Method for preparing aluminum-scandium alloy with high scandium content

A technology of aluminum-scandium content, which is applied in the field of preparation of high-scandium-content aluminum-scandium alloys, can solve the problems of difficult alloy smelting, coarse alloy grains, and fast cooling speed, so as to reduce the homogenization treatment time and significantly refine the grains , the effect of increasing the cooling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

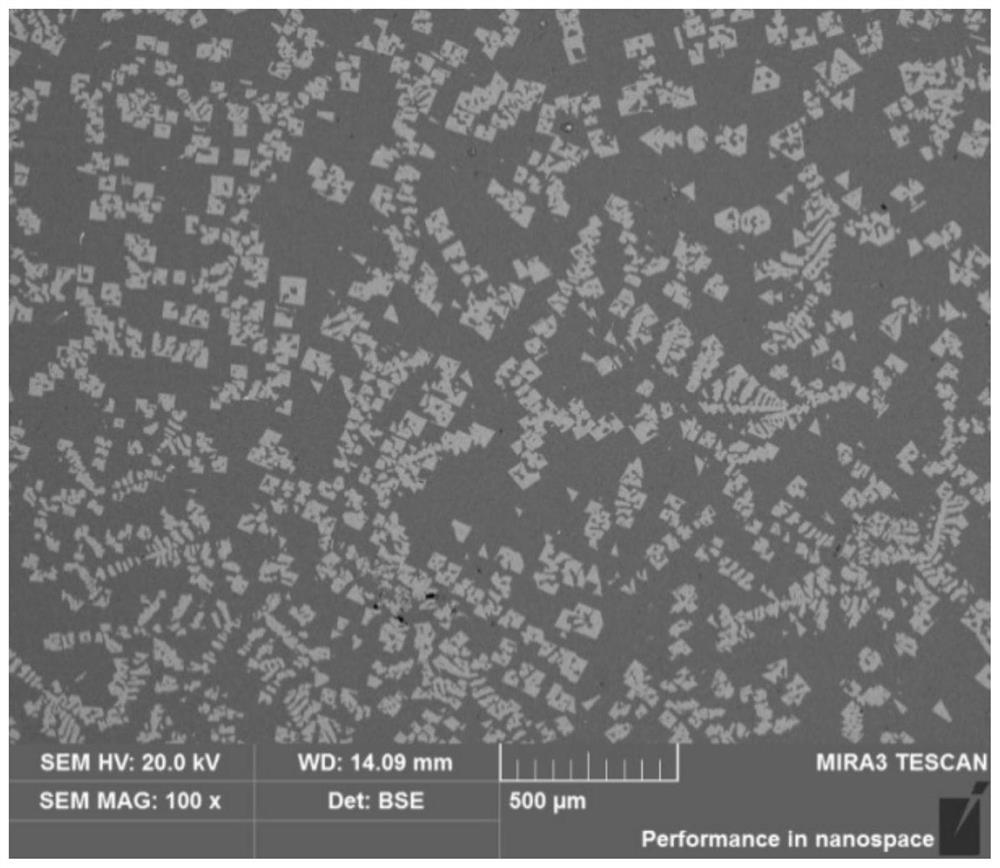

[0042] In this embodiment, the preparation of an aluminum-scandium alloy ingot with a scandium content of 10% is taken as an example for illustration, and the specific steps are as follows:

[0043] S1. Feeding: Weigh 1.6 kg of bulk high-purity metal scandium with a purity of 99.99%, and 14.4 kg of massive high-purity metal aluminum with a purity of 99.99%, and put them into a 50 kg medium-frequency induction melting furnace.

[0044] S2. Vacuuming: Vacuuming after closing the furnace cover, the vacuum degree is lower than 5×10 -2 After Pa, the temperature was raised.

[0045] S3. Melting: continue vacuuming, adjust the power output of the intermediate frequency induction melting furnace to 55KW, and heat up to 1200°C to melt the metal raw material.

[0046] S4. Heat preservation: continue heat preservation for 30 minutes after the metal is completely melted.

[0047] S5. Pouring: fill with high-purity argon, pour the aluminum-scandium alloy liquid into the Φ300×200mm water-...

Embodiment 2

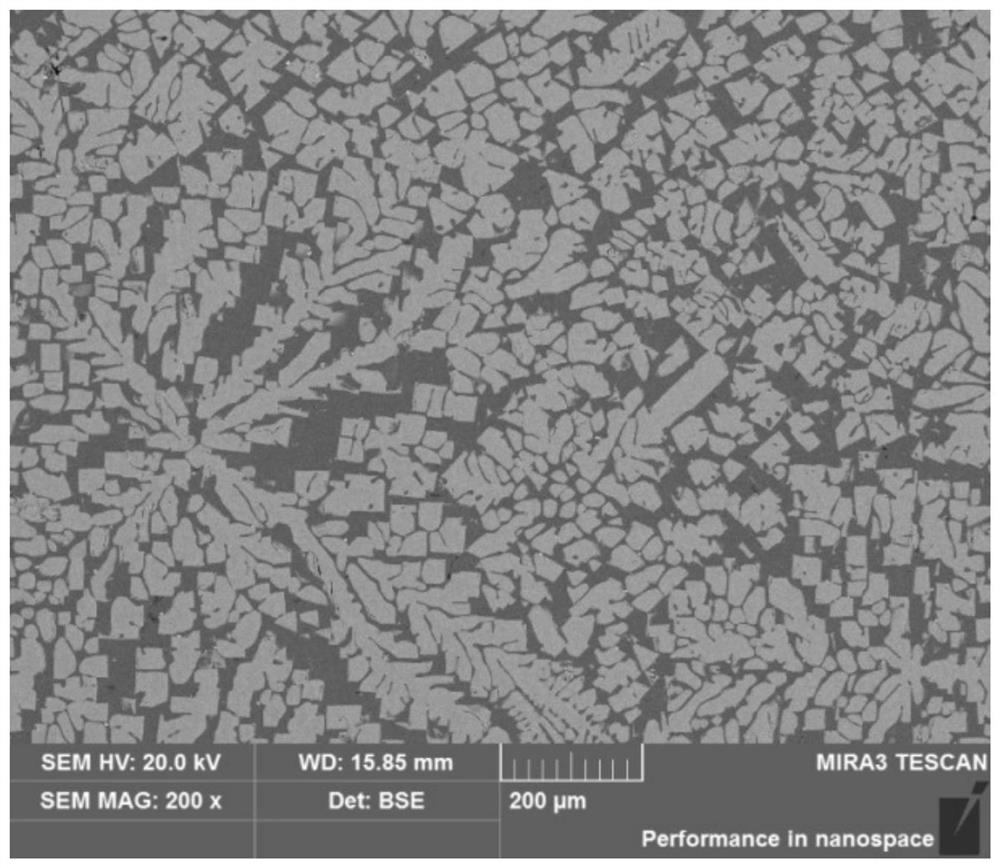

[0050] In this embodiment, the preparation of an aluminum-scandium alloy ingot with a scandium content of 20% is taken as an example for illustration, and the specific steps are as follows:

[0051] S1. Feeding: Weigh 1.5 kg of massive high-purity metal scandium with a purity of 99.99%, and 6 kg of massive high-purity metal aluminum with a purity of 99.99%, and put them into a 20 kg medium-frequency induction melting furnace.

[0052] S2. Vacuuming: Vacuuming after closing the furnace cover, the vacuum degree is lower than 5×10 -2 After Pa, the temperature was raised.

[0053] S3. Melting: continue vacuuming, adjust the output power of the intermediate frequency induction melting furnace to 70KW, and heat up to 1300°C to melt the metal raw material.

[0054] S4. Heat preservation: continue heat preservation for 30 minutes after the metal is completely melted.

[0055] S5. Pouring: fill with high-purity argon, pour the aluminum-scandium alloy liquid into the Φ220×150mm water-...

Embodiment 3

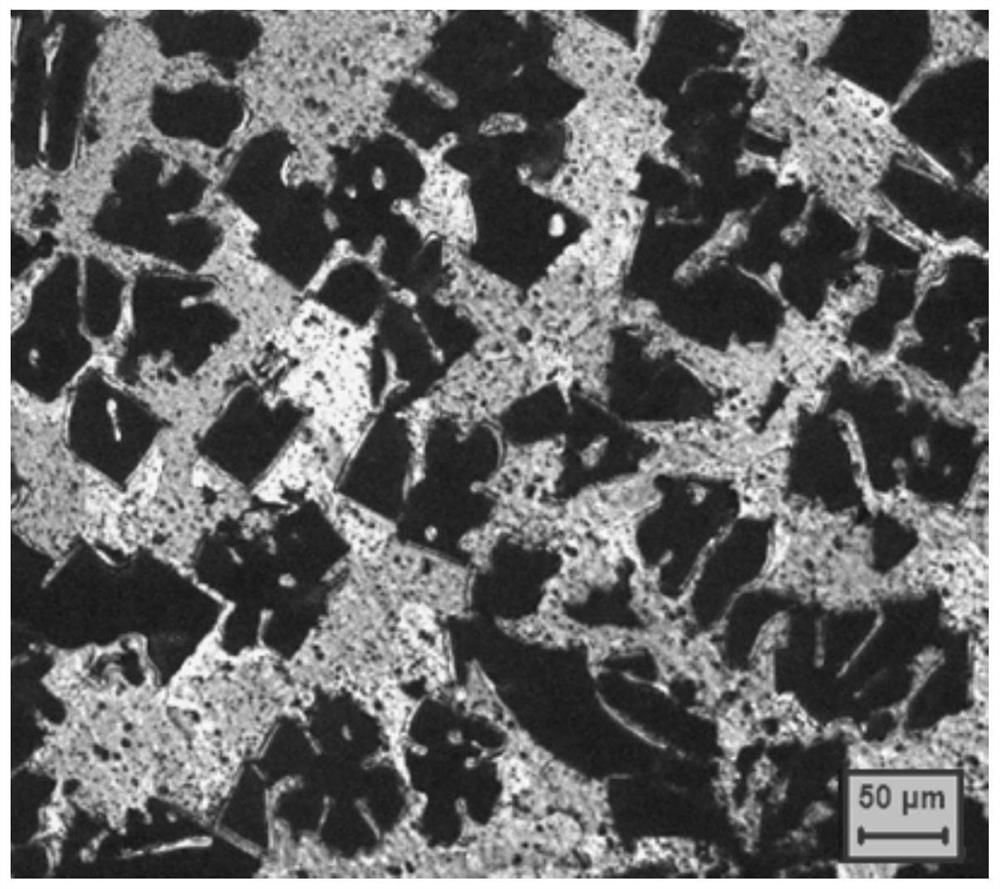

[0079] In this embodiment, the preparation of an aluminum-scandium alloy ingot with a scandium content of 30% is taken as an example for illustration, and the specific steps are as follows:

[0080] S1. Feeding: Weigh 1.2 kg of bulk high-purity metal scandium with a purity of 99.99%, and 2.8 kg of massive high-purity metal aluminum with a purity of 99.99%, and put them into a 10 kg medium-frequency induction melting furnace.

[0081] S2. Vacuuming: Vacuuming after closing the furnace cover, the vacuum degree is lower than 5×10 -2 After Pa, the temperature was raised.

[0082] S3. Melting: continue vacuuming, adjust the output power of the intermediate frequency induction melting furnace to 75KW, and heat up to 1390°C to melt the metal raw material.

[0083] S4. Heat preservation: heat preservation for 30 minutes after the metal is melted.

[0084] S5. Pouring: Fill with high-purity argon, pour the aluminum-scandium alloy liquid into a 200×200×80mm water-cooled copper mold to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com