Homogenization heat treatment method of Al-Zn-Mg-Cu-Zr aluminum alloy

A technology for homogenizing heat treatment of aluminum alloys, applied in the field of homogenizing heat treatment of Al-Zn-Mg-Cu-Zr aluminum alloys, can solve problems such as inapplicability, improve thermal efficiency, avoid microstructure over-burning, and solve coarse The effect of phase back dissolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The composition of aluminum alloy is calculated by mass percentage: Zn6.24wt.%, Mg2.06wt.%, Cu2.09wt.%, Ti<0.06wt.%, Zr0.1wt.%, Fe≤0.08wt.%, Si≤0.03 wt.%, the balance is Al. Semi-continuous casting into 450mm thick specification ingots.

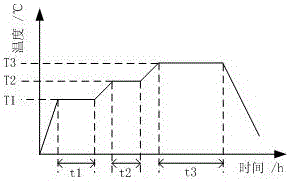

[0030] The alloy adopts the three-stage homogenization heat treatment system of the method of the present invention to carry out homogenization treatment. The specific process is: from room temperature to 400° C. for 10 hours at an average heating rate of 55° C. / h (heating time 6.8 hours), and then continue to heat at 10° C. The average heating rate of ℃ / h (heating time 7h) was raised to 470°C for 3h, and then the average heating rate of 2.5°C / h (heating time 4h) was raised to 480°C for 12h, 18h, 21h and 24h.

Embodiment 2

[0032] The composition of aluminum alloy is calculated by mass percentage: Zn6.42wt.%, Mg2.08wt.%, Cu2.13wt.%, Mn<0.10wt.%, Ti<0.06wt.%, Zr0.1wt.%, Fe≤0.08 wt.%, Si≤0.03wt.%, the balance is Al. Semi-continuous casting into ingots with a thickness of 520 mm.

[0033] The alloy adopts the three-stage homogenization heat treatment system of the method of the present invention to carry out homogenization treatment. The specific process is: from room temperature to 400° C. for 10 hours at an average heating rate of 55° C. / h (heating time 6.8 hours), and then continue to heat at 10° C. The average heating rate of ℃ / h (heating time 7h) was raised to 470°C for 3h, and then the average heating rate of 2.5°C / h (heating time 4h) was raised to 480°C for 12h, 24h and 48h.

Embodiment 3

[0035] The composition of aluminum alloy is calculated by mass percentage: Zn6.39wt.%, Mg2.09wt.%, Cu2.17wt.%, Ti<0.06wt.%, Zr0.1wt.%, Fe≤0.08wt.%, Si≤0.03 wt.%, the balance is Al. Semi-continuous casting into 600mm thick specification ingots.

[0036] The alloy adopts the three-stage homogenization heat treatment system of the method of the present invention to carry out homogenization treatment. The specific process is: from room temperature to 400° C. for 10 hours at an average heating rate of 55° C. / h (heating time 6.8 hours), and then continue to heat at 10° C. The average heating rate of ℃ / h (heating time 7h) was raised to 470°C for 3h, and then the average heating rate of 2.5°C / h (heating time 4h) was raised to 480°C for 24h, 36h and 48h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com