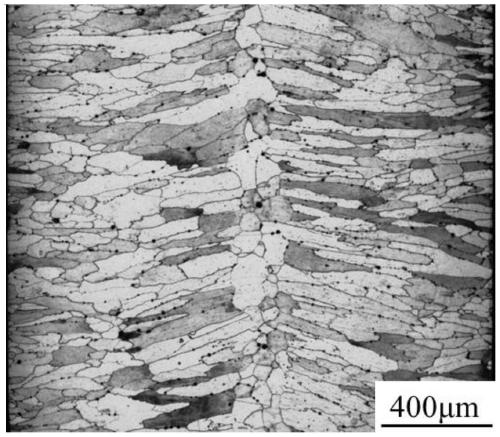

Homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy

The invention relates to a homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy. The homogenization heat treatment method of the Al-Zn-Mg-Cu-Zr aluminum alloy is characterized in that a three-level homogenization heat treatment process for controlling a heating process is used for homogenization heat treatment, and the homogenization heat treatment method comprises the following steps: (1) carrying out low-temperature pre-precipitation, and carrying out a first-level homogenization heat treatment process for promoting precipitation of Al3Zr as a dispersed phase; (2) insulating, and carrying out a second-level homogenization heat treatment process for increasing the overburnt temperature of a structure; and (3) carrying out a long-term uniform insulating process, and carrying out a third-level homogenization heat treatment process for eliminating high-melting-point Al2CuMg. By the heat treatment process, the problem of insufficient soaking in large cast ingots of 7xxx series aluminum alloy can be solved well, a coarse phase does not dissolve in a microscopic structure, an S phase is fully re-dissolved, and meanwhile, uniform precipitation of Al3Zr as the dispersed phase can be regulated and controlled. More importantly, the homogenization heat treatment method is suitable for industrial production of large cast ingots, and has good operability; meanwhile, homogenization heat treatment time can be shortened; and energy consumption of heat treatment is reduced.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

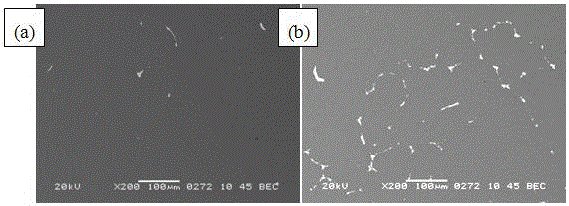

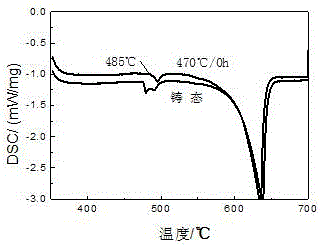

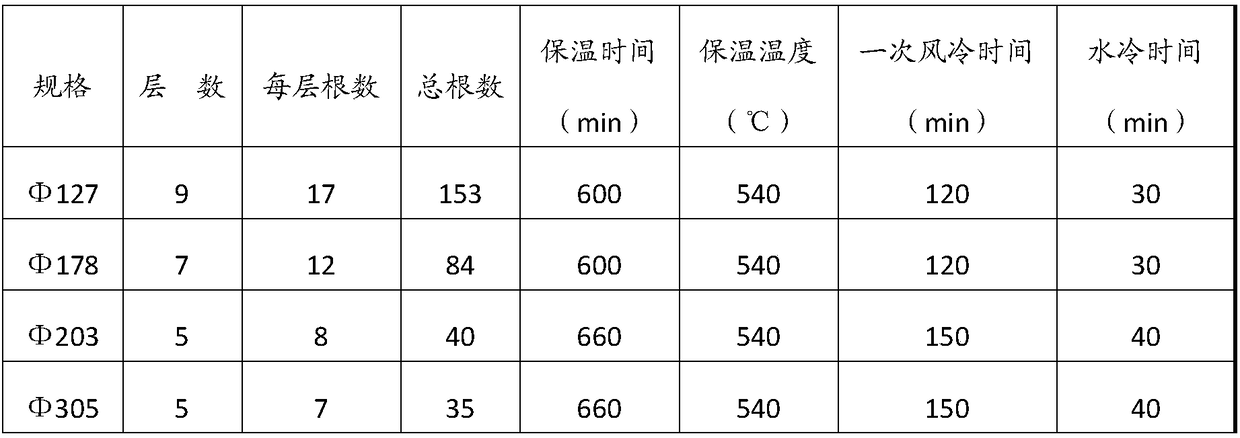

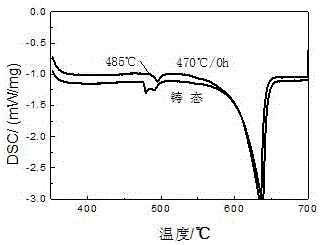

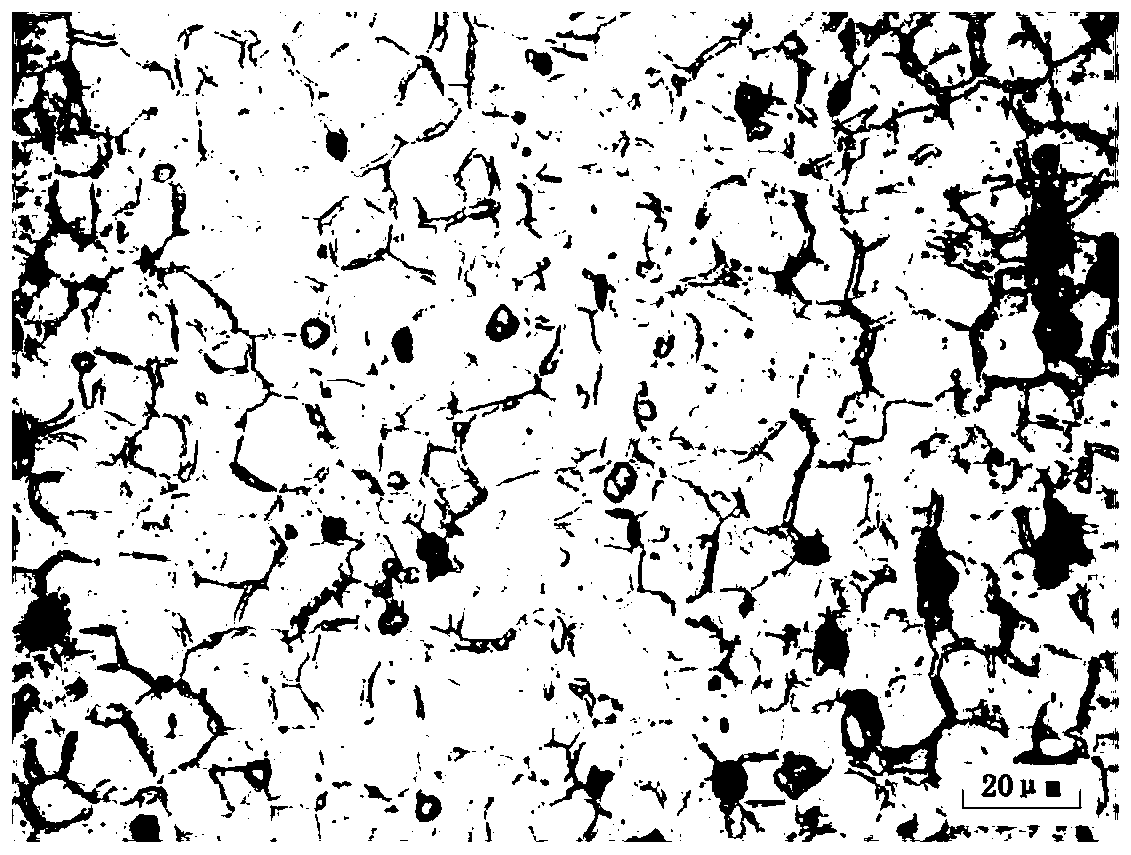

Homogenization process applied in actual production of large-sized 7-series superhard aluminum alloy

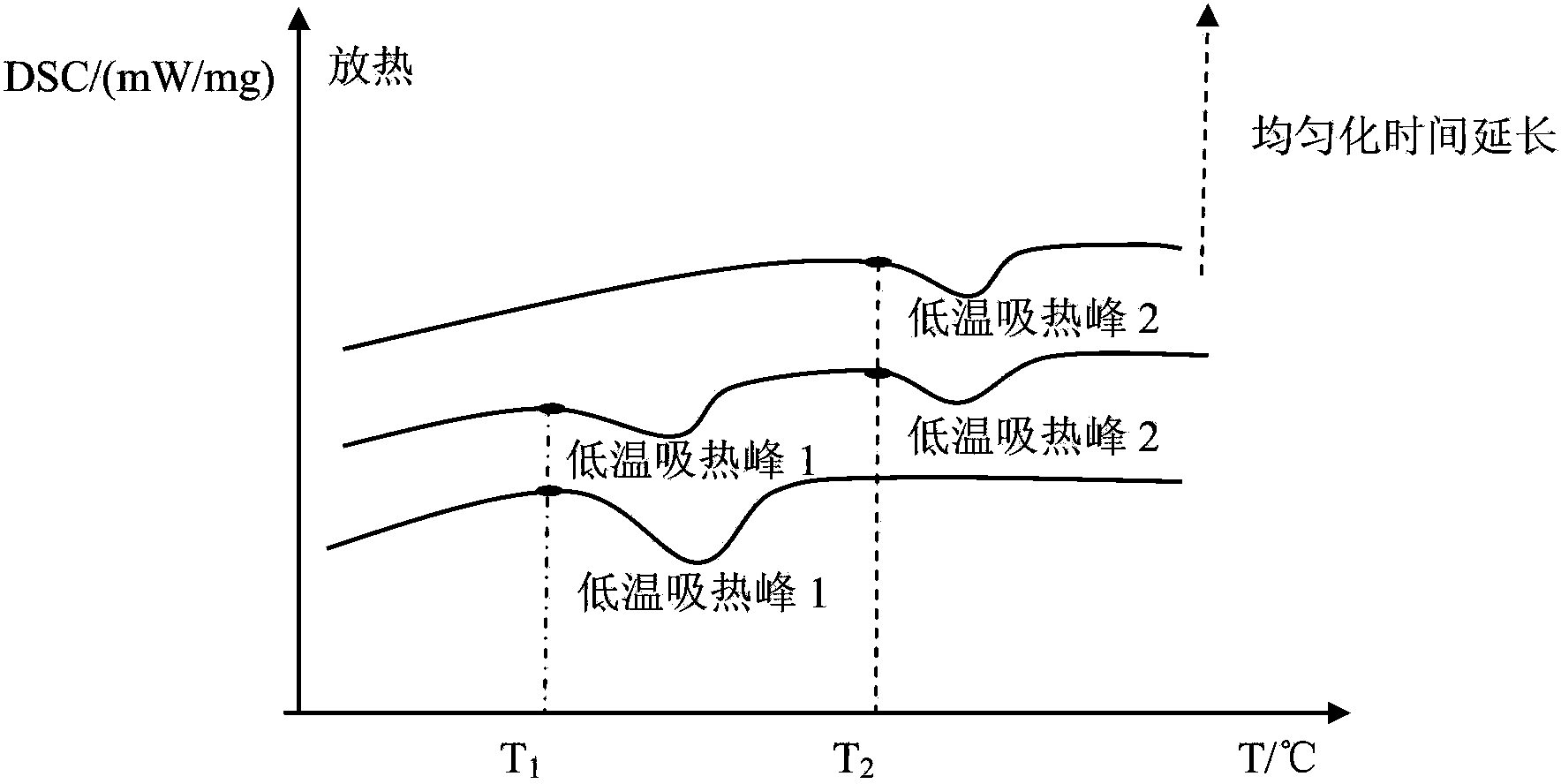

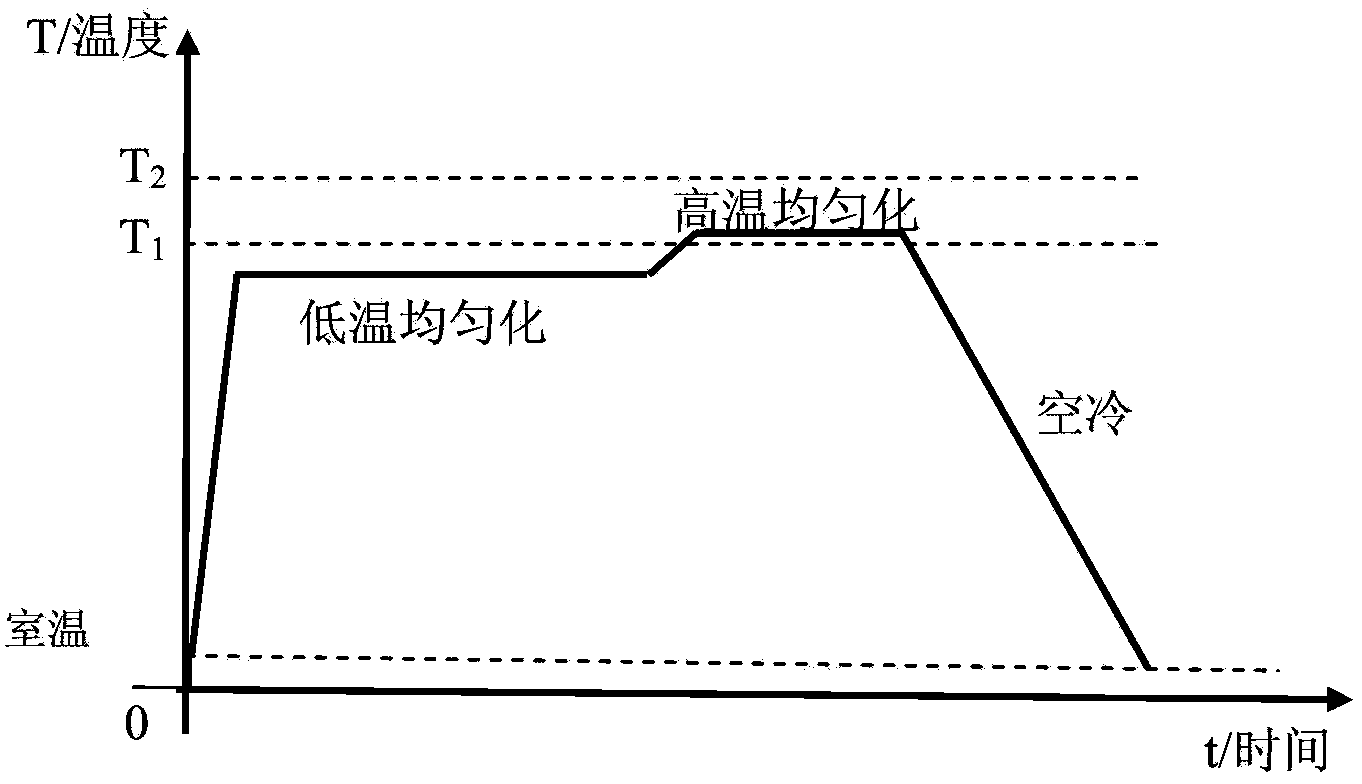

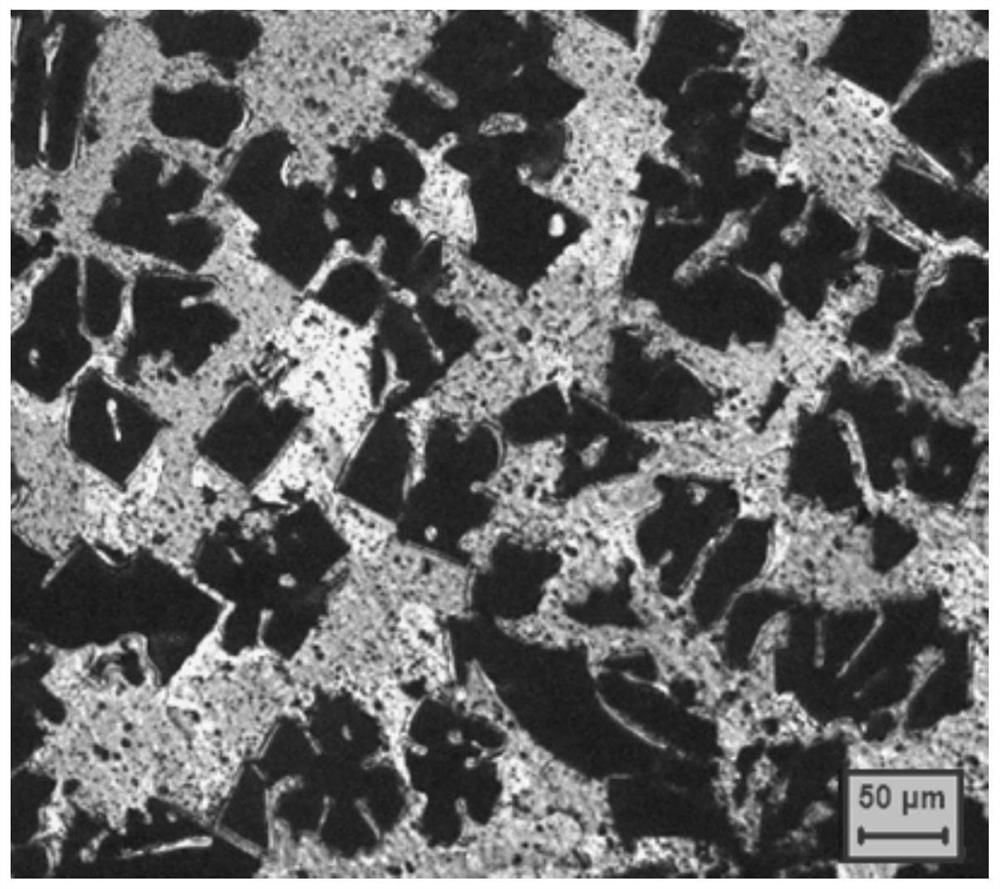

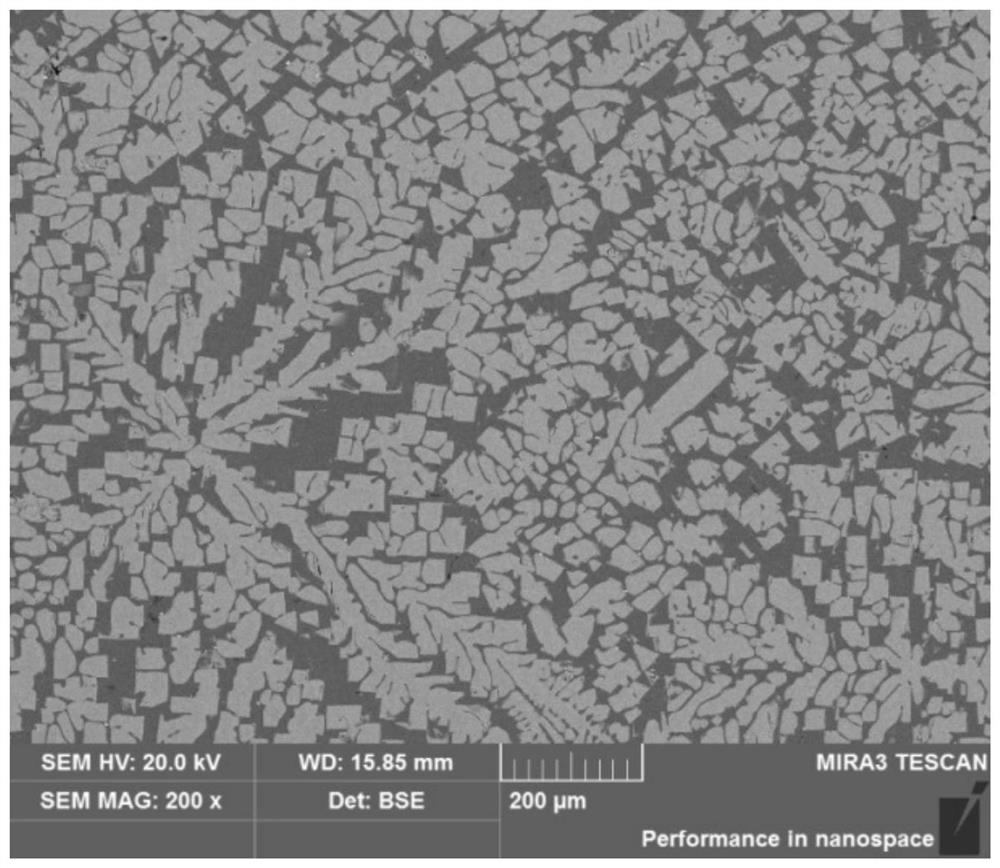

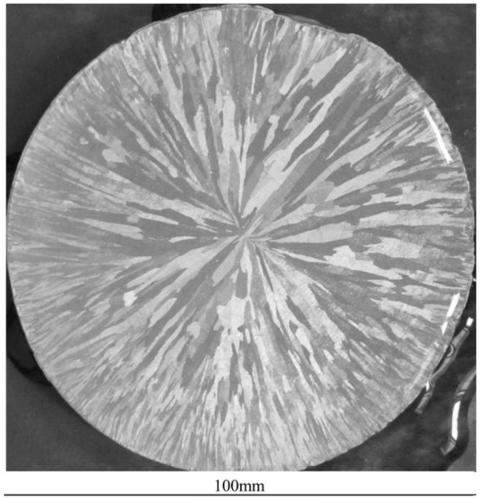

InactiveCN104233127AImprove thermoplasticityEasy to processFurnace typesHeat treatment furnacesFurnace temperatureIngot casting

The invention relates to a homogenization process applied in actual production of a large-sized 7-series superhard aluminum alloy, and the homogenization process solves the problem that the structure of an Al-Zn-Mg-Cu alloy and especially the structure of an alloy formed by adding microelements or an alterant into the Al-Zn-Mg-Cu alloy contain a plurality of more complicated second phases. A large-sized ingot casting is produced by virtue of a continuous casting method, wherein the alloy ingot has well-developed dendritic crystals, so that multiple compositions with low melting points exist among net cells of the dendritic crystals. The homogenization process has the characteristic that the full exertion of potential excellent performance of the large-sized 7-series superhard aluminum alloy is facilitated, and ensures that a homogenization rule is formulated according to an evolvement rule of low-temperature phases in a heat treatment process, i.e., the two-stage homogenized heat treatment with combination of'low-temperature homogenization' and'high-temperature homogenization is adopted. The homogenization process comprises the following steps: firstly carrying out heat preservation on an Al-Zn-Mg-Cu alloy casting blank under a condition of 460 DEG C to 470 DEG C for 6 to 12 hours, slowly rising a furnace temperature to 480 DEG C to 490 DEG C, then carrying out heat preservation at the temperature of 480 DEG C to 490 DEG C for 4 to 12 hours, and carrying out air cooling to a room temperature. According to the homogenization process provided by the invention, the problem that the Al-Zn-Mg-Cu alloy cannot be completely homogenized is solved, the homogenization time of the Al-Zn-Mg-Cu alloy is shortened, and the consumed energy during the heat treatment is saved.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

Method for improving distribution uniformity of reinforced phase in silver metal oxide electric contact material

InactiveCN108950257AImprove uniformityIncrease the concentration of vacanciesElectricitySmelting process

The invention discloses a method for improving distribution uniformity of a reinforced phase in a silver metal oxide electric contact material. A reinforced phase element is prepared into powder, a powder spraying device sprays the reinforced phase element powder into a silver solution through inert gas, vacancy concentration of the reinforced phase element is improved, the relative motion velocity of the reinforced phase element and the silver solution is increased, melting and diffusion velocities of the reinforced phase element in the silver solution can be increased effectively, and distribution uniformity of the reinforced phase in the silver substrate in the silver metal oxide electric contact material is finally improved. The technology can be applied to the production process of all silver metal oxide electric contact materials adopting internal oxidation technology or atomization technology, compared with the traditional internal oxidation technology and atomization technology, the method can significantly shorten uniformization time of the silver alloy smelting process, the volatilization amount of the low-melting-point reinforced phase element in the smelting process isreduced, and environment protection treatment cost is lowered.

Owner:FUDA ALLOY MATERIALS

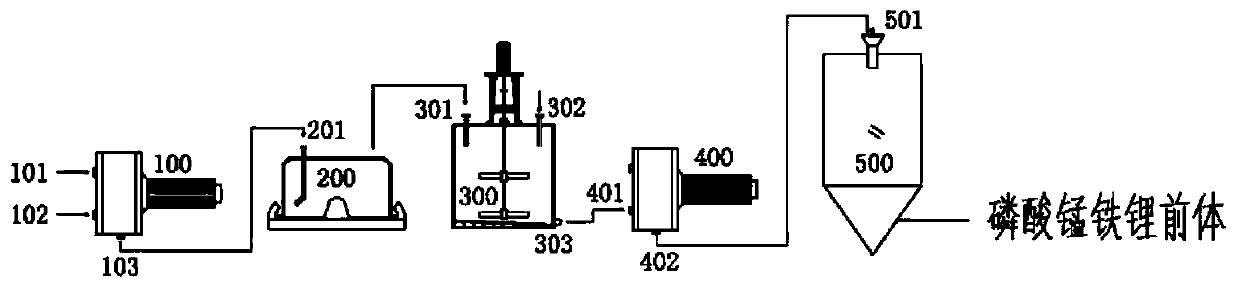

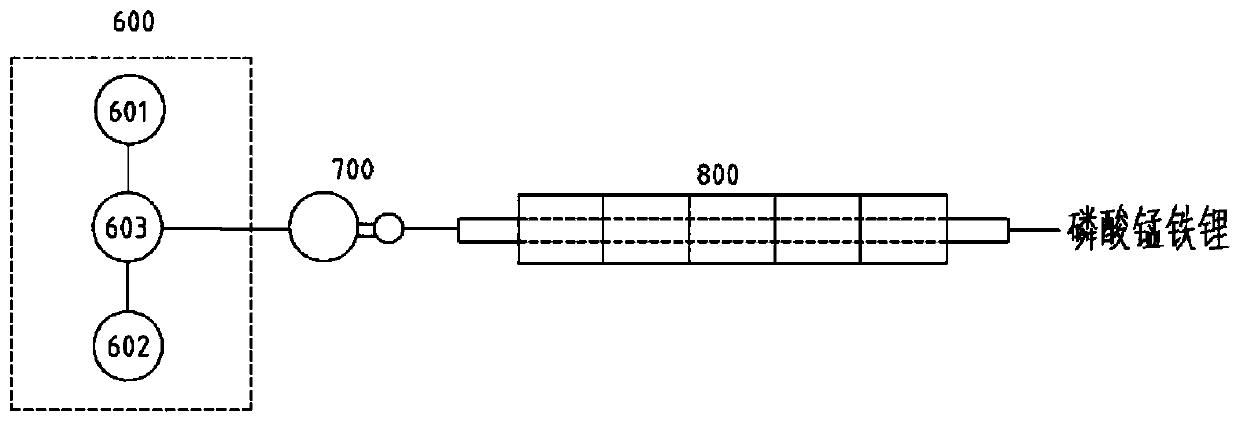

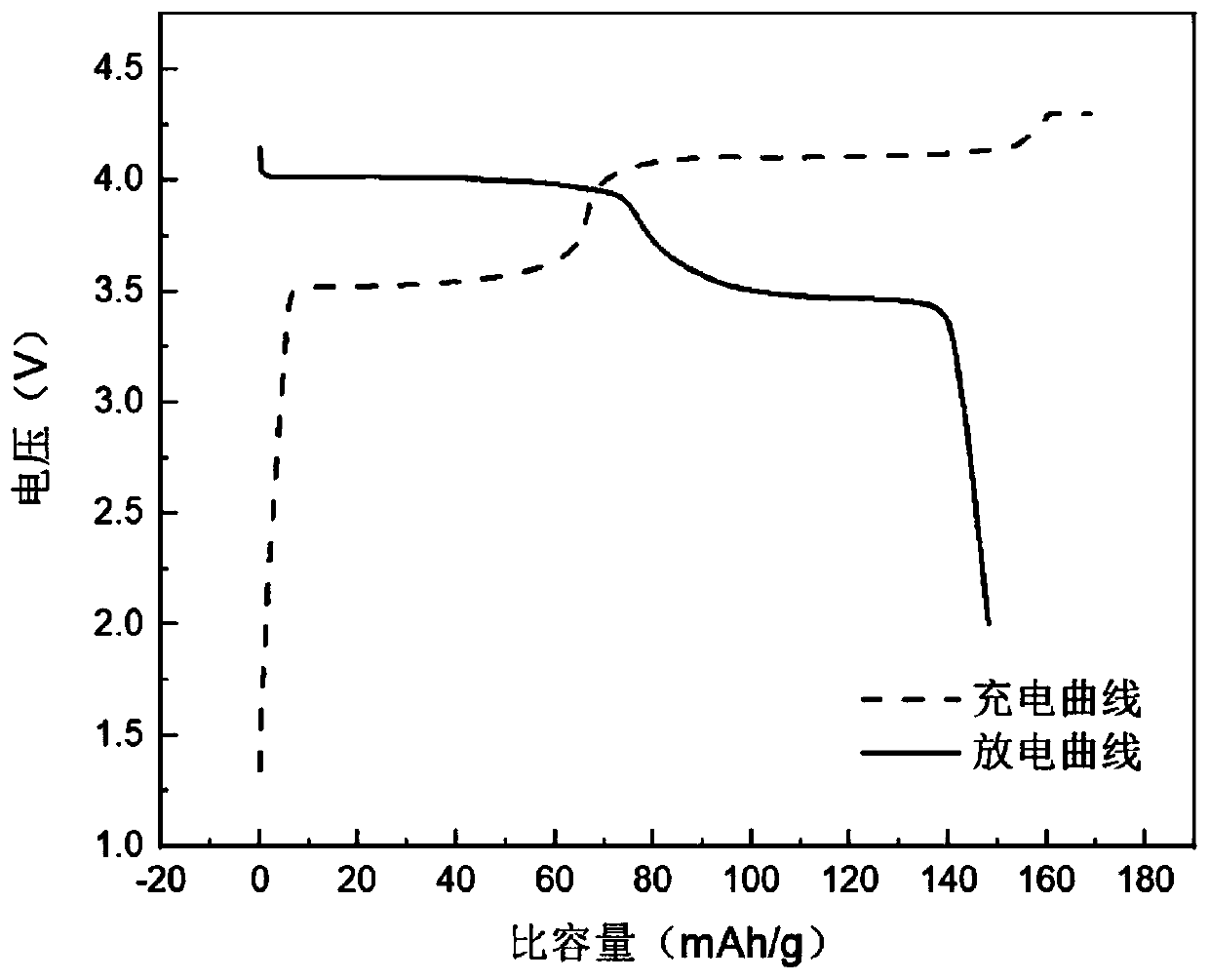

Method for preparing lithium iron manganese phosphate precursor and method for preparing lithium iron manganese phosphate

PendingCN110980682AFine and uniform particle sizeFast manufacturingMaterial nanotechnologyOrganic compound preparationCarbon coatingOXALIC ACID DIHYDRATE

The invention relates to a method for preparing a lithium iron manganese phosphate precursor and a method for preparing lithium iron manganese phosphate. The method for preparing the lithium iron manganese phosphate precursor comprises the following steps: (1) preparing a liquid material A and a liquid material B, wherein the liquid material A is a mixed solution of a manganese salt and an iron salt, and the liquid material B is an oxalic acid or phosphoric acid solution; (2) carrying out a coprecipitation reaction on the liquid material A and the liquid material B in a supergravity rotating bed to obtain a first slurry; (3) washing and filtering the first slurry to obtain a filter cake; (4) mixing the filter cake with water, adding a carbon source, and uniformly stirring to obtain a second slurry; (5) homogenizing the second slurry; and (6) drying the homogenized second slurry to obtain the lithium iron manganese phosphate precursor. The particle size of the lithium iron manganese phosphate precursor prepared by the method is smaller and more uniform than that of a precursor prepared by a traditional method using a reaction kettle, the preparation speed is increased, and carbon coating is uniform.

Owner:JIANGSU LITHITECH CO LTD

Acidic oil-in-water emulsion composition with low water activity, and preparation method and application of acidic oil-in-water emulsion composition

The invention discloses an acidic oil-in-water emulsion composition with low water activity. The acidic oil-in-water emulsion composition comprises the following components in parts by weight: 30-60 parts of vegetable oil, 5-15 parts of polyalcohol, 0.45-2.4 parts of a thickening agent, 2.55-5 parts of an acid agent and 24-59 parts of other base materials. On the basis that oil content is not increased, the polyalcohol of a special content is added to a formula for replacing part of water, so that the polyalcohol interacts with free water and prevents free water from generating bound water, and the content of the free water in a system is reduced; in addition, through compounding of the thickening agent of the special content, the condition that the water activity is reduced so that the stickiness of the system is increased can be controlled, the stickiness is controlled to a stickiness range operable for an industrialized production machine, and the emulsion breaking phenomenon causedby high stickiness, uneven cutting emulsifying or excessive heat is avoided. The technology is improved in the following aspects: raw materials and auxiliary materials which can generate interactionin advance mixing are separated, the feeding sequence is reasonably arranged, the acid agent is firstly added to simplify the operation technology, the homogenizing time is shortened, and the efficiency is improved.

Owner:GUANGZHOU HAODAO FOOD CO LTD

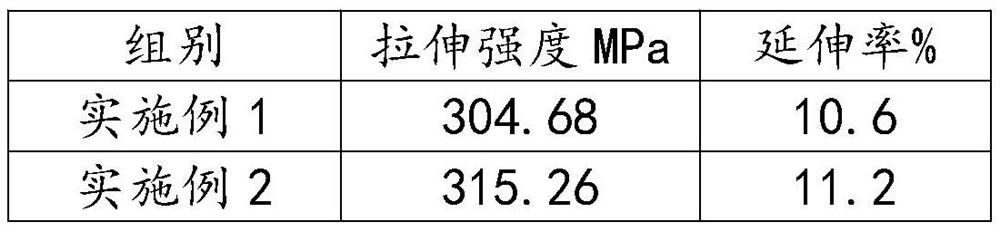

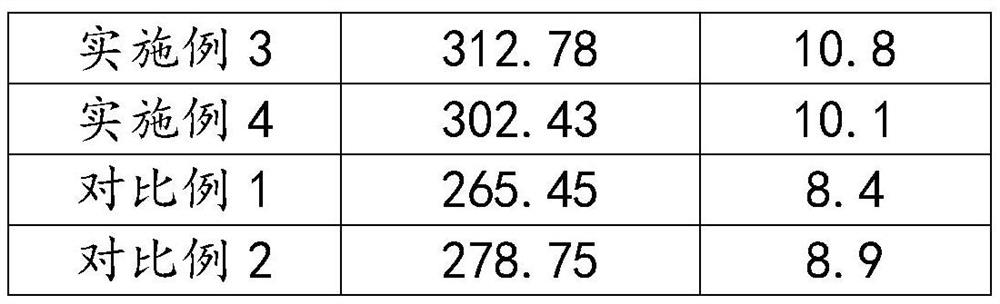

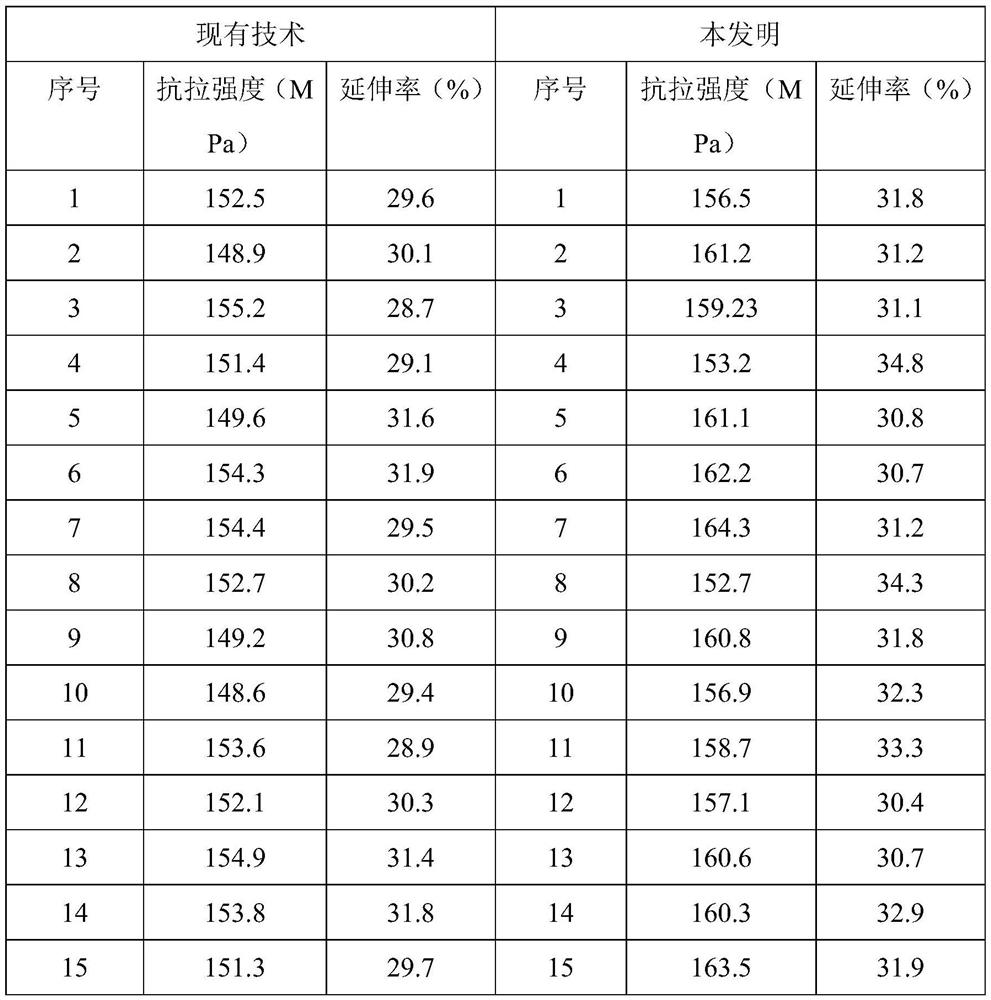

6-series aluminum alloys and preparation method thereof

The invention relates to 6-series aluminum alloys. The 6-series aluminum alloys are composed of the following components in percentage by weight: 0.75-1.1% of magnesium, 0.01-0.02% of titanium, 0.06-0.13% of manganese, 0.5-0.7% of silicon, 0.55-0.7% of copper, 0.005-0.01% of strontium, 0.002-0.008% of pickaxe, not more than 0.13% of iron, not more than 0.01% of zinc, not more than of 0.01% of chromium and the balance of aluminum. The invention also relates to a preparation method of the 6-series aluminum alloys. The 6 series aluminum alloys have the advantages that alloy mechanical propertiesare obviously improved and glossiness is high after the alloys are subjected to highlight oxidation.

Owner:SICHUAN FURONG TECHNOLOGY CO LTD

Preparation method of instant soybean protein powder

PendingCN111587948AImprove dissolution rateLow energy consumptionProtein composition from vegetable seedsVegetable proteins working-upNutritionMaltodextrin

The invention discloses a preparation method of instant soybean protein powder. The method comprises the following steps of S1, selecting plump soybeans without worm damage, and putting the soybeans into water for soaking; S2, adding water into the soaked soybeans, grinding the soybeans into thick liquid, and centrifugally separating and deslagging the obtained thick liquid to obtain slurry; S3, adjusting the pH of the slurry to 6.5, and adding neutral protease into the slurry for enzymolysis to obtain enzymatic hydrolysate; S4, treating the enzymatic hydrolysate in a high-frequency electromagnetic field to obtain a solubilizing solution; S5, performing rapid heating, flash evaporation and rapid cooling on the mixed solution to obtain a sterilized solution; S6, adding lecithin, beta-cyclodextrin and maltodextrin into the obtained sterilized solution, and performing uniform mixing to obtain a mixed solution; S7, homogenizing the mixed solution for three times to obtain a homogenized solution; S8, carrying out spray drying on the homogenized solution to obtain soybean protein powder; and S9, adding silicon dioxide powder into the obtained soybean protein powder, and performing uniform mixing so as to obtain the instant soybean protein powder. The dispersibility and solubility of the soybean protein powder are improved, nutrition is balanced, and protein is more easily and efficiently absorbed by the human body.

Owner:PINGDINGSHAN TIANJING PLANT ALBUMEN

Preparing method of high-strength aluminum alloy material used for building door and window machining

The invention discloses a preparing method of high-strength aluminum alloy material used for building door and window machining. The aluminum alloy material comprises, by mass percent, 0.9% of silicon, 6.8% of copper, 0.3% of magnesium, 0.8% of iron, 0.8% of manganese, 0.35% of chromium, 0.15% of titanium, 0.07% of strontium, 0.3% of zirconium, 0.8% of boron, 0.1% of rhenium, 0.2% of rare earth and the balance raw material aluminum. Manganese and titanium are added for improving the high-temperature strength of alloy containing copper and silicon, the recrystallization process of the aluminumalloy can be prevented, the recrystallization temperature is increased, the recrystallization grains can be obviously refined, through adding of chromium and zirconium, recrystallization nucleation and growing can be obstructed, the alloy can be subjected to certain strengthening, the toughness of the alloy can be improved, stress corrosion cracking sensitivity can be reduced, strontium has the advantages of being long in metamorphic effective time, good in effect and reproducibility and the like, the casting ingot homogenizing time is reduced, the material mechanical property and plastic machining can be improved, the product surface roughness is improved, and hot rolling and cold rolling are smoothly carried out.

Owner:安徽博安门窗有限公司

Anodic oxidation die-casting aluminum alloy material and preparation method thereof

PendingCN111748714AExpand the scope of applicationImproved surface hardness and mechanical propertiesAnodisationAnodic oxidationCorrosion resistant

The invention discloses an anodic oxidation die-casting aluminum alloy material and a preparation method thereof. The anodic oxidation die-casting aluminum alloy material comprises, by mass percent, 2.5-3.5% of Mg, 0.8-1.2% of Mn, 0.2-0.5% of Co, 0.1-0.2% of Cr, 0.01-0.03%of Sr, less than or equal to 0.2% of Si, less than or equal to 0.15% of Fe, less than or equal to 0.05% of Cu, and the balanceAl. According to the material and the method, by optimizing components of an aluminum-manganese system die-casting aluminum alloy material, the material can achieve a good anodic oxidation effect, thedefects of aluminum alloy surface hardness, wear resistance and the like are overcome, and the application range is expanded; and meanwhile, the preparation method is simple, the corrosion effect ofan aluminum alloy on a casting crucible can be reduced, meanwhile, the plasticity of the aluminum alloy is increased, the generation of defects such as thermal cracks, shrinkage cavities, shrinkage porosity and the like is reduced, a honeycomb porous structure on the surface of an anodic oxidation film generated on the surface of the aluminum alloy through the anodic oxidation process is uniform in dye coloring, and the compact anodic oxidation film formed after pore sealing has high surface hardness, wear resistance and corrosion resistance.

Owner:ANHUI SCI & TECH UNIV

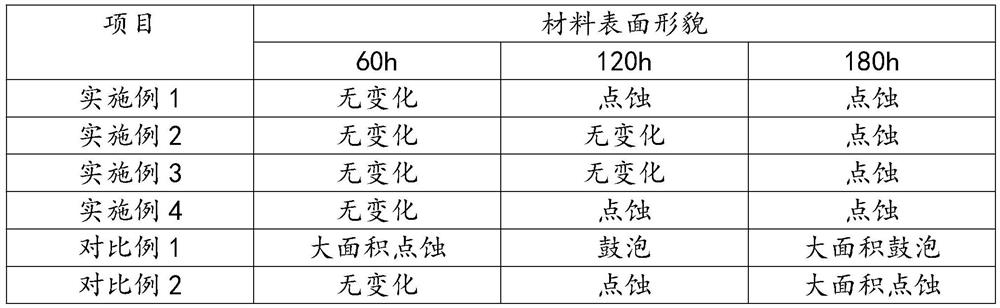

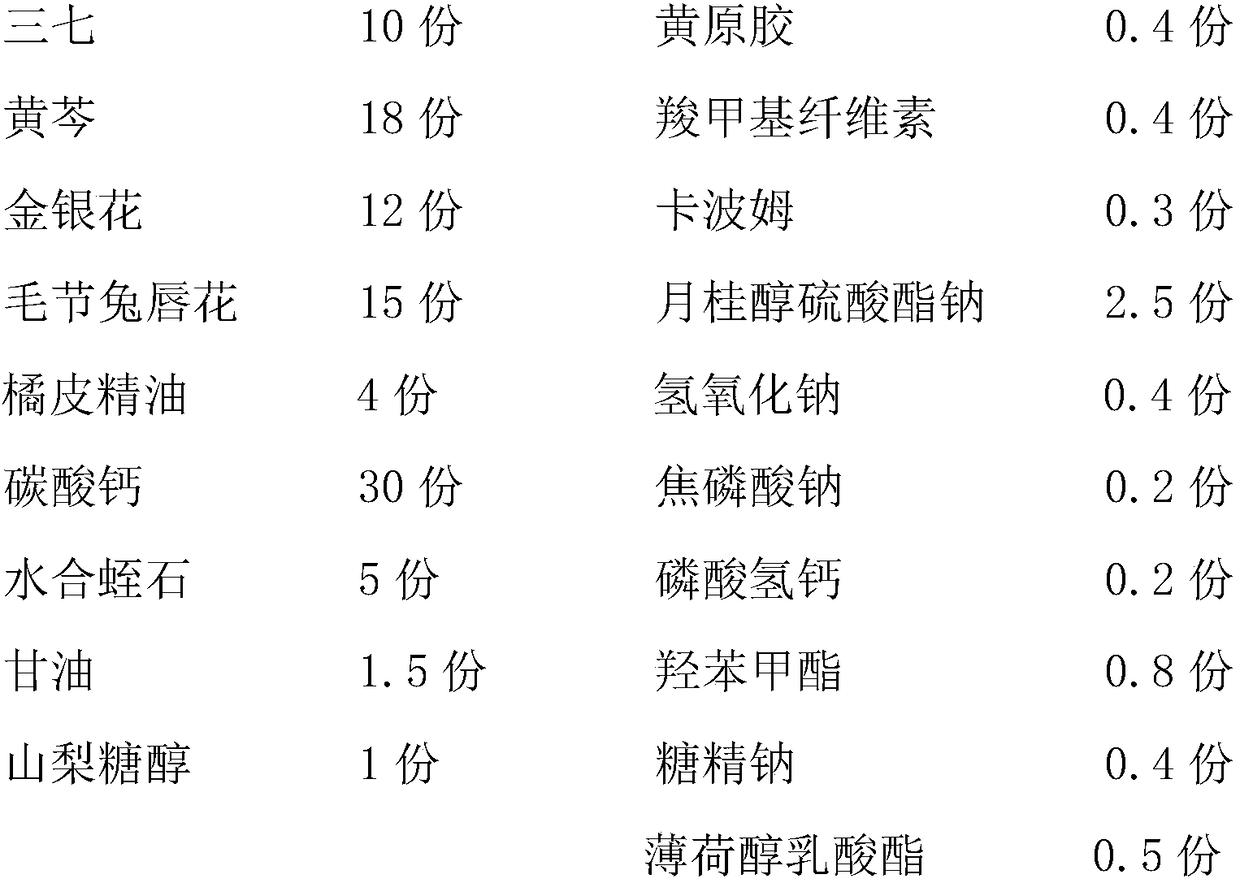

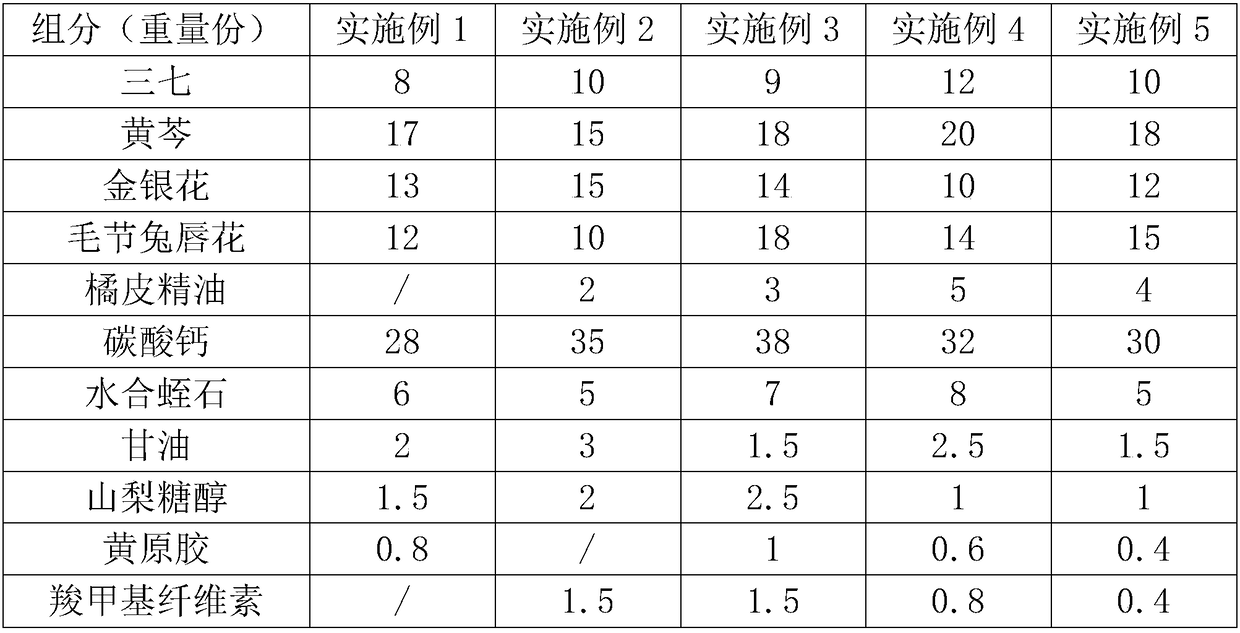

Chinese herbal medicine toothpaste with hemostatic, inflammation-diminishing and bacteriostatic effects and preparation process thereof

InactiveCN108403496AGood antibacterial effectRefreshing tasteCosmetic preparationsToilet preparationsAdditive ingredientBaical Skullcap Root

The invention discloses a Chinese herbal medicine toothpaste with hemostatic, inflammation-diminishing and bacteriostatic effects and a preparation process thereof, which relate to the technical fieldwith components as a characteristic. On the basis of three types of Chinese herbal medicines, i.e. pseudoginseng root, baical skullcap root and honeysuckle flower, the Chinese herbal medicine toothpaste is added with herba lagochilus lanatonodus with anti-inflammation and hemostatic effects and orange peel essence oil with a bacteriostatic effect, the Chinese herbal medicines are reasonably compatible and synergistic, the hemostatic, inflammation-diminishing and bacteriostatic effects of the Chinese herbal medicine toothpaste are excellent and stable, and a novel functional toothpaste is provided for people. The material ratio is optimized by the preparation process for the Chinese herbal medicine toothpaste, so that the quality stability of the prepared paste and the functional ingredients thereof is enhanced, and moreover, the optimization of feeding sequence shortens the time of paste homogenization and reduces the process cost.

Owner:赵朝民

Method for preparing aluminum-scandium alloy with high scandium content

The invention discloses a method for preparing an aluminum-scandium alloy with high scandium content. The method comprises the steps that metal scandium and metal aluminum are weighed according to thescandium content in the aluminum-scandium alloy needing to be prepared; the obtained materials are added into a medium-frequency induction melting furnace, continuously vacuumizing is carried out, and then heating is carried out to 1200-1600 DEG C to melt the metal scandium and the metal aluminum; after complete melting is achieved, alloy liquid is obtained, and heat preservation is carried out for 20-40 min; and high-purity argon is introduced in, the alloy liquid subjected to heat preservation is poured into a water-cooled copper die, circulating water is cooled to 1-15 DEG C by adopting amold circulating water refrigerating system, the cooled circulating water is introduced into the water-cooled copper die to circularly cool the alloy liquid, and cooling and solidifying of the alloy liquid can be completed within 3-8 seconds to obtain an aluminum-scandium alloy cast ingot with scandium content of 5%-99%. According to the method, rapid cooling can be achieved within 3-8 s, the aluminum-scandium alloy with high scandium content which is high in purity, high in compactness, low in segregation, uniform in component and low in cost can be prepared, and the requirement of the current market for the aluminum-scandium alloy with high scandium content is met.

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

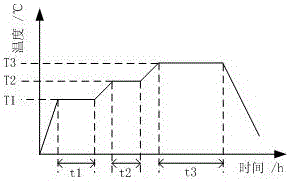

A kind of homogenization heat treatment method of al‑zn‑mg‑cu‑zr aluminum alloy

The invention relates to a homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy. The homogenization heat treatment method of the Al-Zn-Mg-Cu-Zr aluminum alloy is characterized in that a three-level homogenization heat treatment process for controlling a heating process is used for homogenization heat treatment, and the homogenization heat treatment method comprises the following steps: (1) carrying out low-temperature pre-precipitation, and carrying out a first-level homogenization heat treatment process for promoting precipitation of Al3Zr as a dispersed phase; (2) insulating, and carrying out a second-level homogenization heat treatment process for increasing the overburnt temperature of a structure; and (3) carrying out a long-term uniform insulating process, and carrying out a third-level homogenization heat treatment process for eliminating high-melting-point Al2CuMg. By the heat treatment process, the problem of insufficient soaking in large cast ingots of 7xxx series aluminum alloy can be solved well, a coarse phase does not dissolve in a microscopic structure, an S phase is fully re-dissolved, and meanwhile, uniform precipitation of Al3Zr as the dispersed phase can be regulated and controlled. More importantly, the homogenization heat treatment method is suitable for industrial production of large cast ingots, and has good operability; meanwhile, homogenization heat treatment time can be shortened; and energy consumption of heat treatment is reduced.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

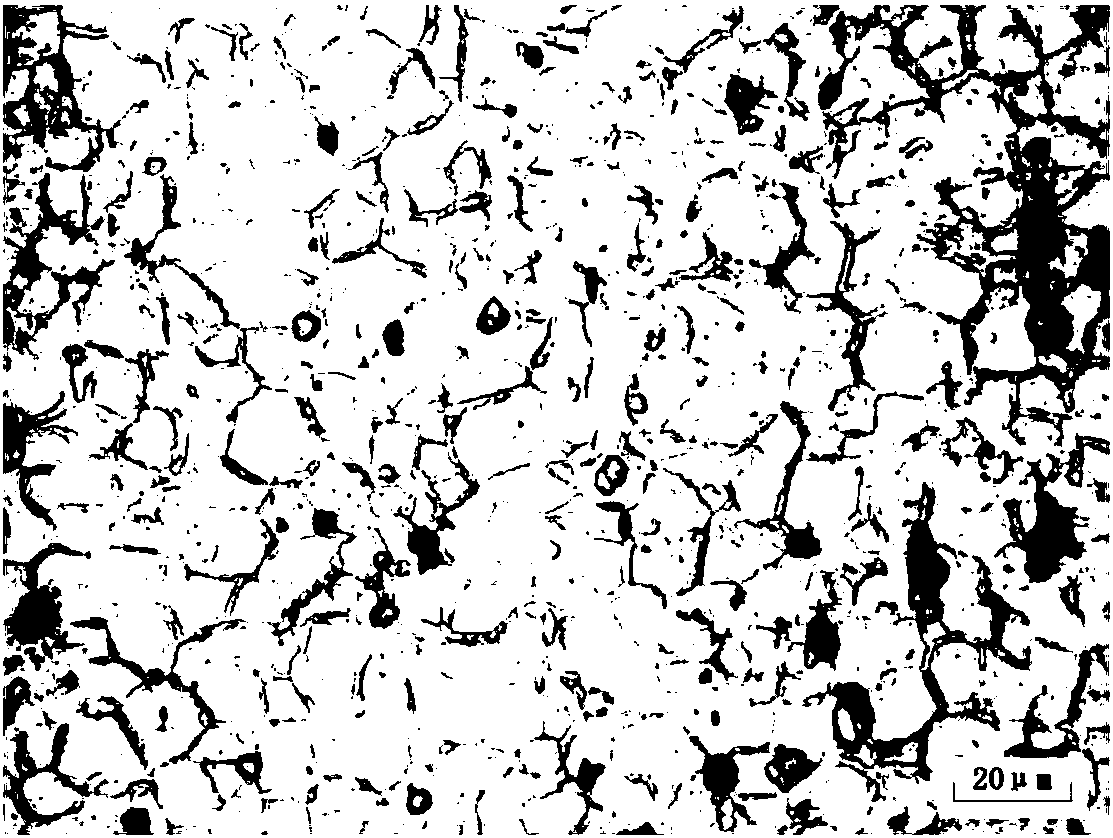

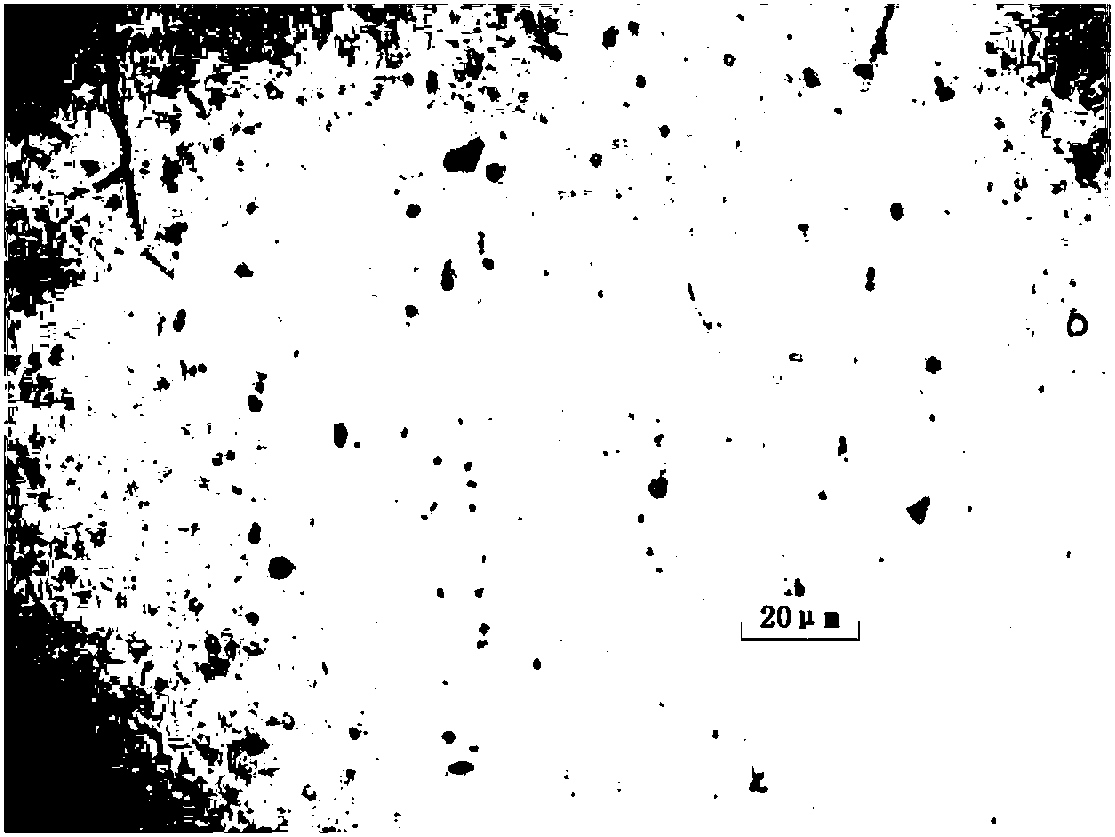

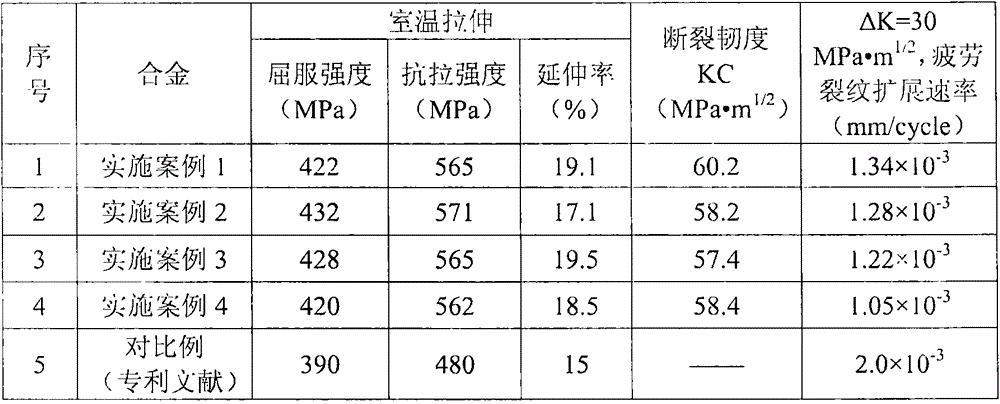

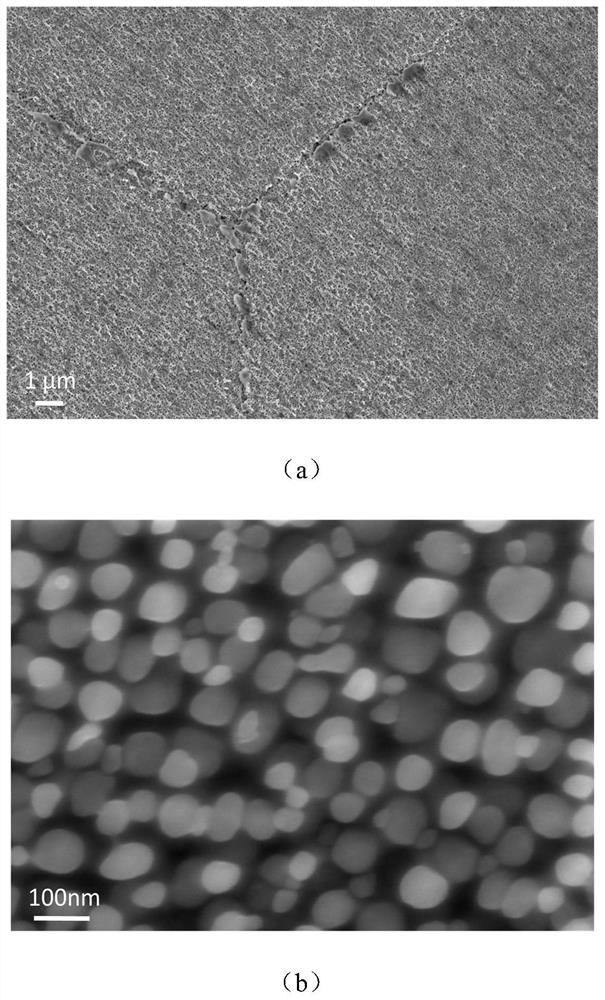

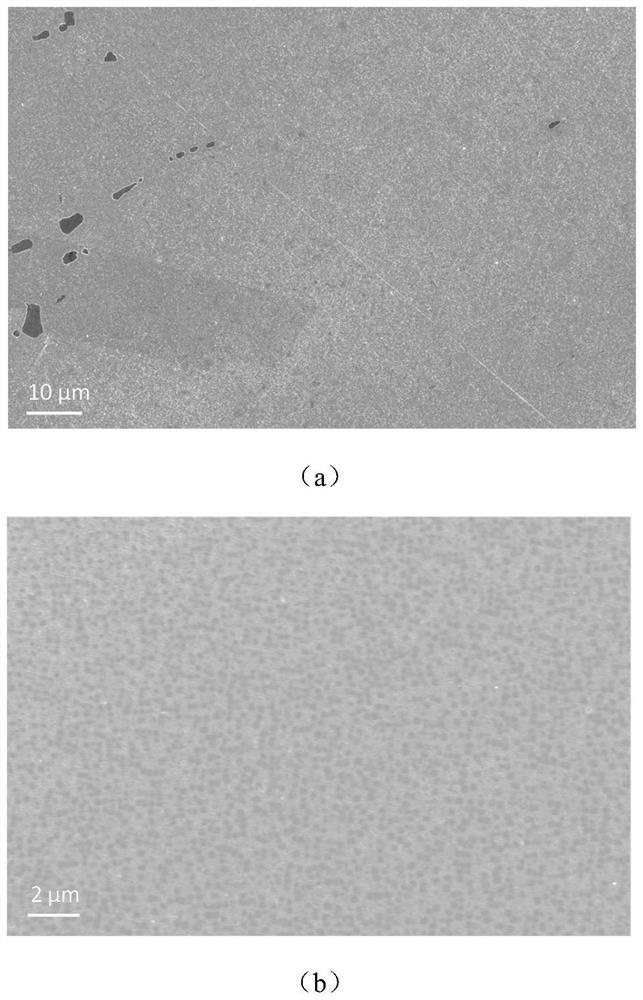

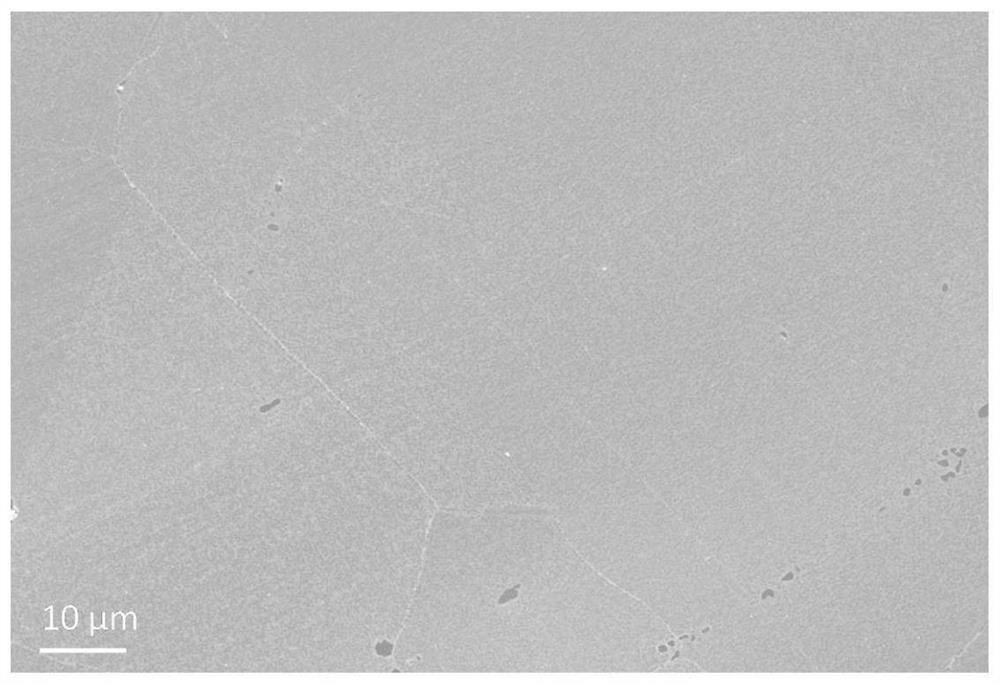

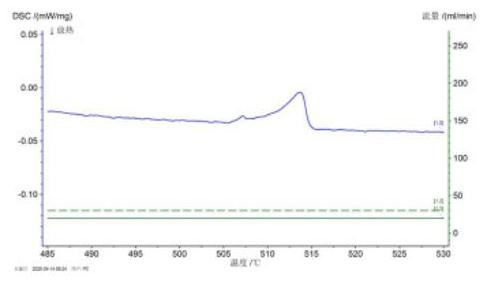

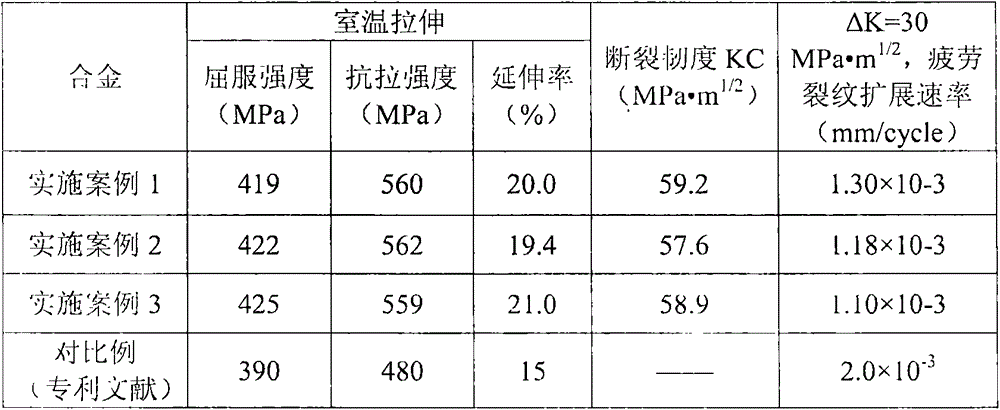

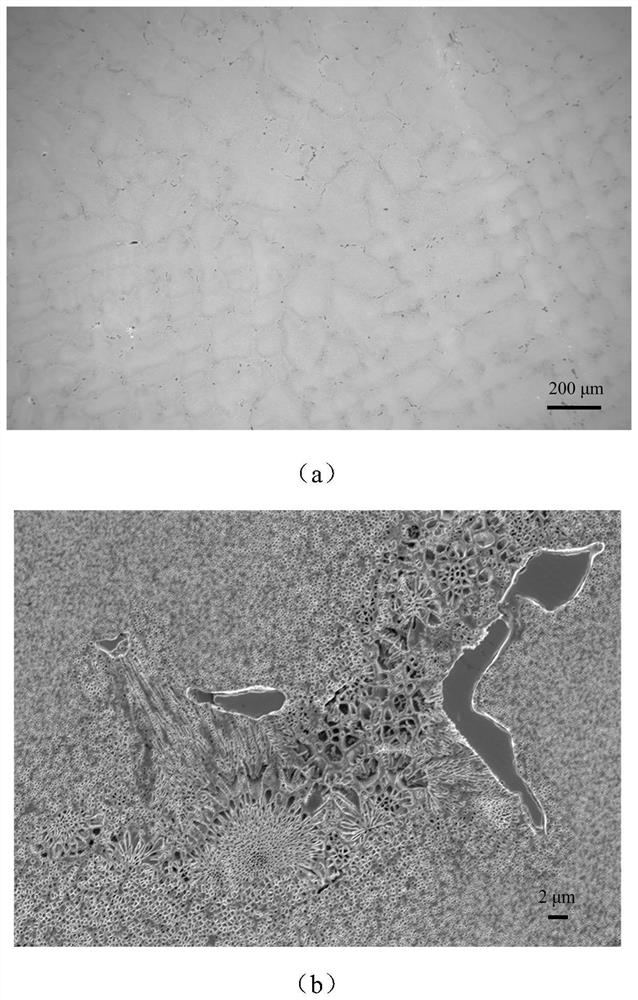

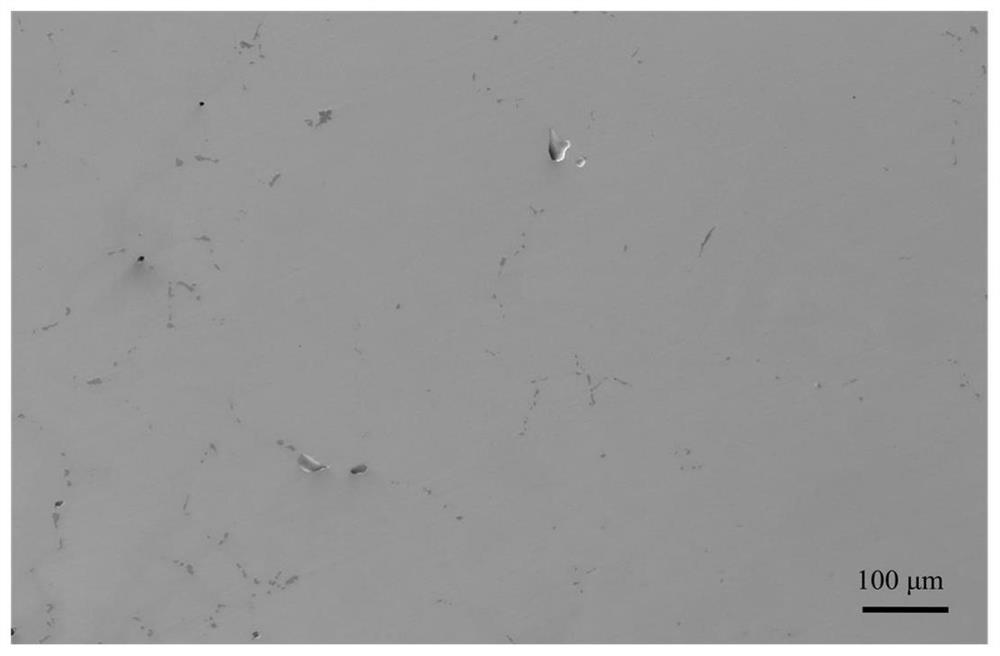

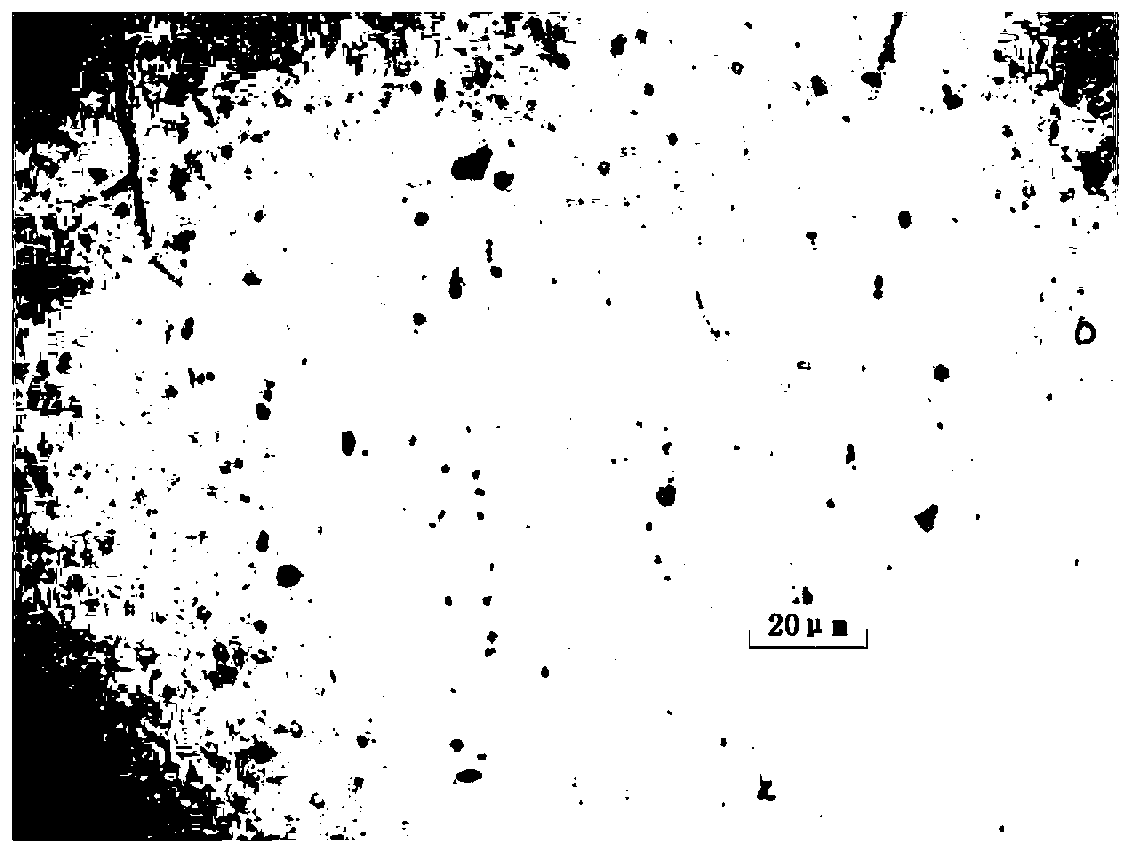

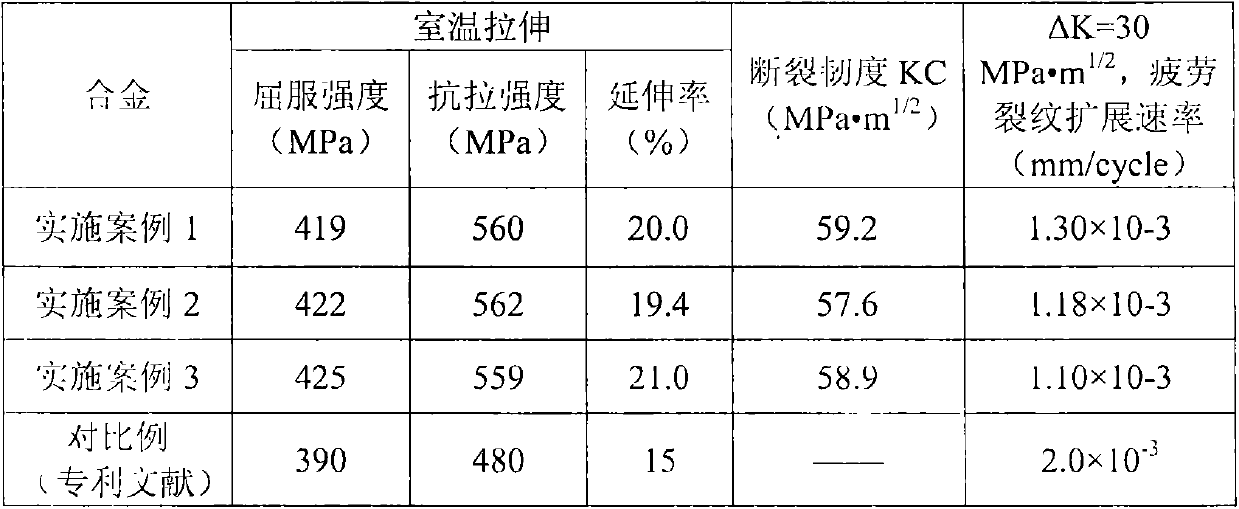

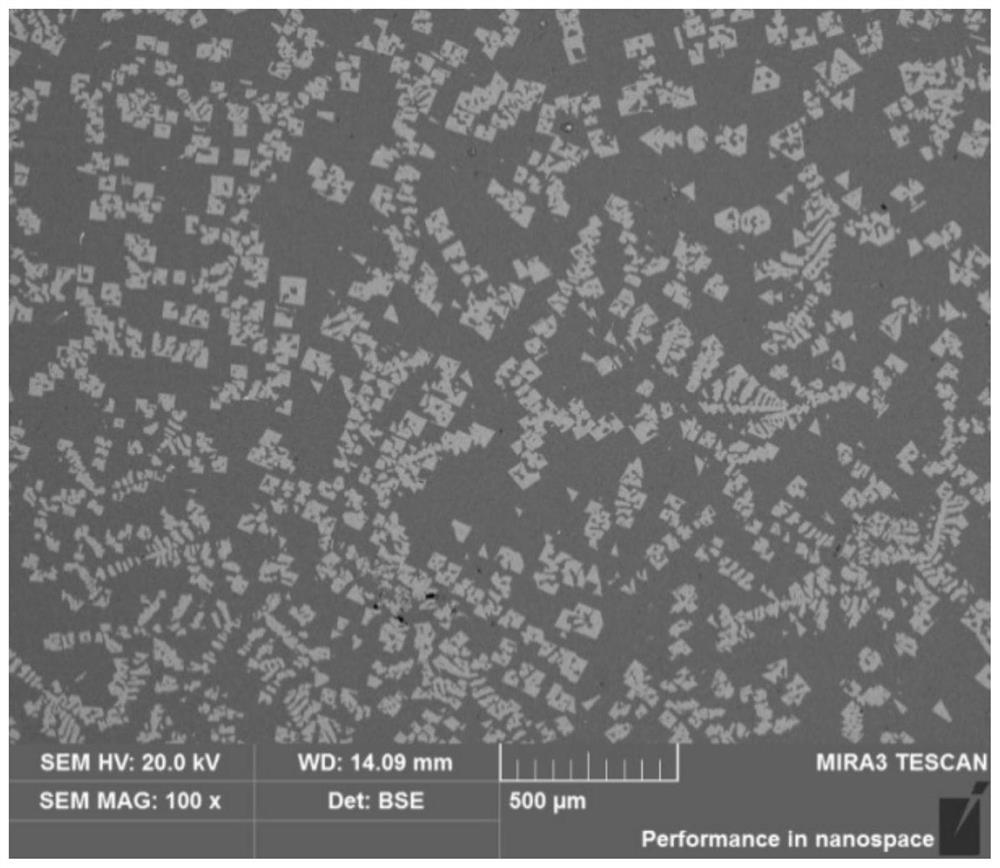

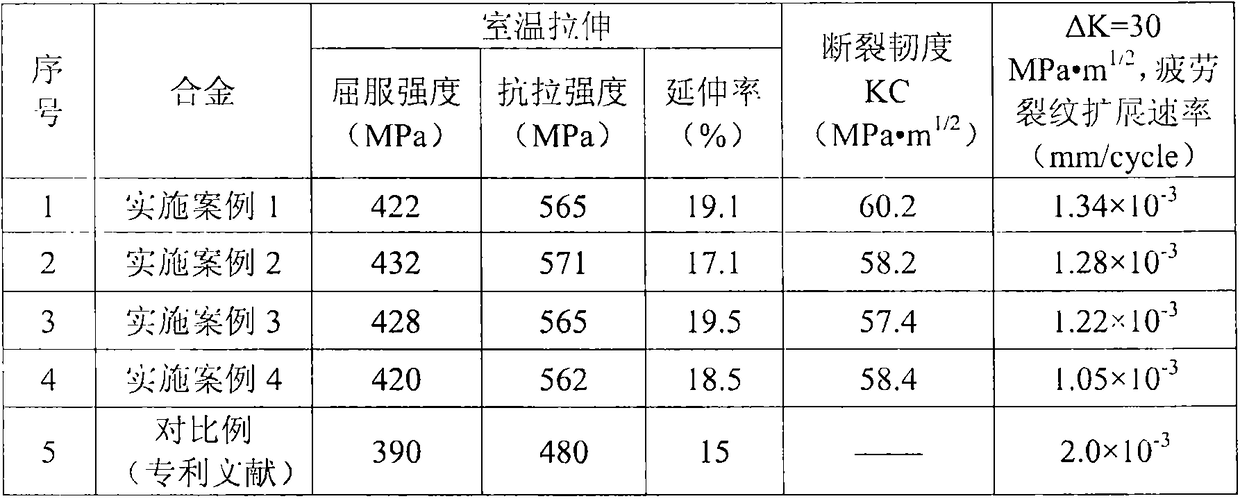

Damage-resistant aluminum alloy and preparation method thereof

The invention provides a damage-resistant aluminum alloy and a preparation method thereof. The damage-resistant aluminum alloy comprises the following components by mass percent: 3.6-4.3%of Cu, 1.0-1.6% of Mg, 0.3-0.8% of Mn, 0.1-0.15% of Zr, 0.1-0.2% of Er, and the balance Al and trace impurity elements, wherein the total content of the trace impurity elements is less than 0.1%. Through adjusting the content of a main alloy element and adding new alloy elements, the aluminum alloy having high resistance to fatigue crack extension and excellent mechanical property is obtained, and the problem that the comprehensive performance of the conventional damage-resistant aluminum alloy is difficult to improve is solved. With the adoption of a water atomization and steam heating mode for homogenizing treatment, the homogenizing time is shortened, the size of a second-phase particle is reduced, and significant effect is exerted on the improvement of the material fracture toughness. The damage-resistant aluminum alloy is simple in technology and low in cost, and large-scale industrial production can be realized easily.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Mo-complex modified low-zinc hot-dip aluminum alloy coating material

InactiveCN103147032AHigh hardnessImprove high temperature strengthHot-dipping/immersion processesSolderabilityAlloy coating

The invention discloses a Mo-complex modified low-zinc hot-dip aluminum alloy coating material. Based on element weight percentage, the alloy is composed of 28%-30% of Zn, 0.01%-0.02% of Sr, 0.1%-2.0% of Li, 0.8%-1.0% of Nb, 0.025%-0.035% of Bi, 0.1%-0.2% of Ti-B, 0.1%-0.8% of a substrate interface reaction buffer agent, and the balance being Al and inevitable trace impurities; and the modifier Mo(CO)6 accounts for 0.5%-0.6% of a total amount of furnace charging materials. The aluminum alloy coating material provided by the invention is a high-quality aluminum alloy coating material used for steel hot-dip and integrates various advantages such as wettability to base steel, strong bonding force, high strength, good elongation, high temperature resistance, thin coating, good corrosion resistance, workability and weldability together.

Owner:GUIZHOU HUAKE ALUMINUM MATERIAL ENG TECH RES

Rapid heat treatment method of high-strength nickel-based superalloy for power station

ActiveCN113957291AHomogenization time shortenedImprove heat treatment efficiencyHeat conservationPlastic property

The invention discloses a rapid heat treatment method of a high-strength nickel-based superalloy for a power station, and belongs to the technical field of metal materials. The alloy comprises the following basic components: 15%-18% of Cr, 15%-20% of Co, 0.5%-1.5% of Ti, 3.5%-4.5% of Al, 8.5%-10% of W, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.5%-1.5% of Nb, 0.03%-0.08% of C and the balance of Ni. The treatment method comprises the following steps: loading the nickel-based alloy into a heat treatment furnace at a charging temperature of less than or equal to 600 DEG C; heating to 1170-1190 DEG C, controlling the heating speed to be 5 DEG C / min, keeping the temperature for 2 hours, then carrying out air cooling, heating to 1020 DEG C, keeping the temperature for 2 hours, carrying out solid solution heat treatment, and not carrying out cooling after solid solution treatment so as to be matched with subsequent heat treatment operation; and selecting the cooling speed based on Jmat pro software, directly cooling a 1020 DEG C heat preservation sample to the room temperature at the speed of 3-80 DEG C / min. The method can obtain better strength and plasticity matching compared with traditional heat treatment by adjusting and controlling the cooling speed, different strength and plasticity matching can be obtained within a certain range, and the heat treatment time and flow are effectively shortened.

Owner:CHINA HUANENG GRP CO LTD +1

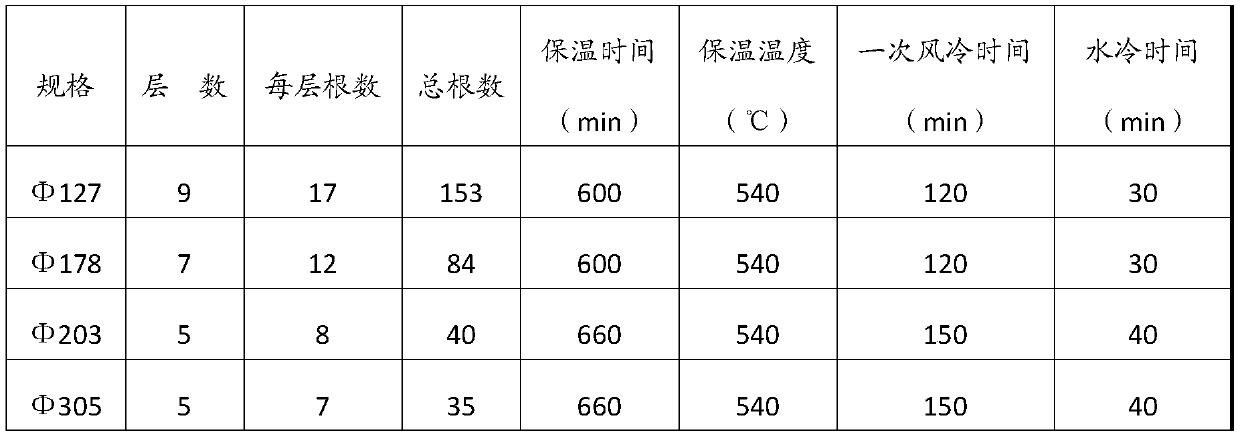

Homogenizing heat treatment process for 6-series aluminum-magnesium-silicon alloy bar

PendingCN114774814AHigh strengthImprove plasticityFurnace typesHeat treatment furnacesSilicon alloyHeat conservation

The invention relates to a homogeneous heat treatment process for a 6-series aluminum-magnesium-silicon alloy bar, and belongs to the technical field of 6-series aluminum-magnesium-silicon alloy heat treatment. The heat treatment process adopts three-section temperature type treatment, and specifically comprises the following steps: the first-section temperature is 347-353 DEG C, and the heat preservation time is 2.4-2.6 hours; the temperature of the second stage is 487-493 DEG C, and the heat preservation time is 2.9-3.1 h; and the temperature of the third stage is 557-563 DEG C, and the heat preservation time is 9.8-10.2 h. Compared with a traditional homogenizing heat treatment process, the method has the advantages that the structure segregation of the product is improved, dendritic crystals in an as-cast structure are basically eliminated, a non-equilibrium eutectic structure at a grain boundary is dissolved in a matrix or is changed into particles, and the eutectic phase area fraction is reduced. Component segregation does not exist in the product, and all alloy elements are evenly distributed. The improvement of the structure inevitably improves the alloy performance, the strength and plasticity of the alloy after heat treatment are improved, and the hardness and conductivity are reduced.

Owner:云南云铝泽鑫铝业有限公司

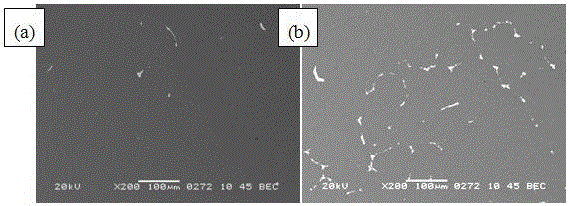

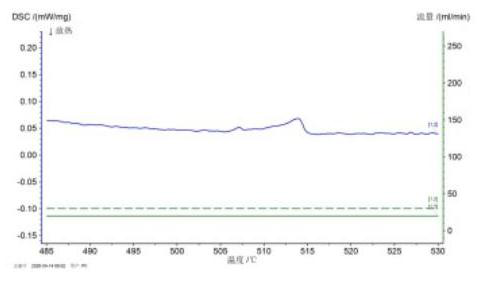

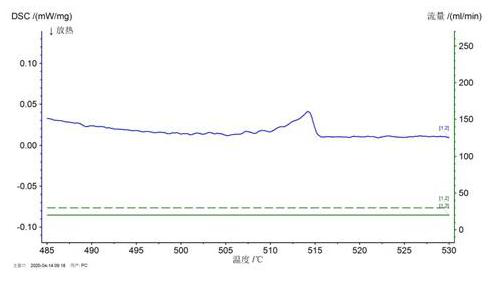

2324 aluminum alloy and homogenization heat treatment method thereof

ActiveCN114737144AHomogenization time shortenedSpeed up the dissolution rateProcess efficiency improvementIngotMelting temperature

The invention relates to a 2324 aluminum alloy and a homogenization heat treatment method thereof, and belongs to the technical field of aluminum alloy heat treatment, and the homogenization heat treatment method of the 2324 aluminum alloy comprises the steps that an aluminum alloy ingot is heated to 494-495 DEG C and then heated to 498-500 DEG C for 25-30 h, and finally the aluminum alloy ingot is air-cooled to 20-25 DEG C. According to the method, by means of slow heating at the melting temperature of the low-melting-point eutectic phase, the influence of the temperature on eutectic phase redissolution is fully exerted, redissolution of the low-melting-point eutectic phase is accelerated under the condition that it is guaranteed that the cast ingot is not overburnt, the redissolution time of theta (Al2Cu) and S (Al2CuMg) formed through non-equilibrium solidification is greatly shortened along with temperature rising, and therefore the casting quality of the cast ingot is improved. The time for homogenizing heat treatment of the aluminum alloy cast ingot is saved to a great extent, the heat treatment cost of the aluminum alloy is saved, and the machining efficiency of the aluminum alloy is improved.

Owner:TIANJIN ZHONGWANG ALUMINUM IND CO LTD

Damage-resistant aluminum alloy and preparation method thereof

The invention provides a damage-resistant aluminum alloy and a preparation method thereof. The damage-resistant aluminum alloy comprises the following components by mass percent: 3.6-4.3%of Cu, 1.0-1.6% of Mg, 0.3-0.8% of Mn, 0.1-0.15% of Zr, 0.1-0.2% of Er, and the balance Al and trace impurity elements, wherein the total content of the trace impurity elements is less than 0.1%. Through adjusting the content of a main alloy element and adding new alloy elements, the aluminum alloy having high resistance to fatigue crack extension and excellent mechanical property is obtained, and the problem that the comprehensive performance of the conventional damage-resistant aluminum alloy is difficult to improve is solved. With the adoption of a water atomization and steam heating mode for homogenizing treatment, the homogenizing time is shortened, the size of a second-phase particle is reduced, and significant effect is exerted on the improvement of the material fracture toughness. The damage-resistant aluminum alloy is simple in technology and low in cost, and large-scale industrial production can be realized easily.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Making method of elastic copper alloy sheet used for spectacle frame

ActiveCN103173647BBright surfaceReduce the degree of oxidationMetal rolling arrangementsEyewearIngot

Owner:BEIJING INST OF NONFERROUS METALS & RARE EARTH

A kind of high-strength corrosion-resistant electrical aluminum-titanium alloy material and preparation method thereof

The invention belongs to the field of alloy materials, and discloses a high-strength and corrosion-resistance aluminum-titanium alloy material for an electrician and a preparation method thereof. The aluminum-titanium alloy material consists of the following components in percentage by weight: 0.05-0.2 wt% of Ti, 0.01-0.15 wt% of Zr, 0.1-0.4 wt% of B, 0.01-0.3 wt% of Mn, 0.01-0.35 wt% of Cr, 0.015-0.1 wt% of Sr, 0.02-1 wt% of rare earth, and the balance of Al. The preparation method comprises the following steps: all the components are prepared to an alloy in a smelting furnace after the batching; the alloy is cast to an aluminum ingot in a deep well casting mode; and the aluminum ingot is extruded by a hot extrusion process to manufacture a product shape accordant with the requirements. The aluminum-titanium alloy material is excellent in stress corrosion resistance, high in strength and excellent in electrical conductivity.

Owner:安徽华淮新材料有限公司

Two-stage homogenization heat treatment method for high-strength nickel-based superalloy cast ingot

PendingCN113981274AImprove thermal deformation abilityReduced rheological resistanceMetallic materialsNickel alloy

The invention discloses a two-stage homogenization heat treatment method for a high-strength nickel-based superalloy cast ingot, and belongs to the technical field of metal materials. The alloy comprises the following basic components: 15%-18% of Cr, 15%-20% of Co, 0.5%-1.5% of Ti, 3.5%-4.5% of Al, 5%-8.5% of W, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.5%-1.5% of Nb, 0.03%-0.08% of C and the balance of Ni. The method comprises the following treatment steps of: loading a nickel alloy ingot into a heat treatment furnace at the temperature of less than or equal to 600 DEG C; heating to 1180-1100 DEG C, controlling the heating speed to be 5-10 DEG C / min, and carrying out first-stage heat treatment; carrying out heat preservation for 12-48 hours at 1180-1100 DEG C, carrying out second-stage heat treatment, controlling the heating speed to be 5 DEG C / min, and carrying out heat preservation for 48-120 hours at 1200-1240 DEG C; and cooling the ingot subjected to heat treatment to below 700 DEG C along with the furnace, and then air-cooling to room temperature, or directly air-cooling. According to the high-strength nickel alloy cast ingot treated through the technology, the eutectic structure in the cast ingot can be effectively eliminated, meanwhile, composition segregation is eliminated, the obtained structure is uniform, the homogenizing heat treatment time is effectively shortened, and energy consumption and production cost are reduced.

Owner:CHINA HUANENG GRP CO LTD +1

A kind of 6 series aluminum alloy and preparation method thereof

The invention relates to 6-series aluminum alloys. The 6-series aluminum alloys are composed of the following components in percentage by weight: 0.75-1.1% of magnesium, 0.01-0.02% of titanium, 0.06-0.13% of manganese, 0.5-0.7% of silicon, 0.55-0.7% of copper, 0.005-0.01% of strontium, 0.002-0.008% of pickaxe, not more than 0.13% of iron, not more than 0.01% of zinc, not more than of 0.01% of chromium and the balance of aluminum. The invention also relates to a preparation method of the 6-series aluminum alloys. The 6 series aluminum alloys have the advantages that alloy mechanical propertiesare obviously improved and glossiness is high after the alloys are subjected to highlight oxidation.

Owner:SICHUAN FURONG TECHNOLOGY CO LTD

A kind of damage-resistant aluminum alloy and its preparation method

The invention provides a damage-resistant aluminum alloy and a preparation method thereof. The damage-resistant aluminum alloy comprises the following components by mass percent: 3.6-4.3%of Cu, 1.0-1.6% of Mg, 0.3-0.8% of Mn, 0.1-0.15% of Zr, 0.1-0.2% of Er, and the balance Al and trace impurity elements, wherein the total content of the trace impurity elements is less than 0.1%. Through adjusting the content of a main alloy element and adding new alloy elements, the aluminum alloy having high resistance to fatigue crack extension and excellent mechanical property is obtained, and the problem that the comprehensive performance of the conventional damage-resistant aluminum alloy is difficult to improve is solved. With the adoption of a water atomization and steam heating mode for homogenizing treatment, the homogenizing time is shortened, the size of a second-phase particle is reduced, and significant effect is exerted on the improvement of the material fracture toughness. The damage-resistant aluminum alloy is simple in technology and low in cost, and large-scale industrial production can be realized easily.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

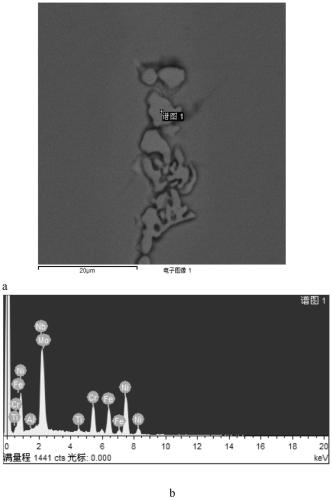

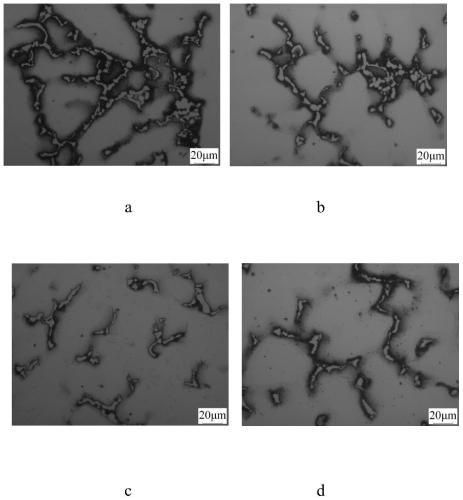

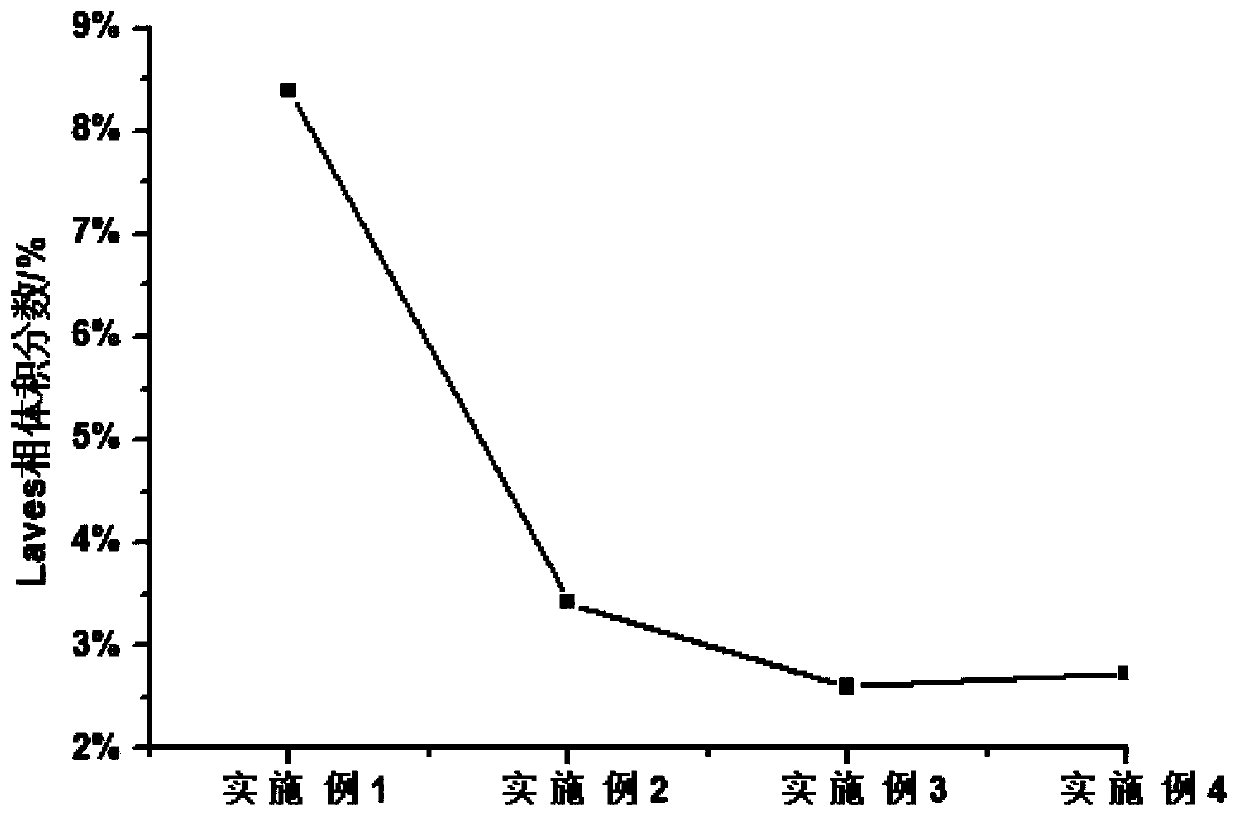

A method for reducing the laves phase in nickel-based superalloy steel ingots

ActiveCN109022925BReduce precipitationReduce the difficulty of subsequent homogenization processingIngotContinuous casting

The invention relates to a method for reducing a Laves phase in a nickel-based high-temperature alloy steel ingot. The method comprises the following steps that firstly, the nickel-based high-temperature alloy serves as a mother alloy; secondly, the mother alloy is taken out, and vacuum induction smelting is carried out, after total melting, refining is carried out, at the refining tail period, the vacuum degree is larger than or equal to 3 Pa, a valve is closed, Ar is inflated to 7 to 9 kPa, a ferrovanadium intermediate alloy is added, sufficient stirring and vibrating are carried out, afterfive minutes, the temperature is adjusted to 1470 to 1500 DEG C, slow continuous casting is carried out, discharging is carried out, and the steel ingot is obtained; thirdly, electroslag smelting is carried out, wherein electroslag with the mass percent of CaF2:CaO:Al2O3:MgO being 60:15:20:5 is used; fourthly, homogenizing annealing is 1140 DEG C*24h. The precipitation proportion of the Laves phase in the solidification process of the steel ingot obtained in the method can be obviously reduced, the steel ingot microstructure uniformity can be improved, the steel ingot subsequent homogenizationtreatment difficulty is reduced, and the mechanical property of the nickel-based high-temperature alloy is ensured.

Owner:CHONGQING MATERIALS RES INST

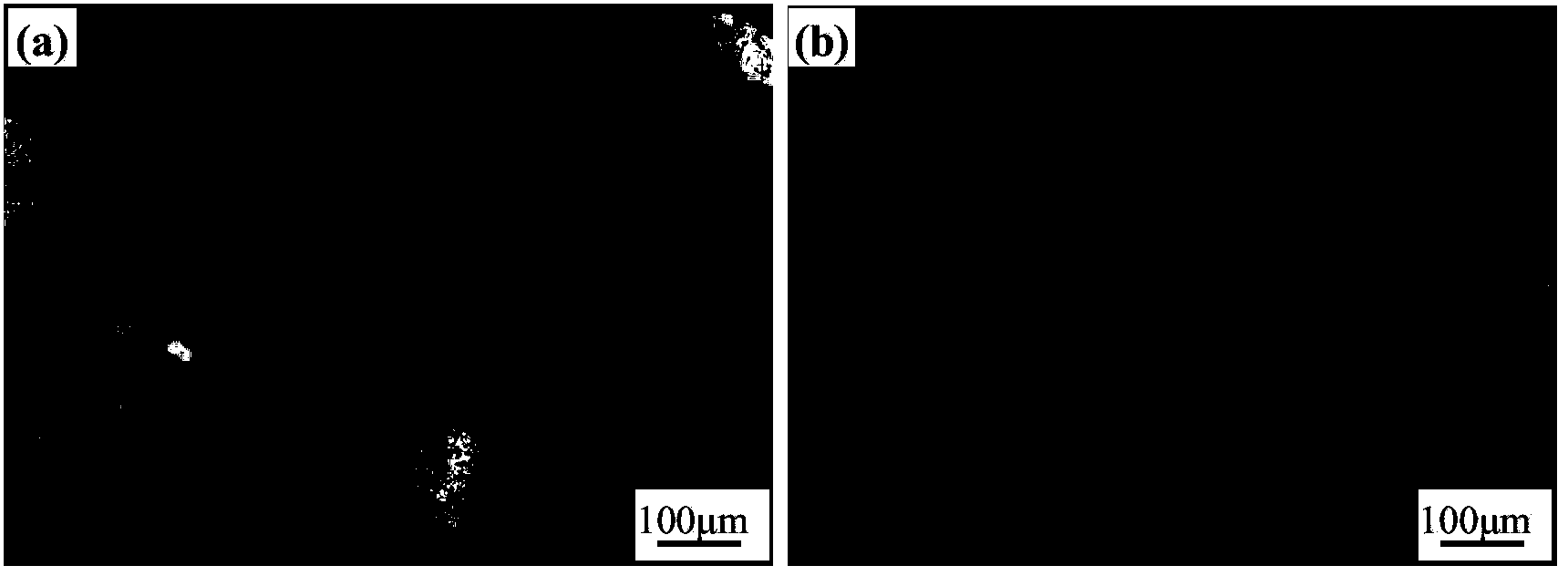

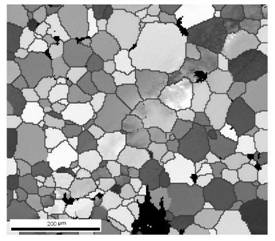

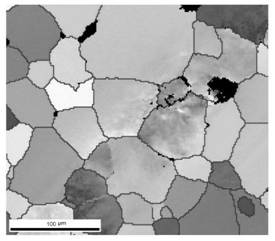

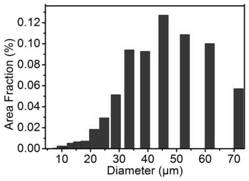

A kind of deformation heat treatment composite process of uniform structure of 7xxx aluminum alloy and its obtaining method

The invention provides a method for obtaining a deformation heat treatment composite process for a uniform structure of 7xxx aluminum alloys, comprising: analyzing the grain structure of an aluminum alloy billet prepared by spray deposition, and judging whether the billet can be directly thermally deformed according to the characteristics of the grain structure; Carry out high-temperature deformation research on the ingot whose grain structure meets the requirements, retain the high-temperature deformation structure, observe the high-temperature deformation structure, and further determine whether the ingot can be directly thermally deformed; set the extrusion deformation process for the alloy that can be directly thermally deformed parameters; The homogenization process parameters of the extruded alloy were studied, and the deformation heat treatment composite process of the uniform structure of the 7xxx aluminum alloy was obtained. The deformation heat treatment composite process of the uniform structure of the 7xxx aluminum alloy provided by the invention is economical, rapid, reasonable and effective, and provides guidance for the preparation of the actual 7xxx series aluminum alloy. The invention also provides a deformation heat treatment composite process for the uniform structure of the 7xxx aluminum alloy.

Owner:CENT SOUTH UNIV

Aluminum alloy monofilament and preparation method thereof

ActiveCN113957301AHigh strengthImprove heat resistanceConductive materialCasting cleaning apparatusSr elementHeat resistance

The invention provides an aluminum alloy monofilament and a preparation method thereof. The aluminum alloy monofilament comprises Al, Sr, B, Sc, Fe, Si, Cr, Mn, V and Ti, wherein the mass percent of Sr is 0.01 wt%-0.05 wt%, the mass percent of B is 0.01 wt%-0.03 wt%, and the mass percent of Sc is 0.01 wt%-0.05 wt%, a proper amount of the Sr element, the B element and the Sc element are added, the conductivity of the aluminum alloy monofilament can be remarkably improved, and the strength and the heat resistance of the aluminum alloy monofilament can be obviously improved; and in addition, the element Sr is also beneficial to reducing the homogenization time of a cast ingot, reducing the size of primary silicon particles and improving the tensile strength, the ductility and other mechanical properties of the aluminum alloy monofilament. In conclusion, the aluminum alloy monofilament has excellent conductivity, excellent heat resistance and an excellent mechanical property.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +3

Method for preparing high scandium content aluminum scandium alloy

The invention discloses a method for preparing aluminum-scandium alloy with high scandium content. The method comprises: weighing metal scandium and metal aluminum according to the content of scandium in the aluminum-scandium alloy to be prepared; adding them to a medium-frequency induction melting furnace, continuously pumping the vacuum, and then raising the temperature to 1200-1600° C. to melt the metal scandium and metal aluminum; completely After melting, the alloy liquid is obtained and kept warm for 20-40 minutes; filled with high-purity argon, pouring the heat-preserved alloy liquid into a water-cooled copper mold, using the mold circulating water refrigeration system to cool the circulating water to 1-15 °C first, and then The cooled circulating water is passed into the water-cooled copper mold to circulate and cool the alloy liquid, and the alloy liquid can be cooled and solidified within 3-8 seconds, and an aluminum-scandium alloy ingot with a scandium content of 5%-99% can be obtained. The present invention can realize rapid cooling within 3-8s, and can produce high-scandium-content aluminum-scandium alloys with high purity, high density, low segregation, uniform composition, and low cost, which meets the current market demand for high-scandium-content aluminum-scandium alloys .

Owner:HUNAN RARE EARTH METAL MATERIAL RES INST

Multi-solvent system lithium ion battery negative electrode proportioning method

PendingCN112838185AHomogenization time shortenedHomogenization process is simpleElectrode manufacturing processesSecondary cellsElectrically conductiveLithium electrode

The invention discloses a multi-solvent system lithium ion battery negative electrode proportioning method which comprises the following steps: 1) taking the following raw materials: a negative electrode active matter, a conductive agent, a thickening agent, deionized water, a binder and a modifier in a mass ratio of (90-97): (0.5-2.5): (1-2.5): (80-120): (0.5-2.5): (2.5-10); 2) putting the negative electrode active matter, the conductive agent and the thickening agent into a stirring barrel, and stirring to form mixed powder; 3) adding a part of deionized water into the stirring barrel, stirring for 10-45 minutes at a low speed, and performing stirring revolution at 10-30 rpm and rotation at 300-600 rpm; 4) adding the rest deionized water, quickly stirring for 90-150 minutes, revolving at the speed of 20-50 rpm, and rotating at the speed of 800-1500 rpm; 5) adding a binder, rapidly stirring for 30-60 minutes, carrying out revolution at the speed of 20-50 rpm, and carrying out autorotation at the speed of 500-1500 rpm; and 6) adding a modifier, quickly stirring for 10-30 minutes, revolving at 20-50 rpm, and rotating at 500-1500 rpm. According to the multi-solvent system lithium ion battery negative electrode proportioning method disclosed by the invention, the powder is uniformly mixed, the slurry performance is stable, the slurry homogenizing time is shortened, and the slurry production efficiency is improved.

Owner:SUZHOU YOULION BATTERY INC

A kind of preparation method of fe-cr-al electrothermal alloy thin-gauge cold-rolled sheet containing yttrium

The invention provides a method for preparing thin-specification cold-rolled plates of Fe-Cr-Al electrothermal alloy containing yttrium. The preparation process is: (1) According to the composition ratio of Fe‑Cr‑Al electrothermal alloy, add yttrium with a mass fraction of 0.01 to 0.1%; (2) Classify each raw material, put it into a vacuum induction melting furnace step by step, and smelt Obtain molten steel; (3) Pour the molten steel into a double-roller thin strip casting and rolling mill for casting and rolling, and prepare an yttrium-containing Fe-Cr-Al electrothermal alloy cast strip; (4) Conduct "two single-pass heating" on the cast strip. The composite production process of "rolling + annealing + pickling + repeated cold rolling" is used to prepare thin-specification cold-rolled plate products with cast strips. The solidification structure of the Fe-Cr-Al electrothermal alloy cast strip prepared by the invention is 50 to 150 times more refined than the solidification structure of the conventional process, which improves the processing performance; greatly shortens the thin-specification cold rolling of the Fe-Cr-Al electrothermal alloy The preparation process of the plate, and the mechanical properties of the thin-format cold-rolled plate are equivalent to those of the conventional thin-format cold-rolled plate, and the high-temperature oxidation resistance is better than that of the conventional thin-format cold-rolled plate.

Owner:NORTHEASTERN UNIV LIAONING

A kind of damage-resistant aluminum alloy and its preparation method

The invention provides a damage-resistant aluminum alloy and a preparation method thereof. The damage-resistant aluminum alloy comprises the following components by mass percent: 3.6-4.3%of Cu, 1.0-1.6% of Mg, 0.3-0.8% of Mn, 0.1-0.15% of Zr, 0.1-0.2% of Er, and the balance Al and trace impurity elements, wherein the total content of the trace impurity elements is less than 0.1%. Through adjusting the content of a main alloy element and adding new alloy elements, the aluminum alloy having high resistance to fatigue crack extension and excellent mechanical property is obtained, and the problem that the comprehensive performance of the conventional damage-resistant aluminum alloy is difficult to improve is solved. With the adoption of a water atomization and steam heating mode for homogenizing treatment, the homogenizing time is shortened, the size of a second-phase particle is reduced, and significant effect is exerted on the improvement of the material fracture toughness. The damage-resistant aluminum alloy is simple in technology and low in cost, and large-scale industrial production can be realized easily.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com