A kind of deformation heat treatment composite process of uniform structure of 7xxx aluminum alloy and its obtaining method

A deformation heat treatment and composite process technology, applied in the field of aluminum alloys, can solve the problems of time-consuming and energy-consuming, high processing cost, low production efficiency, etc., and achieve the effects of shortening the homogenization time, reducing the temperature, and saving energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

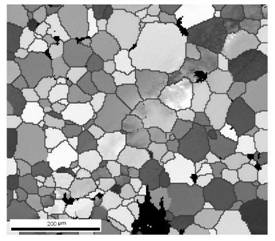

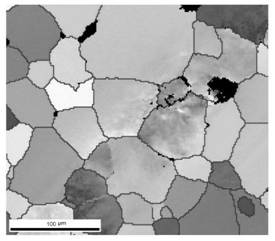

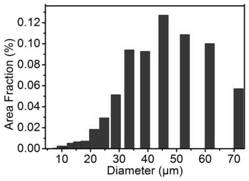

[0074] Figure 1 ~ Figure 3 EBSD (Electron Backscatter Diffraction) photographs and grain size distribution statistical diagrams of 7055 aluminum alloy ingots at different magnifications were sprayed and deposited. 72 μm, the size distribution is not uniform, and the grains with a diameter of about 45 μm account for the largest proportion; the specific process and process parameters of the spray deposition are:

[0075] Melting-atomization-spraying-deposition-solidification, 5 stages; this process has a fast solidification speed, and the temperature drop rate can reach 10 3-5 K / s, the microstructure of the formed ingot is fine equiaxed grain, and the composition segregation is small. The main process parameters are: pouring temperature 850°C, atomization gas velocity 30m 3 / min, the metal flow rate is 35kg / min, the gas metal ratio is 1, the air pressure is 0.8MPa, the spray angle is 30°, the deposition disc-nozzle distance is 220mm, and the deposition disc rotation speed is ...

Embodiment 2

[0087] According to the spray deposition process in Example 1, a 7055 aluminum alloy ingot with the same composition was prepared; the obtained aluminum alloy ingot was subjected to hot extrusion at an extrusion temperature of 420° C. and an extrusion ratio of 6.25 to obtain an extruded alloy; The obtained extruded alloy was heat-treated at 450°C for 6 hours and then at 470°C for 1 hour to obtain a heat-treated alloy; the obtained heat-treated alloy was subjected to aging treatment at 120°C / 12h to obtain a hot-processed 7055 aluminum alloy.

[0088] The thermally processed 7055 aluminum alloy prepared in Example 2 of the present invention is tested for mechanical properties (according to the standard method of GB / T 228-2002 "Metallic Materials Tensile Test Method at Room Temperature"), and the test results are: the average mechanical properties are yield strength, tensile strength The strength and elongation are respectively: 712MPa, 730MPa, 7.2%. The thermal processing techno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com