Homogenization process applied in actual production of large-sized 7-series superhard aluminum alloy

A hard aluminum alloy and homogenization technology is applied in the field of homogenization process used in the actual production of large-scale 7-series superhard aluminum alloys, which can solve the problems of incomplete homogenization of Al-Zn-Mg-Cu alloy, etc. Low cost, high efficiency, the effect of improving processability and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

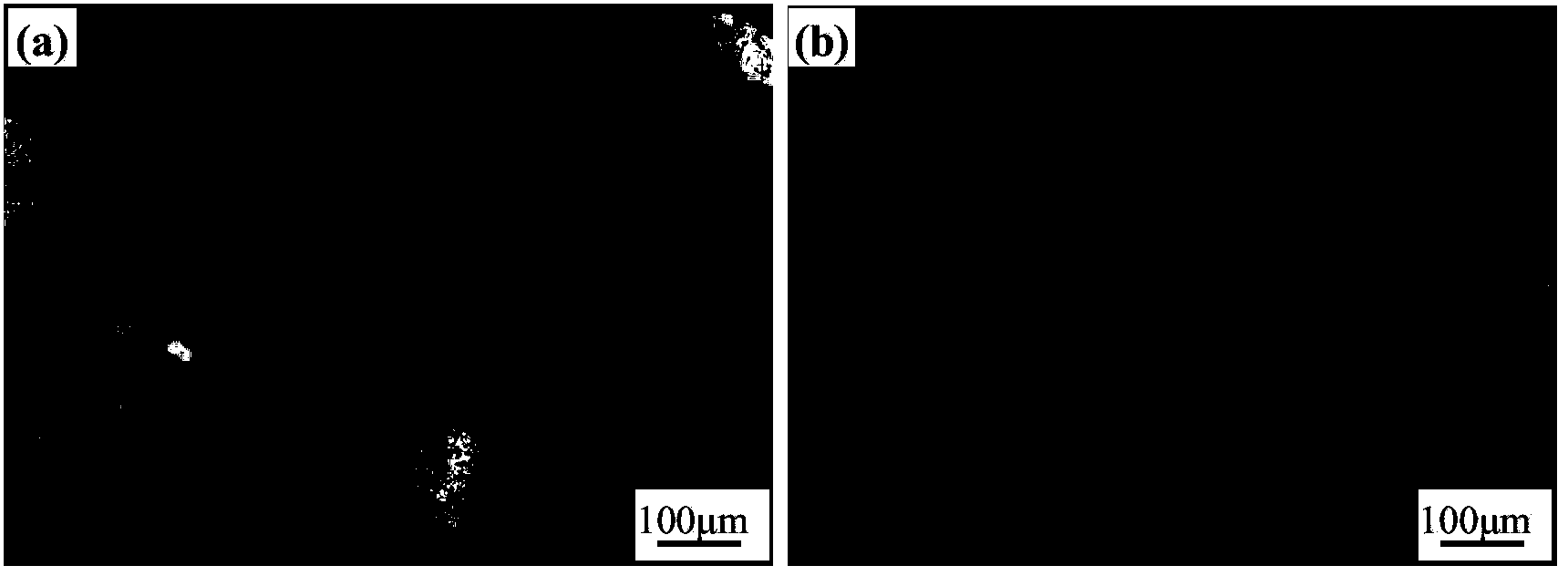

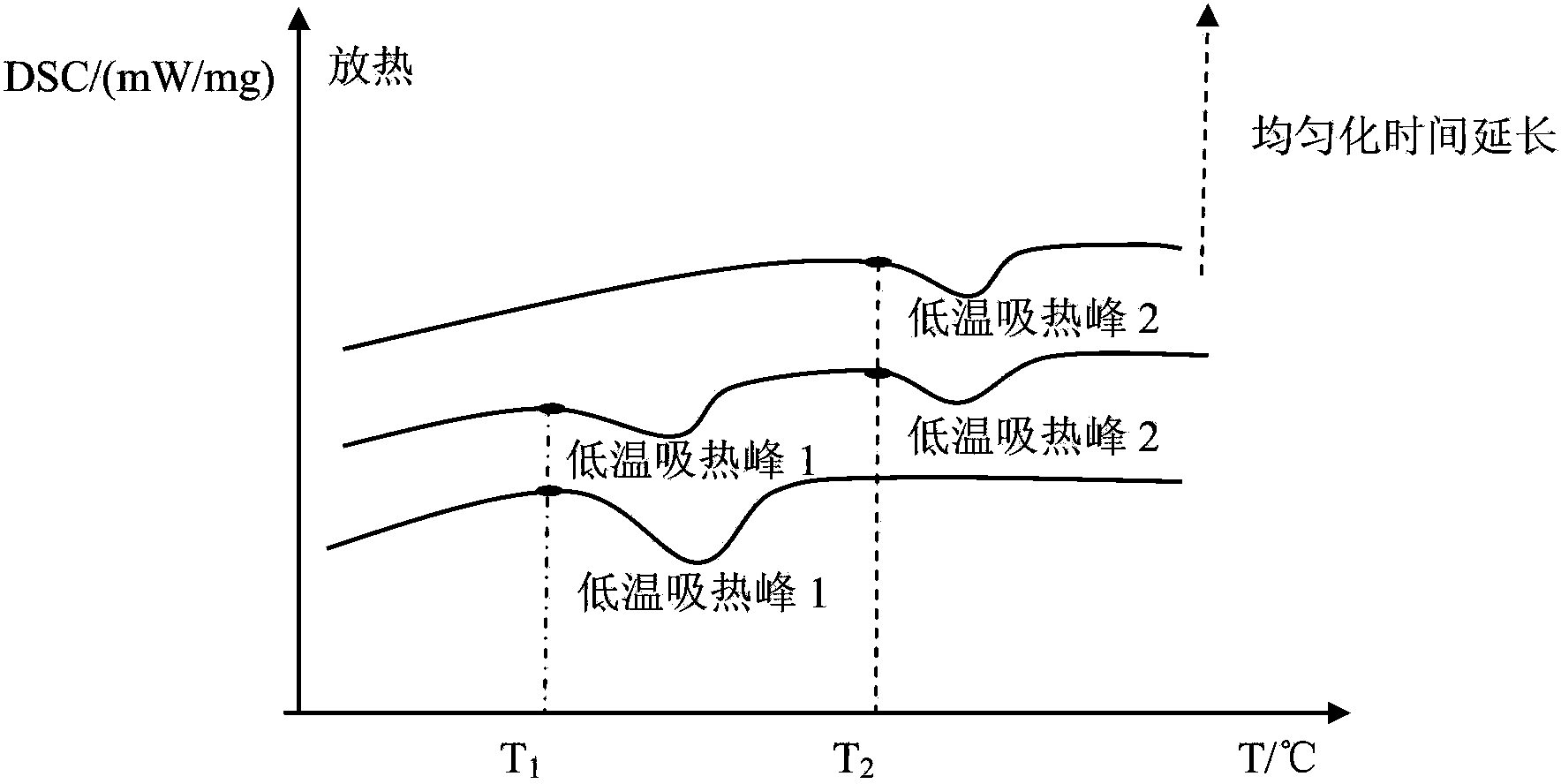

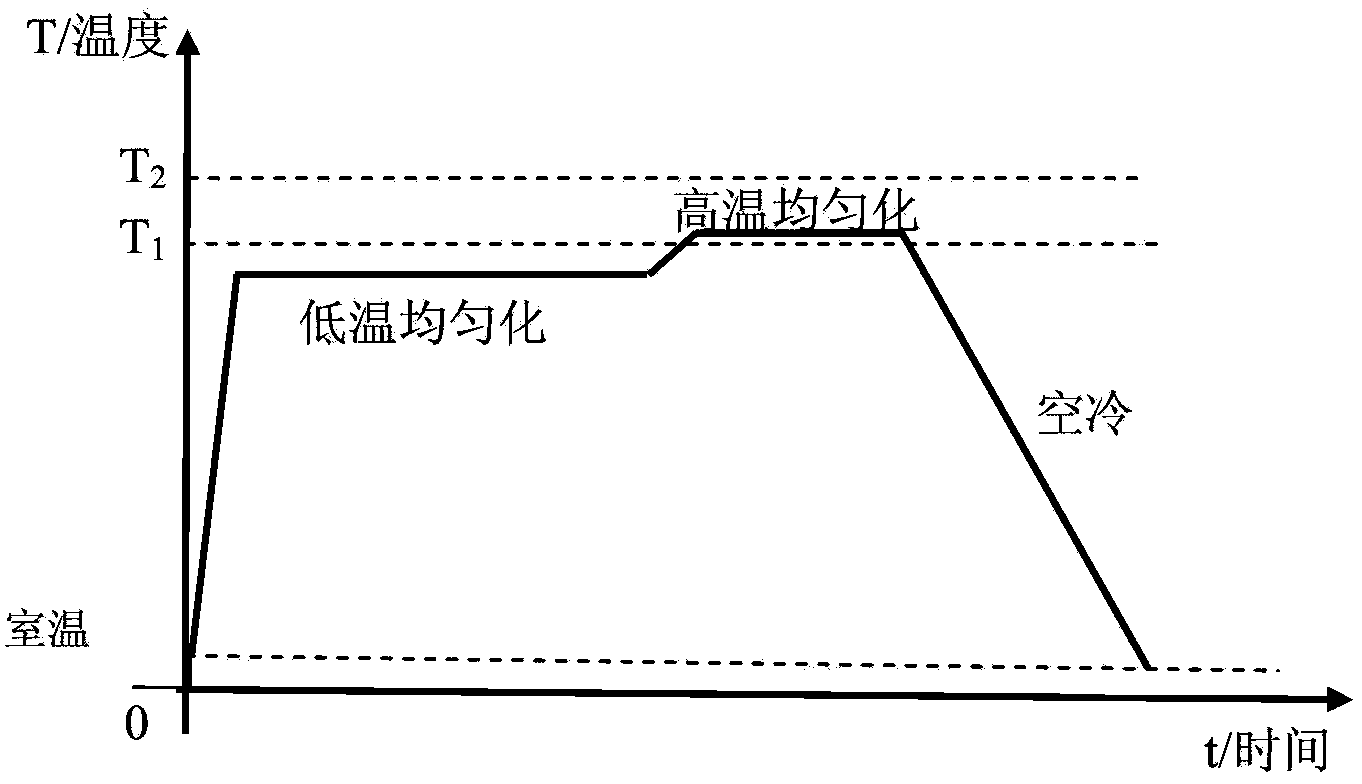

[0025] The Al-Zn-Mg-Cu alloy ingot is subjected to two-stage homogenization treatment, firstly heat preservation at 460°C for 6h, then raise the temperature to 480°C at a heating rate of 0.2-0.5°C / min, hold heat for 12h, and air-cool to room temperature.

Embodiment 2

[0027] The Al-Zn-Mg-Cu alloy ingot is subjected to two-stage homogenization treatment. First, it is kept at 460°C for 10h, and then the temperature is raised to 490°C at a heating rate of 0.2-0.5°C / min, kept at 6h, and air-cooled. to room temperature.

Embodiment 3

[0029] The Al-Zn-Mg-Cu alloy ingot is subjected to two-stage homogenization treatment. First, it is kept at 470°C for 12h, and then the temperature is raised to 480°C at a heating rate of 0.2-0.5°C / min, kept at 8h, and air-cooled. to room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com