Rapid heat treatment method of high-strength nickel-based superalloy for power station

A technology of nickel-based superalloy and rapid heat treatment, which is applied in the field of alloy materials and can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1: The experimental materials are smelted according to the following proportions, mass percentage Cr: 15% to 18%, Co: 15% to 20%, Ti: 0.5% to 1.5%, Al: 3.5% to 4.5%, W: 8.5% % to 10%, Si: ≤0.5%, Mn: ≤0.5%, Nb: 0.5% to 1.5%, C: 0.03% to 0.085%, and the balance is Ni. After casting, the finished product is obtained after homogenization and hot rolling.

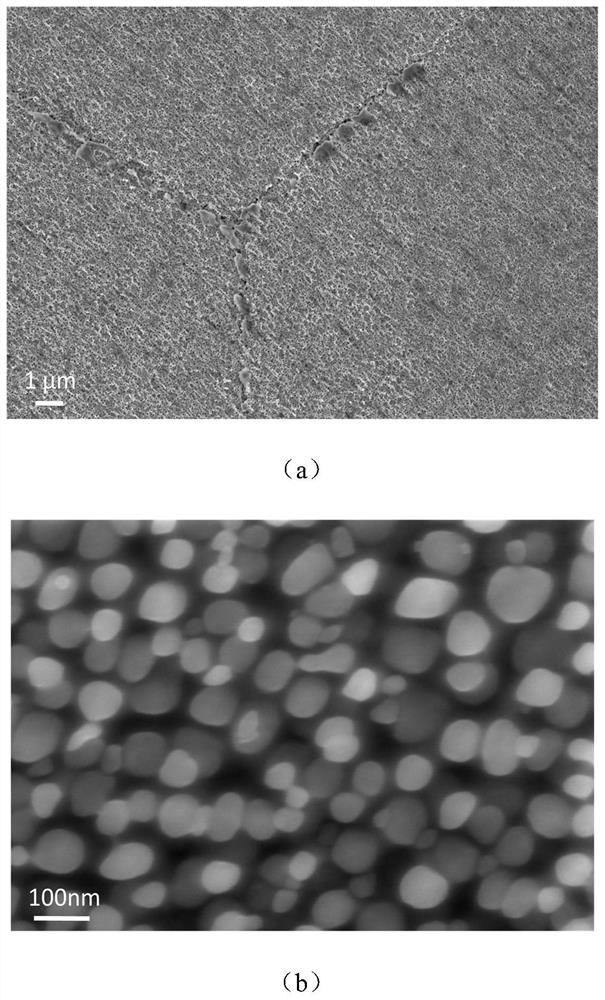

[0021] The nickel alloy of this embodiment has undergone traditional solution + aging treatment, that is, the rolled alloy is kept at 1120° C. for 4 hours for solution treatment, and after air cooling to room temperature, it is kept at 760° C. for 8 hours, and then heated to 860° C. for 2 hours. hours, then air-cool to room temperature. Such as figure 1 Shown is the scanning electron micrograph of the processed tissue, grain boundaries figure 1 a shows that the grain size is about 70-120 μm, and there are discontinuous carbides, figure 1 b shows that there are a large number of dense precipitates in the crysta...

Embodiment 2

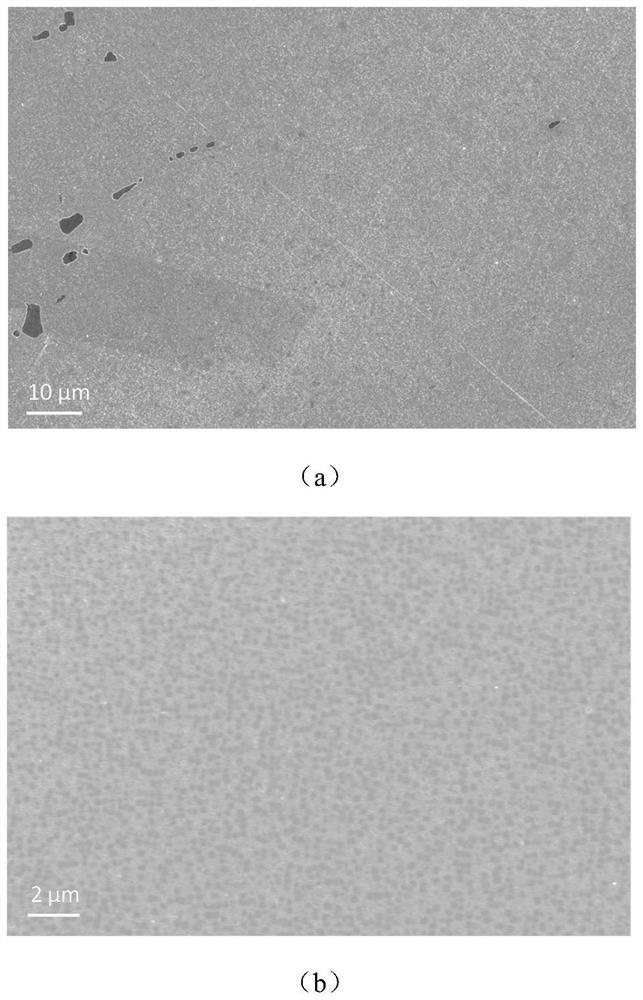

[0022] Example 2: The method provided by the present invention is used for the alloy of Example 1 to carry out single-step rapid treatment of different processes on the nickel alloy, solid solution at 1180 ° C for 2 hours and air cooling, followed by 1020 ° C for 2 hours and directly cooling at about 80 ° C / min to Room temperature, according to this example, the morphology of the tissue after rapid processing is as follows: figure 2 . according to figure 1 and figure 2 It can be clearly found in the displayed microstructures before and after homogenization that after the treatment formulated by the present invention, the morphology and quantity of the carbides at the grain boundaries and the precipitation strengthening phases in the grains of the two are similar. Table 1 is a comparison table of the tensile properties at room temperature of the traditional solid solution + aging three-step heat treatment and the rapid heat treatment of this example. It can be seen that t...

Embodiment 3

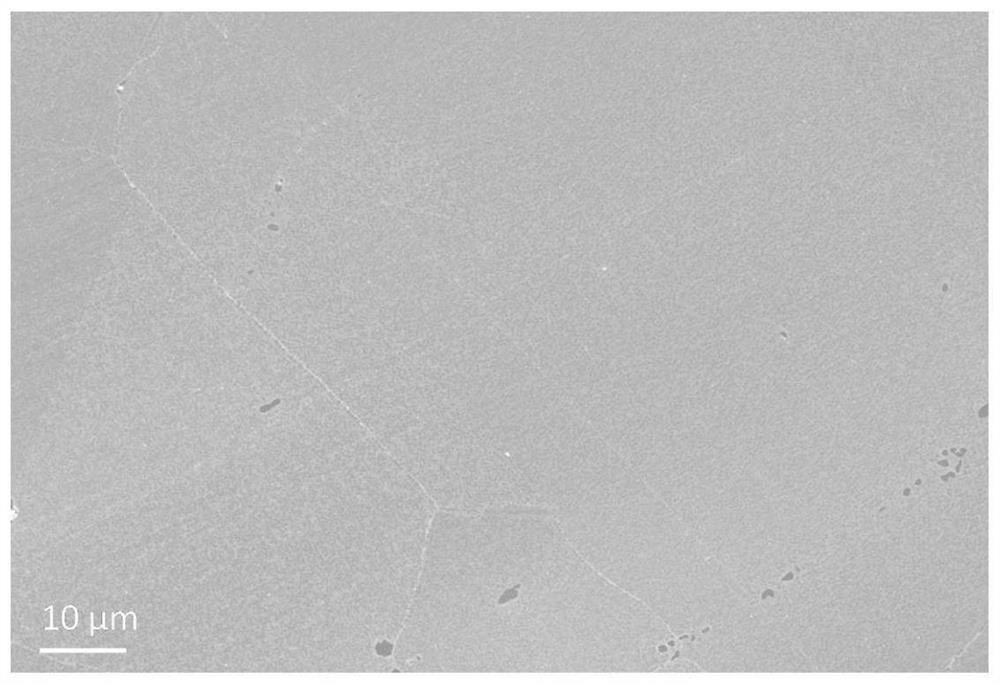

[0025] Example 3: The method provided by the present invention is used for the alloy of Example 1 to perform single-step rapid treatment of nickel alloys in different processes, solid solution at 1180°C for 2 hours and air cooling, and then directly cool to room temperature at 3°C / min after holding at 1020°C for 2 hours , according to this example, the tissue morphology after rapid processing is as follows image 3 . Table 2 is a comparison table of the tensile properties at room temperature of the traditional solid solution + aging three-step heat treatment and the rapid heat treatment of this example. It can be seen that its strength and plasticity are superior to the traditional heat multi-step treatment process. At the same time, for large parts, due to the lack of rapid cooling, the internal stress generated during the cooling process can be greatly prevented from initiating cracks, which will eventually lead to cracking.

[0026] Table 2 Example 1 and Example 3 Room Tem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com