Electroslag remelting slag material for preparing high silicomanganese nitrogen-containing stainless steel

A technology of electroslag remelting and stainless steel, which is applied in the field of metal materials, can solve the problems that are not conducive to the improvement of purity, the reduction of non-metallic inclusions, the deterioration of thermal processing performance of materials, and the deterioration of thermoplasticity of materials, so as to promote large-scale application , Good thermoplasticity, less burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The method for preparing high-silicon-manganese nitrogen-containing stainless steel by adopting the slag described in the present invention is,

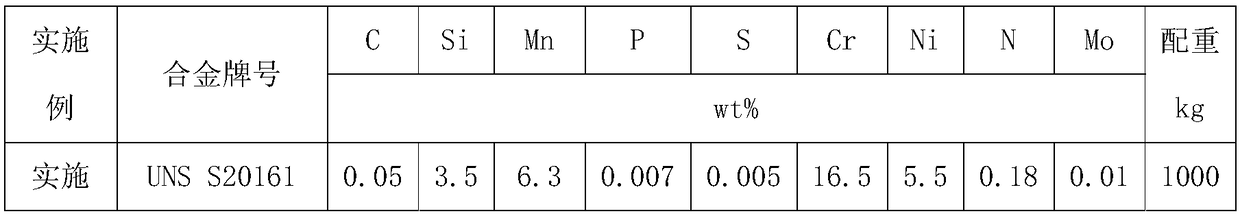

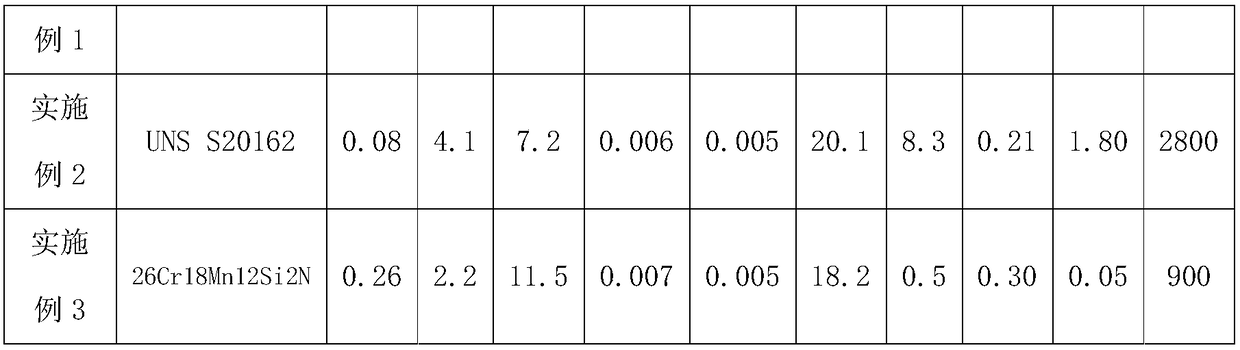

[0024] 1) For the American standard S20161, S20162, national standard 26Cr18Mn12Si2N and other high-silicon-manganese nitrogen-containing stainless steels, use vacuum induction furnace or electric arc furnace for melting, and cast them into cylindrical electrode rods. The diameter of the electrode rods is Φ170~Φ400mm (corresponding to melting Cylindrical electroslag ingot with a diameter of Φ380~Φ600mm). Electroslag remelting is carried out after the surface of the electrode rod is polished or sanded to reveal a metallic luster.

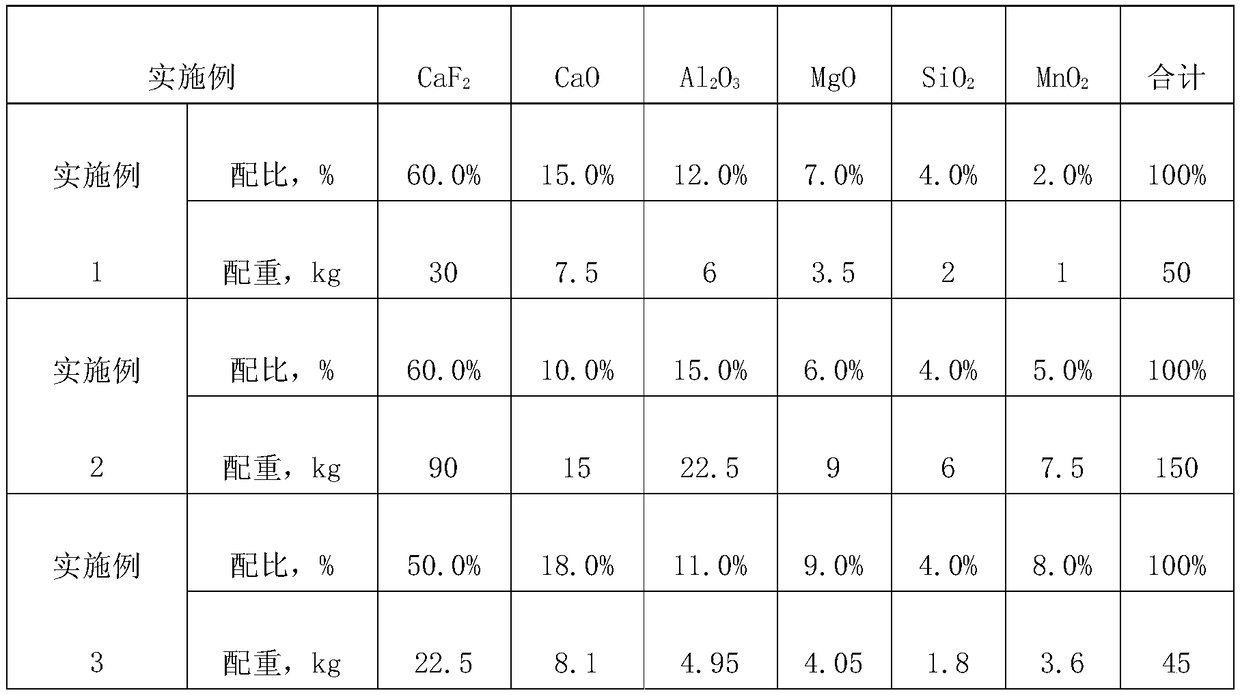

[0025] 2) Prepare the slag according to the ratio in Table 1, the weight of the slag is 45-130kg, and the slag is baked at 800°C for 8-16 hours. Heat the slag material to the molten state and pour it into the crystallizer or directly melt the slag in the crystallizer to start the arc. The remelted e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com