Homogenizing heat treatment process for 6-series aluminum-magnesium-silicon alloy bar

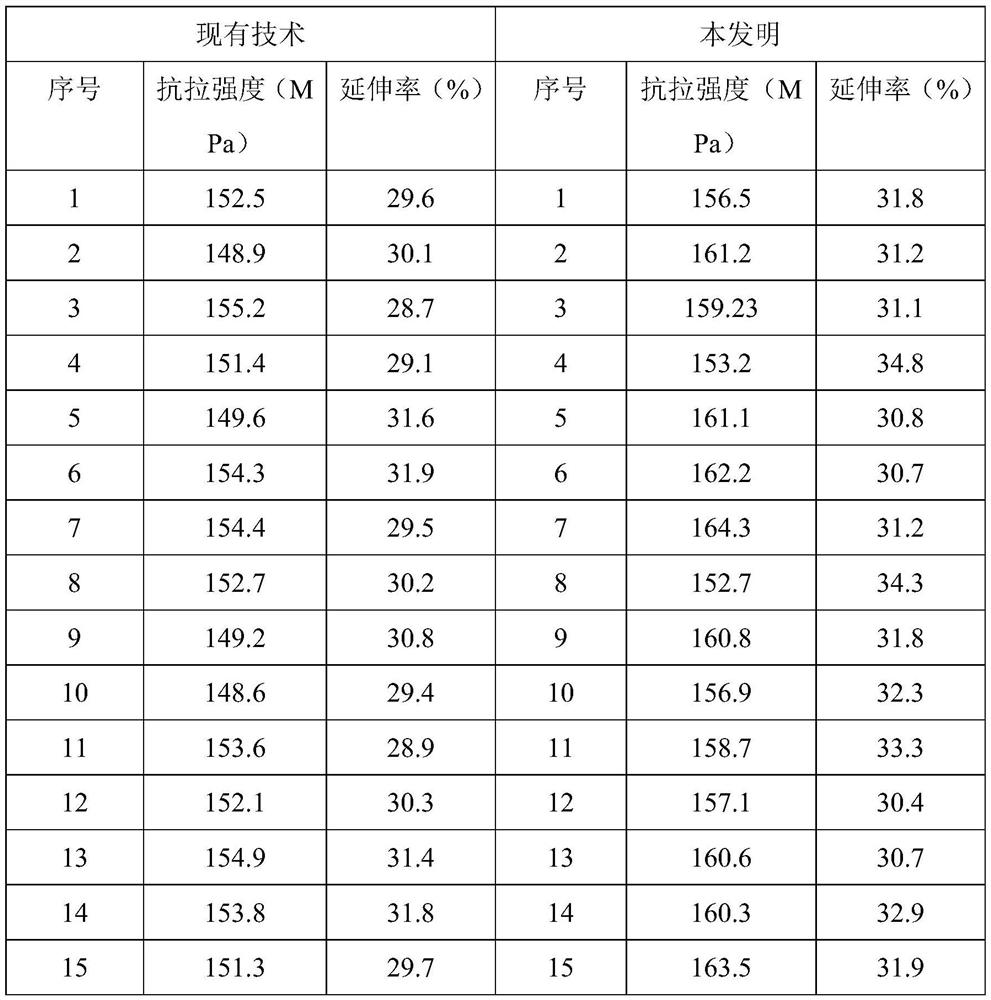

An aluminum-magnesium-silicon and process technology, which is applied in the field of homogeneous heat treatment of 6-series aluminum-magnesium-silicon alloy bars, can solve the problems of insufficient resolubilization of low melting point copper-containing phases, incomplete homogenization, and poor temperature uniformity. Achieving the effect of shortened homogenization time, improved physical properties, and decreased hardness and conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

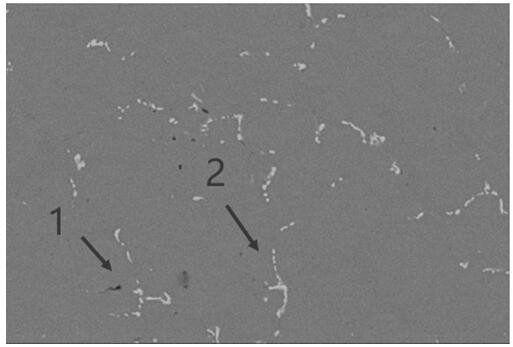

Image

Examples

Embodiment 1

[0022] A homogeneous heat treatment process for 6-series aluminum-magnesium-silicon alloy bars, the heat treatment process adopts three-stage temperature treatment, specifically: the temperature of the first stage is 347°C, and the holding time is 2.6h; the temperature of the second stage is 487°C, The holding time is 2.9h; the temperature of the third stage is 557°C, and the holding time is 10.2h.

Embodiment 2

[0024] A homogeneous heat treatment process for 6-series aluminum-magnesium-silicon alloy bars, the heat treatment process adopts three-stage temperature treatment, specifically: the temperature of the first stage is 353°C, and the holding time is 2.4h; the temperature of the second stage is 493°C, The holding time is 2.9h; the temperature of the third stage is 563°C, and the holding time is 9.8h.

Embodiment 3

[0026] A homogeneous heat treatment process for a bar material of a 6-series aluminum-magnesium-silicon alloy. The heat treatment process adopts a three-stage temperature treatment, specifically: the heat treatment process adopts a three-stage temperature treatment. The temperature of the second stage is 490°C, and the holding time is 3h; the temperature of the third stage is 560°C, and the holding time is 10h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com