6-series aluminum alloys and preparation method thereof

An aluminum alloy and alloying technology, applied in the field of 6 series aluminum alloy and its preparation, can solve the problem that the strength is difficult to meet the high-end products, and achieve the effect of reducing the ingot homogenization time, high gloss, and solving serious material texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

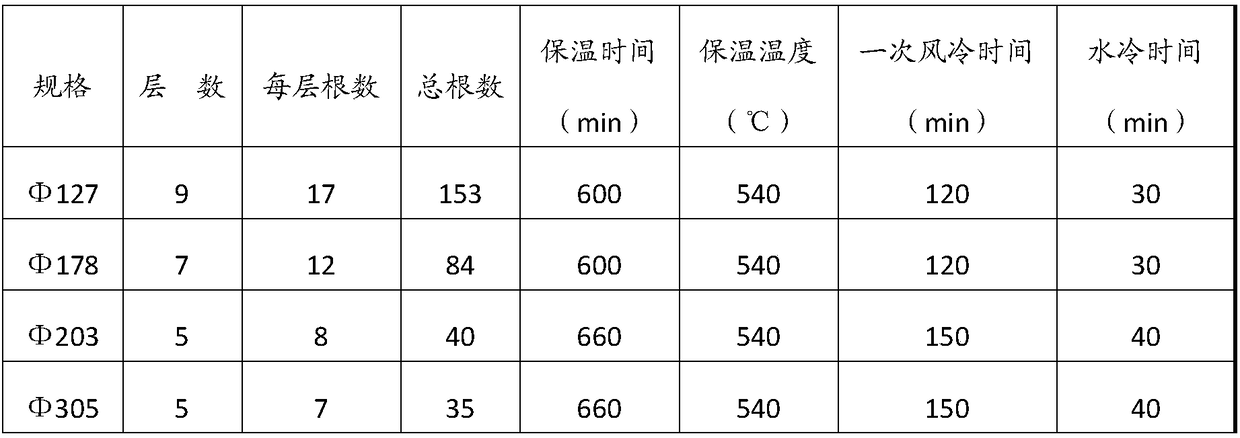

[0016] A method for preparing a 6-series aluminum alloy. According to the composition of the above-mentioned 6-series aluminum alloy, batching, melting, slag removal, alloying, casting, homogenizing annealing and sawing operations are sequentially performed to obtain the 6-series aluminum alloy. Aluminum alloy, the temperature of the casting operation is greater than or equal to 695-705°C, and the hydrogen content is controlled not to exceed 0.12ml / 100gAl during the casting operation; the holding temperature of the homogenization operation is 535-545°C, and the holding time is 600 -660min.

[0017] As can be seen from the foregoing description, the beneficial effects of the present invention are:

[0018] (1) The 6-series aluminum alloy of the present invention is designed with 0.88-0.92% magnesium, 0.012-0.016% titanium, 0.07-0.10% manganese, 0.56-0.60% silicon, no more than 0.11% iron, 0.55-0.63% Copper, not higher than 0.01% of zinc and not higher than 0.01% of chromium, w...

Embodiment 1

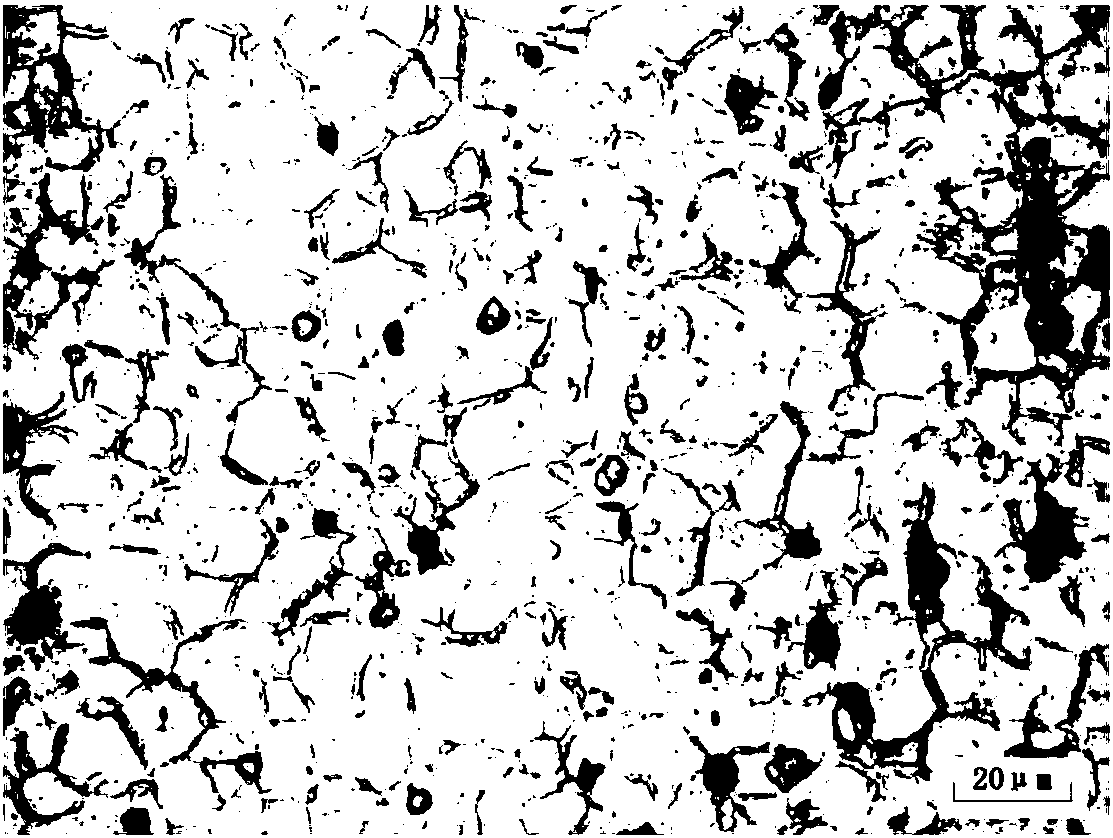

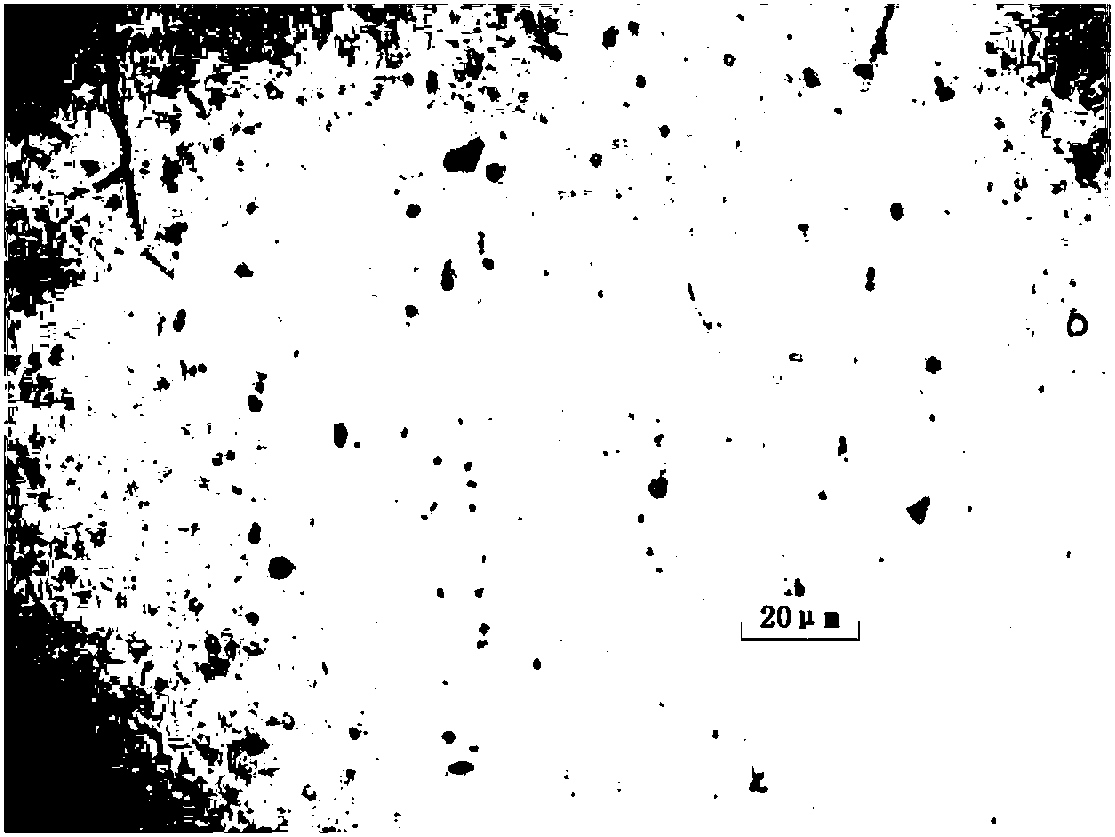

[0031] Please refer to Figure 1-2 , Embodiment 1 of the present invention is:

[0032] The preparation method of the 6 series aluminum alloy of the present embodiment comprises the following steps:

[0033] (1) Composition of the 6-series aluminum alloy: the 6-series aluminum alloy consists of the following components by weight percentage: 0.75% magnesium, 0.01% titanium, 0.06% manganese, 0.5% silicon, 0.55% copper, 0.005% % strontium, 0.002% pick, not higher than 0.13% iron, not higher than 0.01% zinc and not higher than 0.01% chromium, and the balance is aluminum; among them, the content of total impurity elements in 6 series aluminum alloys The content of a single impurity element in the 6-series aluminum alloy is 0.03%.

[0034] (2) Perform batching, melting, slag removal, alloying, casting, homogenizing annealing, and sawing operations in sequence according to the composition of the 6-series aluminum alloy to obtain the 6-series aluminum alloy, and the temperature of t...

Embodiment 2

[0035] Please refer to Figure 1-2 , the second embodiment of the present invention is:

[0036] The preparation method of the 6 series aluminum alloy of the present embodiment comprises the following steps:

[0037] (1) Composition of the 6-series aluminum alloy: the 6-series aluminum alloy is composed of the following components by weight percentage: 1.1% magnesium, 0.02% titanium, 0.13% manganese, 0.7% silicon, 0.7% copper, 0.01 % strontium, 0.008% pickaxe, no more than 0.13% iron, no more than 0.01% zinc and no more than 0.01% chromium, and the balance is aluminum; among them, the content of the total impurity elements of the 6 series aluminum alloy The content of a single impurity element in the 6-series aluminum alloy is 0.02%.

[0038] (2) Perform batching, melting, slag removal, alloying, casting, homogenizing annealing, and sawing operations in sequence according to the composition of the 6-series aluminum alloy to obtain the 6-series aluminum alloy, and the temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com