Patents

Literature

40results about How to "Reduced susceptibility to stress corrosion cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Aluminum alloy for 480 MPa-class aluminum alloy oil pipe and pipe manufacturing method thereof

The invention discloses an aluminum alloy for a 480 MPa-class aluminum alloy oil pipe. The aluminum alloy comprises the following components by weight percent: 5.10-6.90% of Zn, 1.10-1.80% of Mg, 0.05-0.20% of Cu, 0.10-0.30% of Mn, 0.10-0.30% of Cr, 0.01-0.02% of Ti, 0.15-0.2% of Zr and the balance of Al and unavoidable impurities, wherein in the unavoidable impurities, the content of the Si is not greater than 0.15 of the total weight of the aluminum alloy and the content of Fe is not greater than 0.15 of the total weight of the aluminum alloy. The manufacture method of the aluminum alloy pipe comprises the following steps: (1) smelting the raw materials according to the weight percentage, performing external refining and casting to obtain a pipe blank; (2) performing three-stage homogenization treatment; (3) squeezing under high temperature; (4) performing twin-stage solid solution treatment, quenching and cooling; (5) prestretching and deforming; and (6) performing twin-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Semi-solid die-casting aluminum alloy material and die-casting molding method using same

A semi-solid die-casting aluminum alloy material comprises 6%-9% of Si, 0-0.3% of Cu, 0.25%-0.55% of Mn, 0.2%-0.5% of Mg, 0.6%-1.2% of Fe, 0-0.15% of Ni, 0-0.15% of Zn, 0-0.15% of Pb, 0-0.05% of Sn, 0-0.2% of Ti, 0-0.15% of impurities, and the balance Al. The content of Si is controlled to be 6%-9% and the content of Fe is controlled to be 0.6%-1.2%, so that the good die-casting molding performance, corrosion resistance and demoulding effect are ensured; meanwhile, 0.25%-0.55% of Mn is added to form a MnAl6 compound, so that the harmful effect of iron is effectively weakened; also, Mn can hinder the recrystallization process of aluminum alloy, the recrystallization temperature is increased, and favorable conditions are provided for the semi-solid pulping process of alloy slurry; in addition, 0.2%-0.5% of Mg is contained properly so as to improve the tensile strength.

Owner:FUJIAN KINRUI HIGH TECH CO LTD

Formula for casting aluminum alloy hubs

The invention discloses a formula for casting aluminum alloy hubs. The formula is prepared from, by weight, 6.5-7.5% of Si, 0.28-0.45% of Mg, 0-0.12% of Fe, 0-0.02% of Cu, 0.02-0.05% of Mn, 0.04-0.05% of Zn, 0.10-0.20% of Ti, 0.2-0.6% of Sr, 0.01-0.05% of Cr, 0.01-0.02% of Zr, 0.025-0.05% of B, 0.4-0.8% of mixed light rare earth and the balance Al. Due to the fact that Sr and the mixed rare earth metal serve as an alterant together, the surface defects of alloy phases can be overcome, surface tension on a new-phase interface and an old-phase interface is reduced, and the problem that compactness is reduced when only Sr is added is avoided. Zr, Ti, Cr and Al work together, the cast structure is further refined, and the hardness and the toughness of aluminum alloy are improved.

Owner:GUANGDONG DCENTI AUTO PARTS STOCK LTD

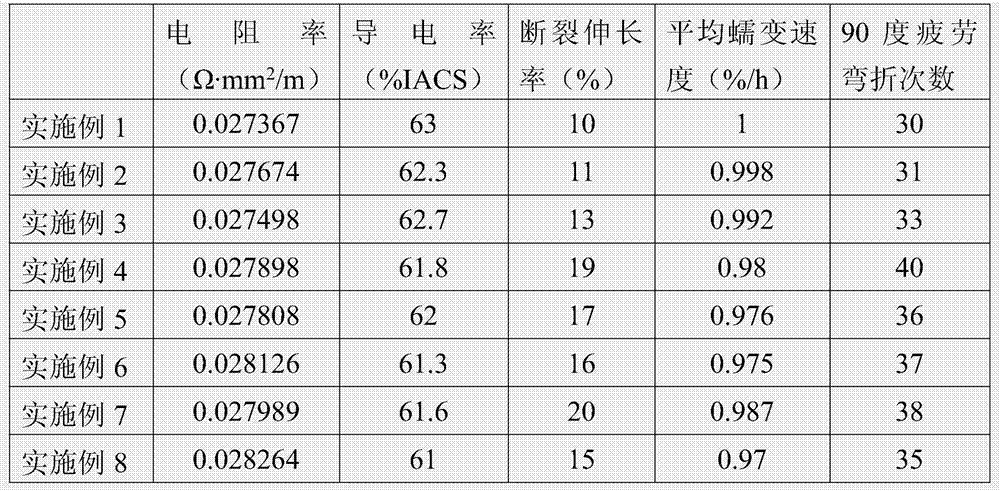

Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, aluminum alloy cable and preparation method of alloy cable

PendingCN104294093AImprove performanceImprove mechanical strength, tensile propertiesMetal/alloy conductorsCable/conductor manufactureCoalOmega

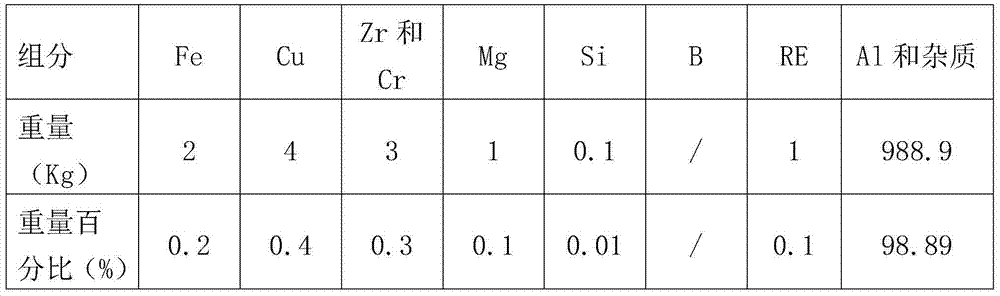

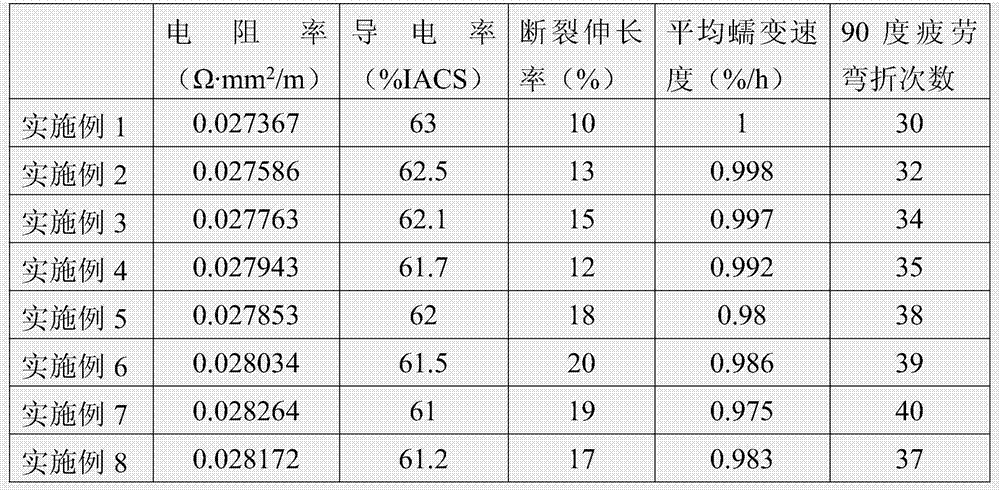

The invention discloses an Al-Fe-Cu-Mg aluminum alloy for cables for coal mines, which comprises 0.2-1.1% of Fe, 0.01-0.4% of Cu, 0.01-0.4% of Mg, 0-0.1% of Si, 0-0.2% of B, and the balance of Al and impurities, wherein the electrical resistivity of the aluminum alloy is not greater than 0.028264 Omega.mm<2> / m, the elongation at break is not less than 10%, and the number of times of 90-degree fatigue bending is greater than or equal to 30. An aluminum alloy cable is prepared by the steps of melting, casting and rolling the aluminum alloy material so as to obtain an aluminum alloy rod, carrying out drawing, bunch-stranding and softening on the aluminum alloy rod so as to obtain an aluminum alloy cable core, and carrying out extruded insulation, cabling, extruded sheathing or armoring on the cable core; and the prepared aluminum alloy cable has the characteristics of high strength, high electric conductivity, good bending performance and the like, and can satisfy the requirements on the properties of cables in the field of coal mines.

Owner:ANHUI JOY SENSE CABLE

Aluminum alloy for anti-chloridion-corrosion type aluminum alloy oil pipe and pipe manufacturing method of aluminum alloy

The invention discloses aluminum alloy for an anti-chloridion-corrosion type aluminum alloy oil pipe and a pipe manufacturing method of the aluminum alloy. The aluminum alloy comprises, by weight, 6.90%-7.49% of Zn, 2.10%-2.30% of Mg, 0.05%-0.10% of Cu, 0.10%-0.30% of Mn, 0.10%-0.30% of Cr, 0.01%-0.02% of Ti, 0.15%-0.2% of Zr, 0.05%-0.1% of Sc, and the balance Al and inevitable impurities. The strength performance of the aluminum alloy is improved significantly through matching of the high-content Zn and the low-content Mg. The strength and the repeated loading resistance of the aluminum alloy are improved through the appropriate-content Mn and the appropriate-content Cr, and the good plasticity and toughness of the aluminum alloy are ensured. The micro-content Ti, the micro-content Zr and the micro-content Sc serve as supplement and improvement. The structure stability and the performance reliability of the aluminum alloy are ensured through grain refinement and precipitation strengthening. The aluminum alloy for the anti-chloridion-corrosion type aluminum alloy oil pipe is high in overall specific strength, good in corrosion resistance, low in cost, good in processability and high in qualified product ratio.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

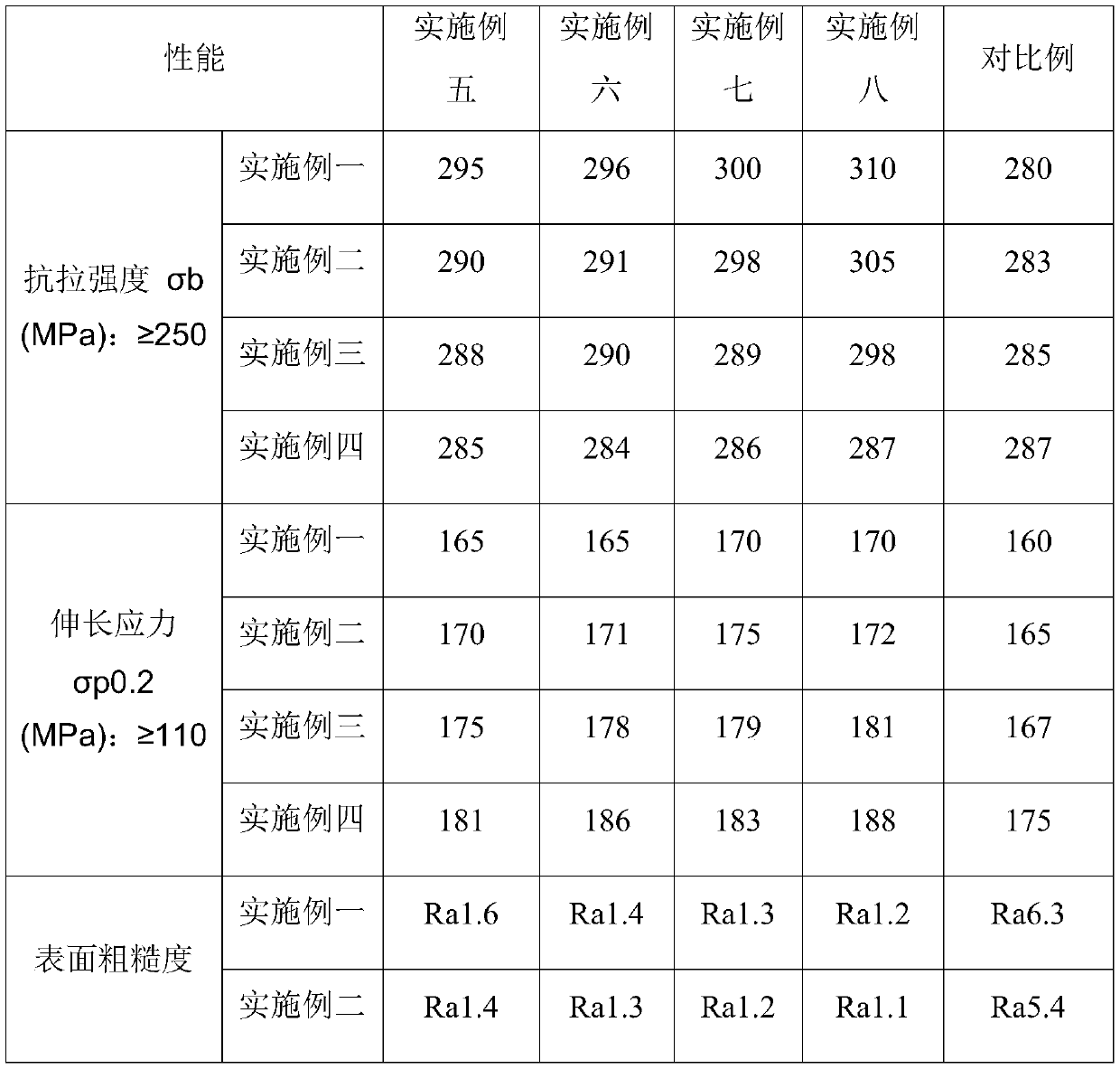

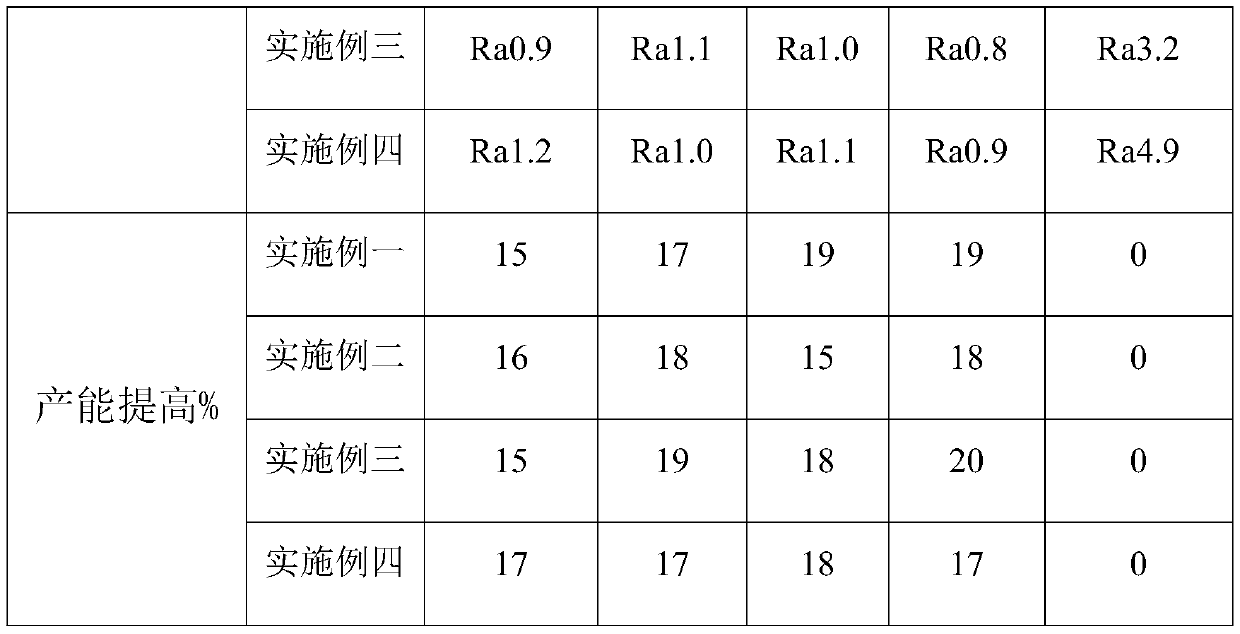

Preparation method of aluminum alloy sectional material for producing solar energy frame

The invention discloses a preparation method of an aluminum alloy sectional material for producing a solar energy frame, and relates to the field of aluminum alloys. The problem of poor quality of theproduct surface in the process of producing solar energy frame parts by using the aluminum sectional material is solved. According to the technical key point, the preparation method of the aluminum alloy sectional material for producing the solar energy frame comprises the following steps that smelting is carried out, specifically, an aluminum silicon intermediate alloy, an aluminum iron intermediate alloy, an aluminum copper intermediate alloy, an aluminum manganese intermediate alloy, an aluminum magnesium intermediate alloy, an aluminum chromium intermediate alloy, an aluminum zinc intermediate alloy and an aluminum titanium intermediate alloy are extracted and charged in a furnace for smelting according to proportional ingredients of components, then a magnesium ingot is added into the furnace according to component proportion, stirring is carried out, continuous smelting is carried out, and then slagging off is carried out; refining is carried out, specifically, the furnace temperature is adjusted to the refining temperature, and slagging off is carried out; casting is carried out, specifically, on-line wire feeding refining is carried out by adopting an aluminum titanium boron wire to obtain a casting bar; extrusion is carried out, specifically, the aluminum casting bar is heated and a mould is extruded, extrusion is carried out, and the aluminum alloy sectional materialis obtained; and cutting is carried out, specifically, the aluminum alloy sectional material is cut into segments according to a certain length, and the purpose of improving the yield and surface quality of the aluminum alloy sectional material is achieved.

Owner:WUJIANG CITY XINSHEN ALUMINUM TECH DEV +1

Lightweight aluminum alloy profile

The invention discloses a lightweight aluminum alloy profile. The lightweight aluminum alloy profile comprises the following components of, in percentage by weight, copper, magnesium, silicon, zinc, lithium, manganese, titanium, vanadium, boron, nickel, chromium, iron, rare earth metals, and and the balance aluminum and inevitable impurities, wherein the rare earth elements are any one or more mixtures of lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium. According to the lightweight aluminum alloy profile, the aluminum is taken as a main raw material, various metal materials are added, the manufactured aluminum alloy is light in weight, so that lightweight of the material is achieved; by adding the copper into the aluminum alloy, the mechanical property of the aluminum alloy can be improved, and the machinability of the aluminum alloy becomes better; and by adding the silicon into the aluminum alloy, the fluidity of the aluminum alloy during casting can be improved, best fluidity is obtained from eutectic to hypereutectic, and meanwhile, the tensile strength, the hardness, the machinability and the strength at high temperature of the aluminum alloy can be improved.

Owner:安徽鑫铂铝业股份有限公司

Aluminum alloy guide wire suitable for overhead power transmission line and manufacturing method for aluminum alloy guide wire

InactiveCN107557621AImprove corrosion resistanceEasy to shapeMetal/alloy conductorsUltimate tensile strengthGuide wires

The invention relates to an aluminum alloy wire suitable for overhead transmission lines, belonging to the technical field of aluminum alloy wires, which is made of the following components in mass percentage: Mg2.0~3.2%; Si3.5~4.5%; Mn0.2 ~0.3%; Cr: 0.1~0.2%; Zr0.18~0.25%; Ti0.35~0.40%; Yb0.15~0.3%; the balance is Al and impurities with content ≤0.05%. The invention provides an aluminum alloy wire, which can improve the strength and corrosion resistance of the aluminum alloy wire while enhancing the conductivity of the aluminum alloy wire, so as to meet the needs of harsh environments.

Owner:国网河南省电力公司西峡县供电公司

Al-Fe-Mg-Cr aluminum alloy for coal mine cable and aluminum alloy cable

PendingCN104299675AImprove performanceHigh mechanical strengthMetal/alloy conductorsCable/conductor manufactureElectrical conductorHigh intensity

The invention discloses Al-Fe-Mg-Cr aluminum alloy for a coal mine cable and an aluminum alloy cable. Aluminum alloy materials comprise, by weight, 0.2% to 1.1% of Fe, 0.01% to 0.4% of Mg, 0.001% to 0.2% of Cr, 0% to 0.1% of Si, 0% to 0.2% of B, and the balance of Al and impurities. The aluminum alloy materials are processed through the smelting technology, the casting technology and the rolling technology so that an aluminum alloy rod can be obtained, then, the aluminum alloy rod is drawn, bunched into strands and softened so that an aluminum alloy cable core can be obtained, and next, the conductor cable core is subjected to extruded insulation, cabling and extruded jacketing or armoring so that the aluminum alloy cable can be made. The Al-Fe-Mg-Cr aluminum alloy for the coal mine cable has the advantages of being high in strength and electric conductivity, good in bending property and the like. The aluminum alloy cable made from the aluminum alloy can meet the requirements for the performance of the cable in the coal mine field.

Owner:ANHUI JOY SENSE CABLE

High-strength graphene and rare-earth aluminium alloy

The invention discloses a high-strength graphene and rare-earth aluminium alloy. The grapheme and rare-earth aluminium alloy comprises an aluminium alloy matrix and graphene. The composition of the aluminium alloy matrix comprises, by mass, 1.2-1.8% of Cu, 0.18-0.25% of Si, 0.08-0.2% of Cr, 0.6-0.8% of Mg, 0.1-0.2% of Mn, 0.3-0.4% of Fe, 0.3-0.5% of Zn, 0.02-0.06% of Ti, 0.1-0.2% of V, 0.1-0.2% of Ni, 0.04-0.07% of Mo, 0.05-0.12% of Zr, 0.04-0.08% of Nd, 0.04-0.06% of La, 0.03-0.05% of Ce, and the balance Al. The high-strength graphene and rare-earth aluminium alloy has good mechanical properties such as strength, toughness and the like.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

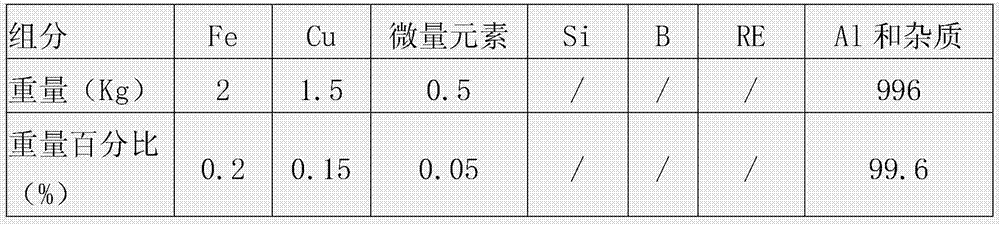

Al-Fe-Cu aluminum alloy for coal mine cable and aluminum alloy cable

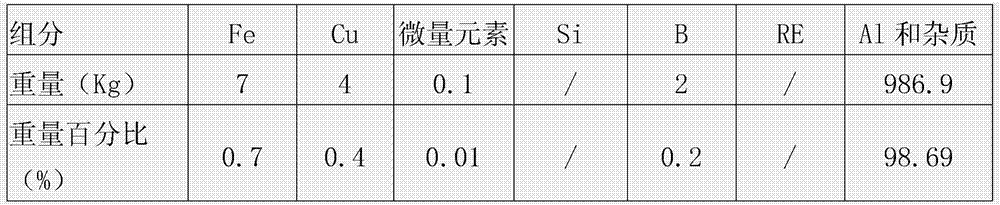

PendingCN104299674AImprove performanceHigh mechanical strengthMetal/alloy conductorsCable/conductor manufactureElectrical conductorTrace element

The invention discloses Al-Fe-Cu aluminum alloy for a coal mine cable and an aluminum alloy cable. Aluminum alloy materials comprise, by weight, 0.2% to 1.1% of Fe, 0.01% to 0.4% of Cu, 0% to 0.1% of Si, 0% to 0.2% of B, 0.001% to 0.3% of trace elements, and the balance of Al and impurities. The aluminum alloy materials are processed through the smelting technology, the casting technology and the rolling technology so that an aluminum alloy rod can be obtained, then, the aluminum alloy rod is drawn, bunched into strands and softened so that an aluminum alloy cable core can be obtained, and next, the conductor cable core is subjected to extruded insulation, cabling and extruded jacketing or armoring so that the aluminum alloy cable can be made. The Al-Fe-Cu aluminum alloy for the coal mine cable has the advantages of being high in strength and electric conductivity, good in bending property and the like. The aluminum alloy cable made from the aluminum alloy can meet the requirements for the performance of the cable in the coal mine field.

Owner:ANHUI JOY SENSE CABLE

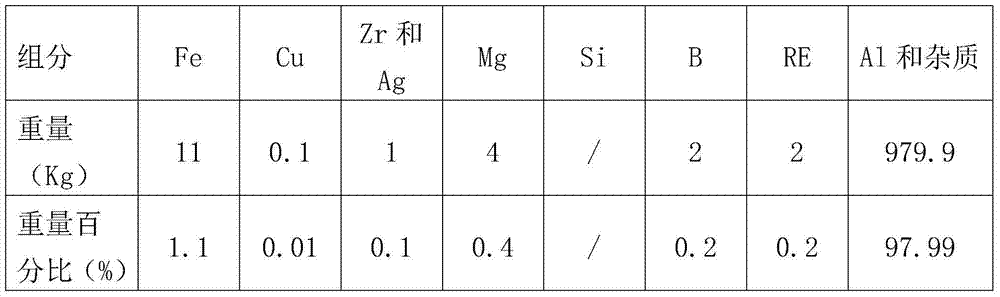

Al-Fe-Mg aluminum alloy for coal mine cable and aluminum alloy cable

PendingCN104299672AImprove performanceHigh mechanical strengthMetal/alloy conductorsCable/conductor manufactureElectrical conductorTrace element

The invention discloses Al-Fe-Mg aluminum alloy for a coal mine cable and an aluminum alloy cable. Aluminum alloy materials comprise, by weight, 0.2% to 1.1% of Fe, 0.01% to 0.4% of Mg, 0% to 0.1% of Si, 0% to 0.2% of B, 0.001% to 0.3% of trace elements, and the balance of Al and impurities, wherein the trace elements comprise at least two of Zr, Mn, Cr and Ag. The aluminum alloy materials are processed through the smelting technology, the casting technology and the rolling technology so that an aluminum alloy rod can be obtained, then, the aluminum alloy rod is drawn, bunched into strands and softened so that an aluminum alloy cable core can be obtained, and next, the conductor cable core is subjected to extruded insulation, cabling and extruded jacketing or armoring so that the aluminum alloy cable can be made. The Al-Fe-Mg aluminum alloy for the coal mine cable has the advantages of being high in strength and electric conductivity, good in bending property and the like. The aluminum alloy cable made from the aluminum alloy can meet the requirements for the performance of the cable in the coal mine field.

Owner:ANHUI JOY SENSE CABLE

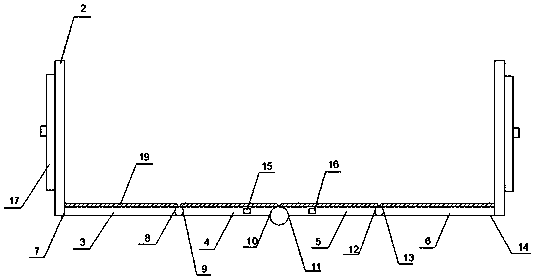

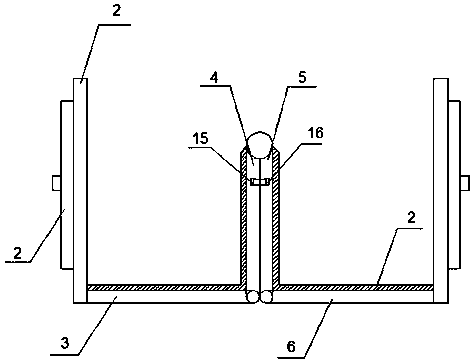

High-heat-dissipation air-ventilation tray type cable bridge

Owner:JIANGSU HUAQIANG ELECTRIC EQUIP

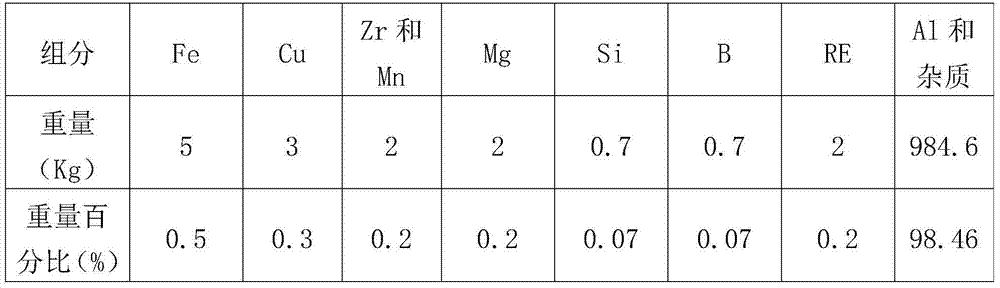

Preparing method of high-strength aluminum alloy material used for building door and window machining

The invention discloses a preparing method of high-strength aluminum alloy material used for building door and window machining. The aluminum alloy material comprises, by mass percent, 0.9% of silicon, 6.8% of copper, 0.3% of magnesium, 0.8% of iron, 0.8% of manganese, 0.35% of chromium, 0.15% of titanium, 0.07% of strontium, 0.3% of zirconium, 0.8% of boron, 0.1% of rhenium, 0.2% of rare earth and the balance raw material aluminum. Manganese and titanium are added for improving the high-temperature strength of alloy containing copper and silicon, the recrystallization process of the aluminumalloy can be prevented, the recrystallization temperature is increased, the recrystallization grains can be obviously refined, through adding of chromium and zirconium, recrystallization nucleation and growing can be obstructed, the alloy can be subjected to certain strengthening, the toughness of the alloy can be improved, stress corrosion cracking sensitivity can be reduced, strontium has the advantages of being long in metamorphic effective time, good in effect and reproducibility and the like, the casting ingot homogenizing time is reduced, the material mechanical property and plastic machining can be improved, the product surface roughness is improved, and hot rolling and cold rolling are smoothly carried out.

Owner:安徽博安门窗有限公司

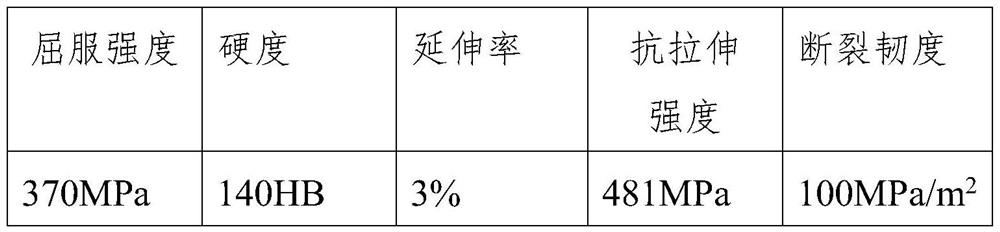

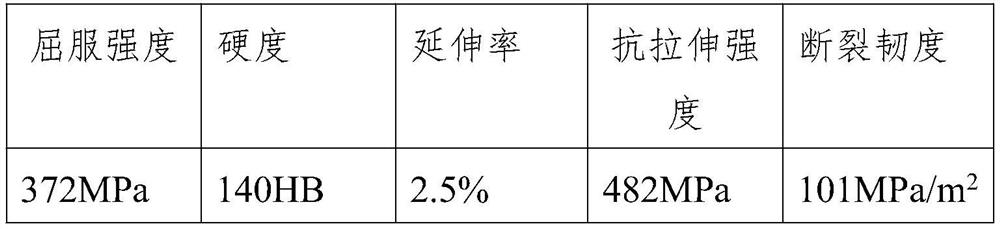

A kind of aluminum alloy for 480mpa grade aluminum alloy oil pipe and its pipe material manufacturing method

An aluminum alloy for a 480MPa grade aluminum alloy oil pipe according to the present invention comprises Zn: 5.50-6.90%, Mg: 1.75-1.80%, Cu: 0.05%, Mn: 0.10-0.30%, Cr: 0.10-0.30% in weight percentage , Ti: 0.01-0.02%, Zr: 0.15-0.18%, and the rest are Al and unavoidable impurities; among the unavoidable impurities, the content of Si is not more than 0.15% of the total weight of the aluminum alloy, and the content of Fe is not more than the total weight of the aluminum alloy 0.15%. A method for manufacturing an aluminum alloy pipe, comprising the following steps: 1) smelting and refining the above-mentioned raw materials to obtain a pipe billet; 2) three-stage homogenization treatment; 3) extruding at high temperature; 4 ) by two-stage solution treatment and quenching and cooling; 5) pre-stretching deformation; 6) by two-stage artificial aging treatment.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Aluminum alloy for chloride ion corrosion-resistant aluminum alloy oil pipe and method for manufacturing the same

The invention discloses aluminum alloy for an anti-chloridion-corrosion type aluminum alloy oil pipe and a pipe manufacturing method of the aluminum alloy. The aluminum alloy comprises, by weight, 6.90%-7.49% of Zn, 2.10%-2.30% of Mg, 0.05%-0.10% of Cu, 0.10%-0.30% of Mn, 0.10%-0.30% of Cr, 0.01%-0.02% of Ti, 0.15%-0.2% of Zr, 0.05%-0.1% of Sc, and the balance Al and inevitable impurities. The strength performance of the aluminum alloy is improved significantly through matching of the high-content Zn and the low-content Mg. The strength and the repeated loading resistance of the aluminum alloy are improved through the appropriate-content Mn and the appropriate-content Cr, and the good plasticity and toughness of the aluminum alloy are ensured. The micro-content Ti, the micro-content Zr and the micro-content Sc serve as supplement and improvement. The structure stability and the performance reliability of the aluminum alloy are ensured through grain refinement and precipitation strengthening. The aluminum alloy for the anti-chloridion-corrosion type aluminum alloy oil pipe is high in overall specific strength, good in corrosion resistance, low in cost, good in processability and high in qualified product ratio.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Aluminium alloy and preparation technology thereof

The invention discloses an aluminum alloy and a preparation process thereof, belonging to the technical field of metal material smelting. The aluminum alloy comprises the following components in parts by weight: 80-92 parts of Al, 2-6 parts of Mg, and 3-3 parts of Zn 7 parts, Cu 0.8-3.2 parts, Si 3-8 parts, Cr 0.1-0.5 parts, Ge 0.1-0.3 parts, Zr 0.12-0.18 parts. The invention provides an aluminum alloy and a preparation process thereof, which have the advantages of effectively reducing quenching residual stress and not being easily deformed in subsequent machining.

Owner:朱旭

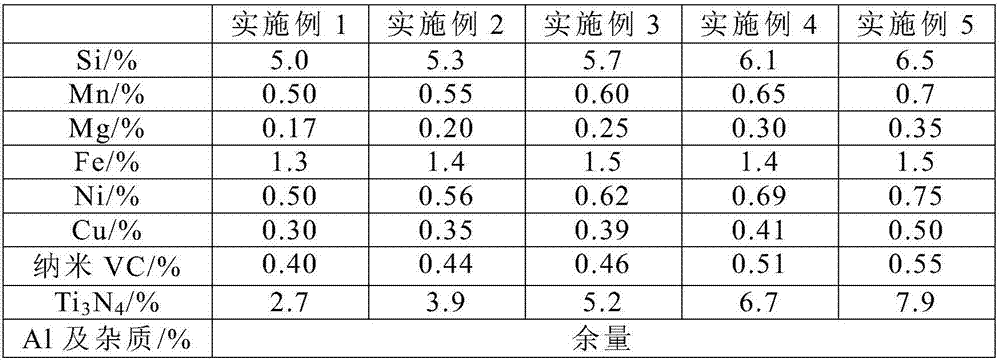

Turn seat supporting plate and preparation method thereof

The invention provides a turn seat supporting plate which is made of aluminum alloy. The aluminum alloy comprises the following ingredients in mass percent: 5.0-6.5% of Si, 0.5-0.7% of Mn, 0.17-0.35%of Mg, 1.3-1.5% of Fe, 0.5-0.75% of Ni, 0.3-0.5% of Cu, 0.4-0.5% of nanometer VC, 2.8-7.9% of Ti3N4 and the balance of Al and inescapable impurities. The turn seat supporting plate has the beneficialeffects of good mechanical property, light mass, high flexibility and stable performance.

Owner:TIANJIN SAIXIANG M&E ENG CO LTD

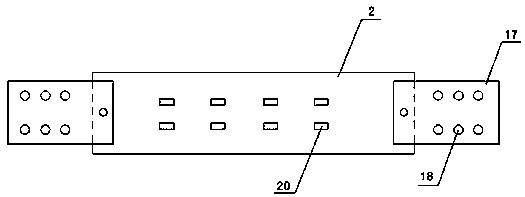

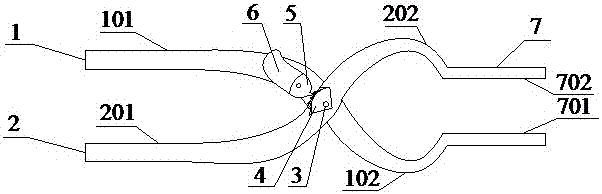

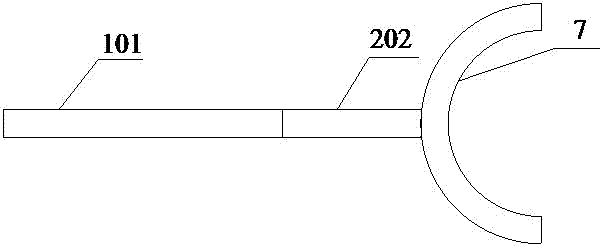

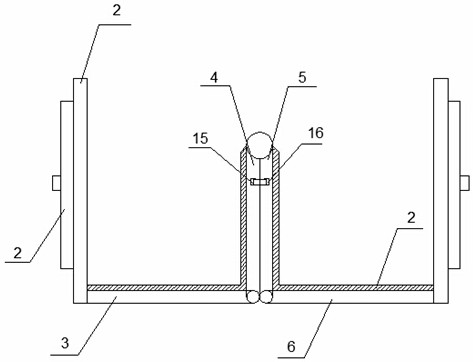

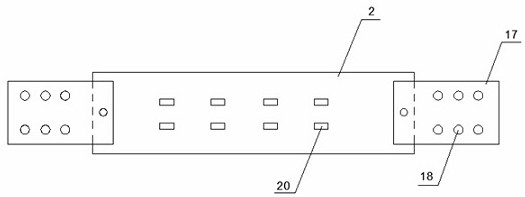

Special fixing tool for power transformation equipment sulfur hexafluoride gas detection

InactiveCN107490657AEasy to holdHigh strengthGas analyser construction detailsSulfur hexafluorideEngineering

The invention relates to a special fixing tool for power transformation equipment sulfur hexafluoride gas detection, and belongs to the technical field of electrical test assisting tools of substations. The special fixing tool for the power transformation equipment sulfur hexafluoride gas detection comprises a first clamp body and a second clamp body which are symmetrically connected, wherein a positioning mechanism is arranged at a junction of the first clamp body and the second clamp body; arc-shaped pressing parts are arranged at the end parts of clamping parts of the first clamp body and the second clamp body; the first clamp body and the second clamp body are made of aluminum alloy; the aluminum alloy is prepared from the following components in percent by mass: 2.0-3.2% of Mg, 3.5-4.5% of Si, 0.2-0.3% of Mn, 0.1-0.2% of Cr, 0.18-0.25% of Zr, 0.35-0.40% of Ti, 0.15-0.3% of Yb and the balance of Al and impurities with the content being lower than or equal to 0.05%. The special fixing tool for the power transformation equipment sulfur hexafluoride gas detection is simple in structure, high in material strength, resistant to corrosion and convenient to mount and detach, and can remarkably reduce potential safety hazards caused by frequent detachment of screws in the SF6 gas detection process.

Owner:国网河南省电力公司超高压公司 +1

High-strength graphite rare earth aluminum alloy conductor

ActiveCN107017036AReduce the degree of reunionLow densityConductive materialMetal/alloy conductorsRare earthGraphite

The invention discloses a high-strength graphite rare earth aluminum alloy conductor. An aluminum alloy matrix comprises, by mass percentage, 0.05-0.08 of Y, 0.05-0.08 of Er, 0.01-0.03 of Pr, 1-1.5% of Cu, 0.15-0.2% of Si, 0.15-0.25% of Cr, 0.05-0.1% of Ca, 0.15-0.25% of Mn, 0.1-0.25% of Fe, 0.15-0.2% of Ni, 0.2-0.45% of Zn, 0.08-0.15% of Ti, 0.035-0.045% of Sr, 0.07-0.12% of Zr, with the balance being Al. The high-strength graphite rare earth aluminum alloy conductor presented by the invention has good mechanical properties, such as strength and toughness, and has good resistance to high temperature, impact resistance and electrical conductivity.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

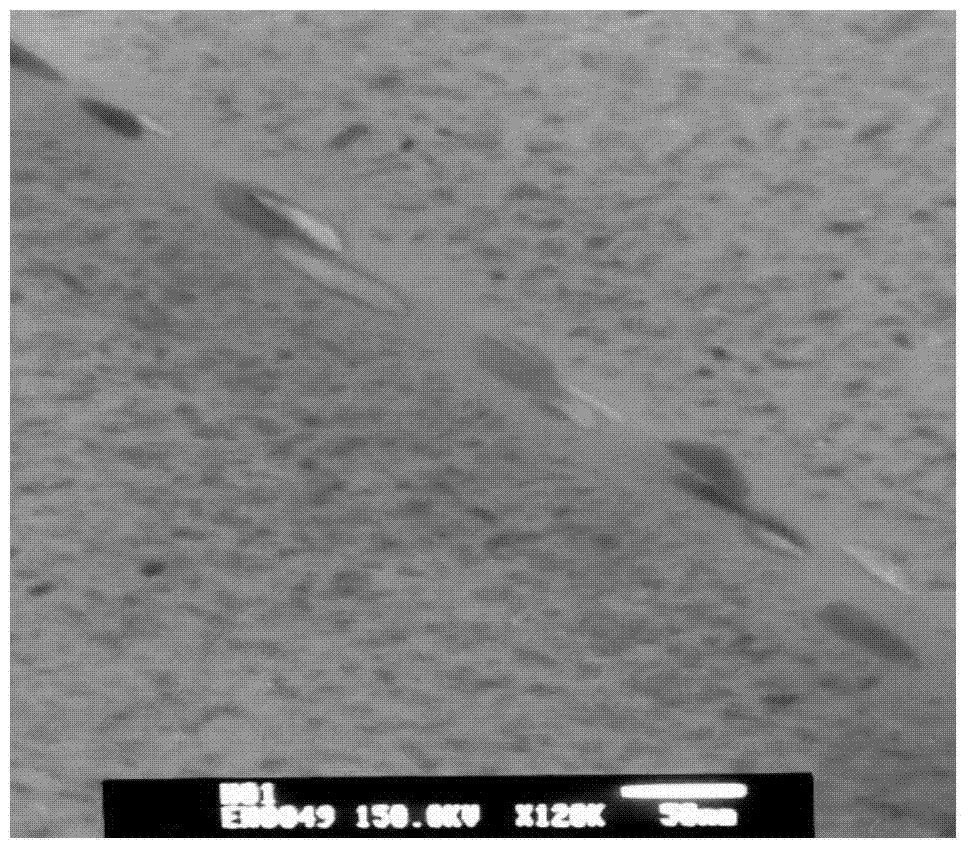

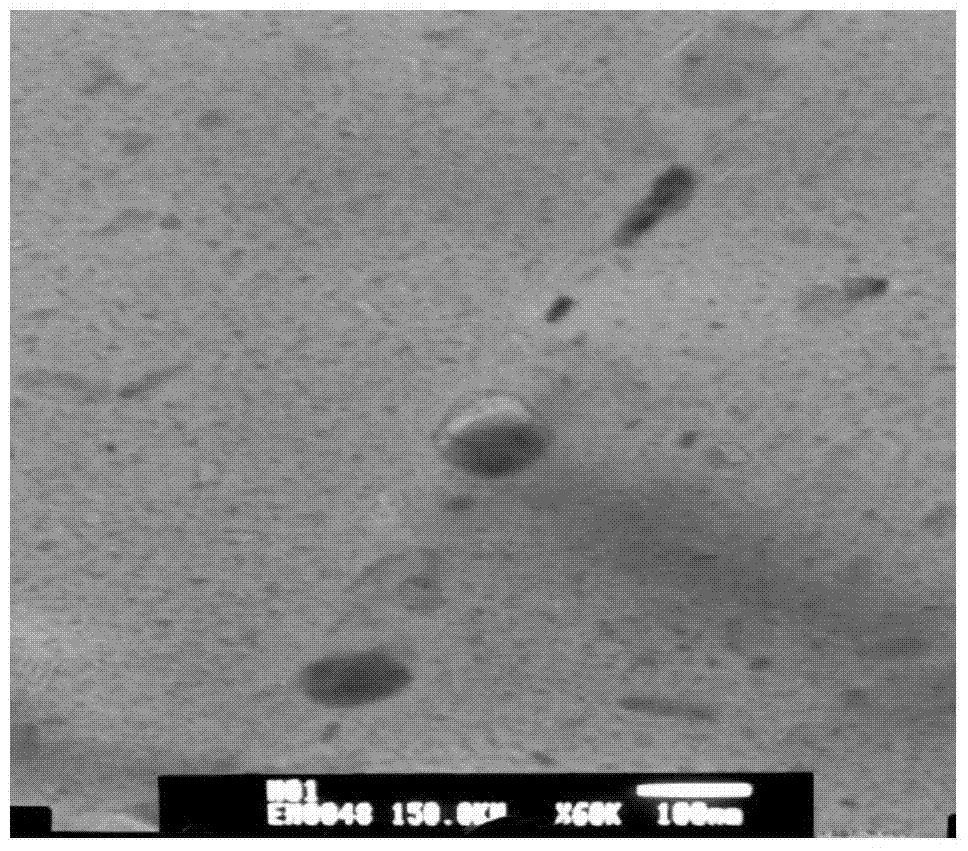

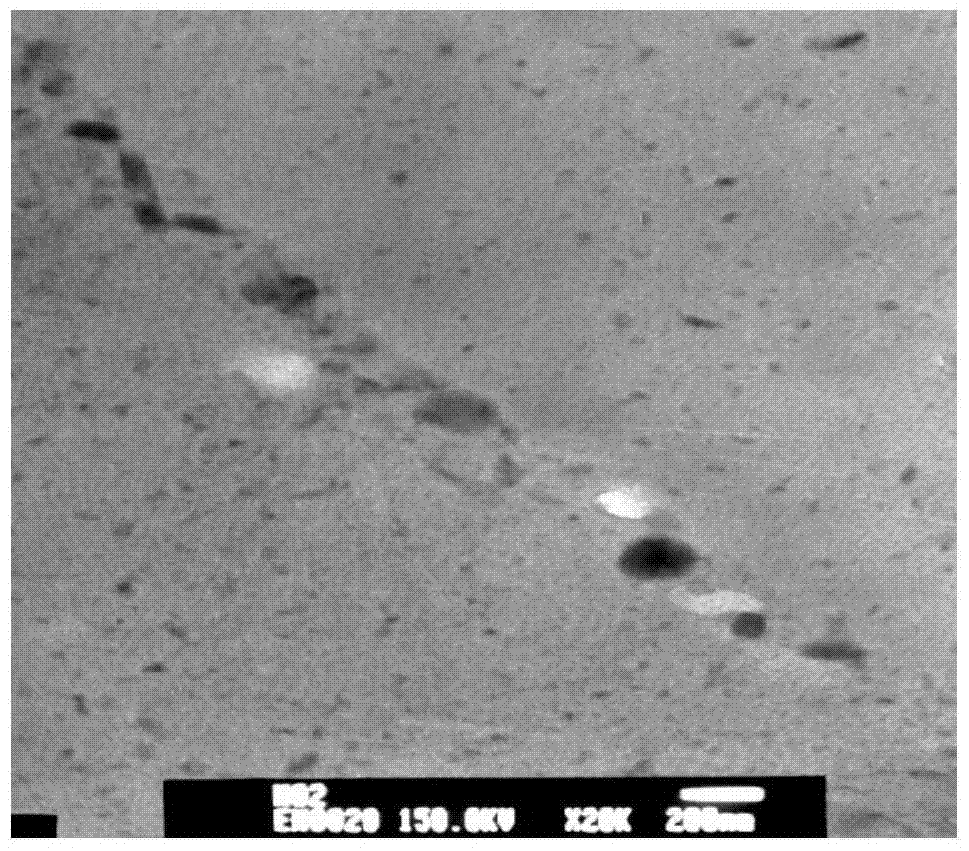

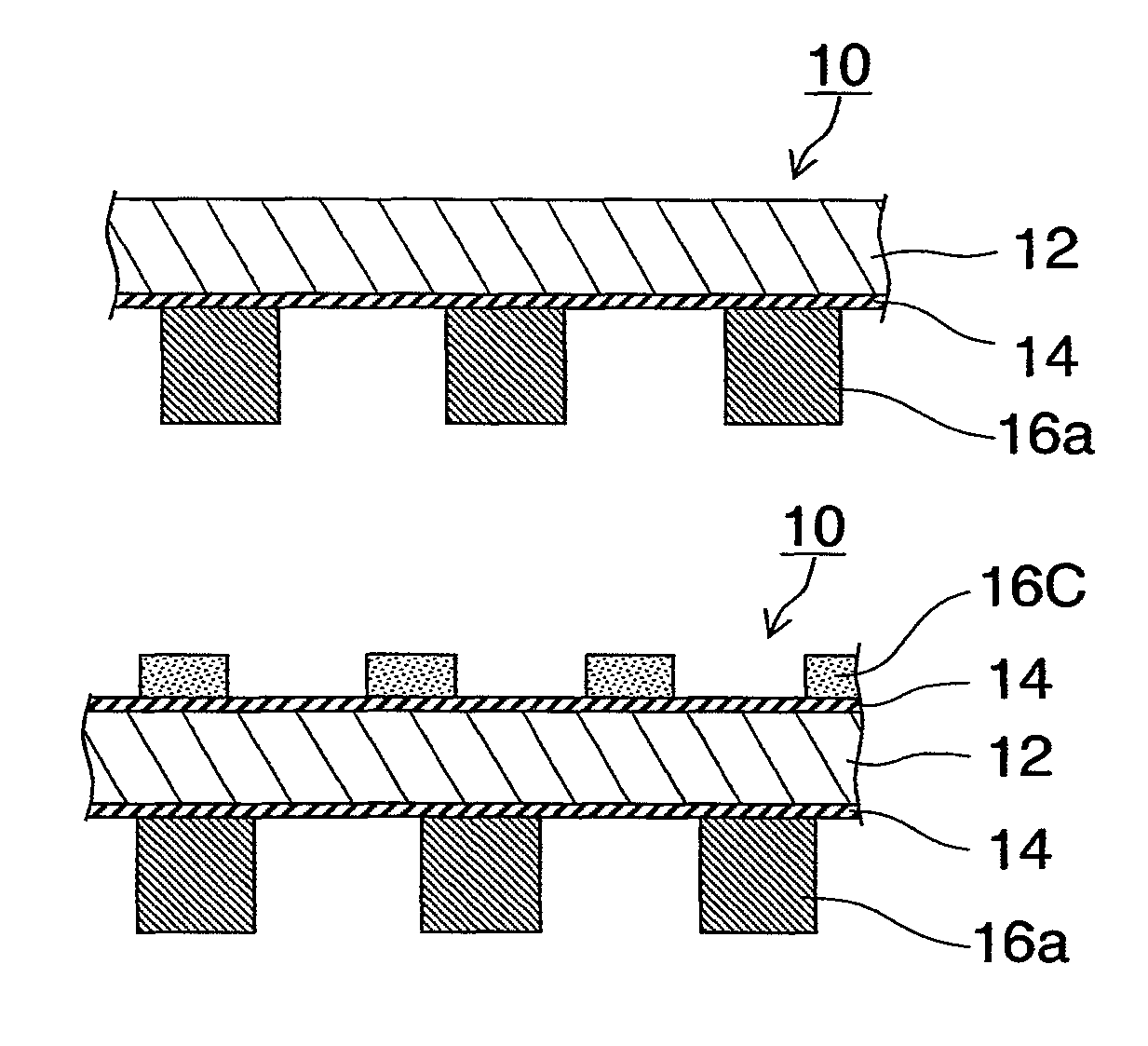

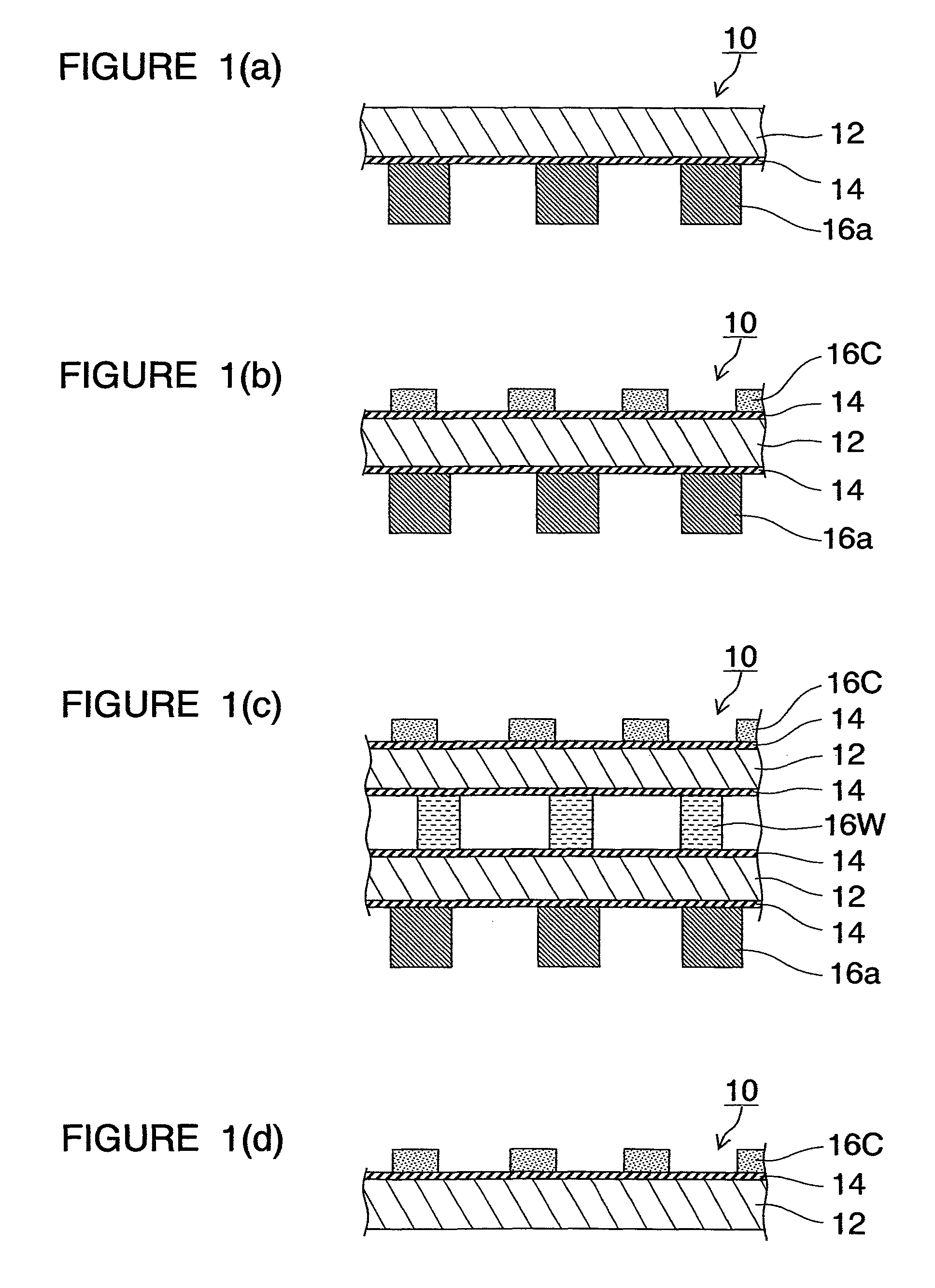

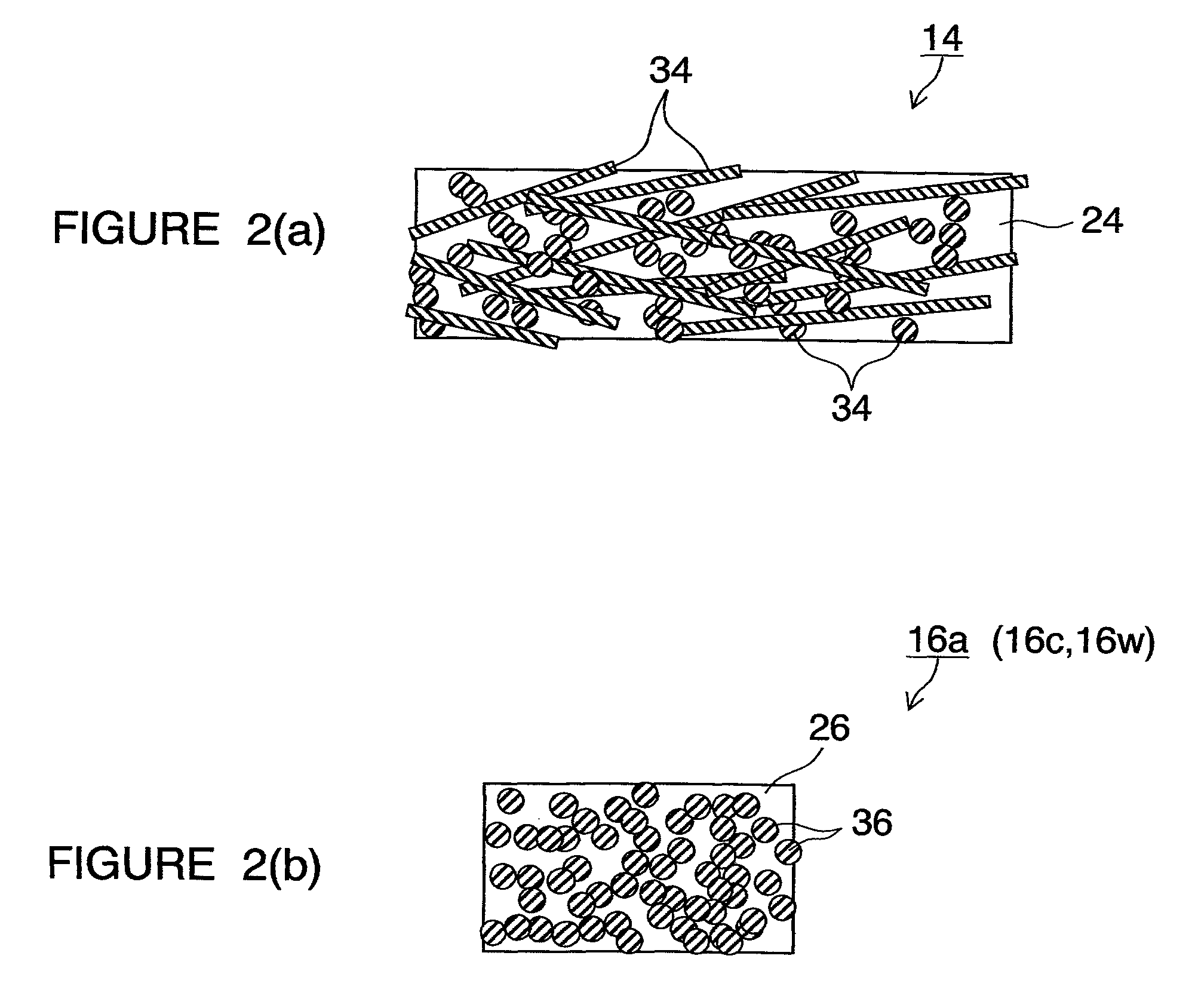

Metallic separator for fuel cells and method of manufacturing the metallic separator

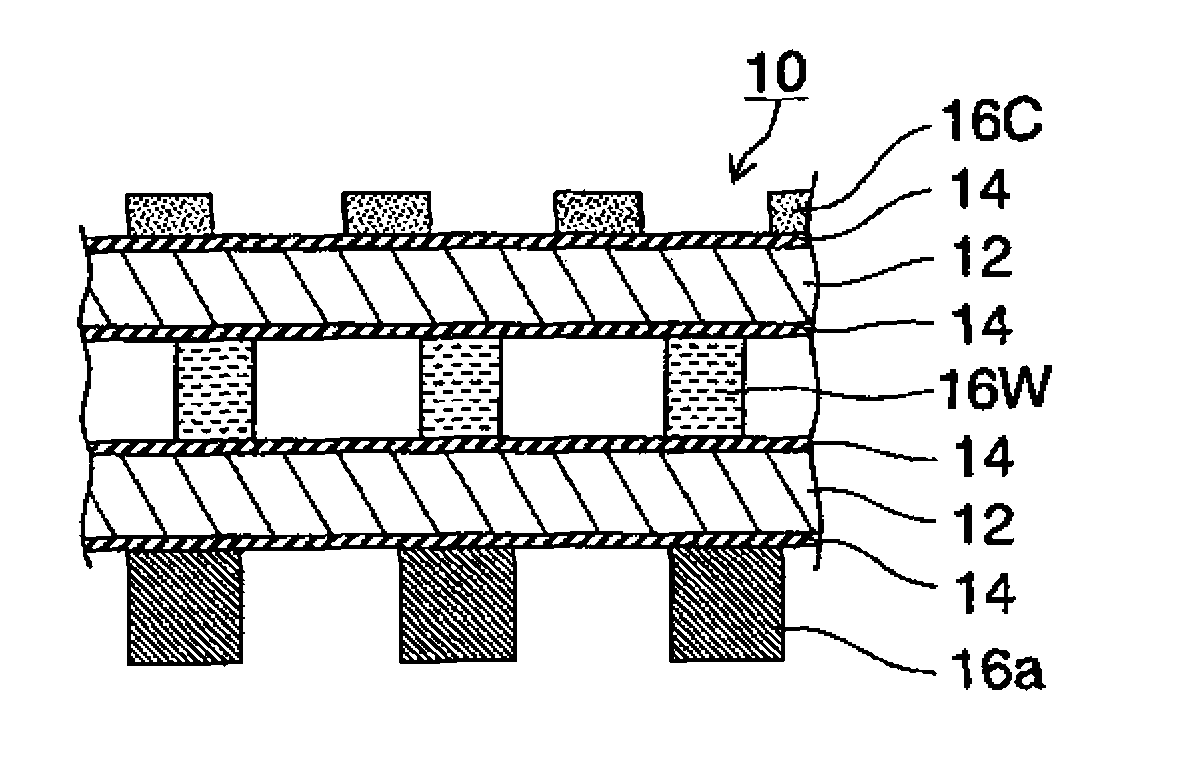

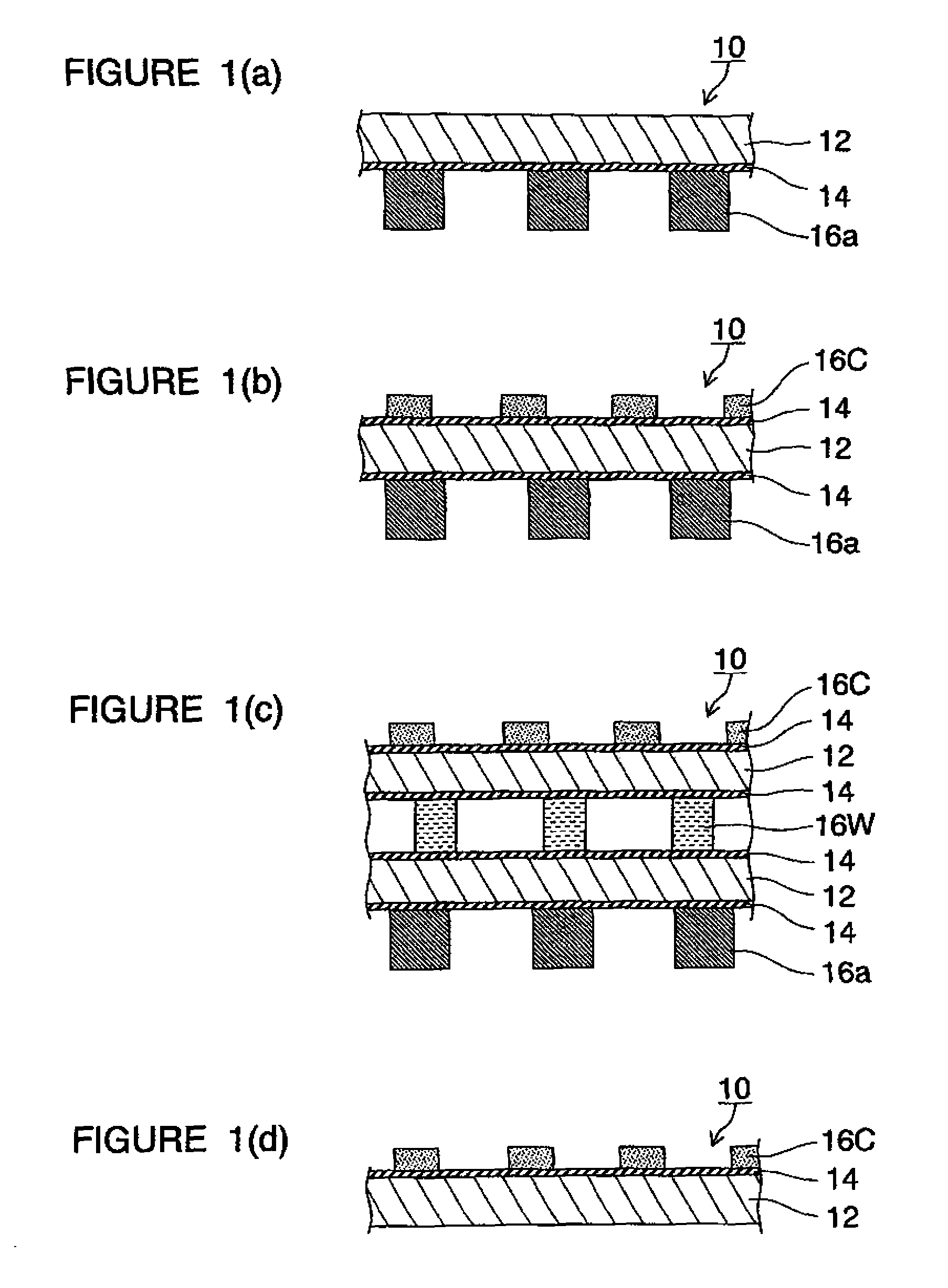

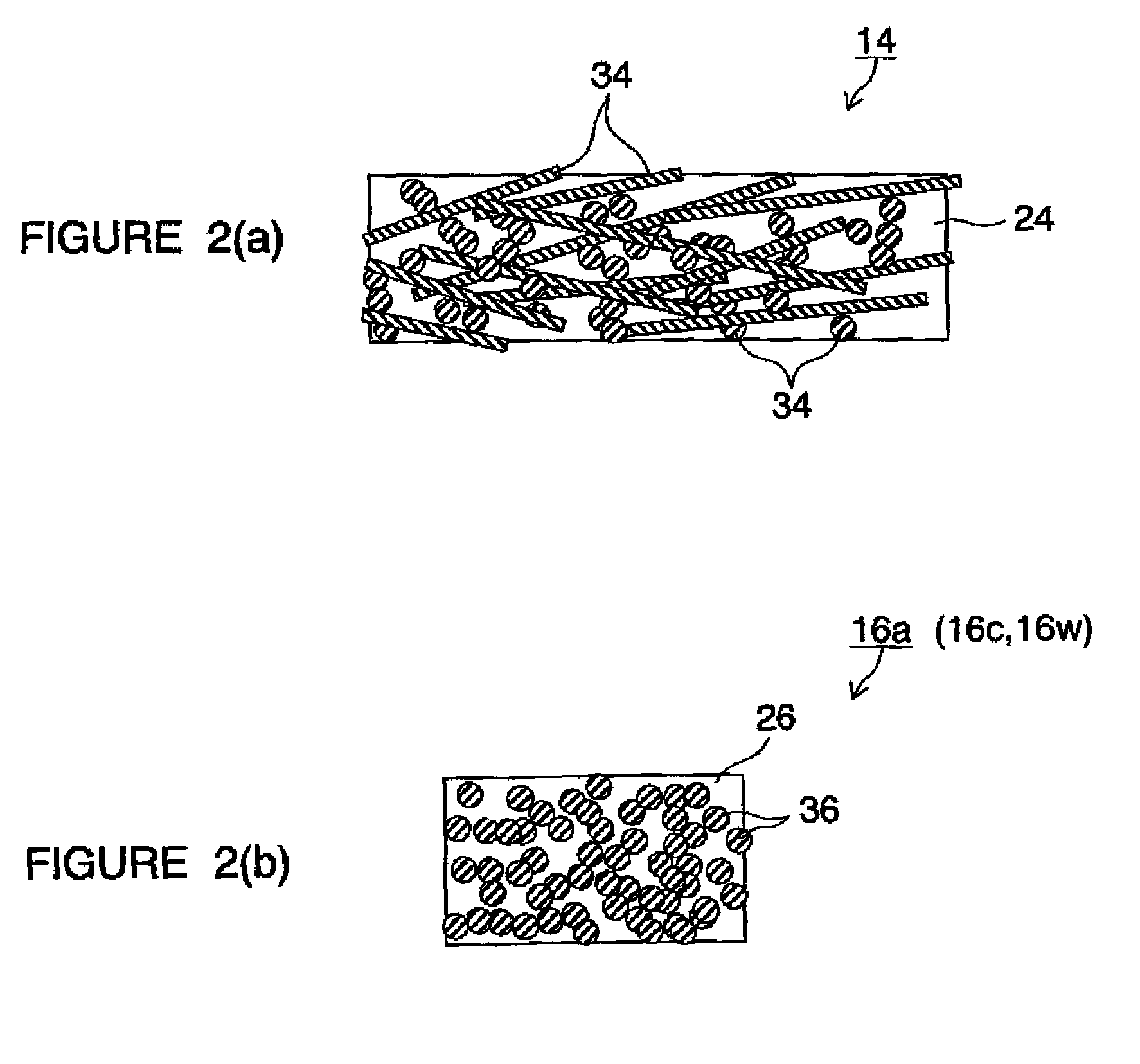

ActiveUS9431666B2Reduced susceptibility to stress-corrosion crackingImprove corrosion resistanceFuel cell auxillariesSolid electrolyte fuel cellsFuel cellsStress corrosion cracking

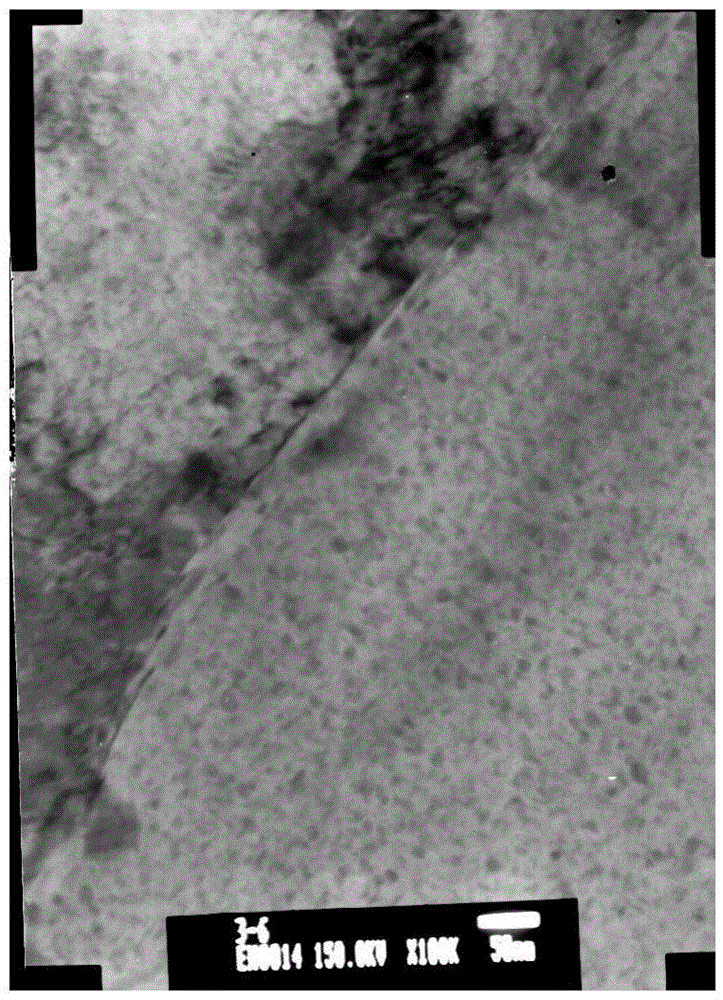

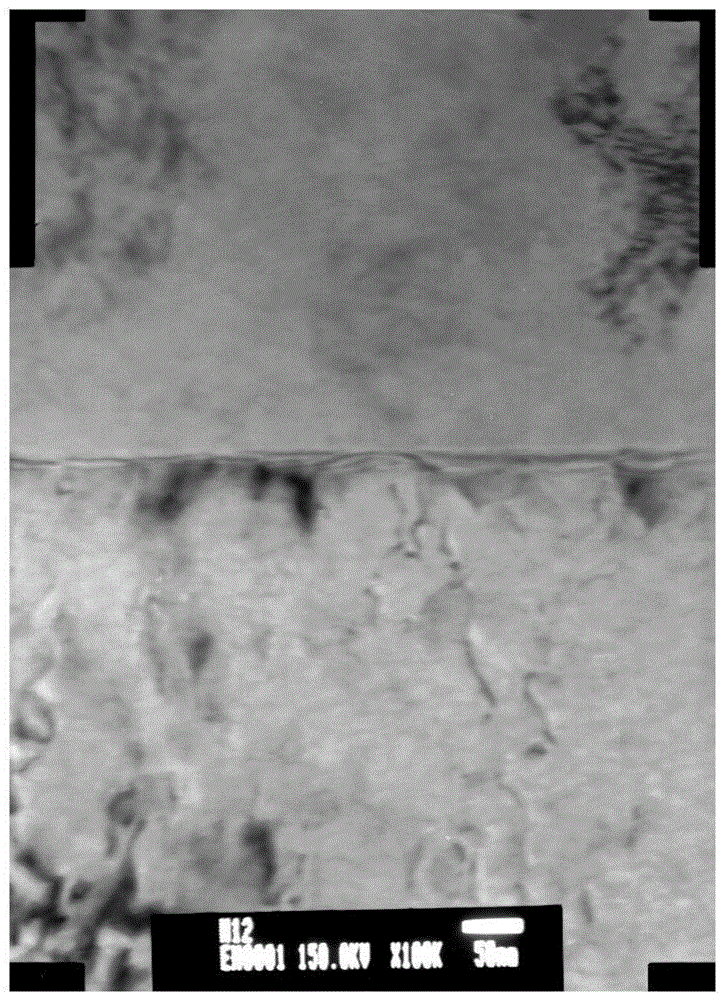

A metallic separator for fuel cells having a metal plate, an electroconductive coating layer covering at least a surface in front and back surfaces of the metal plate which contacts a raw material and / or a reaction product, and an electroconductive channel-forming member disposed on a surface of the coating layer and forming a channel for the raw material and / or the reaction product and / or a channel for a cooling medium for cooling. A surface layer on the metal plate has a tensile residual stress within such a range that no stress-corrosion cracking occurs.

Owner:UNIVERSITY OF YAMANASHI

High-strength and high-tenacity aluminum alloy material

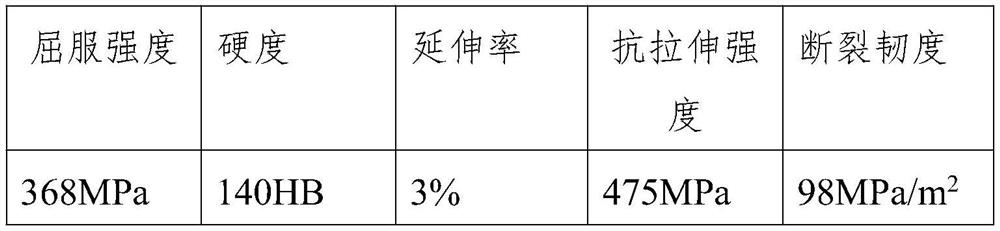

InactiveCN106756298AImprove toughnessReduced susceptibility to stress corrosion crackingAluminium alloy

The invention relates to a high-strength and high-tenacity aluminum alloy material. The high-strength and high-tenacity aluminum alloy material comprises 9.5%-11.0% of Si, 1.5%-3.5% of Cu, 0.05%-2% of Fe, 1.0%-1.5% of Mn, 0.4%-0.6% of Mg, 0.1%-0.2% of Cr, 0.01%-0.2% of Pb, 0.1%-0.2% of Ti, 0.01%-0.02% of Ni, 1%-3% of Zn, 0.1%-0.4% of Sn and the balance Al. Through material composition changing, the high-strength and high-tenacity aluminum alloy material is obtained, the problem that a cast aluminum alloy is insufficient in strength is solved, and good application prospects are achieved.

Owner:宁波星源卓镁技术股份有限公司

Metallic separator for fuel cells and method of manufacturing the metallic separator

ActiveUS9099690B2Easily causedReduce generationFinal product manufactureFuel cell auxillariesSurface layerFuel cells

A metallic separator for fuel cells having a metal plate, an electroconductive coating layer covering at least a surface in front and back surfaces of the metal plate which contacts a raw material and / or a reaction product, and an electroconductive channel-forming member disposed on a surface of the coating layer and forming a channel for the raw material and / or the reaction product and / or a channel for a cooling medium for cooling. A surface layer on the metal plate has a tensile residual stress within such a range that no stress-corrosion cracking occurs.

Owner:UNIVERSITY OF YAMANASHI

Preparation method of titanium-aluminum alloy target material

InactiveCN112410739AHigh strengthImprove toughnessVacuum evaporation coatingSputtering coatingUltimate tensile strengthMaterials science

The invention discloses a preparation method of a titanium-aluminum alloy target material. According to the technical scheme, the preparation method of the titanium-aluminum alloy target material comprises main material powder, ingredient powder and trace powder, and further comprises the following steps that S1, the main material powder, the ingredient powder and the trace powder are mixed to beuniform, large-particle impurities are filtered out, powdery particles with the equal size are reserved, and mixed powder is obtained; and S2, the mixed powder remained after filtering in the step S1is poured into medical alcohol for soaking and cleaning; The preparation method of the titanium-aluminum alloy target material has the beneficial effects that the titanium-aluminum alloy target material is prepared by adding the ingredient powder composed of silicon powder and magnesium powder and the trace powder composed of chromium powder and then adopting a powder metallurgy method, the strength of the alloy is improved, the casting performance, the corrosion resistance and the welding performance are all improved, the finally prepared titanium-aluminum alloy target material is excellent in performance, balanced in attributes in all aspects and simple in production process, and therefore the production cost can be reduced, and production is more economical.

Owner:光洋新材料科技(昆山)有限公司

Shock-preventive solar energy module capable of effectively preventing side frame oxide film from cracking

The invention discloses a shock-preventive solar energy module capable of effectively preventing a side frame oxide film from cracking. The shock-preventive solar energy module capable of effectively preventing the side frame oxide film from cracking comprises a side frame used for the solar energy module, wherein the side frame is manufactured from an aluminum alloy material; the aluminum alloy material comprises the following components in percentage by mass: 0.001 to 0.004% of C, 13.3 to 13.5% of Si, 0.21 to 0.23% of Fe, 0.12 to 0.14% of Cu, 0.11 to 0.13% of Zr, 0.02 to 0.04% of Ti, 0.001 to 0.002% of Ca, 0.003 to 0.005% of Hg, 0.13 to 0.15% of Pt, 0.22 to 0.24% of Pb, 0.01 to 0.03% of Cr, 0.42 to 0.46% of rare earth, 0.24 to 0.28% of assistant, and the balance Al.

Owner:RENESOLA JIANGSU LTD

A tray-type cable tray with high heat dissipation and air permeability

Owner:JIANGSU HUAQIANG ELECTRIC EQUIP

A kind of high-strength corrosion-resistant electrical aluminum-titanium alloy material and preparation method thereof

The invention belongs to the field of alloy materials, and discloses a high-strength and corrosion-resistance aluminum-titanium alloy material for an electrician and a preparation method thereof. The aluminum-titanium alloy material consists of the following components in percentage by weight: 0.05-0.2 wt% of Ti, 0.01-0.15 wt% of Zr, 0.1-0.4 wt% of B, 0.01-0.3 wt% of Mn, 0.01-0.35 wt% of Cr, 0.015-0.1 wt% of Sr, 0.02-1 wt% of rare earth, and the balance of Al. The preparation method comprises the following steps: all the components are prepared to an alloy in a smelting furnace after the batching; the alloy is cast to an aluminum ingot in a deep well casting mode; and the aluminum ingot is extruded by a hot extrusion process to manufacture a product shape accordant with the requirements. The aluminum-titanium alloy material is excellent in stress corrosion resistance, high in strength and excellent in electrical conductivity.

Owner:安徽华淮新材料有限公司

Track aluminum profile

ActiveCN114438382AHigh strengthImprove room temperature tensile propertiesExtrusion control devicesSolution treatmentUltimate tensile strength

The invention discloses a rail aluminum profile and a preparation method thereof. The rail aluminum profile comprises the following main components in percentage by mass: 1.35-1.5% of Mg, 0.1-0.2% of Si, 2.0-4.0% of Zn (Zn = 2.7 Mg), 0.09-0.12% of V, 1.0-2.2% of Mn, 3.5-4.5% of Cu, 0.1-1.3% of Cd, 0.1-0.3% of Cr, 0.1% of mischmetal, 0.01-0.05% of Ti and the balance of aluminum and inevitable impurities, the content of Zr accounts for 0.04-0.08%, and the balance is Al. According to the method, raw materials are prepared according to the mass ratio, semi-continuous casting is used, and the extrusion process and the solution treatment process are optimized, so that the strength and the tensile property of the track are greatly improved, the loading capacity of the track is enhanced, meanwhile, the stability of a track sliding groove is improved, and the requirement for the performance of the track in industrial manufacturing is met.

Owner:JIANGYIN MUXIANG ENERGY SAVING DECORATION MATER

A kind of formula of cast aluminum alloy wheel hub

The invention discloses a formula for casting aluminum alloy hubs. The formula is prepared from, by weight, 6.5-7.5% of Si, 0.28-0.45% of Mg, 0-0.12% of Fe, 0-0.02% of Cu, 0.02-0.05% of Mn, 0.04-0.05% of Zn, 0.10-0.20% of Ti, 0.2-0.6% of Sr, 0.01-0.05% of Cr, 0.01-0.02% of Zr, 0.025-0.05% of B, 0.4-0.8% of mixed light rare earth and the balance Al. Due to the fact that Sr and the mixed rare earth metal serve as an alterant together, the surface defects of alloy phases can be overcome, surface tension on a new-phase interface and an old-phase interface is reduced, and the problem that compactness is reduced when only Sr is added is avoided. Zr, Ti, Cr and Al work together, the cast structure is further refined, and the hardness and the toughness of aluminum alloy are improved.

Owner:GUANGDONG DCENTI AUTO PARTS STOCK LTD

A kind of high-strength graphene rare-earth aluminum alloy

The invention discloses a high-strength graphene and rare-earth aluminium alloy. The grapheme and rare-earth aluminium alloy comprises an aluminium alloy matrix and graphene. The composition of the aluminium alloy matrix comprises, by mass, 1.2-1.8% of Cu, 0.18-0.25% of Si, 0.08-0.2% of Cr, 0.6-0.8% of Mg, 0.1-0.2% of Mn, 0.3-0.4% of Fe, 0.3-0.5% of Zn, 0.02-0.06% of Ti, 0.1-0.2% of V, 0.1-0.2% of Ni, 0.04-0.07% of Mo, 0.05-0.12% of Zr, 0.04-0.08% of Nd, 0.04-0.06% of La, 0.03-0.05% of Ce, and the balance Al. The high-strength graphene and rare-earth aluminium alloy has good mechanical properties such as strength, toughness and the like.

Owner:ANHUI NANYANG NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com