2324 aluminum alloy and homogenization heat treatment method thereof

A technology for homogenizing heat treatment and aluminum alloy, which is applied in the direction of improving process efficiency, etc., can solve the problems of aging precipitation power reduction, reducing the solid solubility of aluminum alloy matrix, and reducing the mechanical properties of alloys, so as to save homogenization time and speed up recovery. Dissolving speed, speeding up the effect of fully redissolving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A. Ingredients: Calculate the amount of each aluminum alloy raw material and prepare the aluminum alloy raw material according to the proportion, Si: 0.026%, Fe: 0.067%, Cu: 4.263%, Mn: 0.605%, Mg: 1.506%, Cr: 0.001%, Zn: 0.02%, Ti: 0.023%, and the balance is Al.

[0048] B. Melting and casting: The prepared aluminum alloy raw materials are added to the melting furnace and evenly mixed and then smelted into liquid aluminum alloy. After standing, refining, slag removal, on-line degassing, and filtering processes, the liquid aluminum alloy is melted and cast into aluminum alloy. Ingot, the ingot size is 450×1680×6500mm.

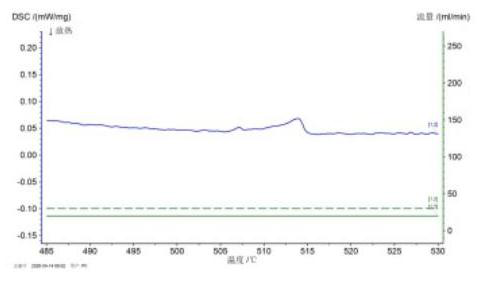

[0049] C. Homogenization: The aluminum alloy ingot is heated to 495°C at a speed of 40°C for 4h in an air furnace, then heated to 500°C at a rate of 0.2°C for 4h, and then air-cooled to 20°C. The total time from 495°C to 499°C is 25h.

Embodiment 2

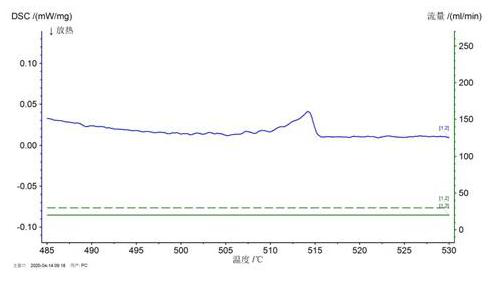

[0051] In this example, in step C, the aluminum alloy ingot is heated to 494°C at a speed of 40°C for 4h in an air furnace, and then heated to 500°C at a rate of 0.22°C for 4h, and the shared time is 27h from 494°C to 500°C.

Embodiment 3

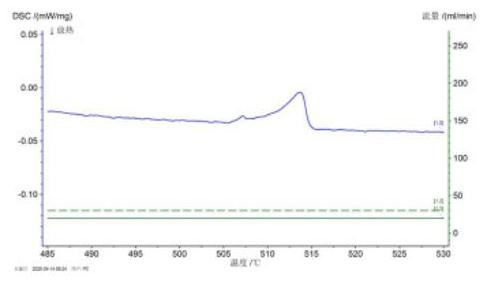

[0053] In this example, in step C, the aluminum alloy ingot is heated to 495°C at a speed of 40°C for 4h in an air furnace, and then heated to 499°C at a rate of 0.13°C for 4h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com