Track aluminum profile

A technology of aluminum profiles and rails, which is applied in the direction of metal extrusion control equipment, manufacturing tools, metal extrusion, etc., can solve problems such as failure to meet mechanical performance requirements, decline in rail accuracy, and low-strength rails, etc., to achieve finished products High efficiency, thin residual material thickness, and the effect of eliminating coarse crystal rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

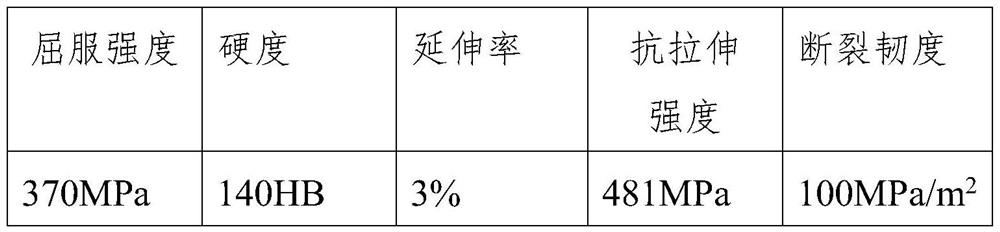

Embodiment 1

[0028]A track aluminum profile, composed of the following elements by weight percentage: Mg content accounts for 1.5%, Si content accounts for 0.2%, Zn content accounts for 4.0%, V content accounts for 0.12%, Mn content accounts for Ratio is 2.2%, Cu content is 4.4%, Cd is 1.3%, Cr is 0.3%, mixed rare earth is 0.1%, Ti is 0.05%, Zr is 0.08%, The balance is Al.

[0029] The preparation method of the track aluminum profile comprises the following steps:

[0030] (1) select elemental metal raw materials with purity ≥ 99.90% according to weight;

[0031] (2) Add aluminum ingots or molten aluminum into the melting furnace, heat and keep it above 740°C, add Si, Mn, Mg, Cu, Zn raw materials, stir until they melt into a liquid state, and then raise the furnace temperature to 930°C , add V, Cd, Cr, Ti, Zr, mixed rare earth raw materials, stir and melt;

[0032] (3) Use argon to purify the above-mentioned alloy melt, refine it in the furnace, remove the slag after refining, let it st...

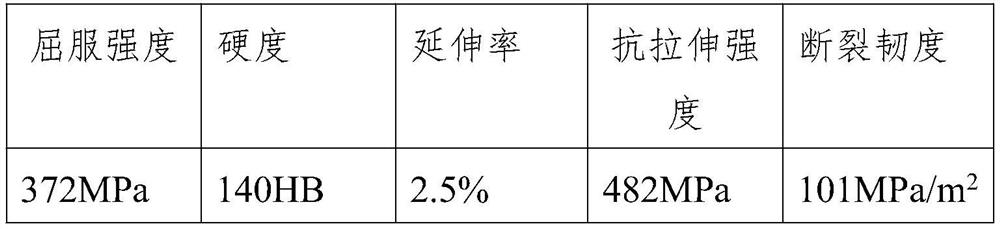

Embodiment 2

[0046] A rail aluminum profile, the main component content is calculated by mass percentage: the proportion of Mg content is 1.35%, the proportion of Si content is 0.13%, the proportion of Zn content is 3.4%, the proportion of V content is 0.1%, and the proportion of Mn content is 2.0%, Cu content accounted for 3.9%, Cd content accounted for 0.7%, Cr content accounted for 0.2%, mixed rare earth content accounted for 0.1%, Ti content accounted for 0.04%, Zr content accounted for 0.06%, the balance is Al.

[0047] The preparation method of the track aluminum profile comprises the following steps:

[0048] (1) select elemental metal raw materials with purity ≥ 99.90% according to weight;

[0049] (2) Add aluminum ingot or molten aluminum into the smelting furnace, heat and keep it above 735°C, add Si, Mn, Mg, Cu, Zn raw materials, stir until it melts into a liquid state, and then raise the furnace temperature to 900°C , add V, Cd, Cr, Ti, Zr, mixed rare earth raw materials, sti...

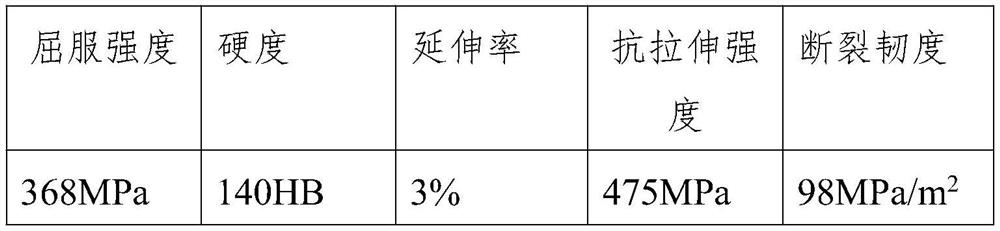

Embodiment 3

[0064] A rail aluminum profile, the main component content is calculated by mass percentage: the proportion of Mg content is 1.4%, the proportion of Si content is 0.15%, the proportion of Zn content is 3.7%, the proportion of V content is 0.10%, and the proportion of Mn content is The content of Cu is 1.0%, the content of Cu is 3.5%, the content of Cd is 0.5%, the content of Cr is 0.1%, the content of mixed rare earth is 0.1%, the content of Ti is 0.01%, and the content of Zr is 0.01%. 0.04%, the balance is Al.

[0065] The preparation method of the track aluminum profile comprises the following steps:

[0066] (1) select elemental metal raw materials with purity ≥ 99.90% according to weight;

[0067] (2) Add aluminum ingot or molten aluminum into the smelting furnace, heat and keep it above 735°C, add Si, Mn, Mg, Cu, Zn raw materials, stir until it melts into a liquid state, and then raise the furnace temperature to 900°C , add V, Cd, Cr, Ti, Zr, mixed rare earth raw materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com