Aluminum alloy for anti-chloridion-corrosion type aluminum alloy oil pipe and pipe manufacturing method of aluminum alloy

An aluminum alloy and corrosion-type technology, which is applied in the field of aluminum alloy for chloride ion corrosion-resistant aluminum alloy tubing and its pipe material, can solve the problems of harsh corrosion environment of the production pipe string and difficulty in meeting the corrosion performance requirements, etc., and achieve the improvement of intragranular Strengthen the nucleation rate of precipitated phase, excellent mechanical properties and corrosion resistance, stable structure and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

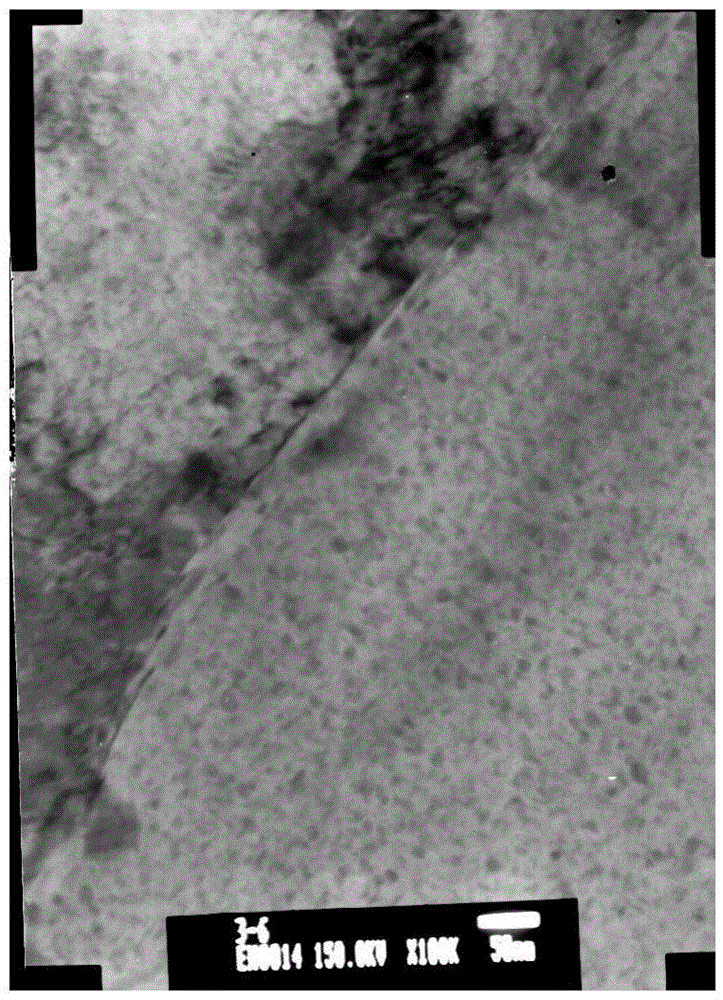

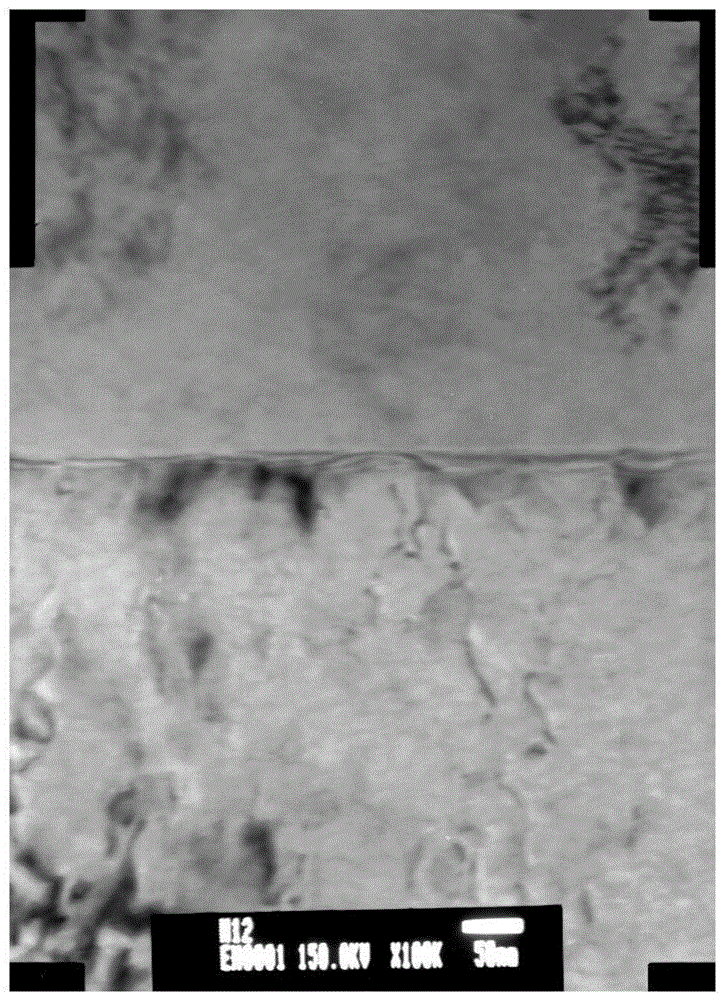

Image

Examples

Embodiment 1

[0038]The present invention is an aluminum alloy for chloride ion corrosion-resistant aluminum alloy tubing, the chemical composition of which includes: 7.49% of Zn, 2.30% of Mg, 0.05% of Cu, 0.26% of Mn, 0.10% of Cr, 0.01% Ti, 0.2% Zr, 0.05% Sc, and the remaining components are Al and unavoidable impurities, wherein the unavoidable impurities include 0.09% Fe and 0.06% Si which account for the total weight of the aluminum alloy.

[0039] The manufacturing method of the above-mentioned aluminum alloy tubing for chloride ion corrosion-resistant aluminum alloy tubing is as follows: the above-mentioned raw materials are smelted and refined outside the furnace, and then cast to obtain a hollow ingot, and the hollow ingot is heated in a heating furnace to 385°C and 465°C respectively. Two-stage homogenization treatment is carried out, and the corresponding holding time is 12h and 24h; the extrusion temperature of the hollow ingot is 425°C, the extrusion ratio is 18.3, and the extrus...

Embodiment 2

[0042] The present invention is an aluminum alloy for chloride ion corrosion-resistant aluminum alloy tubing, the chemical composition of which includes: 6.95% of Zn, 2.15% of Mg, 0.09% of Cu, 0.30% of Mn, 0.20% of Cr, 0.02% Ti, 0.15% Zr, 0.08% Sc, and the remaining components are Al and unavoidable impurities, wherein the unavoidable impurities include 0.08% Fe and 0.06% Si accounting for the total weight of the aluminum alloy.

[0043] The above-mentioned aluminum alloy tubing for chloride ion corrosion-resistant aluminum alloy tubing is manufactured by smelting and refining the above-mentioned raw materials and then casting the hollow ingot, and heating the hollow ingot to 380°C and 465°C respectively in the heating furnace. Two-stage homogenization treatment is carried out, and the corresponding holding time is 12h and 24h; the extrusion temperature of the hollow ingot is 420°C, the extrusion ratio is 18.3, and the extrusion speed is 4mm / s; the two-stage solution treatment ...

Embodiment 3

[0046] The present invention is an aluminum alloy for chloride ion corrosion-resistant aluminum alloy tubing, the chemical composition of which includes: 6.9% of Zn, 2.10% of Mg, 0.10% of Cu, 0.10% of Mn, 0.30% of Cr, 0.02% Ti, 0.17% Zr, 0.10% Sc, and the remaining components are Al and unavoidable impurities, wherein the unavoidable impurities include 0.07% Fe and 0.08% Si accounting for the total weight of the aluminum alloy.

[0047] The manufacturing method of the above-mentioned aluminum alloy tubing for chloride ion corrosion-resistant aluminum alloy tubing is as follows: the above-mentioned raw materials are smelted and refined outside the furnace, and then cast to obtain a hollow ingot, and the hollow ingot is heated in a heating furnace to 380°C and 470°C respectively. Two-stage homogenization treatment is carried out, and the corresponding holding time is 12h and 24h; the extrusion temperature of the hollow ingot is 415°C, the extrusion ratio is 18.5, and the extrusio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com