A kind of stone preparation method and polishing system thereof

A stone and polishing medium technology, applied in the direction of manufacturing tools, metal processing equipment, used abrasive processing equipment, etc., can solve the problem of not being able to obtain polishing uniformity, not considering the impact of polishing products, and not proposing specific solutions, etc. problems, to achieve the effect of easy control, improved gloss, and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

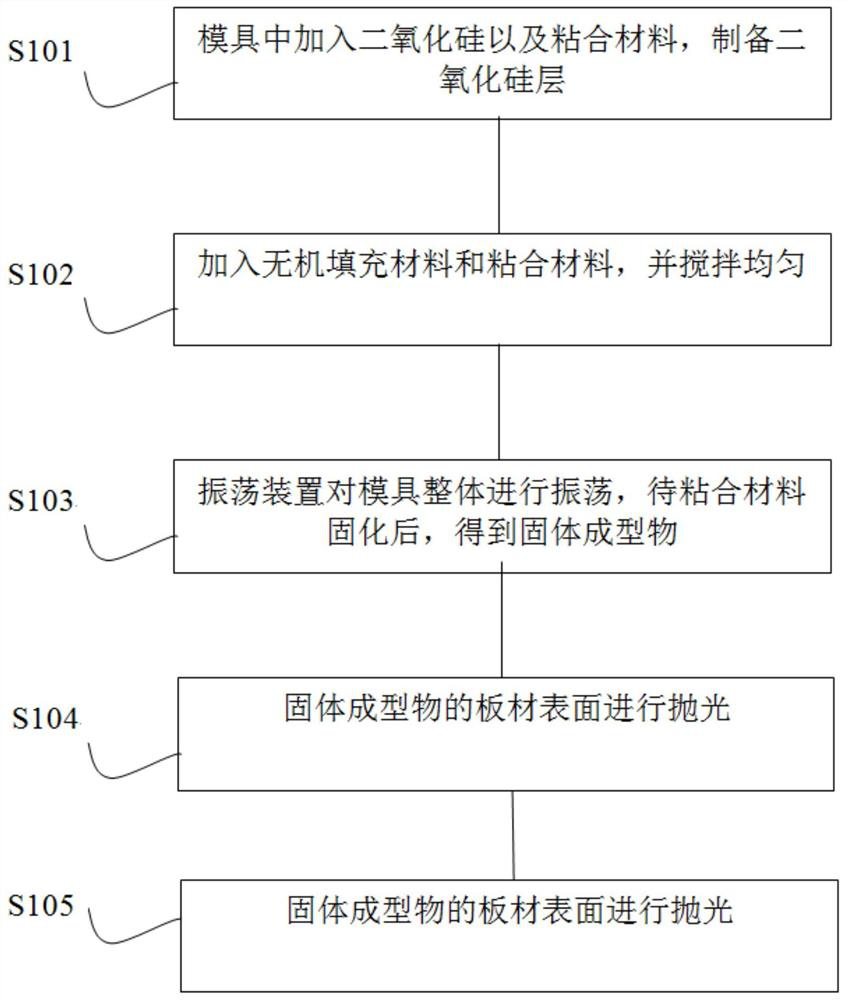

[0035] A method for preparing a stone, comprising the steps of:

[0036] 1) adding silicon dioxide and bonding material into the mold to form a silicon dioxide-containing layer with a thickness of 50-100 μm;

[0037] 2) adding an inorganic filler material and a binder material respectively into the mold, the inorganic filler material being selected from one or more of crushed stones, broken bricks, ceramic particles or chips, glass chips, and quartz particles;

[0038] 3) Stir evenly;

[0039]4) Oscillate the whole mold with an oscillating device, so that the distribution of the inorganic filler material becomes uniform and arranged tightly; use a vacuum device to make the inner space of the mold in a vacuum state, and eliminate the air bubbles in the inorganic filler material and the silicon dioxide-containing layer or defect;

[0040] 5) After the bonding material is cured, the mold is removed to obtain a material layer comprising silicon dioxide, an inorganic filler mater...

Embodiment 2

[0047] A method for preparing a stone, comprising the steps of:

[0048] 1) Add silicon dioxide and an adhesive material twice the amount of silicon dioxide to the mold to form a silicon dioxide-containing layer with a thickness of 50-100 μm;

[0049] 2) Adding 45% inorganic filler material and 20% binding material to the mold, the inorganic filler material is selected from crushed stones, broken bricks, ceramic particles or chips, glass chips, and One or more of quartz particles;

[0050] 3) Stir evenly;

[0051] 4) Oscillate the whole mold with an oscillating device, so that the distribution of the inorganic filler material becomes uniform and arranged tightly; use a vacuum device to make the inner space of the mold in a vacuum state, and eliminate the air bubbles in the inorganic filler material and the silicon dioxide-containing layer or defect;

[0052] 5) After the bonding material is cured, the mold is removed to obtain a material layer comprising silicon dioxide, an...

Embodiment 3

[0064] A method for preparing a stone, comprising the steps of:

[0065] 1) Add silicon dioxide and an adhesive material 3 times the amount of silicon dioxide to the mold to form a silicon dioxide-containing layer with a thickness of 50-100 μm;

[0066] 2) Adding 75% inorganic filler material and 30% binding material to the mold, the inorganic filler material is selected from crushed stones, broken bricks, ceramic particles or chips, glass chips, and One or more of quartz particles;

[0067] 3) Stir evenly;

[0068] 4) Oscillate the whole mold with an oscillating device, so that the distribution of the inorganic filler material becomes uniform and arranged tightly; use a vacuum device to make the inner space of the mold in a vacuum state, and eliminate the air bubbles in the inorganic filler material and the silicon dioxide-containing layer or defect;

[0069] 5) After the bonding material is cured, the mold is removed to obtain a material layer comprising silicon dioxide, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com