A kind of homogenization heat treatment method of al‑zn‑mg‑cu‑zr aluminum alloy

A technology for homogenizing heat treatment and aluminum alloys, which is applied in the field of homogenizing heat treatment of Al‑Zn‑Mg‑Cu‑Zr aluminum alloys, can solve problems such as inapplicability, improve thermal efficiency, avoid microstructure overburning, and solve coarse The effect of phase back dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition of aluminum alloy is calculated by mass percentage: Zn6.24wt.%, Mg2.06wt.%, Cu2.09wt.%, Ti<0.06wt.%, Zr0.1wt.%, Fe≤0.08wt.%, Si≤0.03 wt.%, the balance is Al. Semi-continuous casting into 450mm thick specification ingots.

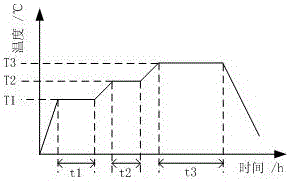

[0030] The alloy adopts the three-stage homogenization heat treatment system of the method of the present invention to carry out homogenization treatment. The specific process is: from room temperature to 400° C. for 10 hours at an average heating rate of 55° C. / h (heating time 6.8 hours), and then continue to heat at 10° C. The average heating rate of ℃ / h (heating time 7h) was raised to 470°C for 3h, and then the average heating rate of 2.5°C / h (heating time 4h) was raised to 480°C for 12h, 18h, 21h and 24h.

Embodiment 2

[0032] The composition of aluminum alloy is calculated by mass percentage: Zn6.42wt.%, Mg2.08wt.%, Cu2.13wt.%, Mn<0.10wt.%, Ti<0.06wt.%, Zr0.1wt.%, Fe≤0.08 wt.%, Si≤0.03wt.%, the balance is Al. Semi-continuous casting into ingots with a thickness of 520 mm.

[0033] The alloy adopts the three-stage homogenization heat treatment system of the method of the present invention to carry out homogenization treatment. The specific process is: from room temperature to 400° C. for 10 hours at an average heating rate of 55° C. / h (heating time 6.8 hours), and then continue to heat at 10° C. The average heating rate of ℃ / h (heating time 7h) was raised to 470°C for 3h, and then the average heating rate of 2.5°C / h (heating time 4h) was raised to 480°C for 12h, 24h and 48h.

Embodiment 3

[0035] The composition of aluminum alloy is calculated by mass percentage: Zn6.39wt.%, Mg2.09wt.%, Cu2.17wt.%, Ti<0.06wt.%, Zr0.1wt.%, Fe≤0.08wt.%, Si≤0.03 wt.%, the balance is Al. Semi-continuous casting into 600mm thick specification ingots.

[0036] The alloy adopts the three-stage homogenization heat treatment system of the method of the present invention to carry out homogenization treatment. The specific process is: from room temperature to 400° C. for 10 hours at an average heating rate of 55° C. / h (heating time 6.8 hours), and then continue to heat at 10° C. The average heating rate of ℃ / h (heating time 7h) was raised to 470°C for 3h, and then the average heating rate of 2.5°C / h (heating time 4h) was raised to 480°C for 24h, 36h and 48h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com