Anodic oxidation die-casting aluminum alloy material and preparation method thereof

A technology for anodizing and casting aluminum alloys is applied in the field of aluminum alloy materials to achieve the effects of improving the toughness of the alloy, a simple preparation method, and reducing the sensitivity of stress corrosion cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

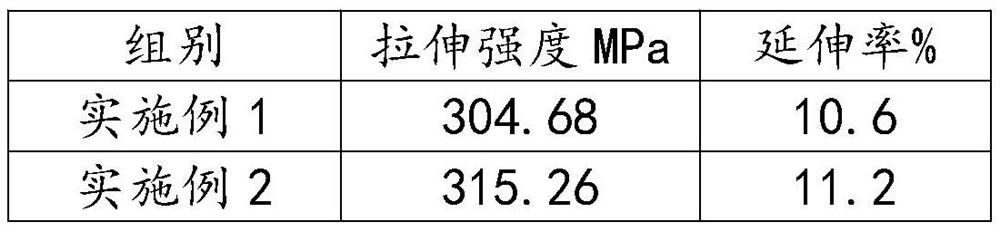

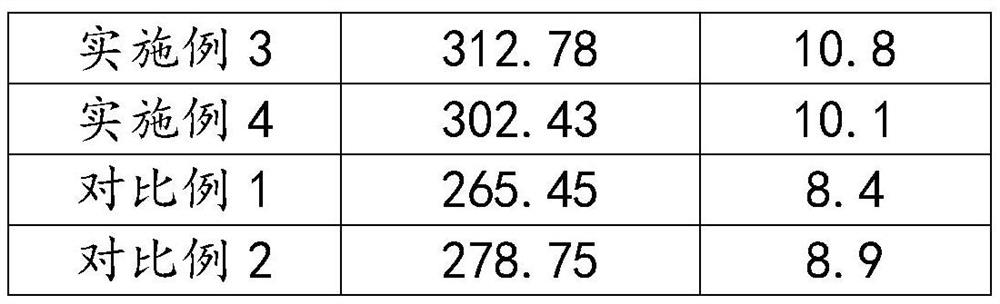

Examples

Embodiment 1

[0035] An anodic oxidation die-casting aluminum alloy material is characterized in that it includes the following components in mass percentage: Mg 2.8%, Mn 0.9%, Co 0.4%, Cr 0.15%, Sr 0.018%, Si 0.14%, Fe 0.08%, Cu 0.02%, Al95.49%.

[0036] A method for preparing an anodized die-casting aluminum alloy material, specifically comprising the following steps:

[0037] (1) Remelt the pure aluminum ingot, and add Al-Si20, Al-Mn10, Al-Co5, Al-Cr10, Al-Sr10 master alloys in sequence when the temperature in the furnace is raised to 730°C until the raw materials are completely melted , to obtain alloy liquid A;

[0038] (2) Heat the alloy solution A at 740°C for 30 minutes, stir for 8 minutes to remove slag and degas, then lower the temperature to 680°C, wrap the magnesium ingot with aluminum foil and place it in the alloy solution A, and wait until it is completely melted to obtain alloy liquid B;

[0039] (3) Stir the melted alloy liquid B evenly for 10 minutes, raise the temperatur...

Embodiment 2

[0050] An anodic oxidation die-casting aluminum alloy material is characterized in that it includes the following components in mass percentage: Mg3.3%, Mn 1.2%, Co 0.35%, Cr 0.18%, Sr 0.024%, Si 0.16%, Fe 0.08%, Cu 0.04%, Al 94.67%.

[0051] A method for preparing an anodized die-casting aluminum alloy material, specifically comprising the following steps:

[0052] (1) Remelt the pure aluminum ingot, and then add Al-Si20, Al-Mn10, Al-Co5, Al-Cr10, Al-Sr10 master alloys in sequence when the temperature in the furnace is raised to 720°C until the raw materials are completely melted , to obtain alloy liquid A;

[0053] (2) Heat the alloy solution A at 730°C for 40 minutes, stir for 10 minutes to remove slag and degas, then lower the temperature to 690°C, wrap the magnesium ingot with aluminum foil and place it in the alloy solution A, and wait until it is completely melted to obtain alloy liquid B;

[0054] (3) Stir the melted alloy liquid B evenly for 10 minutes, raise the t...

Embodiment 3

[0065] An anodic oxidation die-casting aluminum alloy material is characterized in that it includes the following components in mass percentage: Mg 2.8%, Mn 1.05%, Co 0.4%, Cr 0.16%, Sr 0.02%, Si 0.08%, Fe 0.14%, Cu 0.03%, Al95.32%.

[0066] A method for preparing an anodized die-casting aluminum alloy material, specifically comprising the following steps:

[0067] (1) Remelt the pure aluminum ingot, and add Al-Si20, Al-Mn10, Al-Co5, Al-Cr10, Al-Sr10 master alloys in sequence when the temperature in the furnace is raised to 740°C until the raw materials are completely melted , to obtain alloy liquid A;

[0068] (2) Heat the alloy solution A at 740°C for 30 minutes, stir for 8 minutes to remove slag and degas, then cool down to 700°C, wrap the magnesium ingot with aluminum foil and place it in the alloy solution A, and wait until it is completely melted to obtain alloy liquid B;

[0069] (3) Stir the melted alloy liquid B evenly for 10 minutes, raise the temperature to 750°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface microhardness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com